Home » Products » Mechanical Testing » Universal Testing Systems » Instron Industrial Universal Testing Systems up to 2000 kN

Suitable for all applications

Available in a range of sizes and force capacities

Instron Industrial Universal Testing Systems up to 2000 kN

In compliance with ASTM, ISO, and other industry standards, Instron® industrial universal testing instruments are able to carry out a wide range of mechanical tests, such as tension, compression, bending, peeling, ripping, shearing, and friction. These tests may be carried out on a variety of materials. These constructions are capable of withstanding weights of up to 2,000 kN and are offered in a variety of different sizes. Instron can supply you with the testing equipment you require to maintain the integrity of civil infrastructure, whether you need to examine cutting-edge composites and components or high-strength metals and alloys.

Static Hydraulic Industrial Series

Industrial Series

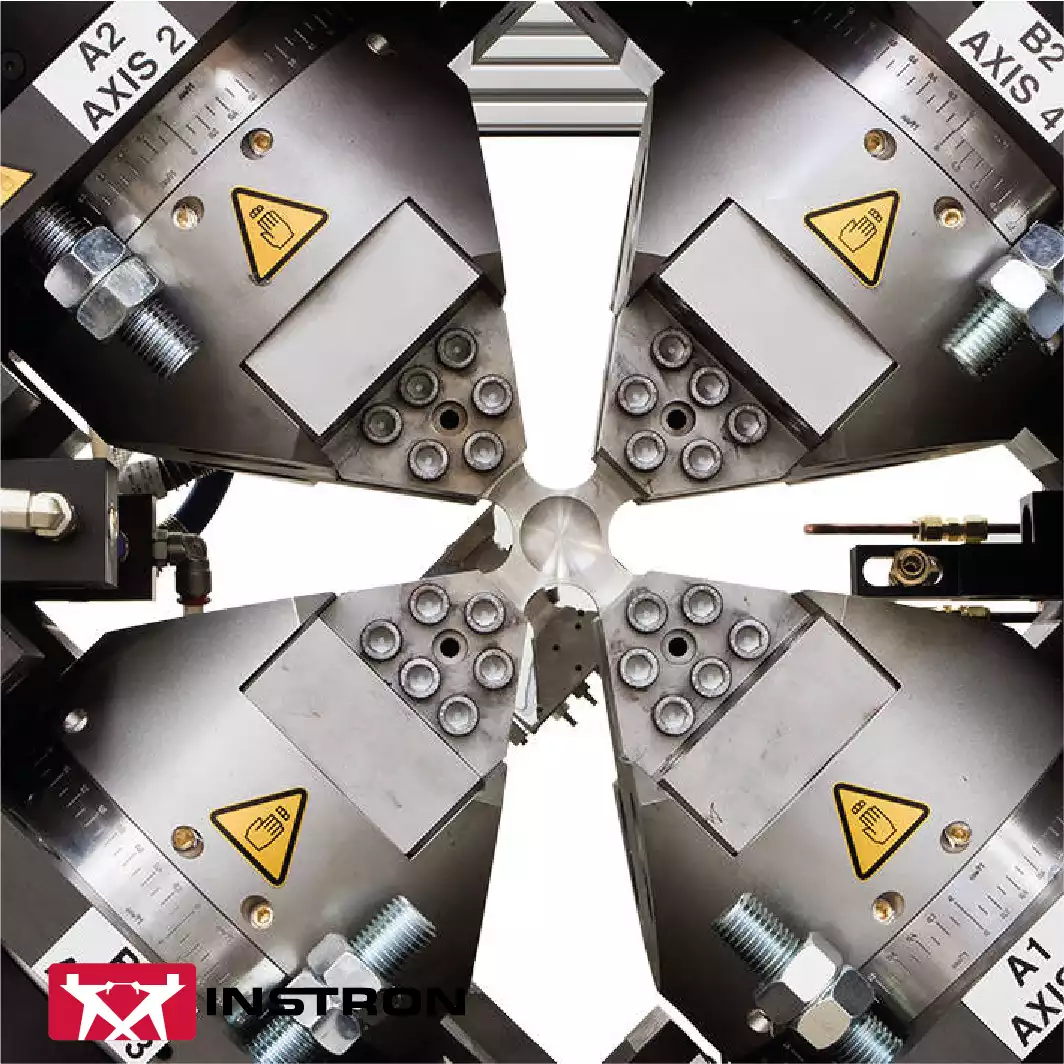

High-Capacity Universal Testing Systems for Tensile, Compression, and Flexure Testing

