Home » Products » Mechanical Testing » Dynamic and Fatigue Testing Systems » Instron Axial-Torsion 8850 Systems

Meets the challenging demands

For static and dynamic biaxial testing

Instron Axial-Torsion 8850 Systems

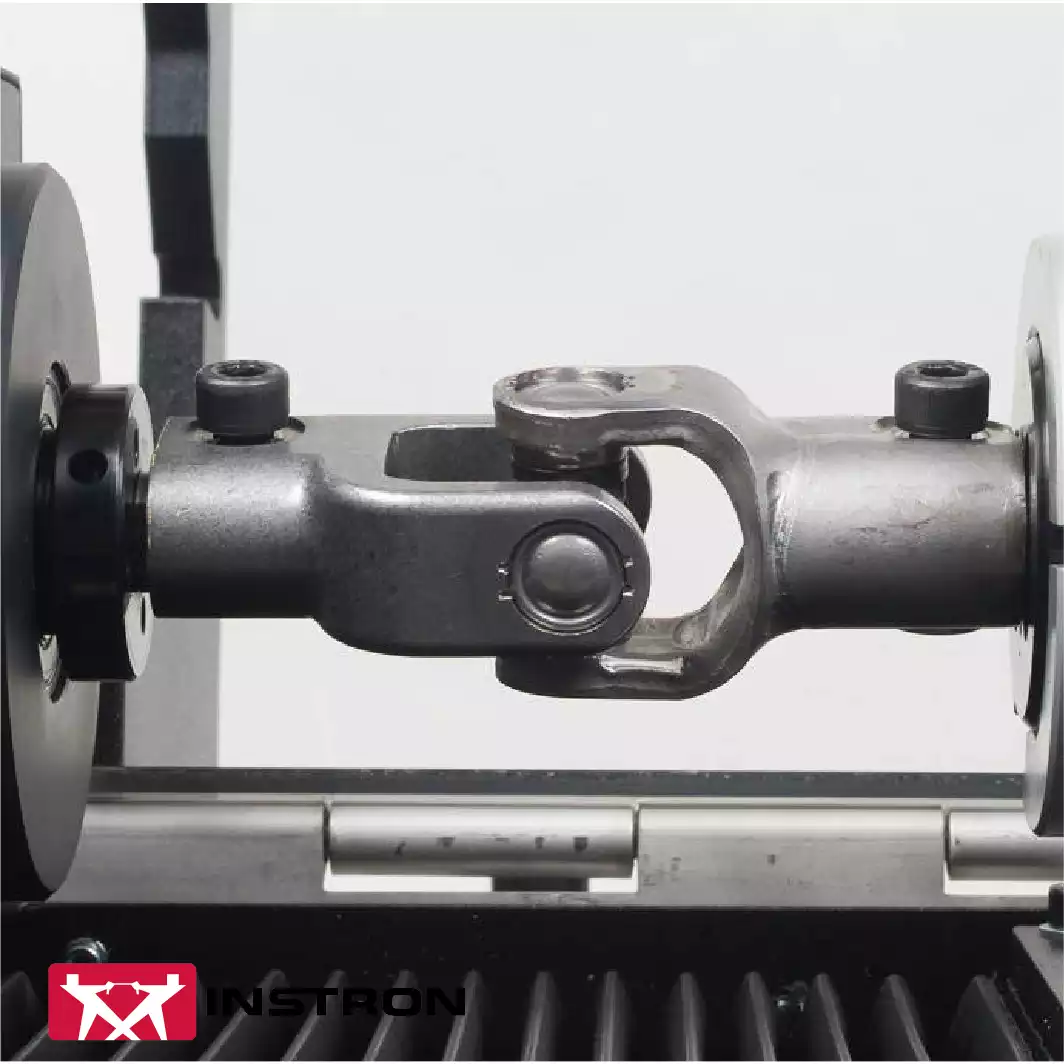

A floor model biaxial servohydraulic dynamic test system, the Instron 8850 series system applies axial and torsional loads to the item through the use of a combined biaxial actuator. The 8850 series features a high-stiffness twin-column frame that is precisely aligned to suit the requirements of a wide variety of static and active biaxial tests. These requirements can be either static or active. To cater to your testing requirements, Instron offers a comprehensive selection of high-capacity axial-torsional instruments and alternatives that can be customized to your specifications. You can configure many different aspects of the frame in a manner that best meets your requirements and simplifies the process overall.

