.webp)

Pilot Plant Equipment

Scaling up from test to small batch quantities

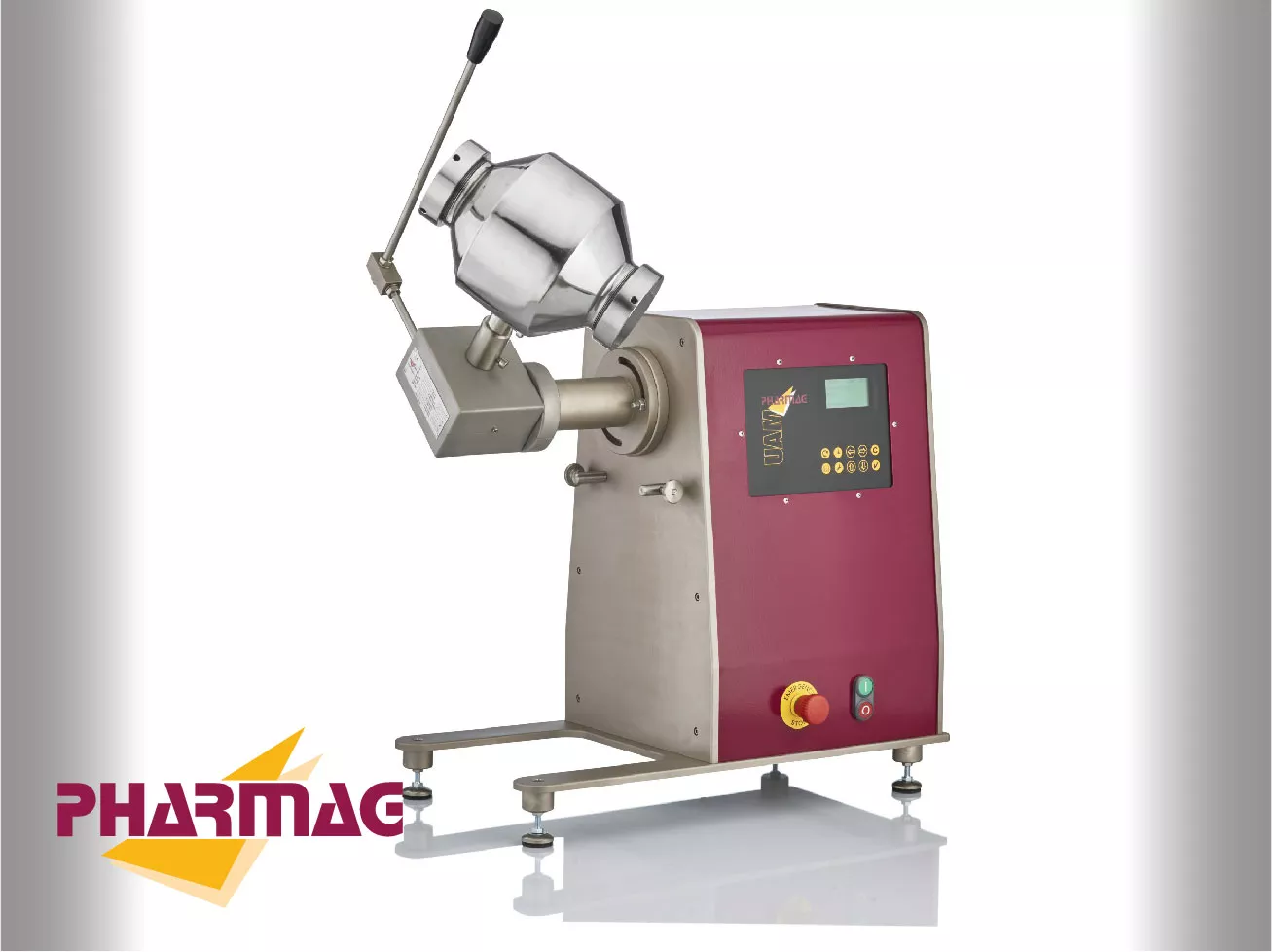

Pharmag Pilot Plant Equipment

The Pharmag Pilot Plant System is designed for specialist applications that include new product development, scaling up from test to small batch quantities and the production of speciality materials that are not necessarily manufactured in large quantities.

This type of equipment is equally suited to the fine chemical and cosmetics environment as well as the pharmaceutical industry. The Pharmag range also finds broad application in Pharmacy teaching departments (universities) and in the manufacture of low volume, speciality Pharmacist products. The basis of the system is the UAM motor drive which employs an industry standardised flange system to connect various interchangeable attachments for different applications. These attachments include mixers, stirrers, granulators and product enhancing tools such as tablet coaters.

Pharmag’s pilot plant systems cover a variety of applications:

1. Filling & dosing

- Dual liquid filling & dosing instrument.

- Ointment dosing & filling apparatus for free flowing viscous materials.

- Suppository and lipstick molding apparatus for mixing, dosing and molding of semi-solids of high melting points.

- Shaped moulds for rectal suppositories and vaginal globules.

2. Particle size reduction

- Ball mill for grinding and mixing solid and crystalline substances.

- Mini ball mill for preparing small samples for analysis.

- Dual roller crusher (dry granulator) for the preparation of granules.

3. Sieving and sorting

- Laboratory sieve shaker.

4. Blending, mixing, homogenization and kneading.

- Planetary mixer ideal mixing of creams, ointments and liquids.

- Homogenizer for homogenization of immiscible fluids.

- Sigma double-arm kneader based on the sigma-blade (Z) principle.

- Triple roller mill for homogenization during preparation of viscous preparations.

- CM-3.5 and CM-7.5 stainless steel cube blenders for different volumes.

- CMP-7.5 and CMP-12 plexiglas cube blenders for different volumes.

- Drum hoop blender for mixing solid materials.

- Double cone blender for sensitive, free flowing powders and granules.

- V-blender for bulk material blends with a very low blending ratio.

- Shear double ribbon blender with a twin set of ribbon blades.

- High speed ploughshare mixer generating an effective fluidized bed mixing.

- Liquid and powder agitator for stirring, agitating and beating of liquids.

5. Particle size enlargement

- Pelletizer for the production of pellets.

- Wet granulator operating according to the oscillating rotor principle.

6. Pilot plant

- UGD Universal Gear Drive transforms mechanical motion from the UAM to a variety of flanged attachments.

- UAM Universal Motor Drive industry-standardized tool with attachment flange.

7. Tablets finishing

- Polishing drum for the polishing of coated tablets.

- Coating pan designed for coating operations of different types of tablets, pellets and granules.

Read more about Pharmag Pilot Plant Equipment

.webp)