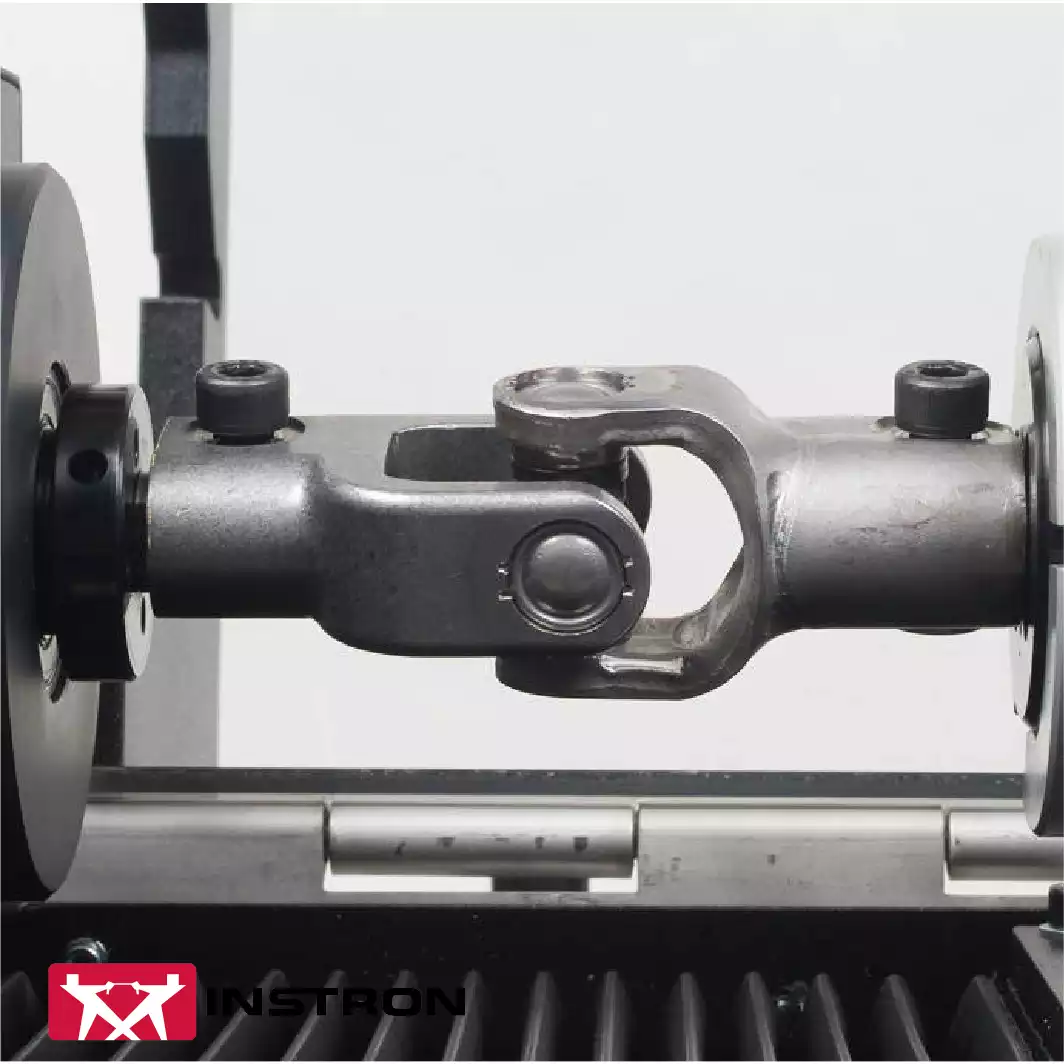

High capacity hydraulic testing machines for tension, compression, and bending make up the Industrial Series. Load capacities for common models typically start at 300 kN (67,500 lbf) and go all the way up to 2,000 kN (450,000 lbf). The big diameter beams and robust components increase the frame's rigidity and durability. Due to the critical nature of ensuring the operator's safety, these models include superior construction and components. Unique configurations, such as frames that function only when compressed, are also possible with custom designs.