Our project engineers will assist you with every stage of the purchasing process, from the initial configuration of your machine to the delivery, installation, and handover of the system.

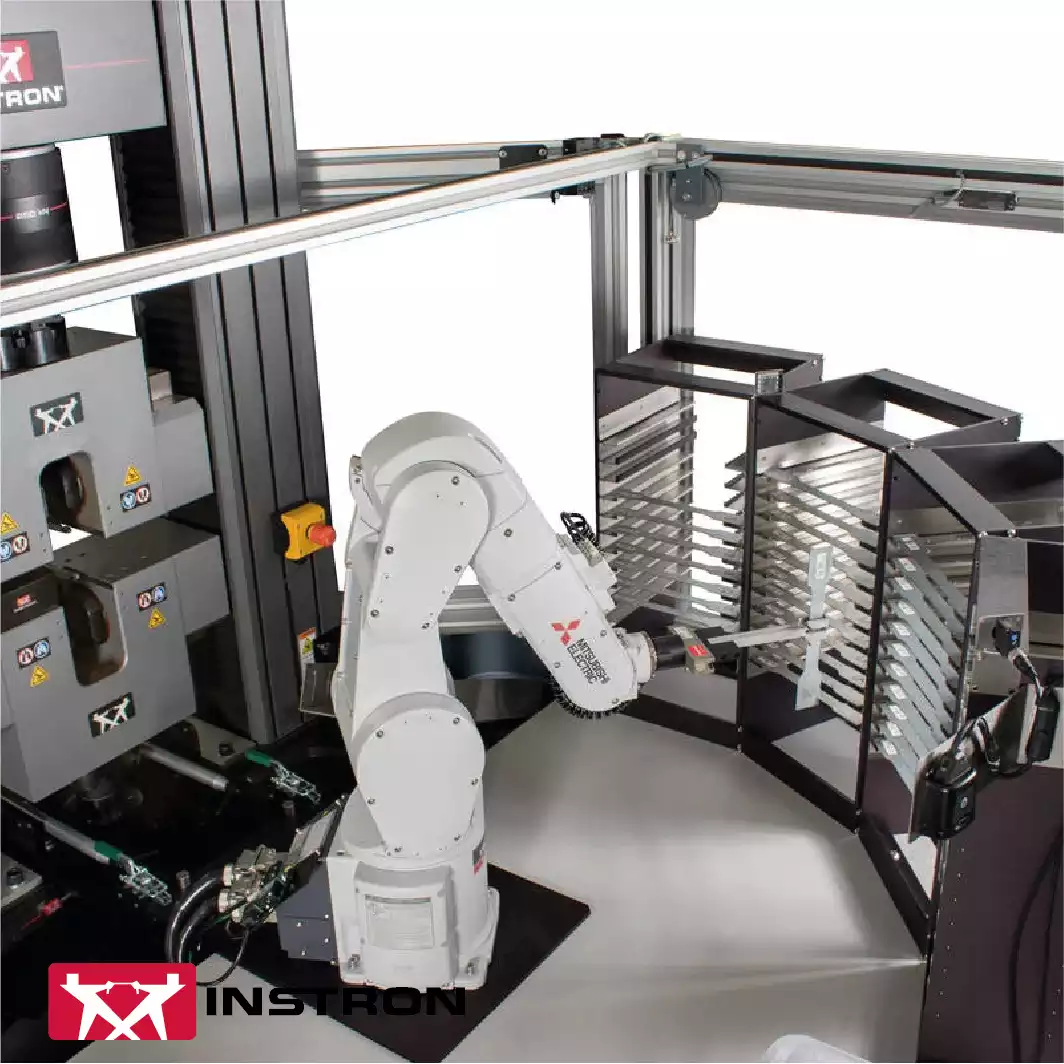

Instron is able to produce completely integrated and ready-to-use turnkey solutions for even the most challenging applications thanks to the 8850 series, the sophisticated capabilities of a two-axis 8800MT digital controller, and an axial-torsional fatigue-rated DynacellTM.

