.webp)

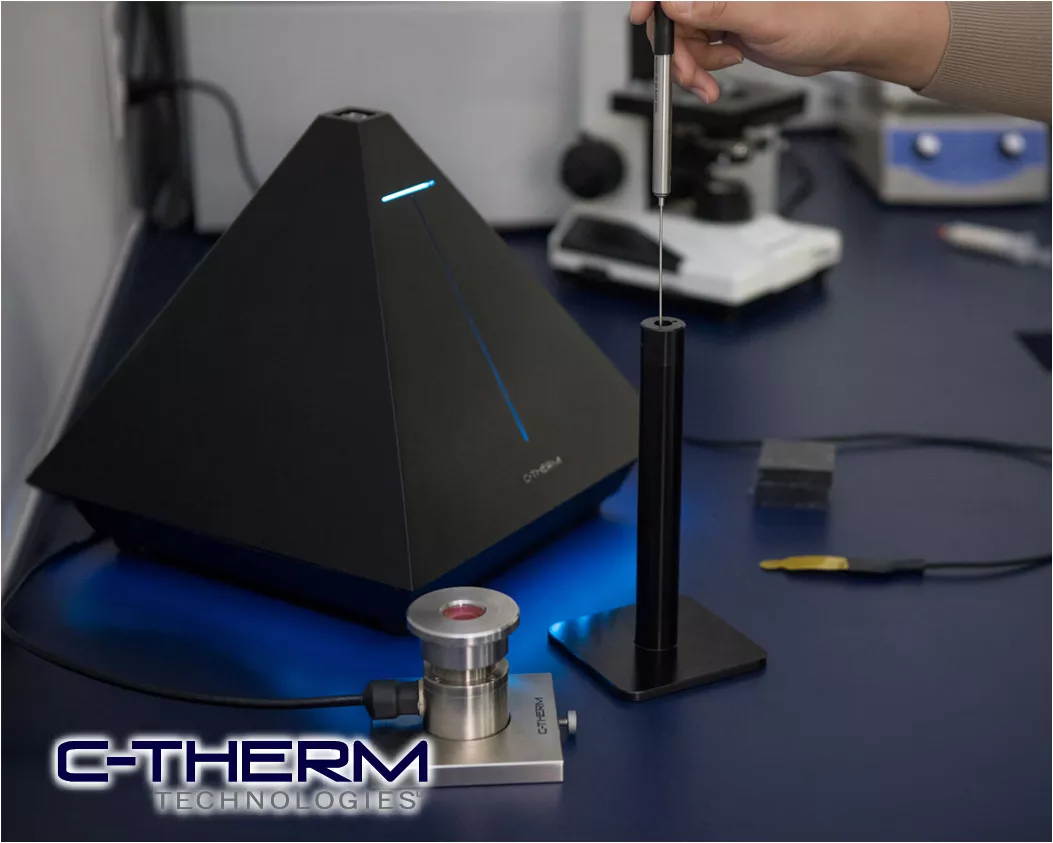

Multiple Sensor Options

1 instrument, 3 methods for thermal conductivity

C-THERM Thermal Conductivity

The C-Therm thermal conductivity platform is a highly modular and versatile analytical system designed to meet the rigorous demands of material characterization across various industries. At its core, the platform integrates three primary transient measurement techniques into a single unit, providing a comprehensive solution for evaluating the thermal transport properties of solids, liquids, powders, and pastes. This multi-sensor approach allows researchers and quality control professionals to select the most appropriate method—whether it be the rapid, single-sided Modified Transient Plane Source (MTPS), the flexible Transient Plane Source (TPS), or the high-precision Transient Hot Wire (THW)—to achieve accurate results across a wide range of thermal conductivity values.

Technically, the system is engineered to provide absolute and indirect measurements of thermal conductivity, thermal effusivity, thermal diffusivity, and specific heat capacity. Its non-destructive nature and minimal-to-zero sample preparation requirements make it an ideal tool for accelerating research and development cycles. By adhering to international standards such as ASTM D7984, ISO 22007-2, and ASTM D7896, the platform ensures that data generated is both reproducible and globally recognized.

