.webp)

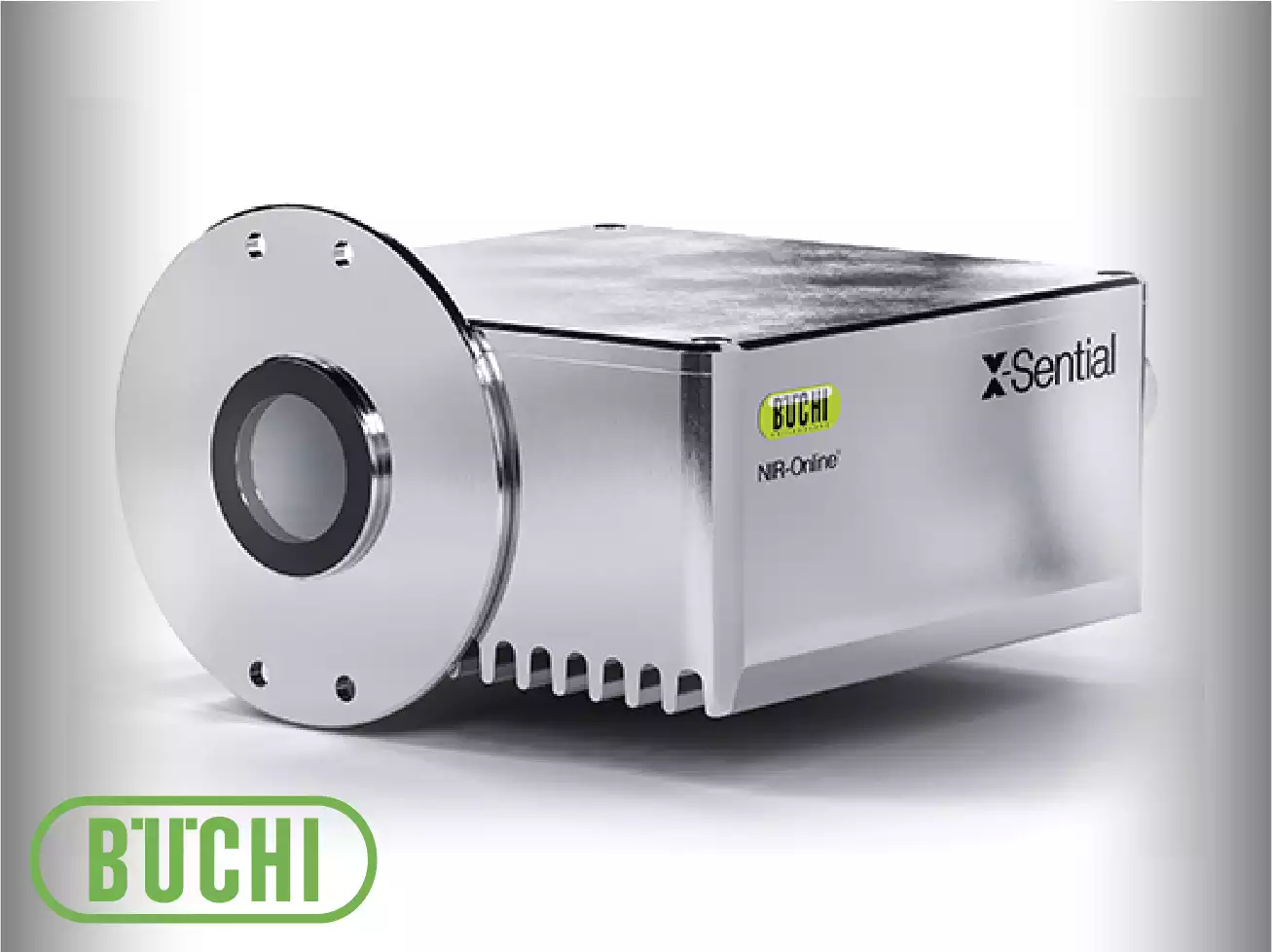

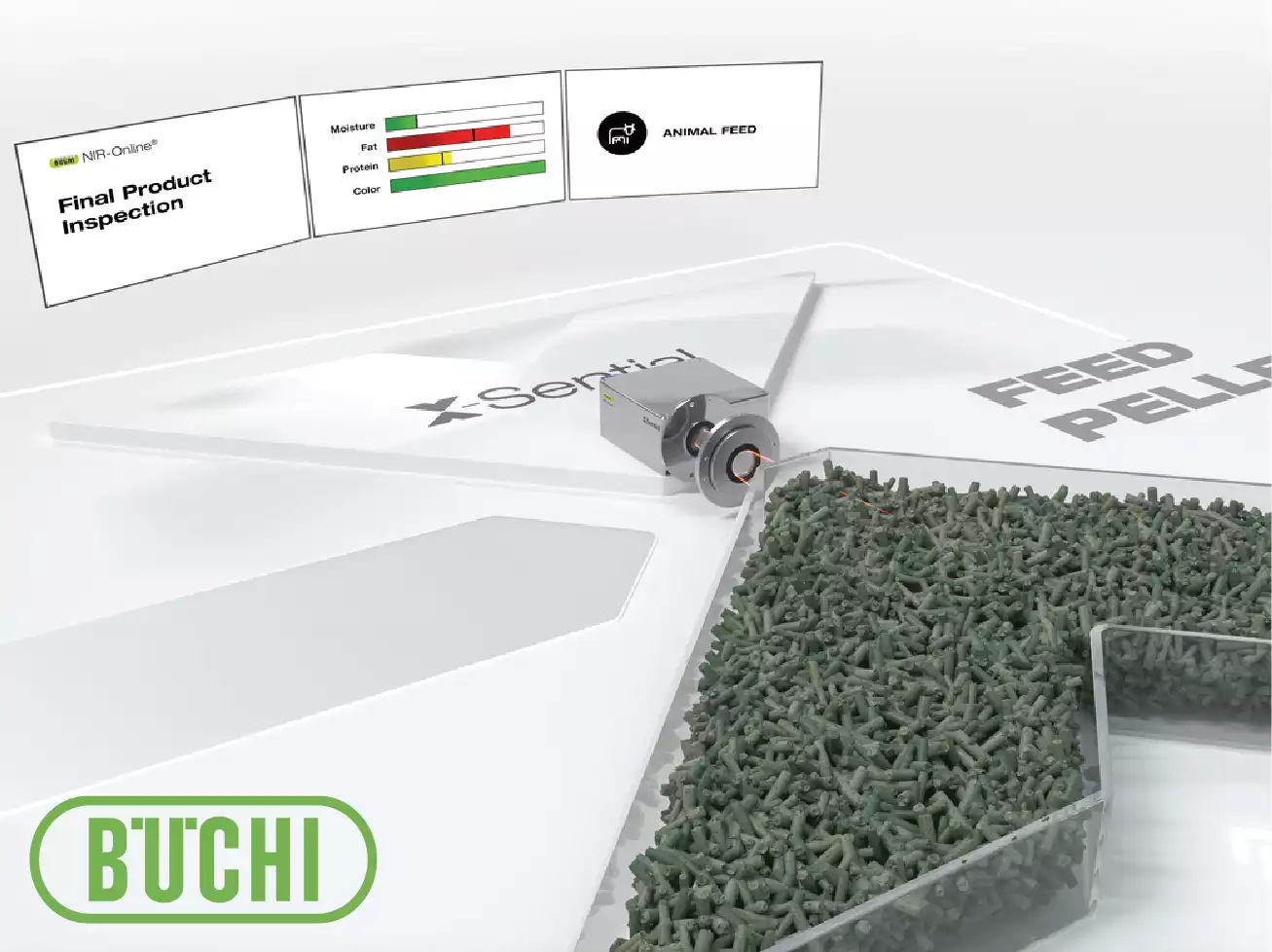

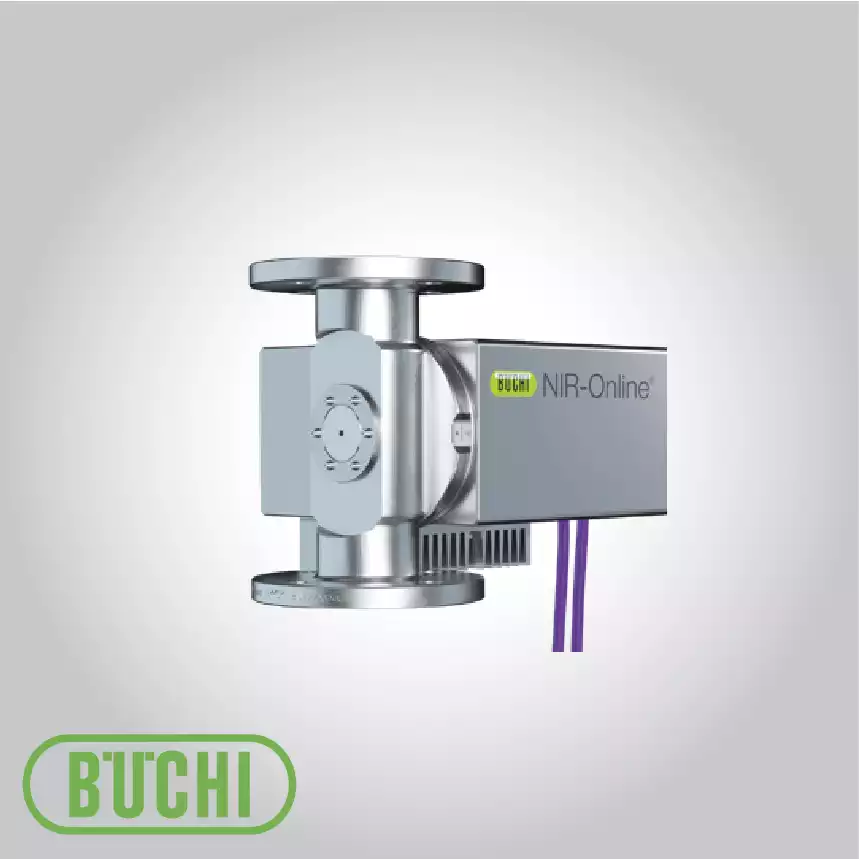

NIR-Online X-Sential

