IUL Inoculation

Advanced Inoculation Solutions for Microbial Analysis

IUL Inoculation

Inoculation instruments are designed to handle a wide range of sample types with precision and consistency. By controlling factors such as sample volume, spreading pattern, and contact pressure, laboratories can ensure even growth distribution across the culture medium. This precision is essential for detecting low microbial counts, evaluating contamination levels, and obtaining statistically reliable data.

Advanced inoculation systems integrate ergonomic design, reproducible mechanics, and hygienic handling to optimize microbial transfer efficiency. By providing consistent inoculation across multiple plates and sample types, these instruments support comparative studies, reduce variability, and allow laboratories to implement standardized testing protocols.

Precision Sample Transfer

Inoculation instruments ensure highly accurate and controlled transfer of microbial samples from source containers to culture media, maintaining the integrity of bacterial, fungal, and yeast specimens. This precision minimizes sample loss, reduces contamination risk, and supports reproducibility across multiple plates and experiments. By controlling variables such as sample volume, pressure, and contact duration, laboratories can achieve reliable analytical outcomes critical for food safety, pharmaceutical quality control, and clinical diagnostics.

Uniform Growth Distribution

Advanced inoculation systems guarantee consistent microbial growth across the culture surface by controlling spreading patterns and inoculation angles. This uniformity is essential for quantitative analysis, accurate colony enumeration, and comparative studies. Achieving even growth distribution enables laboratories to detect low-level contamination, monitor microbial population dynamics, and generate statistically valid results for regulatory compliance and research purposes.