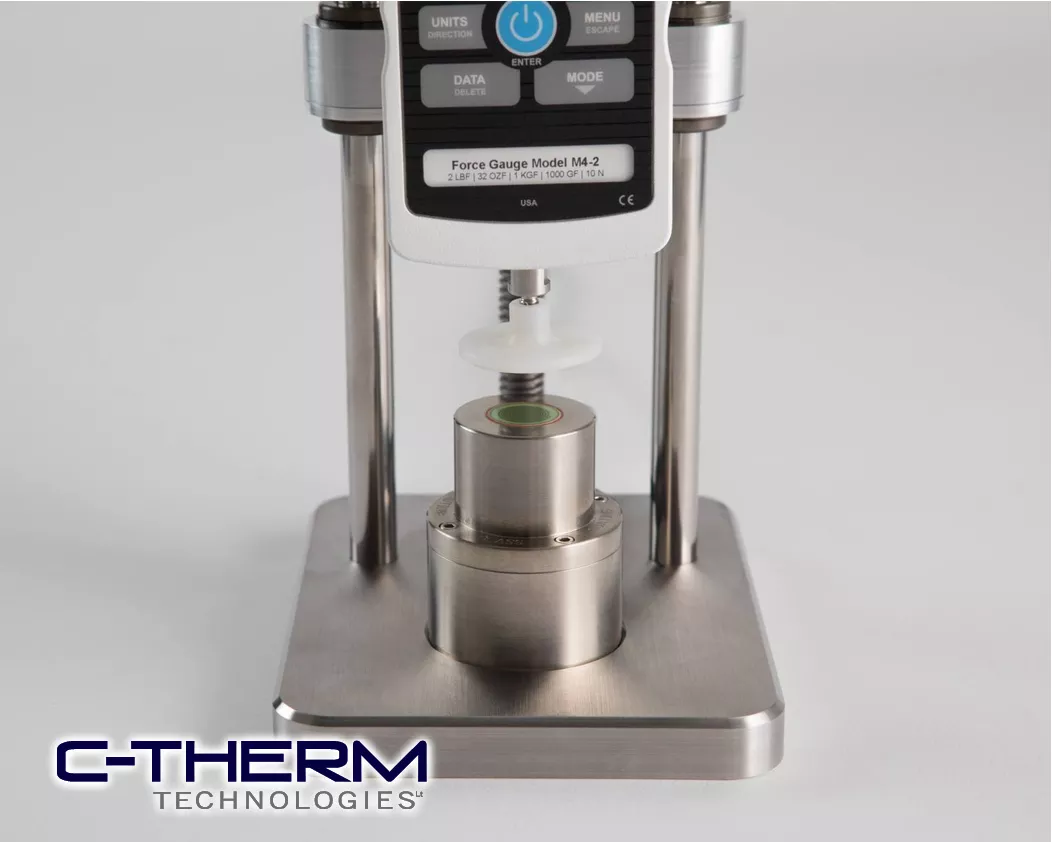

The MTPS Technique: Single-Sided Interfacial Measurement

The Modified Transient Plane Source (MTPS) sensor is a primary technical highlight of this platform. It employs a single-sided, interfacial heat reflectance sensor that applies a momentary constant heat source to the sample surface. This method directly measures thermal conductivity and effusivity without requiring sample preparation or complex geometry. Because the sensor only requires contact with one side of the material, it is uniquely suited for testing solids, liquids, powders, and pastes with high speed, typically yielding results in seconds.