Our Range

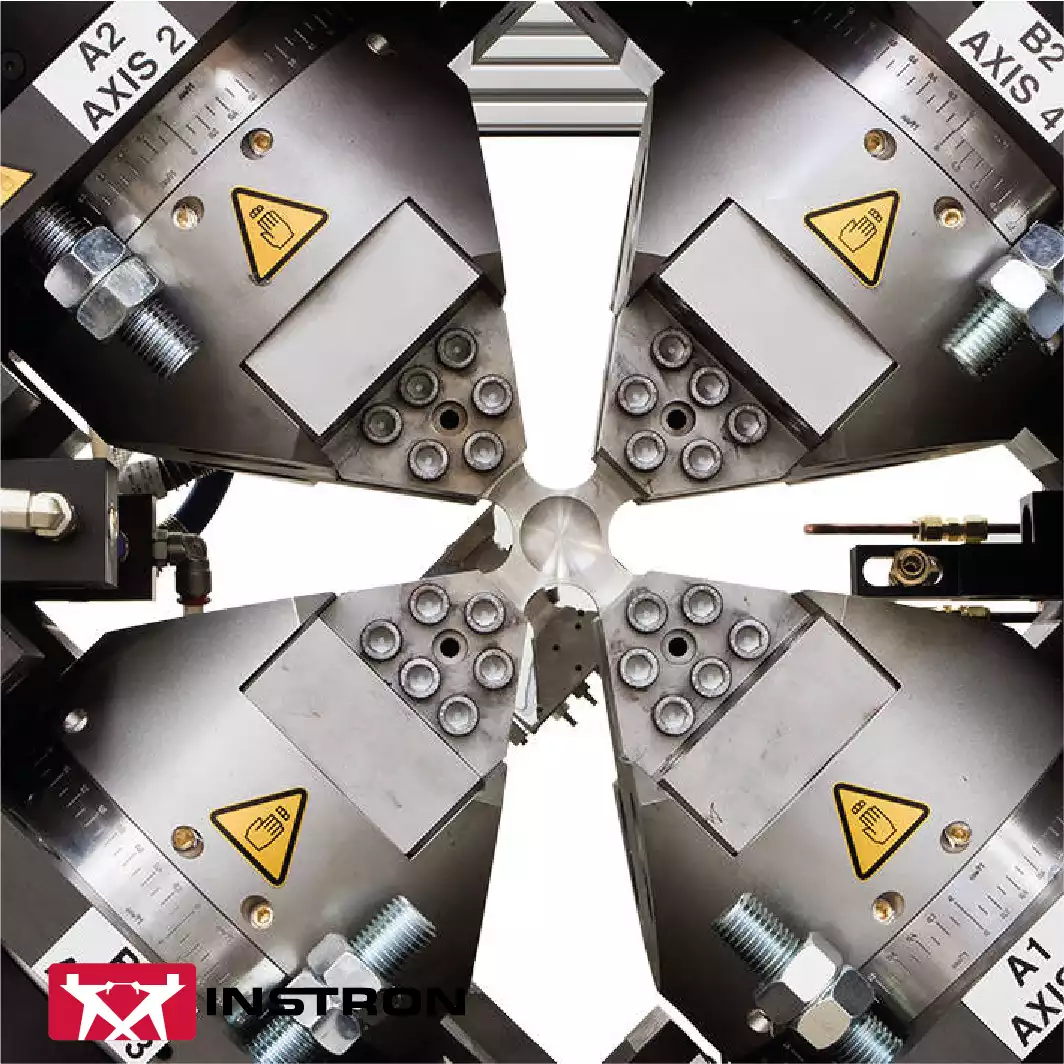

The Instron 8852 system features an axial load capacity of 100 kN (22 kip), a torque capacity of 1000 Nm (8800 in-lb), an axial actuator stroke of 150 mm (6 in), and a rotational stroke of 90°. Additionally, the system has an axial actuator stroke that is six inches long.

The Instron 8854 system has an axial load capacity of about 250 kN (approximately 56 kip), a torque capacity of approximately 2000 Nm (approximately 17700 in-lb), an axial actuator stroke of approximately 100 mm (4 in), and a rotational stroke of approximately 90 degrees.

Read more about Instron Axial-Torsion 8850 Systems here

Related Products

Ask Us A Question

Subscribe to our Newsletter

Receive all our promotions, updates, news and much more...

CONTACT US

Diamond Spectrum for Scientific & Laboratory Equipment Co

Jeddah

Khobar

Taawon Group © 2024 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience

.webp)