Home » Products » Scanning Electron Microscopy » Electron microscopy coating and cryogenic preparation » Quorum Cryo-SEM Preparation Systems

Cryo-SEM Preparation Systems

Cryo preparation techniques

Quorum Cryo-SEM Preparation Systems

Quorum Cryo-SEM preparation systems are technically engineered to overcome the challenges of imaging biological, pharmaceutical, and other hydration-sensitive samples that cannot withstand the high-vacuum and high-temperature environments of standard scanning electron microscopy. By utilizing rapid freezing techniques, such as the use of "slushy" nitrogen, these systems rapidly vitrify the water content within a specimen, preventing the formation of ice crystals that would otherwise damage the cellular or structural integrity.

The technical workflow supported by Quorum systems includes critical steps such as controlled sublimation, fracturing, and sputter coating, all performed under cryogenic conditions. Sublimation allows for the controlled removal of surface ice to reveal underlying structures, while the integrated fracturing tools enable the internal morphology of a sample to be exposed cleanly. To ensure high-quality imaging and prevent charging under the electron beam, the systems incorporate high-resolution coating capabilities.

Rapid Cryo-Fixation and Vitrification Processes

The primary goal of Quorum cryo-preparation is the rapid fixation of hydrated specimens. Technically, this is achieved by plunging the sample into sub-cooled liquid nitrogen (slushy nitrogen) to reach cooling rates that bypass the crystallization phase of water. This process, known as vitrification, turns water into an amorphous, glass-like state, preserving the biological or chemical distribution of elements in their native, liquid-phase configuration without the artifacts associated with chemical fixation or dehydration.

Integrated Vacuum Transfer and Environmental Protection

Maintaining the integrity of a vitrified sample requires complete isolation from atmospheric moisture and heat. Quorum systems utilize a dedicated vacuum transfer device that interfaces between the preparation chamber and the SEM.6 This technical solution ensures that the sample remains under high vacuum and at cryogenic temperatures throughout the transfer process, effectively preventing frost contamination or ice recrystallization that could obscure fine surface details during imaging.

Precision Sublimation for Structural Revelation

In many hydrated samples, the features of interest are obscured by a thin layer of surface ice. Quorum systems provide precise temperature control to initiate controlled sublimation (etching).7 By slightly raising the temperature of the specimen in the vacuum chamber, the surface ice transforms directly into gas, revealing the underlying topography. This process is highly controllable, allowing the user to etch away just enough ice to expose the structural detail required for high-resolution analysis.