Contamination Control and Sterility Assurance

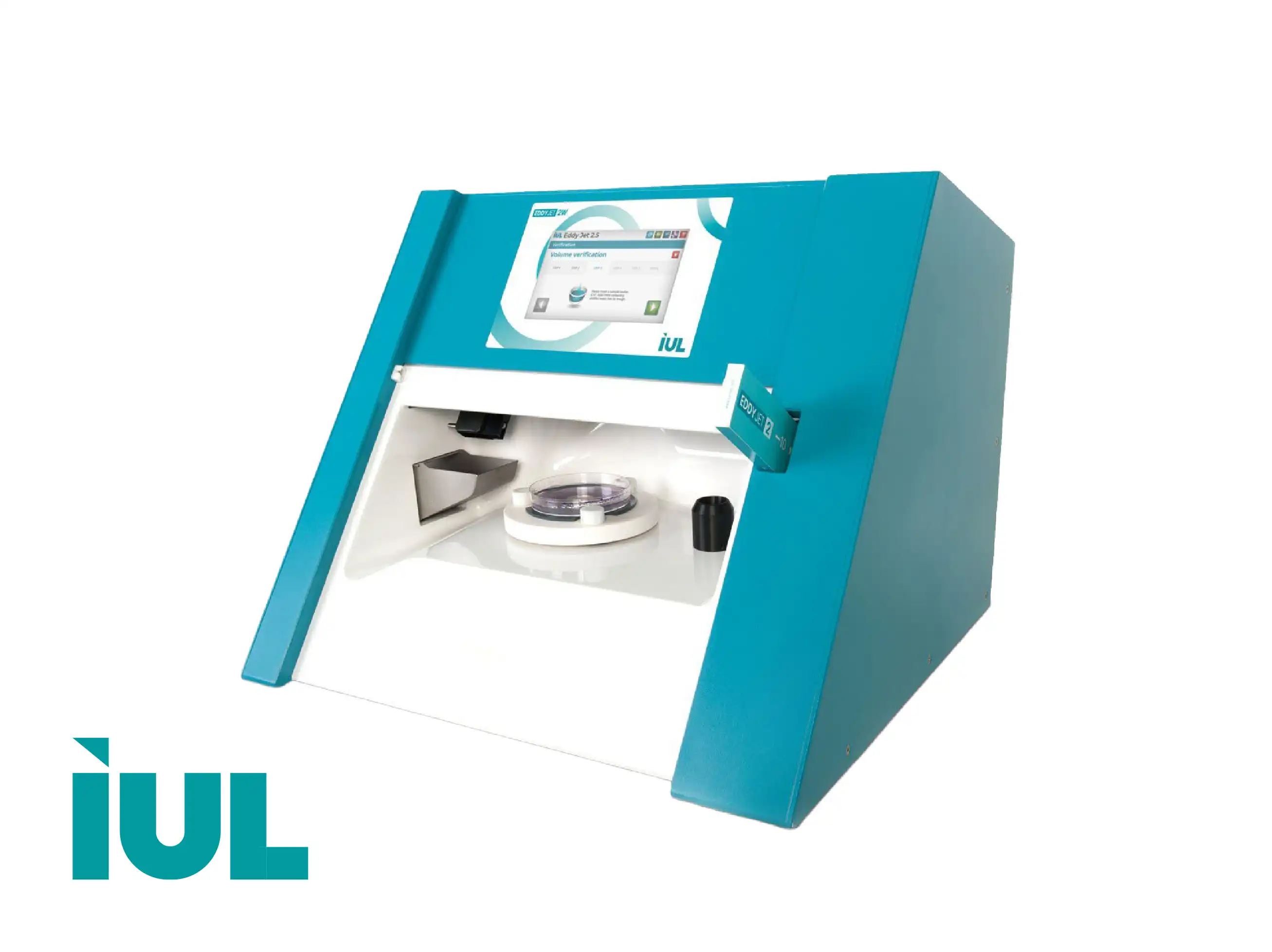

Inoculation instruments integrate sterile handling mechanisms and controlled contact techniques to prevent cross-contamination between samples and reduce external microbial interference. Hygienic design features, including automated sample transfer and enclosed operational chambers, provide an additional layer of safety. Ensuring sterility is critical not only for accurate microbial assessment but also for maintaining laboratory safety standards and preventing errors in sensitive diagnostic and research applications.

Automated High-Throughput Capability

Automation enhances laboratory efficiency by standardizing repetitive inoculation processes and reducing manual handling errors. These systems can process multiple plates or samples simultaneously, increasing throughput and freeing technicians for other critical tasks. High-throughput inoculation is especially important in industrial and clinical laboratories where time-sensitive testing, rapid microbial detection, and large-scale sample processing are standard requirements.

Ergonomics and Operational Safety

Modern inoculation instruments are designed with ergonomic considerations to reduce operator fatigue, minimize repetitive strain injuries, and improve workflow efficiency. Intuitive controls, easy-to-clean surfaces, and user-friendly interfaces allow technicians to perform microbial transfer safely and effectively. These design elements contribute to consistent inoculation performance, lower human error, and a safer working environment in microbiology laboratories.

Compatibility with Diverse Sample Types

Inoculation systems are capable of handling a wide range of sample types, including liquids, swabs, environmental samples, and complex biological specimens. This versatility allows laboratories to perform comprehensive microbial testing across food, water, pharmaceutical, and clinical matrices. The ability to accommodate diverse sample types ensures that laboratories can maintain standardized testing protocols without compromising accuracy or reproducibility.

Standardization and Regulatory Compliance

Reproducible inoculation procedures are essential for meeting industry regulations and laboratory quality standards. These instruments allow laboratories to adhere to strict protocols required by food safety authorities, pharmaceutical regulatory agencies, and clinical laboratory accreditation bodies. Standardization reduces variability between operators and testing sessions, ensuring reliable results for regulatory audits, research publications, and critical quality control applications.

Enhanced Data Reliability and Research Insight

Precise inoculation supports accurate colony counting, microbial detection, and comparative studies, providing a strong foundation for data-driven decision-making. Reliable microbial data allows researchers to optimize experimental designs, monitor contamination trends, and improve process validation. By integrating inoculation with downstream analytical methods, laboratories gain deeper insights into microbial behavior, contributing to advances in microbiology research, industrial quality control, and clinical diagnostics.

Read More About IUL Products Here