Home » Products » Scanning Electron Microscopy » Micro-computed tomography (micro-CT) » Tescan Industrial Applications for Material Science

Tescan Industrial Applications for Material Science

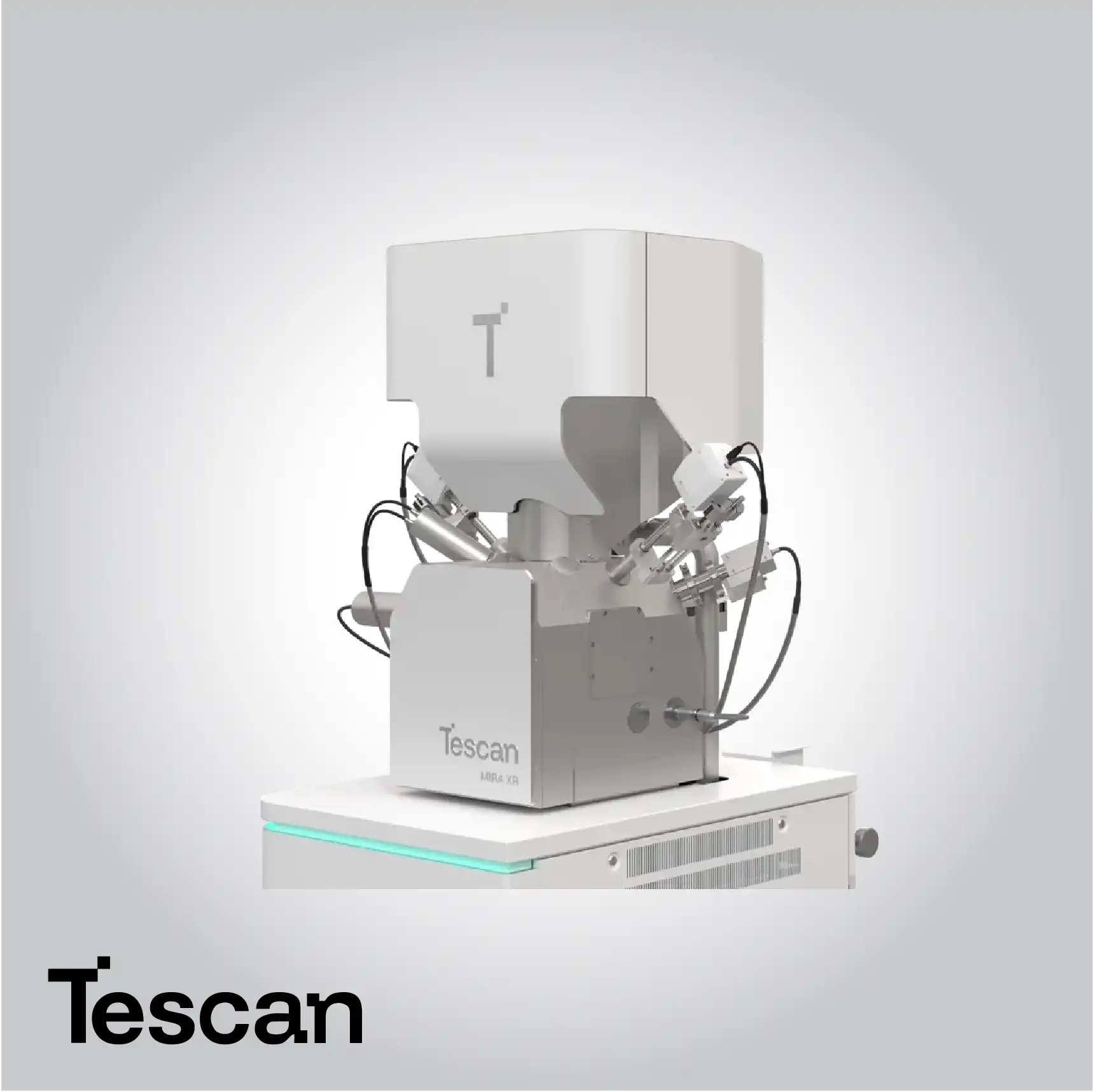

Advanced Micro-CT Imaging for Material Science and Industrial Research

Tescan Industrial Applications for Material Science

Tescan Micro-CT systems for material science and industrial applications provide non-destructive 3D imaging for a wide range of engineering materials, including metals, ceramics, polymers, and composite structures. These systems allow detailed visualization of internal features such as porosity, cracks, inclusions, and fiber orientation, offering precise insight into structural integrity and material performance.

