Boiling Range analysis of Crude Oil

Boiling Range Analyzer for Accurate Crude Oil Characterization

PAC Boiling Range Distillation

Boiling range analysis is a fundamental parameter for characterizing crude oil, providing essential information about its composition, volatility, and fraction distribution. It supports refining, blending, and quality assurance operations, enabling accurate evaluation of product yield, fuel properties, and compliance with industry standards.

PAC’s boiling range analyzer delivers automated, high-precision measurements, ensuring reproducible results with minimal operator intervention. Advanced digital sensors and temperature control allow for accurate determination of initial boiling point (IBP), final boiling point (FBP), and intermediate fractions, critical for understanding crude oil behavior during refining and processing.

Integrated CNS Characterization of Crude Oil

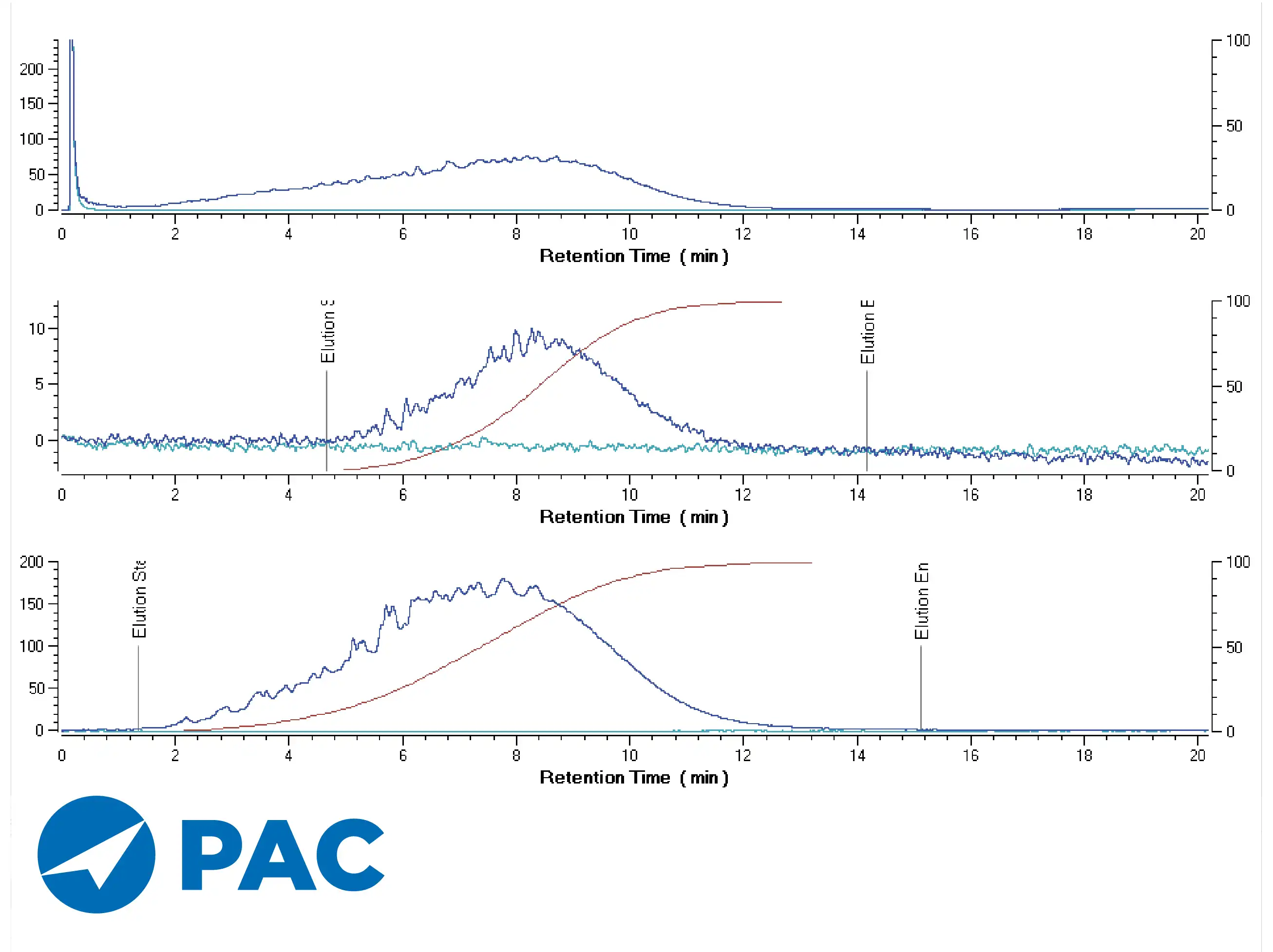

The PAC CNS SimDist is technically engineered to provide more than just a carbon boiling point distribution. It integrates the simultaneous analysis of Carbon (C), Nitrogen (N), and Sulfur (S) within a single chromatographic run. This multi-element approach is essential for refineries to understand the distribution of heteroatoms across the entire boiling range of crude oil. By correlating Sulfur and Nitrogen content with specific boiling fractions, operators can better predict the behavior of the feedstock during secondary conversion processes and hydrotreating.

High-Temperature Simulated Distillation Capabilities

To accurately characterize heavy petroleum fractions and crude oil, the system utilizes high-temperature simulated distillation (HTSD) techniques. The use of robust, high-temperature capillary columns and specialized injection systems ensures that even the heaviest components, such as vacuum residues, are fully eluted and accounted for, preventing the carry-over or discrimination of high-molecular-weight hydrocarbons.

Advanced Chemiluminescence Detection Technology

A technical cornerstone of this system is the use of Sulfur Chemiluminescence Detection (SCD) and Nitrogen Chemiluminescence Detection (NCD). These detectors provide a highly linear and equimolar response to sulfur and nitrogen species, regardless of their chemical structure. This allows the system to quantify the concentration of these elements across the distillation curve with high sensitivity and precision. The specificity of SCD and NCD ensures that there is no interference from the hydrocarbon matrix, which is a critical requirement for accurate crude oil characterization.

Automated Injection and Sample Handling