5980 Series Universal Testing System | Up to 600 kN Force Capacity

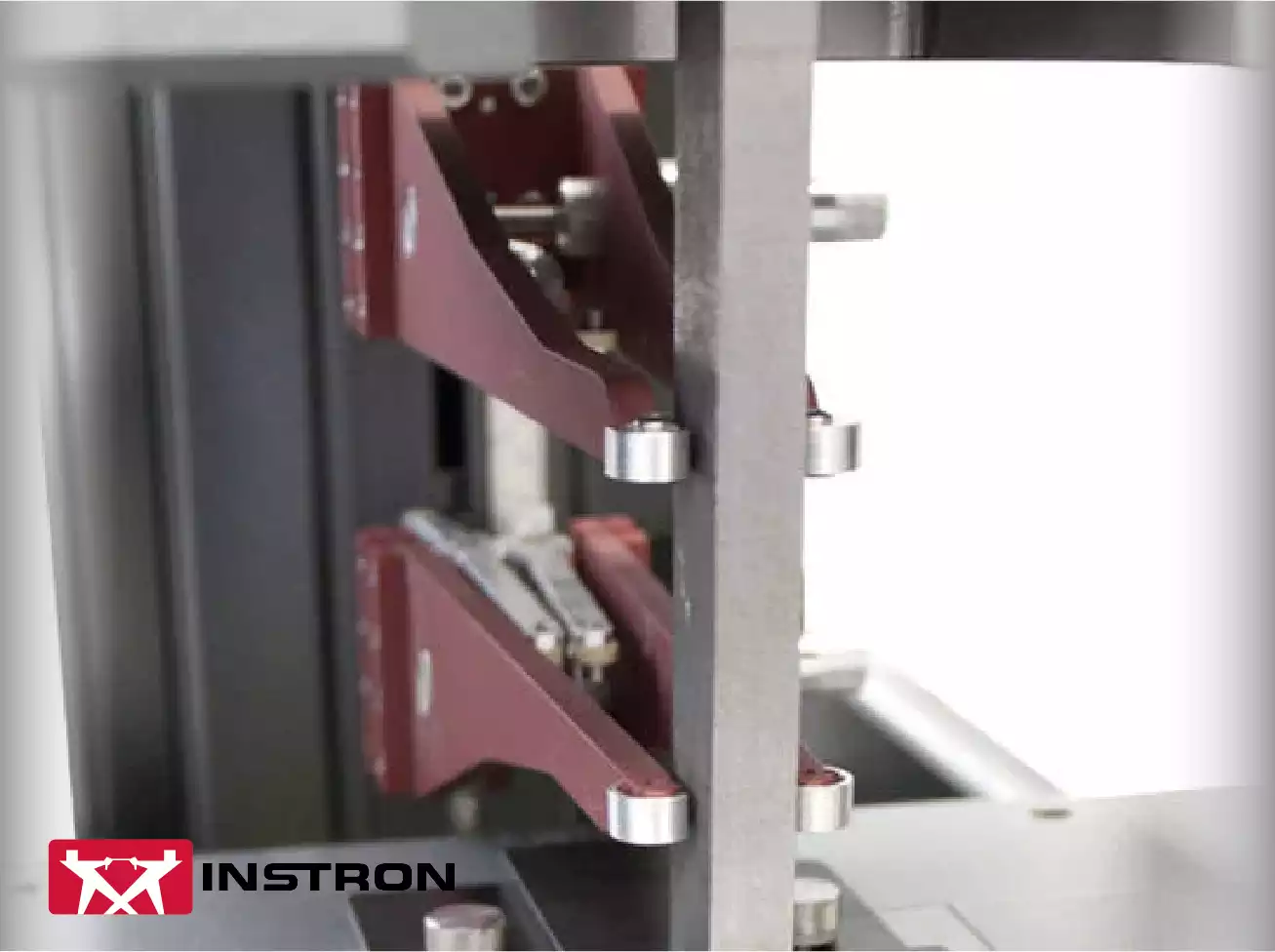

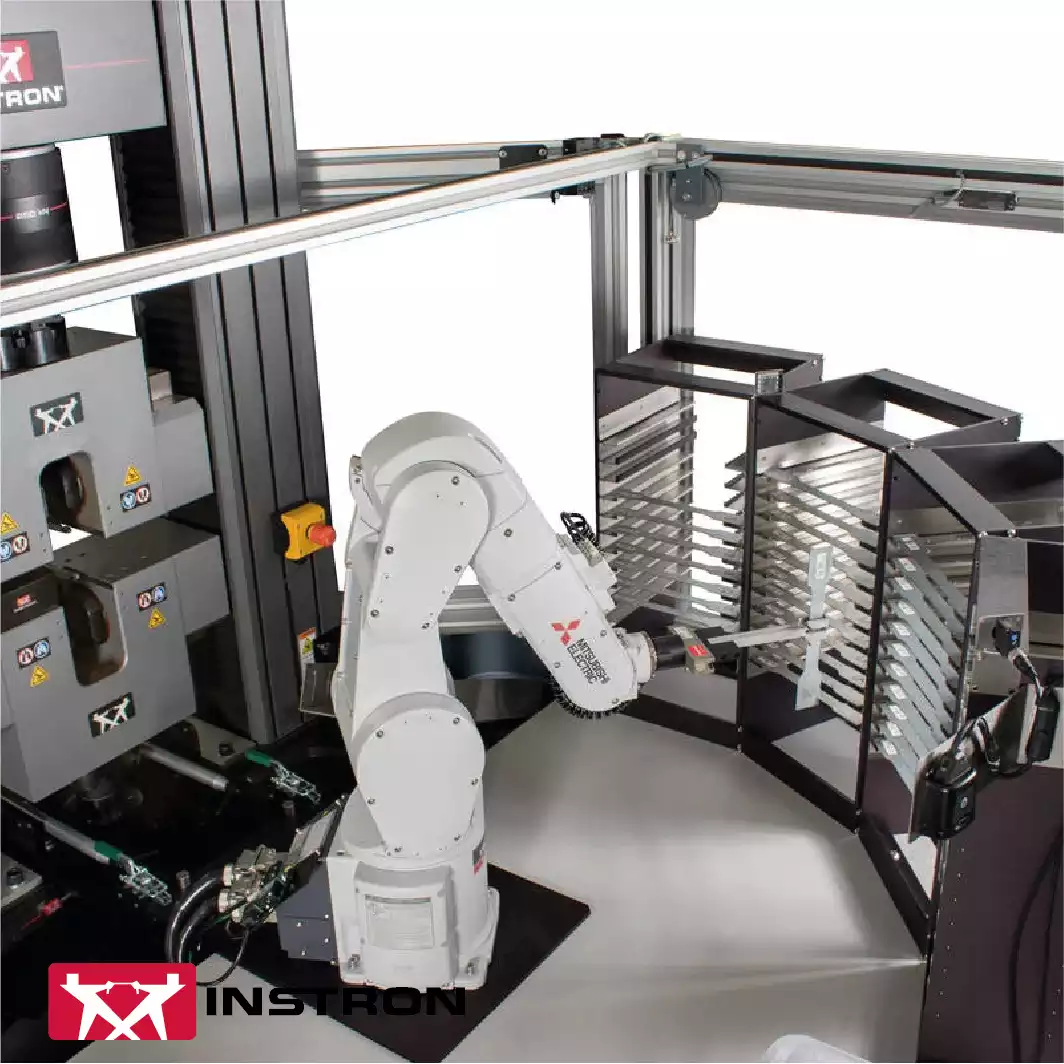

Tension, compression, bending, peeling, shearing, tearing, creeping, and cycling are all possible with the 5980 Series electromechanical universal testing equipment, which can test up to 600 kN of force. These gauges are reliable, long-lasting, and adaptable, making them ideal for a variety of situations. They're equipped with conveniences that speed up and enhance the testing process.

These heavy-duty, floor-standing universal testing machines may be put to work examining everything from bolts and fasteners to plate steel and complex composites. The 5980 Series' very rigid structure is one of its outstanding features. This is especially crucial for testing crystalline polymers, metal alloys, and aerospace composites, all of which require a high degree of strength. Low-stretch drive belts, robust crosshead and base beam, and pre-loaded bearings all contribute to improved performance by providing more precise modulus and strain values and reducing energy storage during testing.

Features

- Accurately measure loads with a reading error of 0.5% down to 1/1000 of the load cell's capacity, and quickly collect data at up to 2,500 points per second in sync.

- Exceeds or meets the criteria of ISO, ASTM, BS, DIN, EN, and AFNOR, among other national and international standards.

- Thousands of test accessories for use in a wide variety of fields and industries, including biomedical, transportation, electronics, materials science, manufacturing, aerospace, textiles, and plastics.

- Equipped with the best calibration, training, preventative maintenance, and technical support in the business, all backed by the largest worldwide service organization in the field.

- Ergonomic handle with a wheel for precision position adjustment, two programmable softkeys, start, stop, and return buttons, and variable speed jog.

Bluehill® Universal Software

With Bluehill® Universal, our most recent static testing software, and the optional operator dashboard we've created to optimize your interaction with Bluehill® Universal's touch interface, you can rest assured that your testing is in line with the most recent revision of testing standards while also benefiting from Bluehill® Universal's ability to streamline your processes.

Read more about Instron Industrial Universal Testing Systems up to 2000 kN here

Related Products

Ask Us A Question

Subscribe to our Newsletter

Receive all our promotions, updates, news and much more...

CONTACT US

Diamond Spectrum for Scientific & Laboratory Equipment Co

Jeddah

Khobar

Taawon Group © 2024 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience

.webp)