Diesel Thermal Oxidation Testing

High-Precision Fuel Stability and Deposit Analysis

PAC Diesel Thermal Oxidation Testing

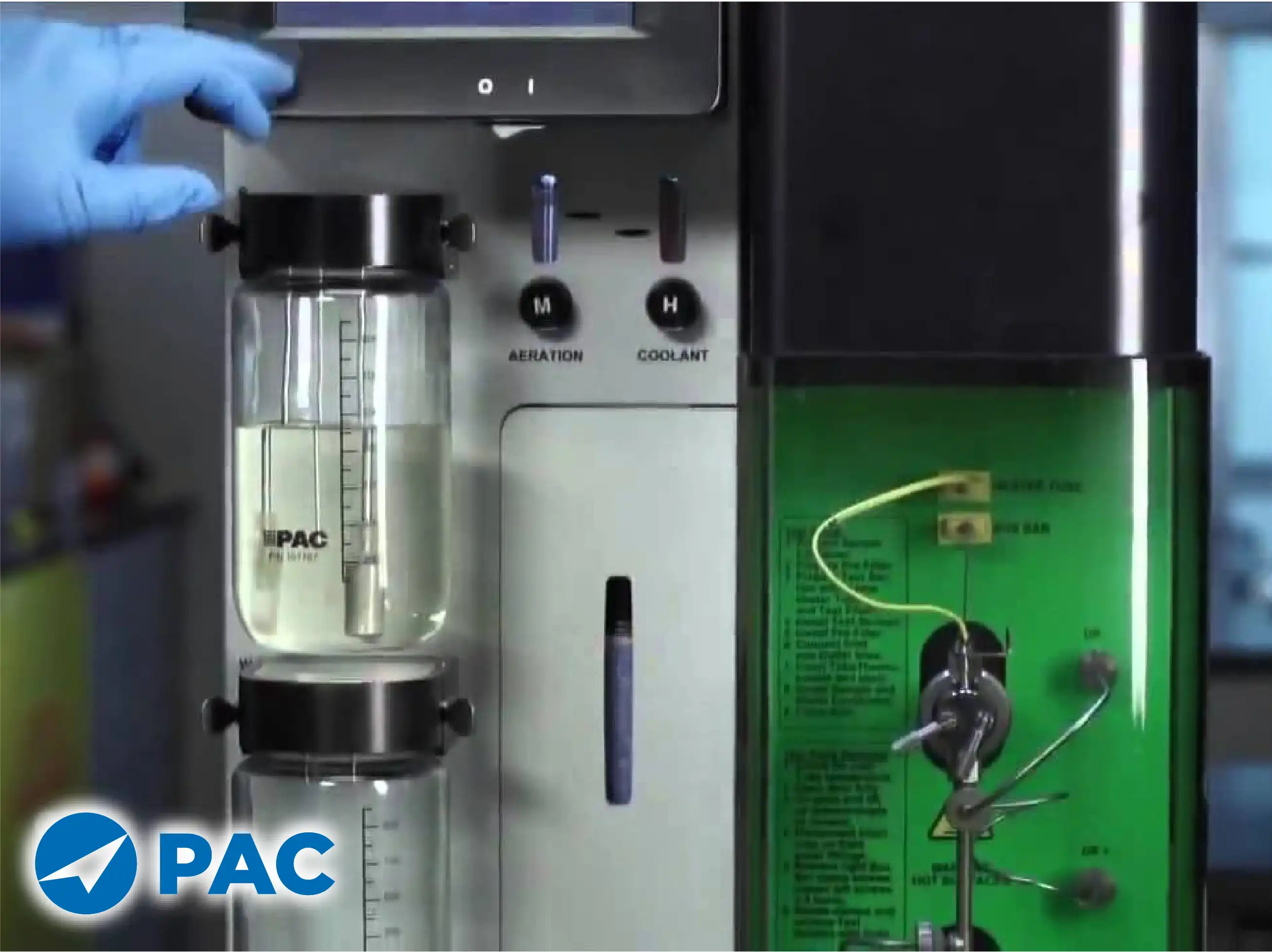

Diesel Thermal Oxidation Testing evaluates the thermal stability of diesel fuels under high-temperature flow conditions that replicate operational stress in engines and fuel systems. This testing assesses the tendency of diesel to form deposits, color changes, and chemical degradation products that can impair injector performance, increase fouling, or reduce combustion efficiency. Accurate evaluation ensures fuel reliability, engine safety, and consistent performance over time.