The system incorporates sophisticated automation for sample introduction to ensure repeatability and minimize manual errors. The automated injection system is technically designed to handle the high viscosity of crude oil samples, often utilizing heated inlets or specialized solvents to ensure a representative sample is introduced into the column. This automation extends to the software control, which manages the temperature ramping of the GC oven and the synchronized triggering of the multiple detectors used in the CNS configuration.

Mass Balance and Recovery Calculations

A vital technical aspect of Simulated Distillation for crude oil is the determination of the non-eluted fraction, or the "residue." The PAC CNS SimDist software performs complex calculations to determine the mass balance of the sample. By comparing the total detector response against an external standard with a known recovery, the system can calculate exactly how much of the sample boiled off and how much remains as a heavy residue. This information is critical for calculating refinery yields and assessing the economic value of different crude assays.

Compliance with International Analytical Standards

The CNS SimDist system is technically aligned with major international standards such as ASTM D2887, D6352, D7169, and D7500. These methods define the parameters for simulated distillation across various petroleum products. By adhering to these standardized protocols, the PAC system ensures that the data generated is globally recognized and comparable. This compliance is essential for trade, regulatory reporting, and ensuring that the refinery's internal quality control meets industry-leading benchmarks for boiling range analysis.

Sophisticated Data Processing Software

The technical performance of the hardware is complemented by a powerful software suite designed specifically for simulated distillation. The software automates the conversion of chromatographic retention times into boiling point temperatures using a calibration curve of known n-alkanes. It also provides specialized modules for CNS correlation, allowing users to overlay sulfur and nitrogen profiles directly onto the carbon distillation curve. This integrated data environment simplifies the interpretation of complex crude oil assays and speeds up the decision-making process in the lab.

Enhanced Refinery Process Optimization

Technically, the detailed boiling range data provided by the CNS SimDist allows for superior refinery process optimization. By knowing the exact distribution of sulfur and nitrogen, process engineers can optimize the catalyst loading in hydrocrackers and desulfurization units. This helps in extending catalyst life and improving the quality of the final products, such as gasoline and diesel. The ability to characterize the crude oil feedstock with such precision directly contributes to the operational efficiency and profitability of the petroleum refining process.

Read More About PAC Products Here

.webp)

.webp)

.webp)

.webp)

.webp)