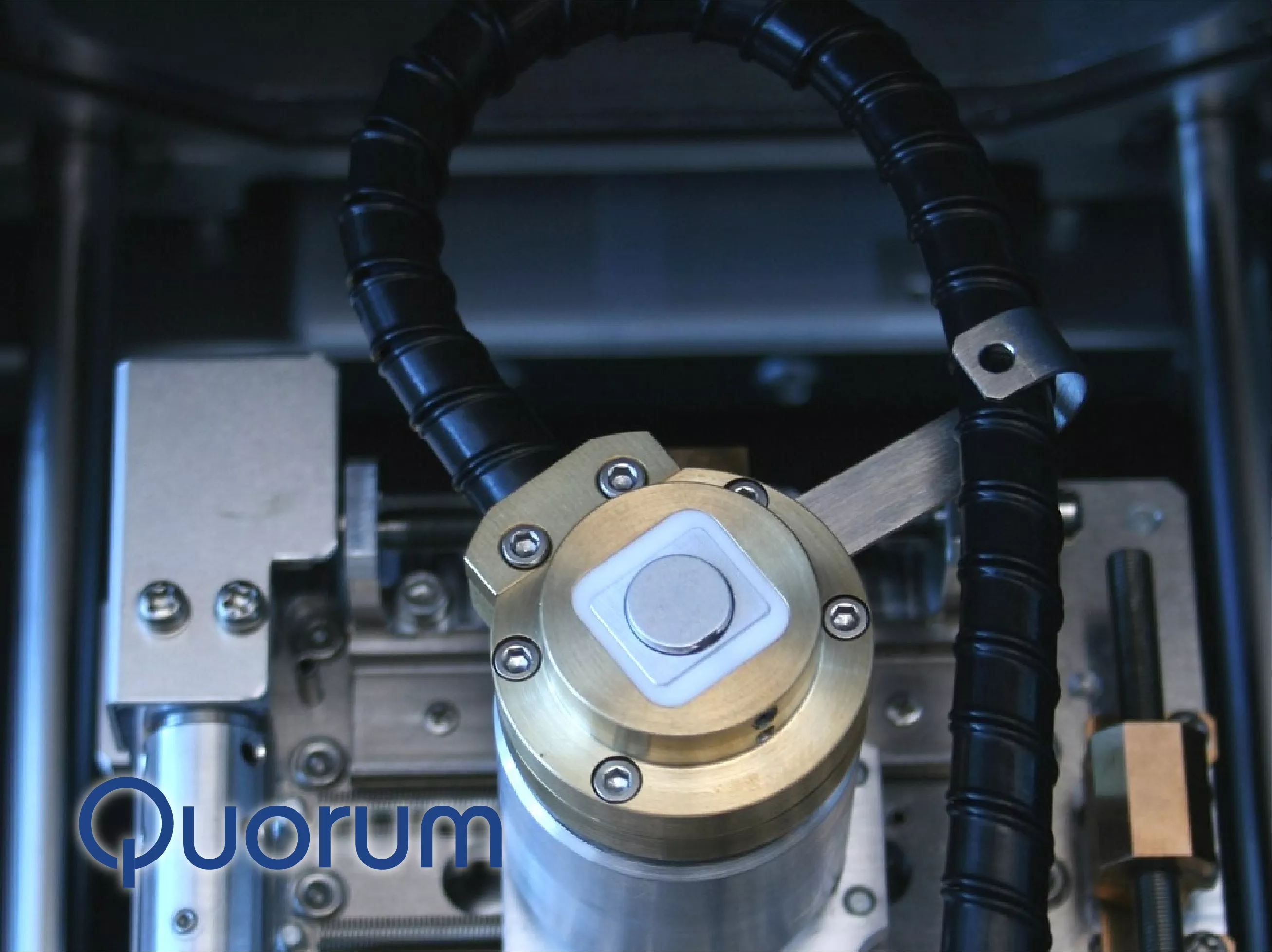

Cold Stage Stability and Thermal Management

The performance of a Cryo-SEM system is heavily dependent on the stability of the microscope's cold stage. Quorum’s stages are technically designed to maintain temperatures below $-185^{\circ}\text{C}$ with minimal thermal drift. Advanced thermal coupling ensures that heat from the electron beam is efficiently dissipated, preventing localized warming of the sample. This stability is crucial for long-duration imaging sessions and for maintaining the vitrified state of sensitive materials during X-ray microanalysis (EDS).

Cryogenic Fracturing and Internal Morphology Exposure

To investigate the internal structure of complex samples, such as tissues or emulsions, Quorum systems feature integrated fracturing tools.8 Within the preparation chamber, the specimen can be precisely fractured while maintained at cryogenic temperatures. Because the sample is brittle, it snaps cleanly along lines of structural weakness, providing an uncontaminated view of the internal surfaces. This allows for the study of cross-sectional morphology that remains undistorted by the pressures of mechanical cutting.9