The system utilizes precision-controlled heater tubes that maintain uniform and stable temperatures along the fuel pathway. Integrated sensors continuously monitor flow rates and temperatures to provide reproducible conditions that meet standardized testing protocols. This precise control allows detailed assessment of diesel thermal stability, deposit formation tendencies, and oxidative behavior under realistic operating conditions.

Assessment of High-Temperature Fuel Stability

The Diesel Thermal Oxidation Tester (DTOT) is technically engineered to simulate the thermal stress that diesel fuel undergoes within high-pressure common rail (HPCR) engines. As fuel is used as a coolant for the injectors and is recirculated to the fuel tank, it is subjected to significant heat. The DTOT evaluates the fuel's tendency to degrade and form insoluble deposits under these conditions. This assessment is critical for preventing injector fouling and fuel filter plugging, ensuring the long-term reliability of modern high-performance diesel engines.

Advanced Heater Tube Technology

The core of the DTOT analytical process involves passing the diesel sample over a specialized heater tube at a controlled flow rate and temperature. Technically, the heater tube acts as a catalyst for the oxidation process. The system monitors the temperature of the tube surface with extreme precision, creating a localized environment where the fuel's thermal limits are tested. Any degradation results in the formation of lacquers or deposits on the tube surface, which are then analyzed to determine the fuel’s thermal stability rating.

Precision Flow and Pressure Regulation

To maintain the integrity of the test, the DTOT utilizes a sophisticated pumping system that ensures a constant and pulse-free flow of fuel over the heater tube. The system also maintains a specific operating pressure, which is essential for mimicking the environment of a fuel system. By strictly governing these pneumatic and hydraulic parameters, the instrument ensures that the results are repeatable and that the oxidation occurs in a manner consistent with international testing protocols, reducing variability between different laboratory sites.

Differential Pressure Monitoring Across the Test Filter

In addition to observing deposits on the heater tube, the DTOT monitors the increase in differential pressure across a precision test filter located downstream of the heating zone. As the fuel oxidizes, it produces fine particulate matter and gums. The rate at which these solids clog the filter provides a quantitative measure of the fuel's "filterability" after thermal exposure. This dual assessment—looking at both surface deposits and filter plugging—provides a comprehensive technical profile of the fuel’s high-temperature behavior.

Automation and User-Independent Operation

The PAC DTOT is designed for fully automated operation, which significantly reduces the potential for operator-induced errors. From the initial priming of the system to the final cooling phase, the instrument manages the entire test cycle. The software controls the temperature ramping, the duration of the fuel exposure, and the data acquisition of pressure and temperature sensors. This automation ensures that the complex sequence of thermal oxidation is performed identically every time, providing high-quality data for refinery process control.

Integration of Advanced Safety Features

Since the DTOT involves heating flammable hydrocarbons to high temperatures, the system is equipped with multiple technical safety layers. These include automatic leak detection, over-temperature protection, and a sophisticated fume extraction interface. The system is designed to shut down safely if any parameter deviates from the safety window. This allows the instrument to operate with minimal supervision in a busy laboratory environment, ensuring the safety of the personnel and the facility.

Evaluation of Biodiesel and Renewable Blends

As the industry shifts toward renewable energy, the DTOT plays a vital role in evaluating the thermal stability of Fatty Acid Methyl Esters (FAME) and other biofuels. Biofuels are technically more prone to oxidation than traditional petroleum diesel. The DTOT allows researchers and fuel blenders to determine how different concentrations of biodiesel affect the overall stability of the fuel blend. This data is essential for optimizing the use of antioxidant additives and ensuring that renewable fuels meet the rigorous standards of engine manufacturers.

Digital Data Management and Traceability

The instrument is integrated with a digital interface that records all test parameters in real-time, including flow rates, tube temperatures, and pressure drops. This data is stored in a permanent electronic record, supporting full traceability and compliance with quality management systems like ISO 17025. The results can be easily exported to a Laboratory Information Management System (LIMS), allowing for the rapid analysis of fuel batches and ensuring that only fuels meeting the thermal stability specifications are released for distribution.

Read More About PAC Products Here

.webp)

.webp)

.webp)

.webp)

.webp)