Home » Products » Analytical Solutions » Automated Reactors & IN SITU » Mettler Toledo Automated Synthesis & Process Development

Automated Lab Reactors

Control and record all reaction parameters

Mettler Toledo Automated Synthesis & Process Development

Chemical Synthesis Reactors

Chemical Synthesis Reactors

The innovative chemical synthesis reactors, EasyMax and OptiMax, are easy-to-use platforms that accurately and precisely control reaction parameters and execute recipes, thus enabling every chemist to perform reactions reproducibly. Experiment procedures can be run unattended, around the clock, all data is automatically recorded, and ready to be instantly shared and reported. Chemical reactors reinvent the way scientists work, enabling their ability to generate more information per experiment, and accelerate the delivery of life-changing products. Automated chemical synthesis reactors are well established in chemical and pharmaceutical industry, and are essential to speed up time-to-market cycles at lower R&D costs.

Synthesis Reactors To Fit Your Chemistry

Discover breakthrough molecules and explore novel synthetic steps using a variety of reactor designs. With a broad application range, the automated chemical reactors pose no limits on your creativity and productivity in the chemical synthesis laboratory. Reactor volumes range from 8 ml tubes to 1 L vessels, one-piece or two-piece reactors fit your chemistry and workflow. Chemical synthesis reactors operate with temperature ranges from -80 to 180 °C, overhead and magnetic stirring, vacuum, ambient to high pressure chemistry. Every chemist can enjoy solving complex chemistry problems using the walk-up chemical synthesis reactors.

Automated Synthesis Reactors for Chemistries at Sub-Ambient Temperature

EasyMax LowTemp expands the design space to a variable temperature range from -90 to 80 °C – for discovery of new synthetic pathways, process optimization and design of reactions at sub-ambient conditions including organometallic reactions (specifically metalation and lithiation). Unlike traditional equipment with discrete temperatures at 0 °C, -21 °C (sodium chloride in ice) and -78 °C (acetone/dry ice), EasyMax LT precisely controls experimental conditions along a broad temperature range – even when unattended.

Ensure Safe, Robust, and Scalable Processes

OptiMax lab reactor systems are designed to ensure safe, robust and scalable processes. Researchers can characterize and optimize chemical reactions in the liter scale before going to manufacturing. OptiMax chemical reactors are applied for go/no-go safety considerations when scaling-up through identifiying enthalpy, heat capacity, heat and mass transfer under process-like conditions. The synthesis reactors are widely applied when engineering particles by (re)crystallization with Particle Size Analyzers.

Automated, Repeatable Chemistry Around the Clock

The chemical reactors are designed to minimize bottlenecks, and maximize efficiency in chemical laboratories. More than ever, scientists are looking to automate tedious and manual chemical synthesis procedures. Automation of reaction conditions, experiment controls, and data collection increases personal productivity, while ensuring safe operations during day and night.

Jacketed Reactor Control & Automation

Jacketed Reactor Automation System

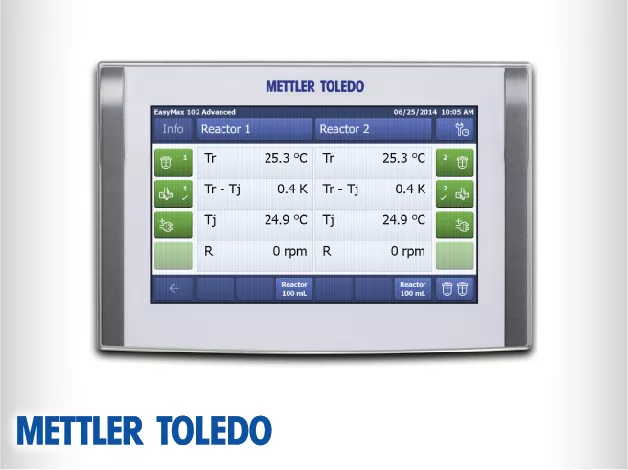

Connect and automate your jacketed reactor in the lab and control thermostats, stirrers and pumps with a single touchscreen interface that provides a consistent control platform across all laboratory reactors. Operating with one interface allows scientists to consistently control reactors on any scale from milliliters to multi-liter – reducing human error and training cost.

Automatically Collect Lab Process Data

Automatically collect process data from all laboratory reactors and sensors, together with data from in situ PAT instruments, including pH, particle size analysis, FTIR spectroscopy and chemical reaction sampling. Ensure that all data is automatically captured – guaranteeing that important information will never be lost again.

Unattended Control 24 Hours a Day

Program experimental sequences for improved lab productivity. The touchscreen or the powerful iC software suite offers bi-directional jacketed lab reactor control allowing scientist to apply both local and PC control to increase productivity – day and night.

Powerful Analysis and Reporting Tools

Reduce the time needed to merge process and analytical data, visualize and identify key reaction events and create smart reports. Automated reporting leads to better history logs, communication and decisions for improved process development and optimization.

Read more about Mettler Toledo Automated Synthesis & Process Development

.webp)