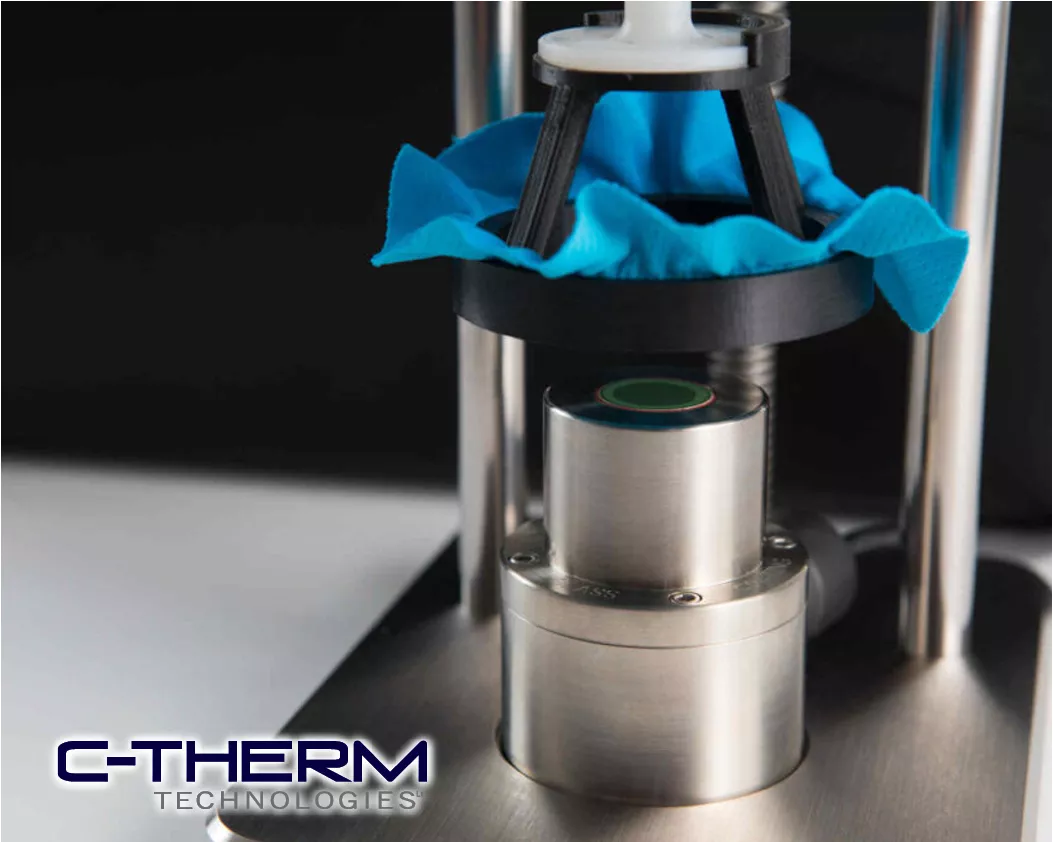

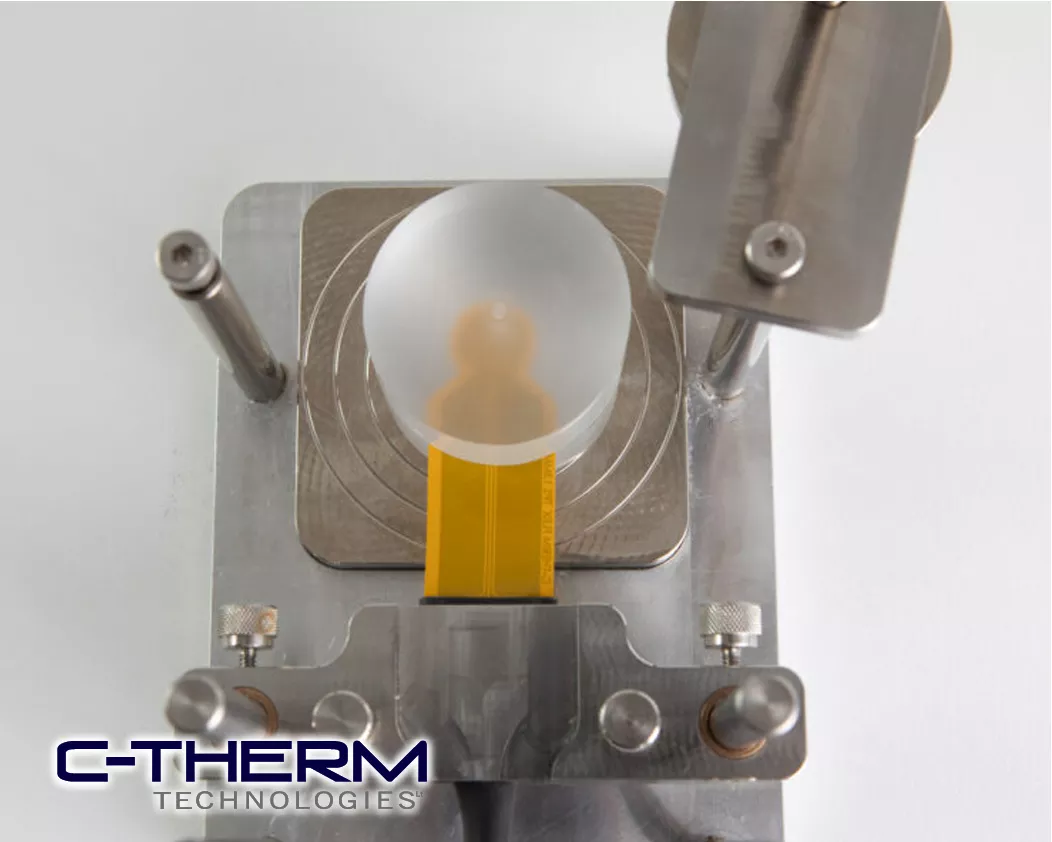

TPS Method: Characterization of Thermal Diffusivity and Heat Capacity

For more comprehensive material analysis, the platform utilizes the Transient Plane Source (TPS) method. This technique is highly flexible, allowing for the characterization of thermal conductivity, thermal diffusivity, and specific heat capacity. Technically, it can be used in a double-sided configuration where the sensor is sandwiched between two sample pieces, or a single-sided configuration for larger or immovable objects. This method is particularly effective for polymers, ceramics, and composites where bulk properties are critical.

