.webp)

Home » Products » Microbiology Laboratory Solutions » Sterilizers and Washers » Fedegari Lab Glassware Washer

Pharma-Grade Lab Glassware Washer

Steam Cleaning, Thema4Lab Control, GAMP5 Compliance

Fedegari Lab Glassware Washer

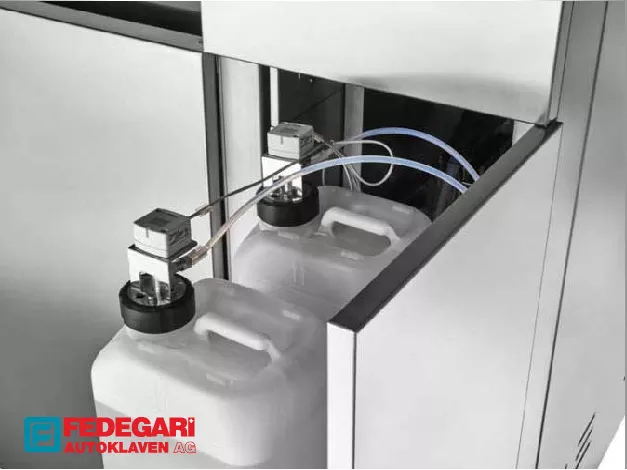

Operational costs are stringently managed through integrated monitoring features, including a sophisticated Conductivity meter positioned on the drain line. This sensor continuously gauges the purity of the rinse water, allowing the process to conclude precisely the moment the required set-point is attained. This continuous, real-time feedback loop ensures that water and other utilities consumption is minimized beyond fixed cycle times, directly translating into significant energy and resource savings across high-volume washing operations.

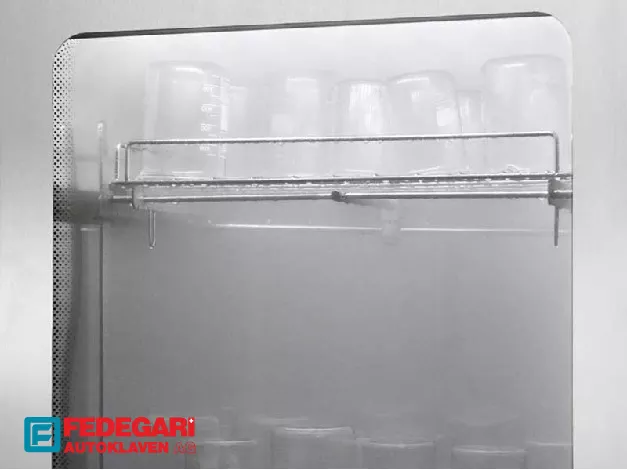

The mechanical Design is built for pharmaceutical-grade cleanliness and durability, utilizing sanitary finishing on all internal piping and hydraulic components. This rigorous approach minimizes the risk of biofilm accumulation and cross-contamination. Moreover, the inclusion of Clean In Place (CIP) readiness and the use of custom-made, hydraulically connected modular trays guarantee a perfect and verifiable wash, addressing the critical requirement for repeatable, high-quality cleaning of delicate and complex laboratory glassware and tools.

The constant uncertainty regarding whether trace contaminants remain after a wash cycle is a major source of process risk. This unit directly mitigates this through a dedicated drain-mounted Conductivity meter, which rigorously monitors the rinse water purity. The system terminates the cycle precisely when the pre-set purity threshold is reached, ensuring that rinsing is not only effective but also maximally resource-efficient, providing verifiable proof of contaminant removal crucial for sensitive downstream applications.

High utility consumption and environmental impact are persistent operational challenges for high-throughput labs. The integrated steam Generator provides a powerful, eco-friendly washing solution that substantially reduces the requirement for chemical detergents and minimizes water usage per cycle. The use of steam's inherent emollient properties on tough residues translates into shorter, more effective cleaning phases, directly lowering the running cost per batch and supporting sustainable lab practices.

Managing and validating cleaning processes in highly regulated environments requires complex software validation and documentation. The Thema4Lab Controller simplifies this significantly, as it is pre-validated according to GAMP5 guidelines and is built on an extensive library of established phase groups. This foundation reduces the substantial effort and financial burden associated with custom software validation, guaranteeing compliance and robust process management from the point of installation.

Inconsistent washing results, especially in hard-to-reach internal surfaces of complex glassware, compromise scientific integrity. This washer leverages the superior Penetration power of steam, which can access intricate geometries and narrow spaces where traditional water sprays often fail. This ensures a comprehensive cleaning outcome, dissolving greasy and sticky soil where conventional methods fall short, thereby protecting the integrity of subsequent experiments and analyses.

Laboratories often face the problem of managing different loading equipment for various instruments (sterilizers and washers), creating clutter and inefficiency. The Compatibility feature ensures that both the external trolleys and the internal modular trays are fully interchangeable with the units from the accompanying sterilizer series. This standardization streamlines the entire processing workflow, reduces the need for multiple sets of expensive loading equipment, and optimizes material transfer between washing and sterilization stages.

Equipment failure during critical wash cycles, leaving the load contaminated, causes significant logistical setbacks. The cleaning process is under perpetual Supervision through dedicated probes that monitor the temperature of the air, water, and steam within the chamber. Real-time temperature verification and an active internal LED lamp that changes color upon alarm provide immediate, evident signals of any deviation, ensuring that cycle integrity is maintained and allowing for prompt intervention to prevent a failed batch.

In a multi-user, multi-application setting, having fixed or non-adaptable internal racks reduces operational flexibility. The system allows for completely Customizable internal trays that connect directly to the unit's hydraulic system. This modularity means users can configure the internal chamber precisely for the unique geometric demands of their specific loads, whether it's specialized glassware or complex tools, maximizing the useful chamber capacity and ensuring all surfaces receive optimal spray coverage.

Ensuring the physical cleanliness of the washer itself is a prerequisite for maintaining the cleanliness of the glassware, often leading to time-consuming manual cleaning protocols. The unit is constructed with a rigorous sanitary Finishing on all piping and components and is designed with CIP (Clean In Place) capability. This internal self-cleaning feature eliminates the need for manual access to critical internal components, ensuring that the machine is contaminant-free and ready for the next cycle without unnecessary downtime.

Read more about Fedegari Lab Sterilizers

.webp)