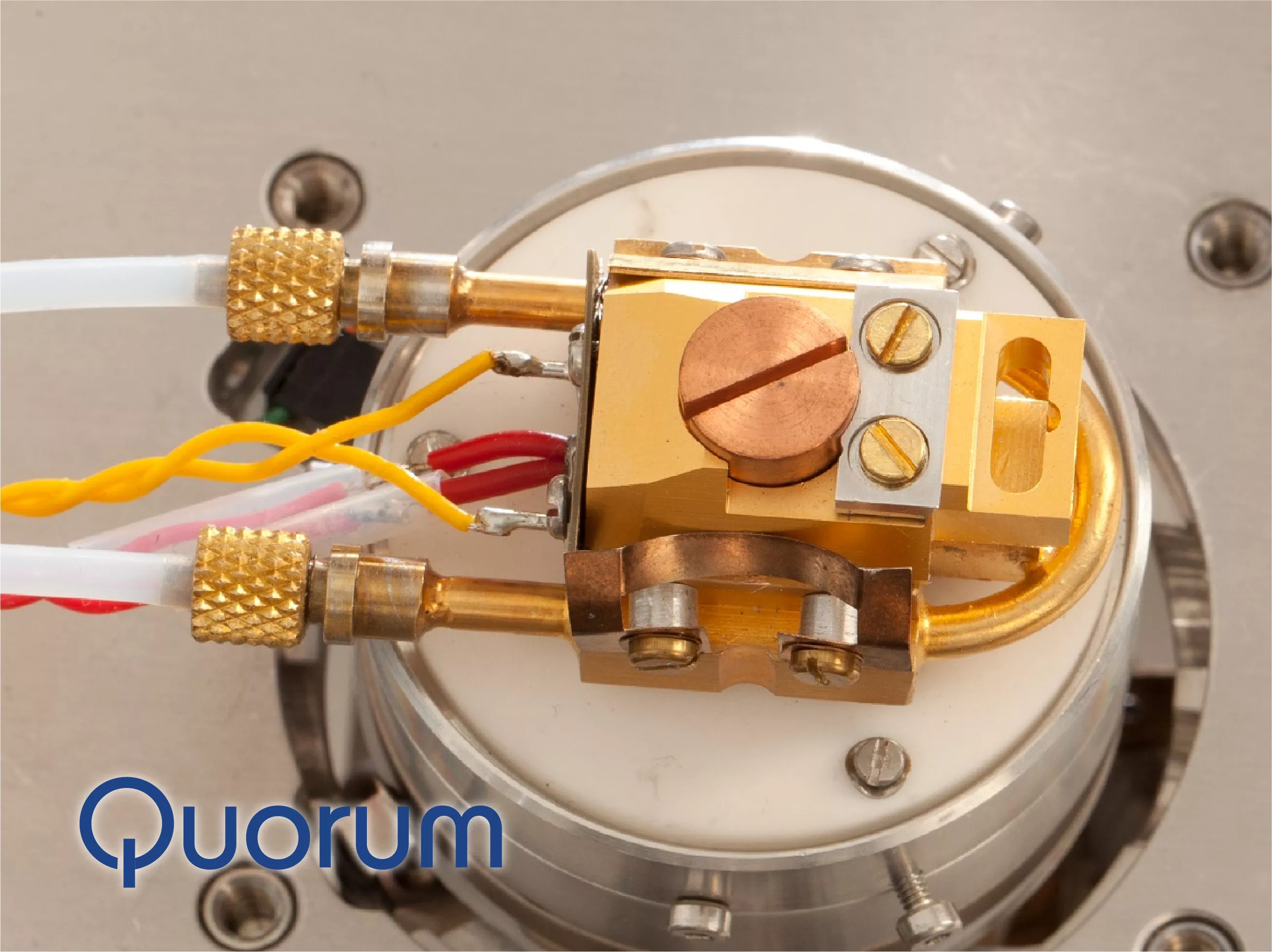

High-Resolution Sputter Coating at Cryogenic Temperatures

Because frozen specimens are non-conductive, they require a conductive coating to prevent electron charging and to improve secondary electron emission.10 Quorum systems incorporate high-resolution sputter coaters within the cryo-preparation chamber.11 These coaters use fine-grain metals like Platinum or Gold-Palladium to create an ultra-thin, continuous film over the specimen.12 The coating process is performed at cryo-temperatures, ensuring the sample remains vitrified while providing the electrical conductivity necessary for nanometer-resolution imaging.

Modular Design and Multi-Microscope Compatibility

The technical architecture of Quorum cryo-systems is designed for modularity, allowing them to be interfaced with a wide variety of scanning electron microscopes from different manufacturers. The systems include specialized adaptors and interface flanges that maintain vacuum integrity while allowing the cryo-transfer device to dock securely. This flexibility ensures that laboratories can upgrade their existing SEM capabilities to include cryo-imaging without requiring specialized, dedicated microscope hardware.

Advanced Control Systems and User Interfaces

Modern cryo-preparation requires precise control over multiple variables including vacuum levels, gas flows, and temperatures.13 Quorum systems feature intuitive touch-screen interfaces that allow for automated sequences or manual control of the preparation parameters.14 Real-time data logging of temperatures and vacuum levels provides the technical documentation required for high-standard research and quality control, ensuring that the preparation conditions are reproducible and verifiable for every specimen run.

Click here for more information about Quorum range of products

.webp)

.webp)