.webp)

Home » Products » IVF and Life Science » IVF Equipment & Solutions » Esco Multi-Zone ART Workstation Class II

Multi-Zone ART Workstation Class II

Providing sample, user and environmental protection.

Esco Multi-Zone ART Workstation Class II

The Esco Multi-Zone ART Workstation Class II is a technically advanced containment system designed specifically for Assisted Reproductive Technology (ART) laboratories. It provides a highly controlled ISO Class 5 environment, utilizing a vertical laminar airflow system to protect sensitive biological samples from airborne contamination. The workstation is engineered with a dual-filtration system, including a pre-filter and a main HEPA filter, ensuring that the air within the work zone is free from particulates and Volatile Organic Compounds (VOCs).

Beyond air quality, this workstation integrates sophisticated thermal management through its multi-zone heated surface technology. The worktop is divided into several independently controlled heating zones, allowing for precise temperature uniformity across the entire surface. This ensures that culture dishes and specimens remain at a constant physiological temperature, typically 37 C, during observation and handling. The technical design also incorporates features for ergonomic comfort and microscopic integration, allowing embryologists to work with high precision over extended periods.

Advanced Vertical Laminar Airflow System

The technical foundation of the workstation is its vertical laminar airflow, which creates a positive pressure environment within the work zone. This downward-moving air acts as a barrier, preventing external contaminants from entering the sterile area. The laminar pattern ensures that any particles generated during manipulation are swept away immediately, maintaining an ISO Class 5 air quality standard. This continuous purification is vital for preserving the viability of gametes and embryos that are extremely sensitive to environmental shifts.

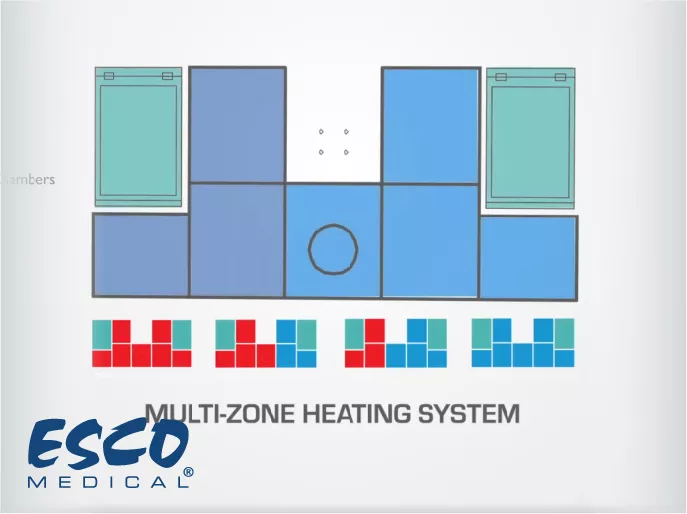

Multi-Zone Heating for Thermal Uniformity

Precision heating is achieved through a specialized multi-zone heated work surface. Each zone is equipped with its own sensor and heating element, allowing the system to compensate for local heat loss caused by cold culture dishes or airflow. This technical configuration prevents "cold spots" on the worktop, ensuring that specimens are always maintained at an optimal 37 C. The independent control allows for high thermal stability, which is essential for preventing temperature-induced stress on sensitive biological cells.

High-Efficiency HEPA and VOC Filtration

To ensure a safe atmosphere for embryo development, the workstation utilizes high-efficiency HEPA filters that remove 9$99.99\%$ of particles larger than 10$0.3\mu\text{m}$.11 Furthermore, specialized VOC filtration is integrated to eliminate volatile organic compounds, which are known to be embryotoxic. This dual-layer filtration strategy ensures that both the physical particulates and chemical gaseous contaminants are removed from the recirculating air, providing an ultra-pure microenvironment for delicate ART procedures.