These Micro-CT systems support a broad spectrum of industrial applications, from manufacturing process monitoring to advanced materials research. By providing a non-invasive method to inspect internal structures, engineers can detect defects early, assess component reliability, and optimize material design. The systems’ high-resolution detectors and adaptive imaging protocols enable visualization of fine microstructural details, including voids, laminations, and fiber orientations in composites. Integrated analytical tools allow comprehensive measurement of volumes, porosity, and structural anisotropy, supporting predictive modeling and enhancing industrial quality assurance practices.

Internal Defect Detection

Micro-CT technology enables highly accurate, non-destructive identification of internal defects such as cracks, voids, delaminations, inclusions, and structural discontinuities that may occur during manufacturing or service life. By capturing volumetric datasets at micrometer-level resolution, engineers can examine the spatial distribution and morphology of defects in three dimensions, allowing for a full understanding of their effect on material integrity and performance. This approach is critical for industries where failure prevention is paramount—such as aerospace, automotive, and additive manufacturing—ensuring that components meet strict reliability and safety standards without requiring destructive sectioning or dismantling.

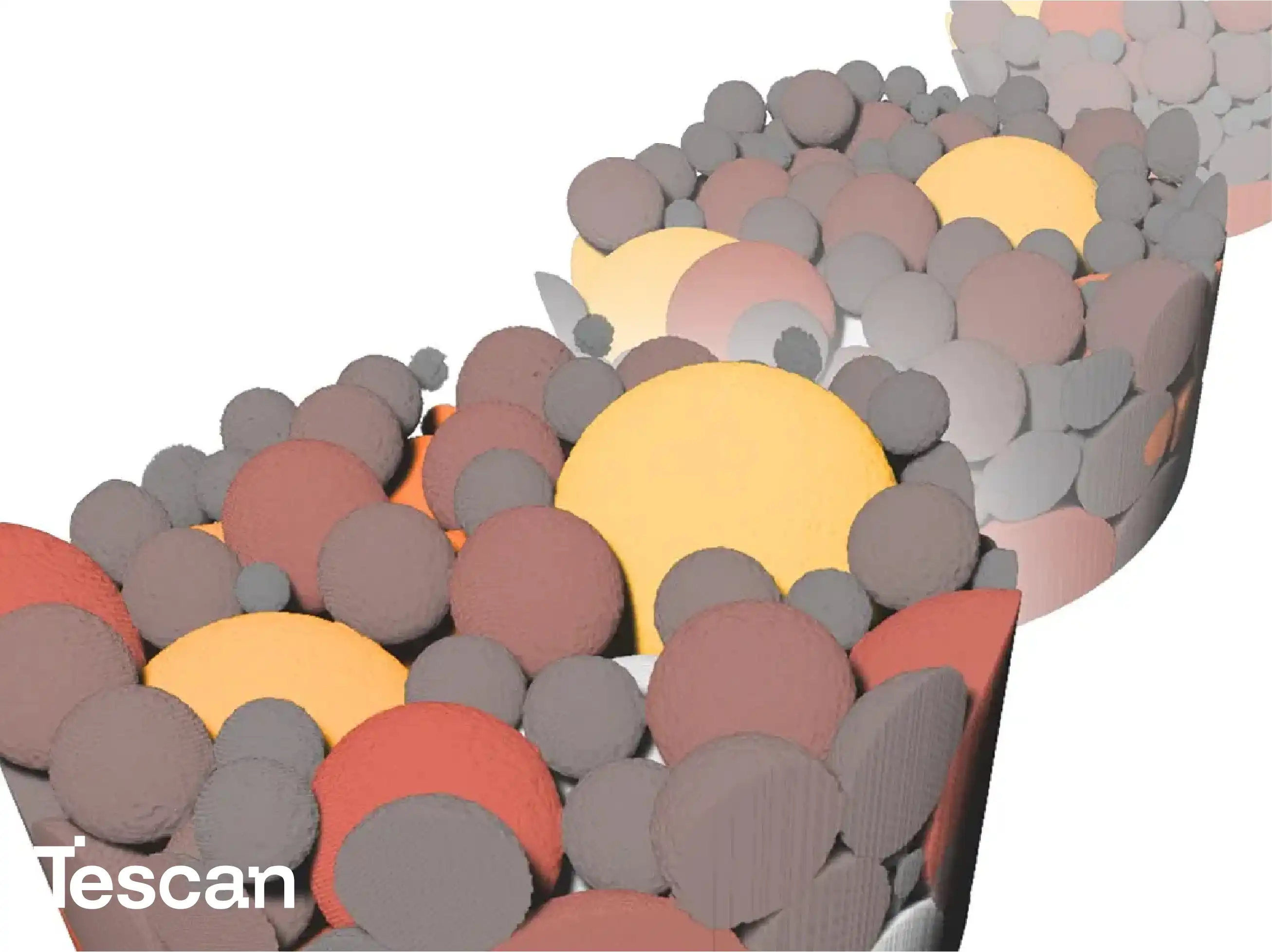

Porosity and Microstructural Characterization

Porosity is a key parameter influencing mechanical, thermal, and fluid transport properties of materials. TESCAN Micro-CT systems allow precise quantification of pore geometry, size distribution, interconnectivity, and volume fraction in metallic, ceramic, and composite samples. By reconstructing 3D volumetric data, researchers can correlate porosity metrics with process parameters, density, and performance outcomes. This non-invasive method provides vital feedback for process optimization, especially in sintered, cast, or additively manufactured components, where uniform density and low porosity are essential for strength and durability.

Fiber Orientation and Composite Structure Analysis

For fiber-reinforced composites, Micro-CT imaging reveals the internal fiber architecture without cutting or damaging the specimen. Researchers can quantify fiber alignment, orientation distribution, and the degree of consolidation between matrix and reinforcement. These measurements are crucial for understanding anisotropic mechanical properties, identifying manufacturing defects such as fiber misalignment or void formation, and validating computational models. The ability to visualize complex 3D fiber networks supports optimization of lay-up processes, resin infusion, and curing parameters to achieve consistent performance in high-load structural components.

