Extraction Solutions

Maximized throughput

Buchi Extraction Solutions

Buchi's portfolio of extraction instruments provides advanced and versatile solutions for chemical analysis in life sciences, food/feed, and environmental sectors. The core technical approach centers on two key methodologies: conventional solvent extraction (including variations like Soxhlet, Hot Extraction, and Twisselmann) and Pressurized Solvent Extraction (PSE). These instruments are engineered to address demanding analytical tasks, allowing for the isolation of target components, such as fat, organic compounds, and natural products, from a variety of matrices including solids and semi-solids.

The efficiency and technical compliance of these solutions are optimized through features like individual process control across multiple positions, high-speed heating, and the use of elevated temperatures and pressures in the PSE method. For applications requiring total fat determination, the extraction phase is often complemented by a dedicated semi-automated acid hydrolysis unit, ensuring compliance with standardized methods (e.g., Weibull-Stoldt, AOAC).

Universal Extractor for Method Versatility

The Universal Extractor is a versatile instrument designed to handle demanding extraction tasks across various matrices, including food, environmental samples, polymers, and natural products. Its defining feature is the capability to simultaneously execute six distinct extraction methods and allows for individual process control at each position. This flexibility supports methods like Soxhlet, Soxhlet Warm, Hot Extraction, Continuous Flow, and Twisselmann. The unit is compatible with various organic solvents having a boiling point below $150^\circ\text{C}$, as well as water, offering a comprehensive platform for optimizing different analytical protocols and achieving highly reproducible results through sophisticated process control.

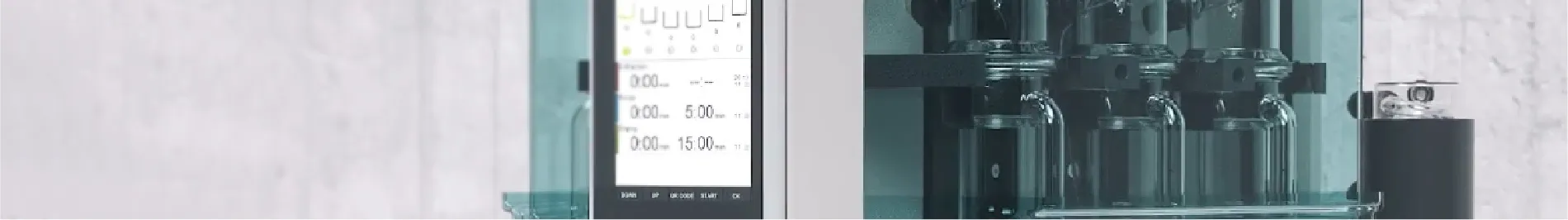

High-Speed Accelerated Solvent Extraction (ASE)

The SpeedExtractor is an automated instrument specifically engineered for Pressurized Solvent Extraction (PSE), a method that accelerates conventional techniques by utilizing elevated temperatures and pressures. This approach is crucial for the rapid isolation of primarily organic compounds from solid or semi-solid matrices, encompassing samples such as environmental samples, food, polymers, and natural products. The parallel nature of the instrument allows for the simultaneous extraction of up to six samples in a single run. The accelerated conditions drastically reduce extraction time, enhancing laboratory productivity and streamlining the overall workflow from sample preparation to final analysis.

Dedicated Fat Extraction for Regulatory Compliance

The FatExtractor is designed for the rapid and compliant determination of fat content in food and feed samples. This specialized instrument offers flexibility through interchangeable glass assemblies which allow operators to readily adapt the unit to execute extractions according to internationally recognized methods such as Soxhlet, Randall, or Twisselmann. The system is optimized for use with common organic solvents including petroleum ether, hexane, and chloroform. Its focus on speed and method compliance makes it essential for high-throughput quality control laboratories where quick, accurate, and regulated fat analysis is required.

Acid Hydrolysis for Total Fat Determination

For the accurate measurement of total fat content in samples, the extraction process must often be preceded by an acid hydrolysis step, such as the Weibull-Stoldt or AOAC standardized methods. The HydrolEx is a dedicated, semi-automated unit that ensures safe and convenient acid hydrolysis by utilizing 4 M Hydrochloric acid to handle up to six samples simultaneously. This instrument is an ideal complement to the fat extractor, as it effectively breaks down complex sample matrices, releasing all bound fat components prior to the solvent extraction phase, thereby ensuring a complete and compliant determination of total fat.

Automation and Productivity in PSE

A key technical advantage of the Pressurized Solvent Extraction instrument is its high degree of automation and parallel processing capability. The instrument facilitates the simultaneous extraction of multiple samples (e.g., six samples in one run). This parallel concept, combined with the accelerated kinetics achieved through high temperature and pressure, maximizes laboratory productivity. Furthermore, the instrument offers a variety of extract collection options designed for seamless synergy with other parallel evaporation and concentration systems, such as the Multivapor and SyncorePlus Analyst, effectively streamlining the entire sample workflow.

Managing Solvents and Extraction Conditions

The selection and management of solvents are critical technical factors in all extraction methods. The general-purpose extractors are compatible with a wide range of organic solvents (boiling point $< 150^\circ\text{C}$) and water. For fat extraction, specific non-polar solvents like petroleum ether and hexane are employed. In the accelerated methods, the system allows for the use of solvent at elevated temperatures and pressures to increase analyte solubility and diffusion rate, thereby accelerating the extraction process without compromising the integrity of the target compounds. Sophisticated internal controls manage these conditions for optimal and reproducible recovery.

Applications in Polymer and Environmental Analysis

Beyond food and feed, the extraction solutions are critical for isolating target compounds from complex matrices in polymer and environmental applications. For polymers, extraction is used to determine additives, unreacted monomers, or residual chemicals. In environmental testing, the instruments are essential for extracting pollutants or contaminants from solid samples. The Universal Extractor and the SpeedExtractor are particularly suited for these demanding applications, providing the necessary method flexibility (Soxhlet variations) or the speed and efficiency (PSE) required to analyze these diverse and challenging sample types.

Ensuring Reproducibility through Process Control

The Buchi extraction instruments are engineered to deliver reproducible extraction processes, which is a fundamental requirement of analytical chemistry. This is achieved through sophisticated process control mechanisms, particularly in the universal and speed extractors. These controls manage parameters such as high-speed heating rates, precise temperature and pressure maintenance, and automated cycle timing. For the universal extractor, the ability to individually control the process at each of the six extraction positions further enhances reproducibility, ensuring that variations in sample size or matrix do not compromise the integrity of the analytical result.

Read More About Buchi Products Here.

.webp)

.webp)

.webp)