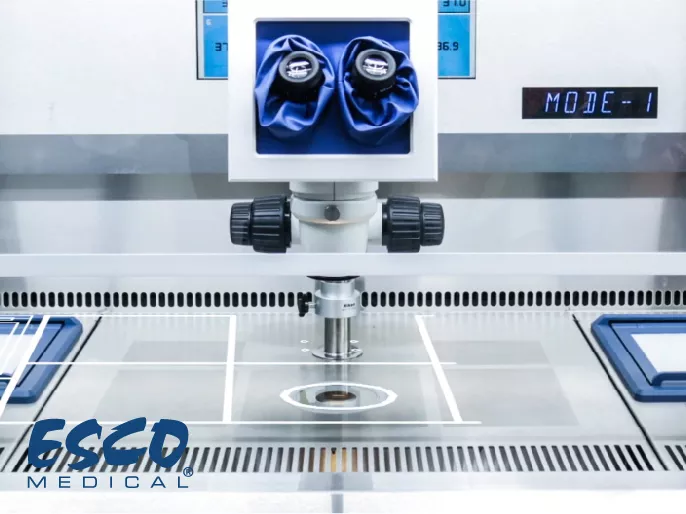

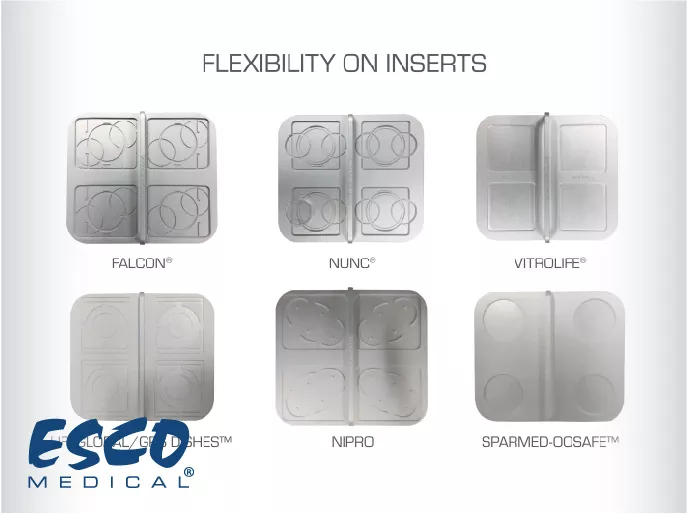

Integrated Microscopic Observation Zones

The workstation is designed for seamless integration with stereo microscopes.12 Specialized glass heating plates or transparent heating zones are embedded directly into the worktop, allowing for continuous temperature control while samples are being observed under the microscope. This technical design eliminates the need to move specimens between separate heated stages and the workstation, minimizing the duration that embryos are exposed to sub-optimal conditions and reducing the risk of accidental spills or contamination.

Ergonomic Design and User Protection

The workstation features an ergonomically sloped front to reduce operator fatigue during long procedures. The Class II design also provides a level of protection for the user by creating an air curtain at the front opening, which prevents potentially hazardous biological materials from escaping the work zone. The technical layout includes adjustable stands and integrated lighting systems that can be customized to provide optimal visibility without generating excessive heat that could interfere with specimen temperature.

Humidification and Gas Supply Integration

Maintaining the correct pH and osmotic balance in culture media is technically supported by integrated gas and humidification ports. The workstation can be equipped with gas flow meters and heated humidification systems that deliver pre-conditioned gas mixtures directly to the work zone or to specialized incubation chambers within the unit.13 This allows embryologists to maintain the required $\text{CO}_{2}$ and $\text{O}_{2}$ levels even while working outside of a standard incubator, ensuring the atmospheric stability of the culture media.

Intuitive Control System and Monitoring

The workstation is governed by a microprocessor-based control system that monitors airflow velocity, filter life, and surface temperatures in real-time. An intuitive LCD or LED interface provides the operator with continuous feedback on all critical parameters. Audible and visual alarms are triggered if any parameter deviates from the set point, providing a technical safeguard that ensures procedures are always conducted under validated, sterile, and thermally stable conditions.

Antimicrobial Coating and Easy Decontamination

The external and internal surfaces of the workstation are treated with an antimicrobial coating to inhibit the growth of bacteria and mold.14 Technically, this silver-ion-based coating provides an additional layer of safety by reducing the bioburden on physical surfaces.15 The work zone is constructed from medical-grade stainless steel with coved corners, making it easy to clean and decontaminate with standard laboratory agents, thereby ensuring long-term sterility and preventing cross-contamination between different patient cycles.

Read more about Esco Multi-Zone ART Workstation Class II