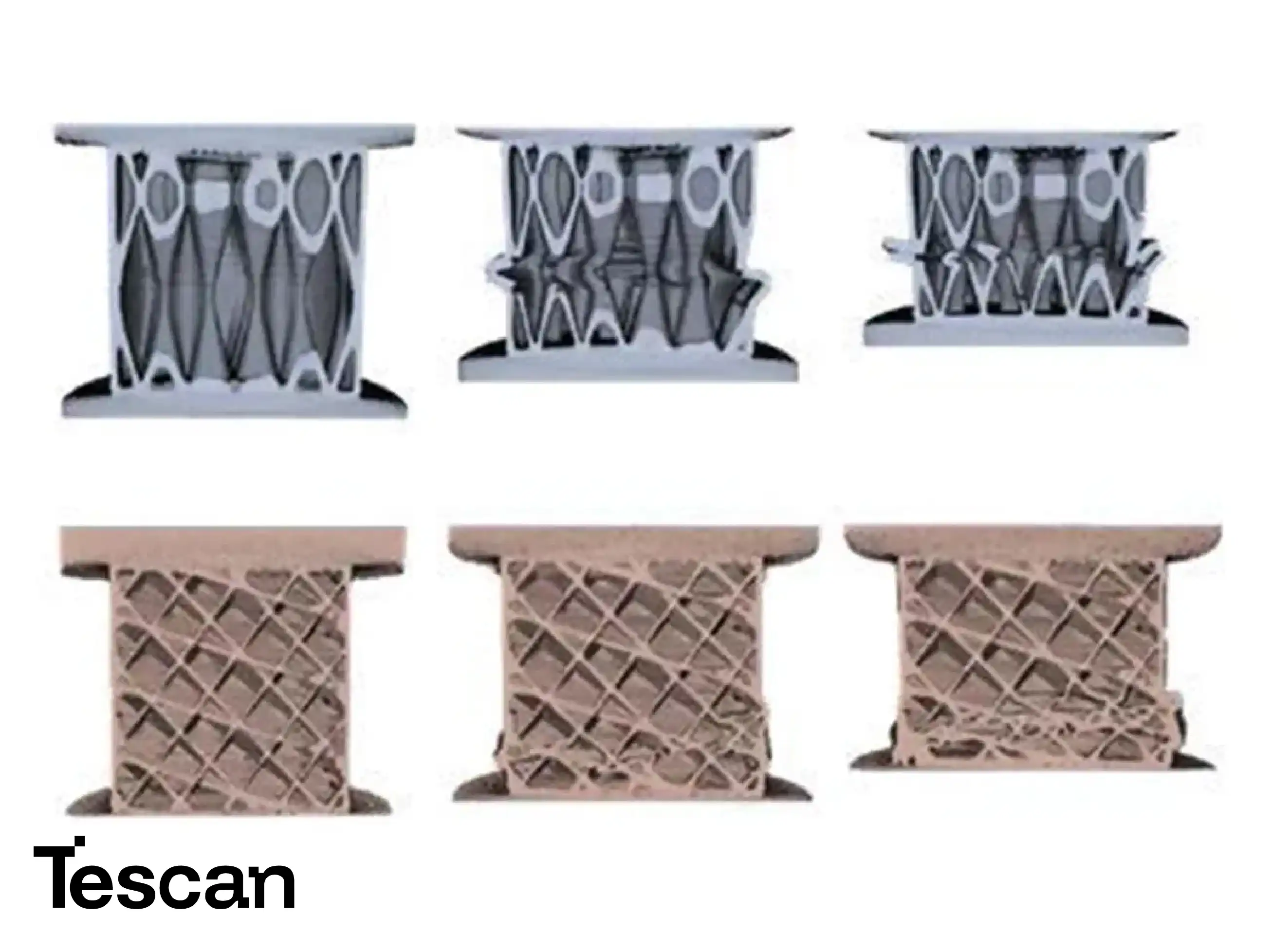

Non-Destructive Component Inspection

Industrial Micro-CT systems offer unparalleled insight into complete manufactured parts, enabling total inspection of internal and external geometries without disassembly. Engineers can perform virtual cross-sections at any angle, measuring wall thickness, identifying hidden cavities, and verifying dimensional accuracy against CAD data. This technique enhances quality assurance workflows by integrating digital twins of physical components for direct comparison, reducing rework and waste. Such capability is invaluable in additive manufacturing and precision machining, where internal channels or lattices cannot be accessed using traditional inspection tools.

Quantitative Structural Characterization

Beyond imaging, TESCAN Micro-CT systems provide quantitative analysis of structural features at both micro- and meso-scales. Through advanced reconstruction algorithms and image segmentation tools, users can calculate parameters such as density gradients, grain morphology, phase distribution, and anisotropy indices. The resulting datasets can be integrated into finite element models for predictive mechanical simulations. Quantitative Micro-CT analysis thus bridges the gap between microstructural observation and macroscopic material behavior, supporting both research and industrial development of high-performance materials.

Failure Analysis and Reliability Assessment

When a component fails, Micro-CT offers a unique way to visualize internal damage and identify the root cause without cutting or altering the sample. The technique reveals crack initiation points, propagation paths, and void coalescence zones, helping correlate mechanical stresses with microstructural weaknesses. By comparing pre- and post-testing scans, researchers can track material degradation, fatigue evolution, and fracture mechanisms in real time. Such insights guide improvements in manufacturing parameters, material processing, and design optimization to enhance product reliability and service lifetime.

Industrial Process Monitoring and Validation

Micro-CT is a powerful tool for process engineers seeking to monitor and optimize industrial workflows. By imaging samples at different production stages, the evolution of internal features can be tracked, allowing correlation between processing variables and final material quality. For additive manufacturing, Micro-CT helps verify layer bonding, detect unmelted particles, and ensure consistent powder deposition. In casting and molding industries, it aids in identifying shrinkage, gas entrapment, or thermal cracking. Continuous feedback from Micro-CT data drives process validation and enables data-driven quality improvement cycles.

