Home » Products » Operational Environment Solutions » Reach-in Simulation Chambers » Binder Drying, Heating and Vacuum drying Chambers

Precision Thermal Chambers

For Drying and Heating Applications

Binder Drying, Heating and Vacuum drying Chambers

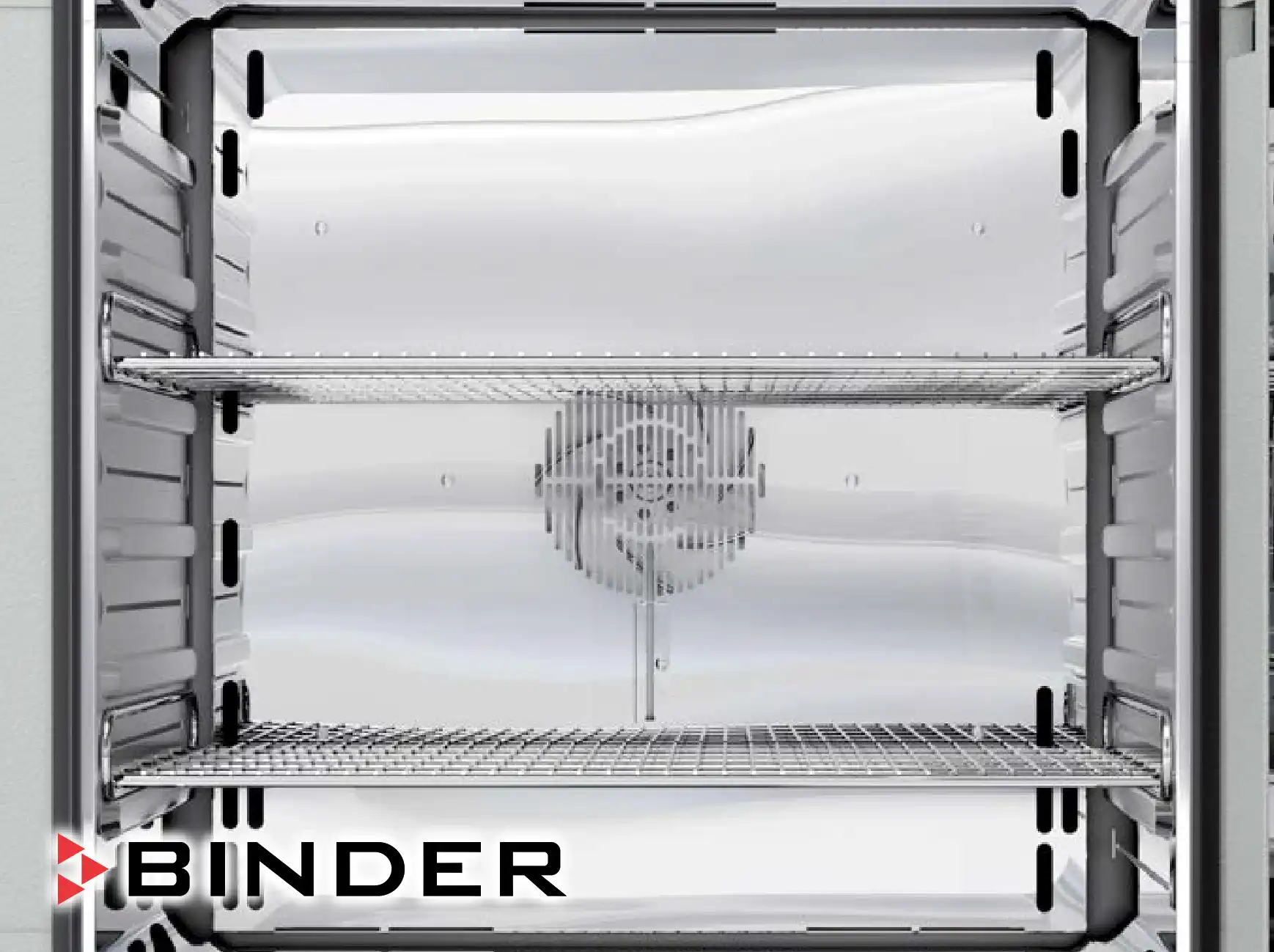

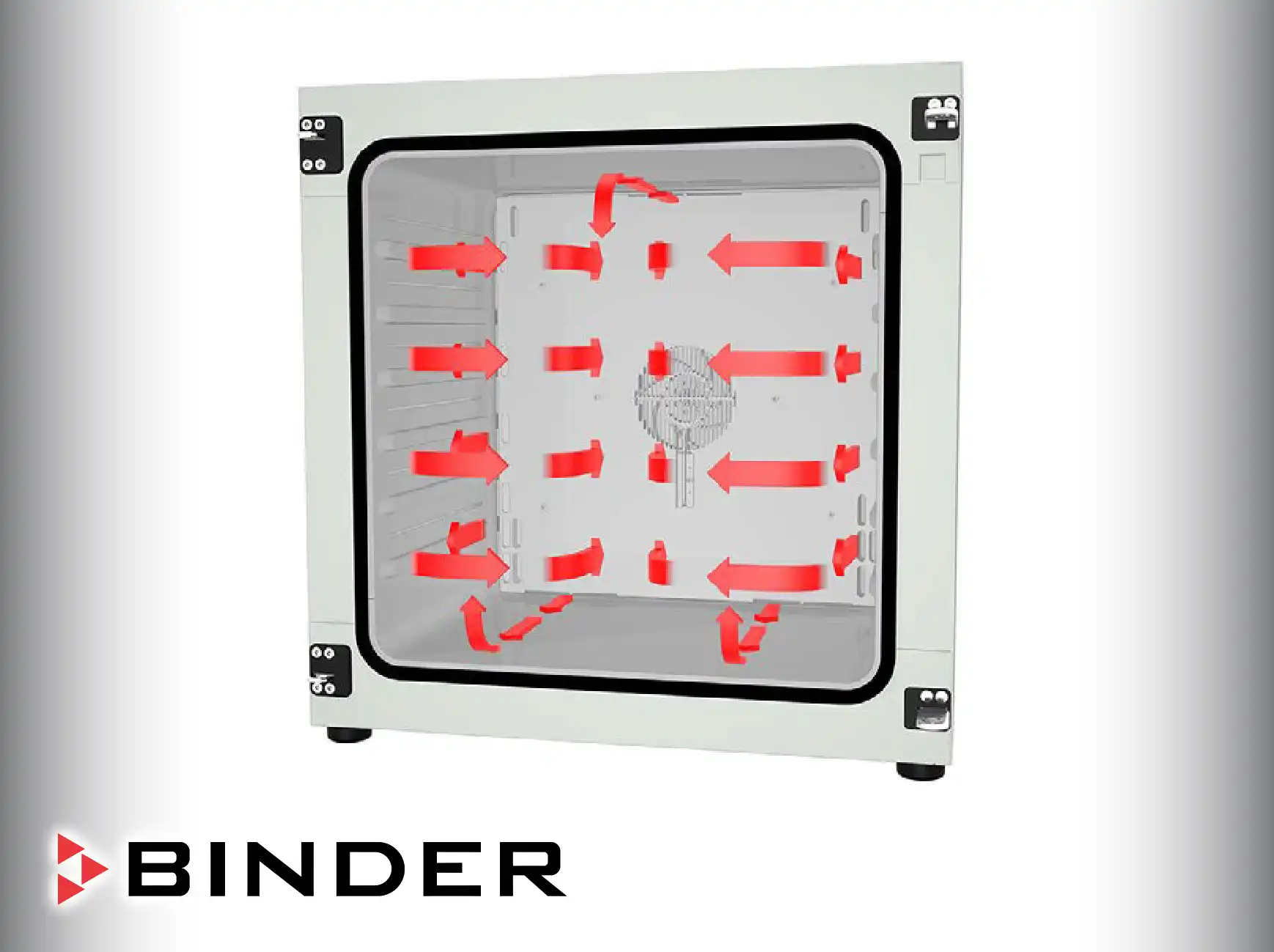

The core technical focus of the Drying and Heating Chambers is to deliver consistent and high-precision thermal performance for reliable heating and rapid drying applications. Operational flexibility is provided by offering a choice between gravity convection for gentle sample treatment and mechanical convection for quick heating and enhanced spatial temperature stability across the working volume.

Vacuum Drying Chambers are specifically designed to enable gentle and highly efficient drying processes, particularly crucial for materials sensitive to high temperatures or requiring rapid solvent removal. This specialized approach ensures residue-free results while mitigating potential thermal damage to the sample, securing the integrity of complex materials during the drying cycle.

Maintaining exceptional temperature accuracy across the entire working range is paramount, as thermal deviations compromise the validity of material testing and drying consistency. The design ensures uniform thermal distribution, eliminating temperature gradients that result in uneven sample processing, thereby guaranteeing reproducible results across all testing cycles.

The provision of selectable convection systems (natural or forced) in Drying and Heating Chambers addresses the need for optimized drying kinetics based on material sensitivity. Forced convection provides rapid heat transfer and short recovery times, essential for high-throughput applications, while gravity convection ensures a non-turbulent environment for fine powders or volatile compounds.