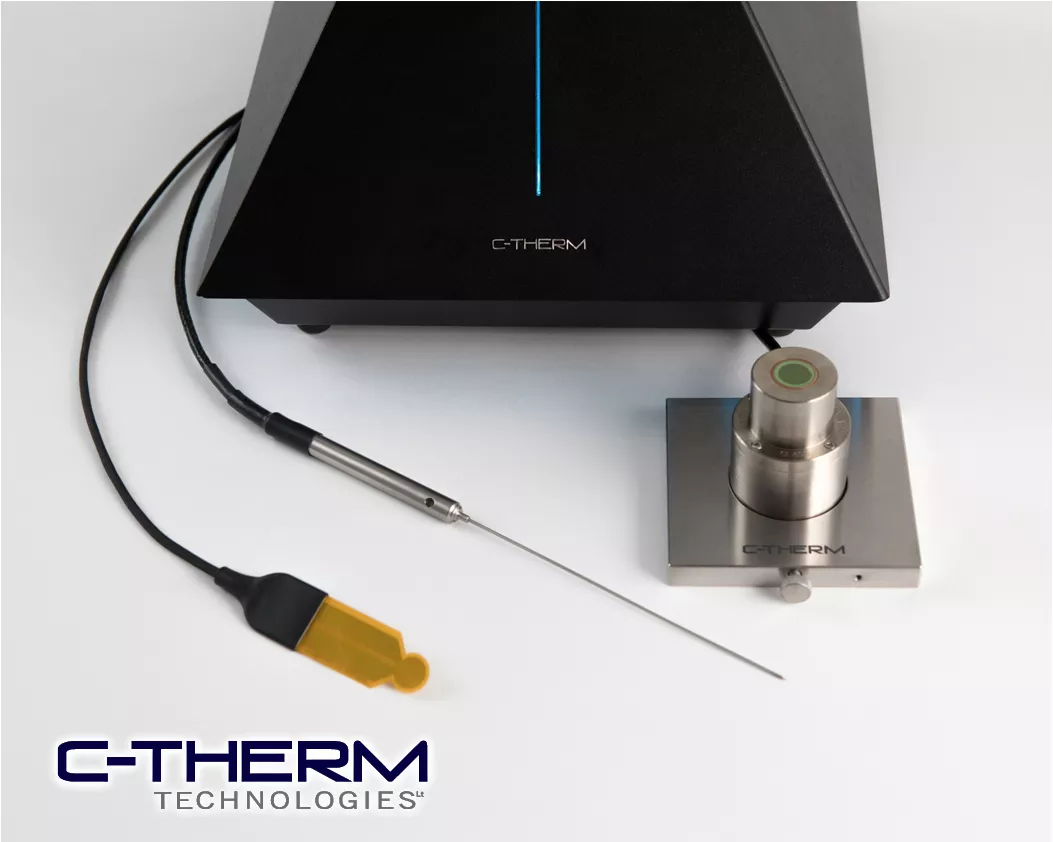

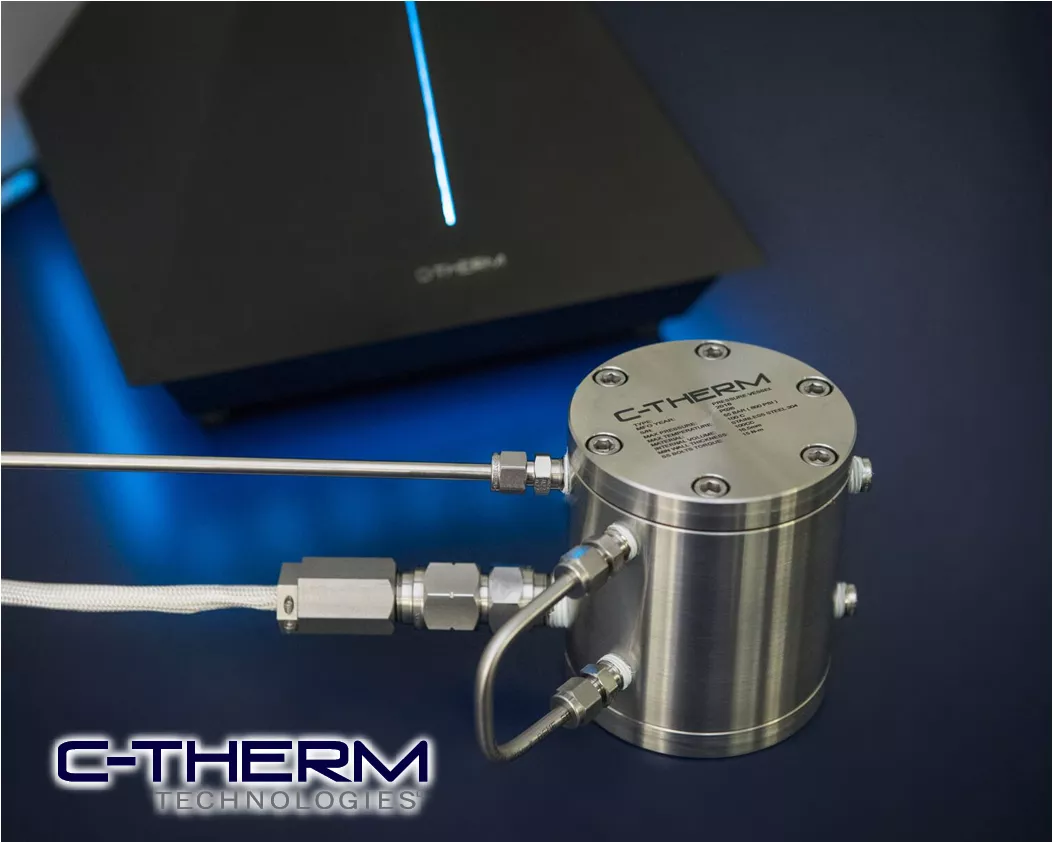

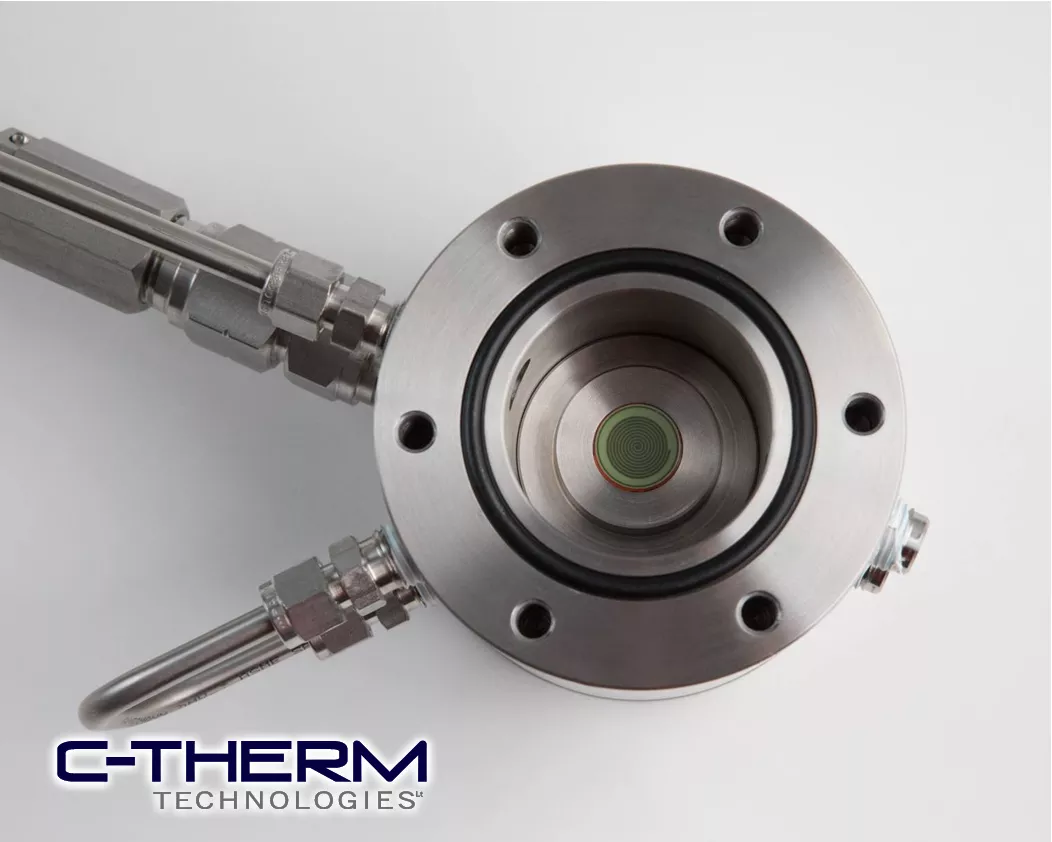

Precision Liquid and Gas Analysis with Transient Hot Wire

The Transient Hot Wire (THW) sensor is specifically engineered for high-precision measurements of liquids, gases, and phase-change materials. Following the ASTM D7896 standard, this method uses a very thin wire that acts as both a heat source and a temperature sensor. By measuring the temperature rise over time, the system calculates the thermal conductivity of the fluid. This technique is designed to minimize convection effects, ensuring high accuracy even for low-viscosity liquids or materials at varying pressures.

Versatile Compatibility with Diverse Material States

A core technical advantage of this system is its ability to handle materials in almost any physical state. This includes everything from rigid solids and soft foams to viscous pastes and volatile liquids. The sensors are designed to accommodate different textures and densities, ensuring that the interface between the sensor and the sample remains consistent. This versatility is essential for laboratories working with emerging materials like nanofluids, thermal interface materials (TIMs), and advanced textiles.