All that is essential for Process Control

BUCHI NIR-Online X-Sential

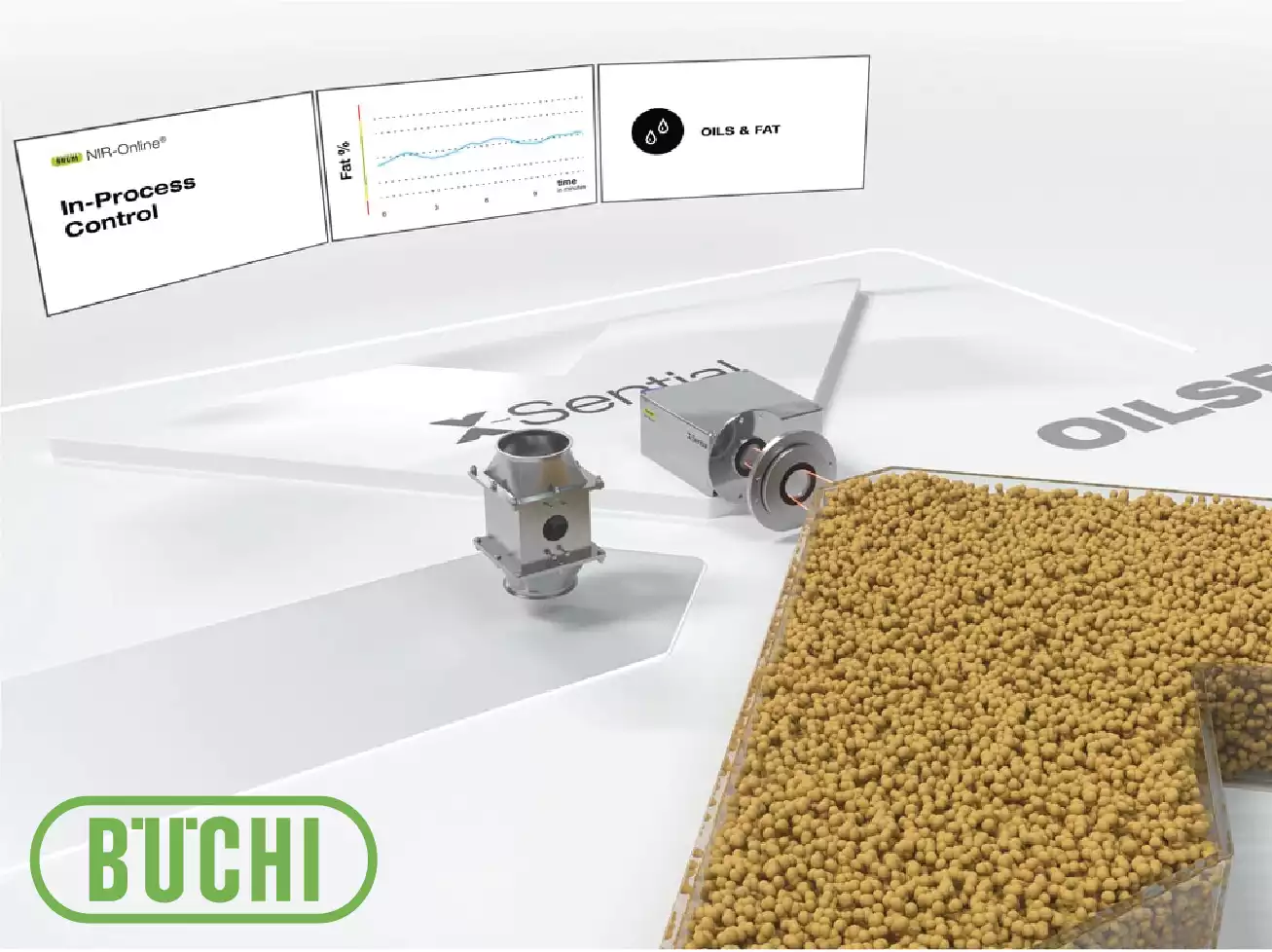

Closely monitoring basic parameters such as moisture, fat or protein is crucial to correct deviations in manufacturing processes. The X-Sential™ has been developed and designed as the most cost-efficient, fit-for-purpose process sensor.

Diode array technology: High speed spectrometer

IP class: Dust & water jet protected (IP69/X9K)

NIR: Wavelength range (900-1,700 nm)

