Diesel Thermal Oxidation Testing

High-Precision Fuel Stability and Deposit Analysis

Diesel Thermal Oxidation Testing

Diesel Thermal Oxidation Testing evaluates the thermal stability of diesel fuels under high-temperature flow conditions that replicate operational stress in engines and fuel systems. This testing assesses the tendency of diesel to form deposits, color changes, and chemical degradation products that can impair injector performance, increase fouling, or reduce combustion efficiency. Accurate evaluation ensures fuel reliability, engine safety, and consistent performance over time.

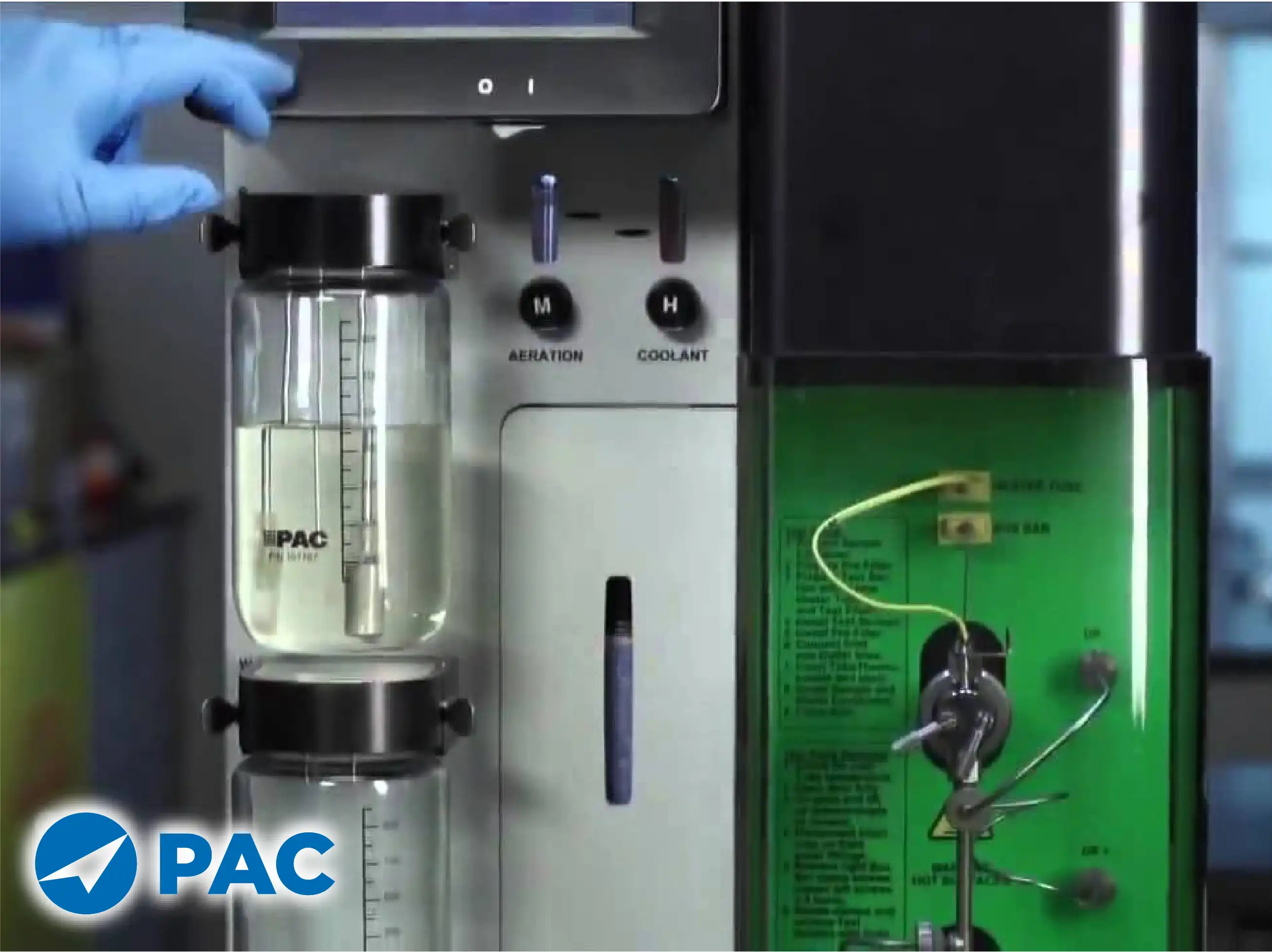

The system utilizes precision-controlled heater tubes that maintain uniform and stable temperatures along the fuel pathway. Integrated sensors continuously monitor flow rates and temperatures to provide reproducible conditions that meet standardized testing protocols. This precise control allows detailed assessment of diesel thermal stability, deposit formation tendencies, and oxidative behavior under realistic operating conditions.

High-resolution monitoring detects the onset and progression of deposit formation on the tube surfaces, including insoluble residues and coking. These measurements provide early warnings of potential fuel-related operational issues. Data collected can be used to evaluate additive effectiveness, optimize fuel formulation, and support quality control in refinery and distribution operations.

Automated operation ensures consistent flow rates, heating ramps, and hold times, allowing repeatable and standardized testing for multiple fuel batches. The system accommodates a wide variety of diesel fuels, including biodiesel blends and conventional distillates, enabling comprehensive analysis of thermal oxidation properties across diverse fuel compositions.

Real-time data acquisition provides detailed monitoring of temperature profiles, deposit accumulation, and oxidative changes throughout the test. The integration of analytical software allows visualization of deposit thickness, degradation trends, and performance metrics. Operators can generate reports, compare fuel lots, and evaluate additive effectiveness efficiently, supporting predictive maintenance and fuel handling decisions.

The testing methodology is non-destructive and preserves the sample integrity, allowing repeated measurements and long-term stability studies. This ensures reliable characterization of diesel thermal behavior and supports accurate assessment of oxidation rates, deposit formation potential, and overall fuel quality.

Robust system construction and high-temperature resistant components enable safe operation in rigorous thermal conditions while maintaining measurement accuracy. Minimal sample preparation and automated operation reduce human intervention and improve laboratory throughput, making the system suitable for research, quality control, and routine monitoring of diesel fuel stability.

By combining precise temperature control, automated testing, and high-resolution deposit monitoring, Diesel Thermal Oxidation Testing provides actionable insights into diesel fuel stability and oxidation behavior. It ensures compliance with international standards, improves engine reliability, supports predictive maintenance, and reduces operational risks associated with deposit formation and fuel degradation.