Non-Destructive Testing and Sample Integrity

Maintaining sample integrity is a critical requirement in modern thermal analysis. The platform’s transient methods are non-destructive, meaning the sample remains unchanged after testing. The heat pulses applied are minimal, preventing thermal degradation or phase changes in sensitive materials. This allows researchers to perform repeated measurements on the same sample or use the sample for subsequent analytical tests, making it a highly efficient solution for high-value material research.

Integration with International Analytical Standards

The platform is technically built to comply with several global standards, ensuring data validity for international trade and scientific publication. These include ASTM D7984 for the MTPS method, ISO 22007-2 for the TPS method, and ASTM D7896 for the THW method. Compliance with these standards guarantees that the measurement methodology follows rigorous scientific protocols, providing users with confidence in the precision and bias of their thermal conductivity data.

Advanced Software and Automated Data Processing

The system is supported by a robust software suite that automates data acquisition and processing. The software features intuitive wizards to guide users through sensor selection and calibration. Technically, it can handle batch testing and automated reporting, reducing the potential for human error. Advanced modules also allow for the analysis of anisotropic materials, where thermal conductivity differs based on direction, providing a 3D understanding of heat flow within a sample.

Modular Design for Future-Proof Research

The modular architecture of the platform allows laboratories to expand their capabilities as their research needs evolve. Users can start with a single sensor type and add others as necessary without requiring a completely new instrument. This plug-and-play functionality ensures that the laboratory remains at the forefront of thermal analysis technology. The platform also supports various environmental accessories, such as pressure cells and temperature chambers, to test materials under real-world operating conditions.

Read More About C-therm Products Here.