For materials that are highly sensitive to thermal degradation, the Vacuum Drying Chambers employ negative pressure to significantly lower the boiling point of solvents. This enables highly efficient, low-temperature drying, protecting the integrity of complex or heat-labile materials that would otherwise be damaged by conventional thermal processing.

Safety is a critical design feature, particularly when processing flammable materials, where chambers are engineered to comply with stringent safety standard specifications. This compliance involves specialized construction and control mechanisms to mitigate ignition risks, ensuring a secure environment for hazardous drying operations that exceed standard thermal testing requirements.

Residue-free drying is a fundamental requirement, especially for quality control and analytical sample preparation. The chamber design, including internal surfaces and air/vacuum flow management, is optimized to prevent deposition or contamination from previous cycles, ensuring the purity of the final processed material.

The robust engineering allows for demanding temperature stress testing applications that require long-duration exposure to elevated temperatures. The heating and control systems are built for reliability and longevity under continuous high-thermal load conditions, maintaining specified setpoints accurately over extended testing periods.

The versatility of the chambers, spanning from simple drying to complex temperature stress protocols, highlights the flexibility of the thermal control architecture. This comprehensive capability allows technical teams to consolidate various heating and drying processes into reliable, single-source equipment, optimizing laboratory floor space utilization.

For unique or highly specialized processing requirements, the availability of customized solutions underscores a commitment to adapting core heating and vacuum technologies. This provides a mechanism to meet non-standard operational envelopes or integrate specific material handling and sensor systems not found in standard laboratory equipment configurations.

Click here to know more about Binder inucators