Product

Complete outstanding quality and functionality are delivered through METTLER TOLEDO's comprehensive range of laboratory balances and analytical instruments that provides users with flexibility and precision.

Boiling Range

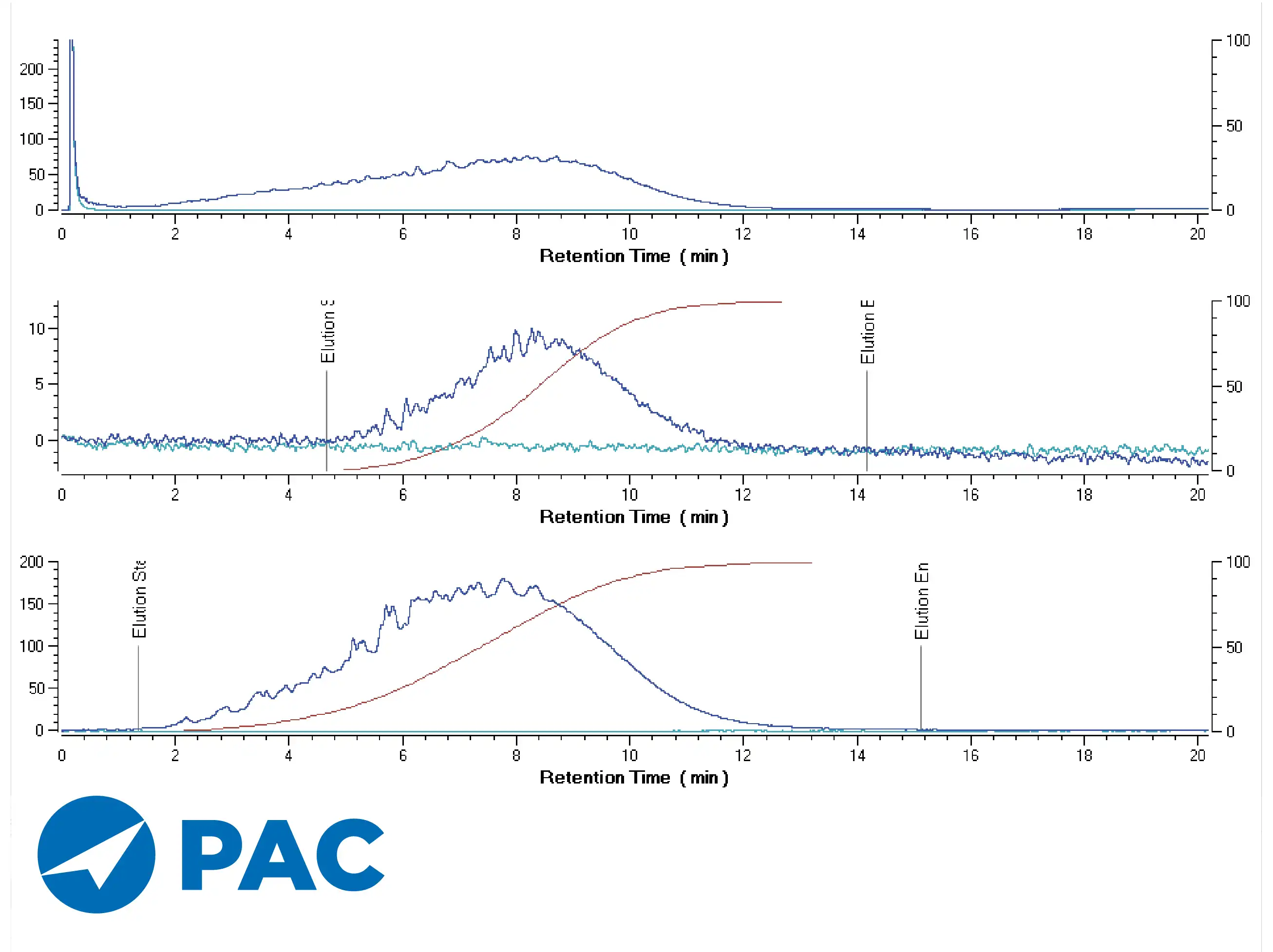

Boiling range analysis is a fundamental parameter for characterizing crude oil, providing essential information about its composition, volatility, and fraction distribution. It supports refining, blending, and quality assurance operations, enabling accurate evaluation of product yield, fuel properties, and compliance with industry standards.

PAC’s boiling range analyzer delivers automated, high-precision measurements, ensuring reproducible results with minimal operator intervention. Advanced digital sensors and temperature control allow for accurate determination of initial boiling point (IBP), final boiling point (FBP), and intermediate fractions, critical for understanding crude oil behavior during refining and processing.

The system accommodates a wide variety of crude oil samples, from light sweet crudes to heavy sour varieties, with high thermal stability and consistent temperature profiles. This ensures that high-boiling fractions are accurately analyzed without thermal cracking or sample degradation, maintaining the integrity of the measurement.

Automated sample handling and temperature ramping streamline the analysis, reducing sample volume requirements while enhancing laboratory efficiency. Minimal operator involvement increases reproducibility and safety, making the system suitable for both research laboratories and high-throughput industrial testing environments.

High-resolution data acquisition provides detailed boiling range curves and accurate calculation of recovery percentages for each fraction. This allows laboratories to monitor batch-to-batch consistency, assess crude quality, and optimize refining processes based on volatility and compositional information.

The analyzer integrates with laboratory information management systems (LIMS) for seamless data logging, reporting, and traceability. Automated calibration routines and quality verification checks further enhance reproducibility and reliability, ensuring compliance with international standards such as ASTM D2887 and ISO 3405.

Boiling range determination is critical for refining operations, fuel certification, and R&D projects. The system helps engineers and chemists predict product yield, design fractionation processes, and evaluate crude oil suitability for specific applications, improving overall operational efficiency and product quality.

Combining automation, advanced temperature control, and high-precision detection, PAC’s boiling range analyzer delivers reliable, reproducible, and detailed results. Laboratories and industrial facilities benefit from streamlined workflows, reduced sample consumption, and accurate characterization of crude oil volatility and fraction distribution.