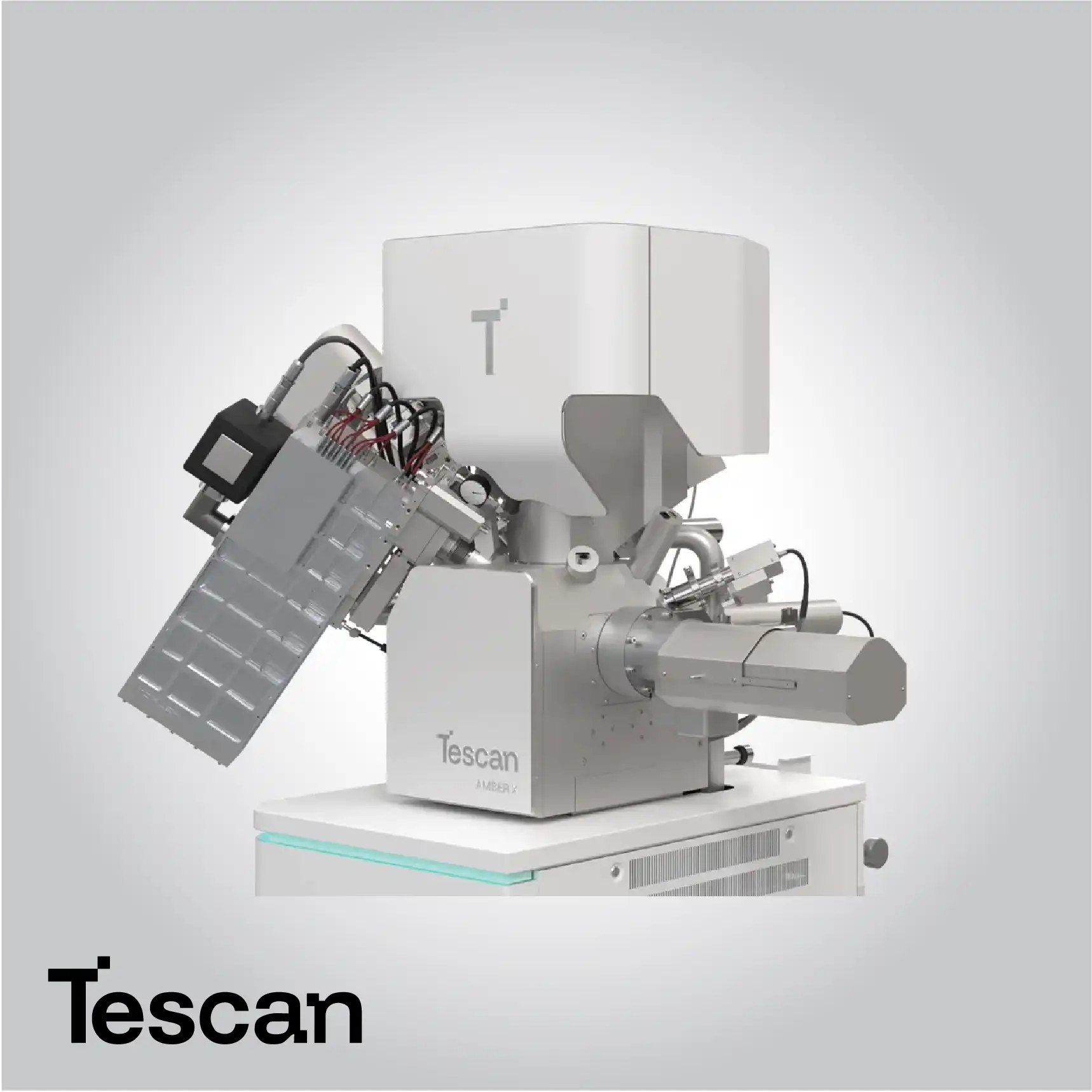

Advanced Materials Development and Innovation

TESCAN Micro-CT systems play a key role in the development of next-generation materials and manufacturing technologies. Their ability to provide non-destructive 3D visualization at high spatial resolution accelerates research on lightweight alloys, functional ceramics, and novel composite architectures. Combined with in-situ capabilities, dynamic studies can be performed under mechanical, thermal, or environmental loading, providing real-time insight into structural evolution. This approach empowers engineers and scientists to design materials with tailored properties, bridging the gap between microstructure design and industrial scalability.

Read more about Tescan products here