Ease of use

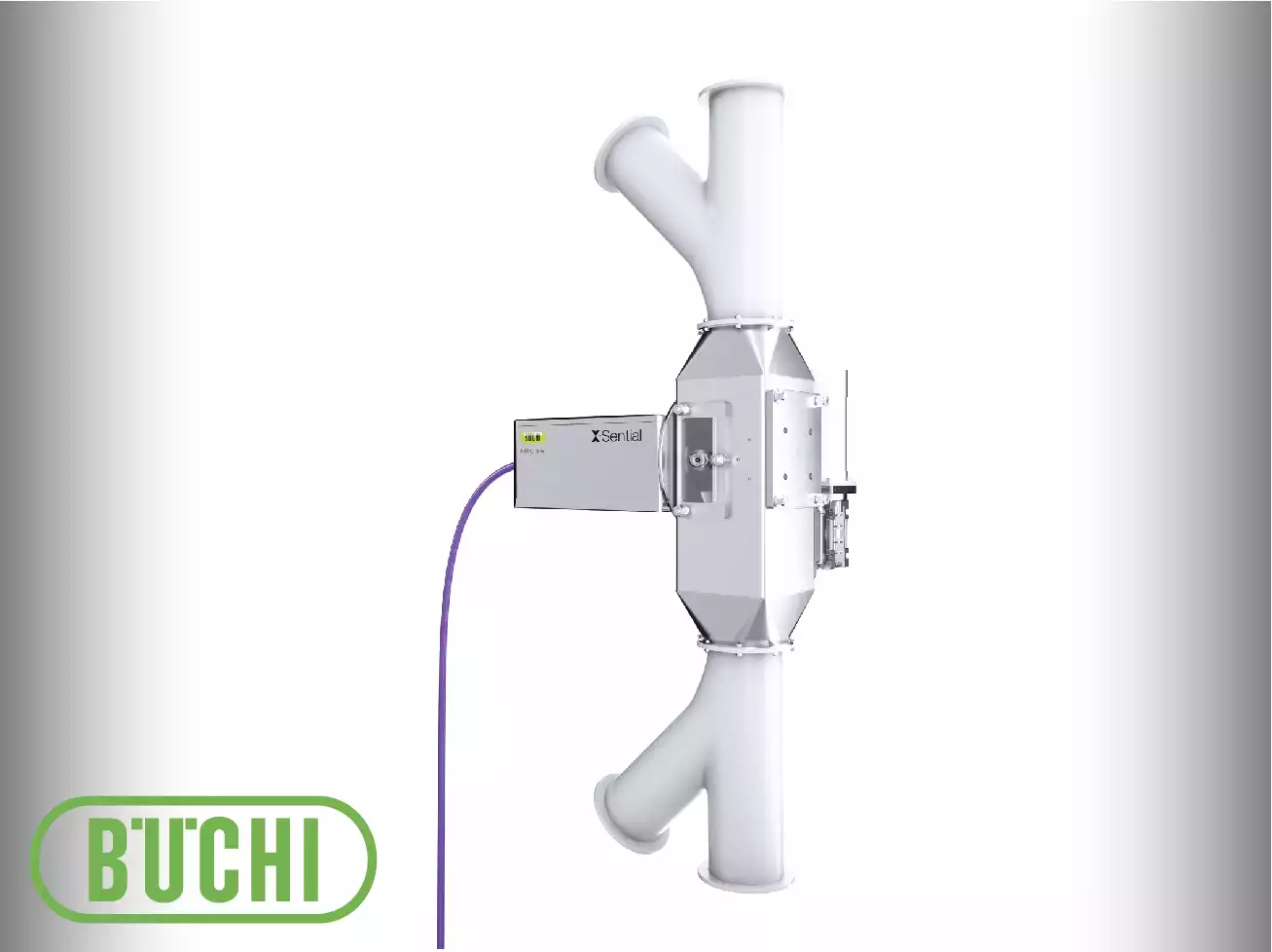

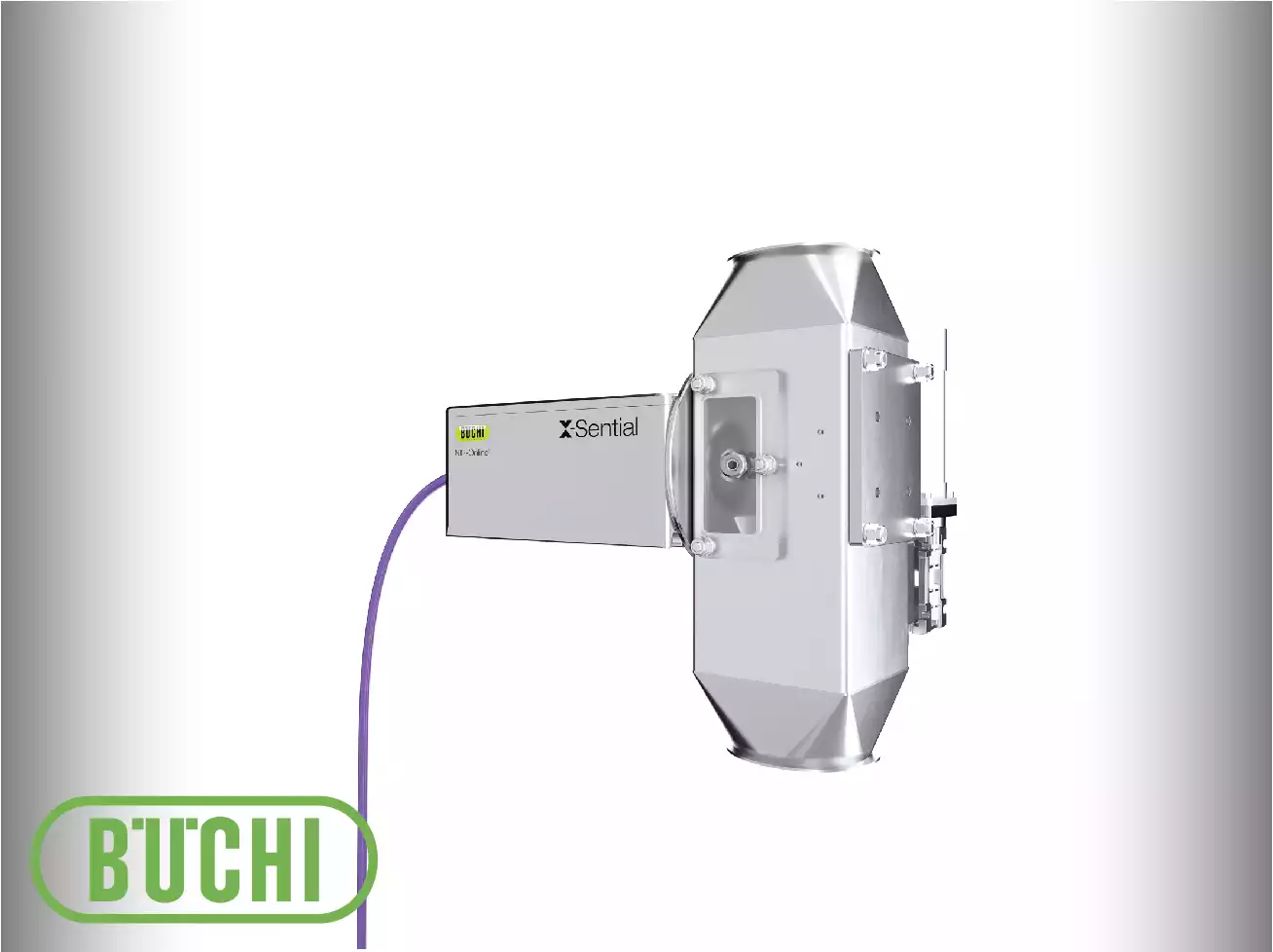

With its unique AutoCal functionality there is no need of expert knowledge to operate the X-Sential™. The process sensor can be easily implemented into your existing quality control routines. A wide range of process adapters allows easy integration into production lines. NIR-Online offers the user optional device independent HMI solutions.

Cost-efficiency

The functional design of the NIR-Online X-Sential™ is fit-for-purpose and therefore very cost effective. The average payback time is less than one year. There is no need for commercial calibration databases or extensive in-house calibration development. It is possible to determine basic quality parameters of raw materials and finished products in large quantities. This minimizes out-of-spec production and rework and allows to correct your processes in real-time.

Extensive process expertise

The NIR-Online X-Sential™ has a dust and water jet-protected sensor enclosure (IP69/X9K). A wide range of ambient and product temperatures is possible using temperature-stabilized spectrometers. The sensor is a turnkey solution for fast, fluctuating or discontinuous product flows. The integration into process control systems is straightforward.

AutoCal

Most convenient software tool available on the market for automated calibration development and maintenance. Valuable calibration data remains with you at all times - no need to outsource to external agencies. Simply enter the new reference value into the software and confirm via a simple click. No export/import functions, no manual calibration routines or extensive background in chemometrics are required. Eliminate the need to develop extensive in-house calibrations or purchase calibration data bases.

Triple temperature stabilization

1. Reliable measurements for product temperature up to 70°C

2. Water chiller for product temperatures up to 130°C

3. Air nozzle that enables analyzer operation in environments with temperatures of up to 55°C (voids ATEX).

Certified safety for harsh environment

Safe operation of your NIR device in harsh environments, certified with the highest testing criteria (IP69/X9K). Maximum safety through ingress protection and fulfillment of hygienic requirements for all materials in contact with the product.

Read more about BUCHI NIR-Online X-Sential