.webp)

ProxiMate NIR Instrument

Optimized Analysis for the Food & Feed Industry

Buchi ProxiMate NIR Instrument

The Buchi ProxiMate is a high-performance, at-line NIR spectrometer engineered to provide rapid and reliable quality control in the demanding environments of the food and feed industries. This compact instrument is designed to be placed directly where results are needed most—on the production floor. With its robust IP69 ingress protection and food-grade stainless steel housing, the ProxiMate is completely dust and waterproof, allowing it to be pressure-hosed down alongside other production machinery.

Technically, the instrument operates across the 900 – 1700 nm NIR range, with an optional visible light (VIS) sensor covering 400 – 900 nm for simultaneous color analysis and enhanced parameter accuracy. The ProxiMate utilizes an intuitive touchscreen interface and automated calibration tools like AutoCal, which simplifies the development and maintenance of analytical models without requiring expert chemometric knowledge. By enabling non-destructive testing of parameters such as moisture, protein, fat, and ash in less than a minute, it significantly reduces production downtime and ensures that finished products consistently meet quality specifications.

Robust At-Line Design and IP69 Protection

The ProxiMate is engineered for extreme robustness, specifically tailored for at-line use in harsh industrial settings. It features an IP69 protection rating, meaning the entire unit is completely sealed against dust and can withstand high-pressure water jets and steam cleaning. This allows the instrument to reside directly next to mixers, blenders, or conveyors without risk of damage. The stainless steel body is resistant to common acidic and alkaline detergents used in food safety sanitation protocols, ensuring long-term durability in corrosive environments.

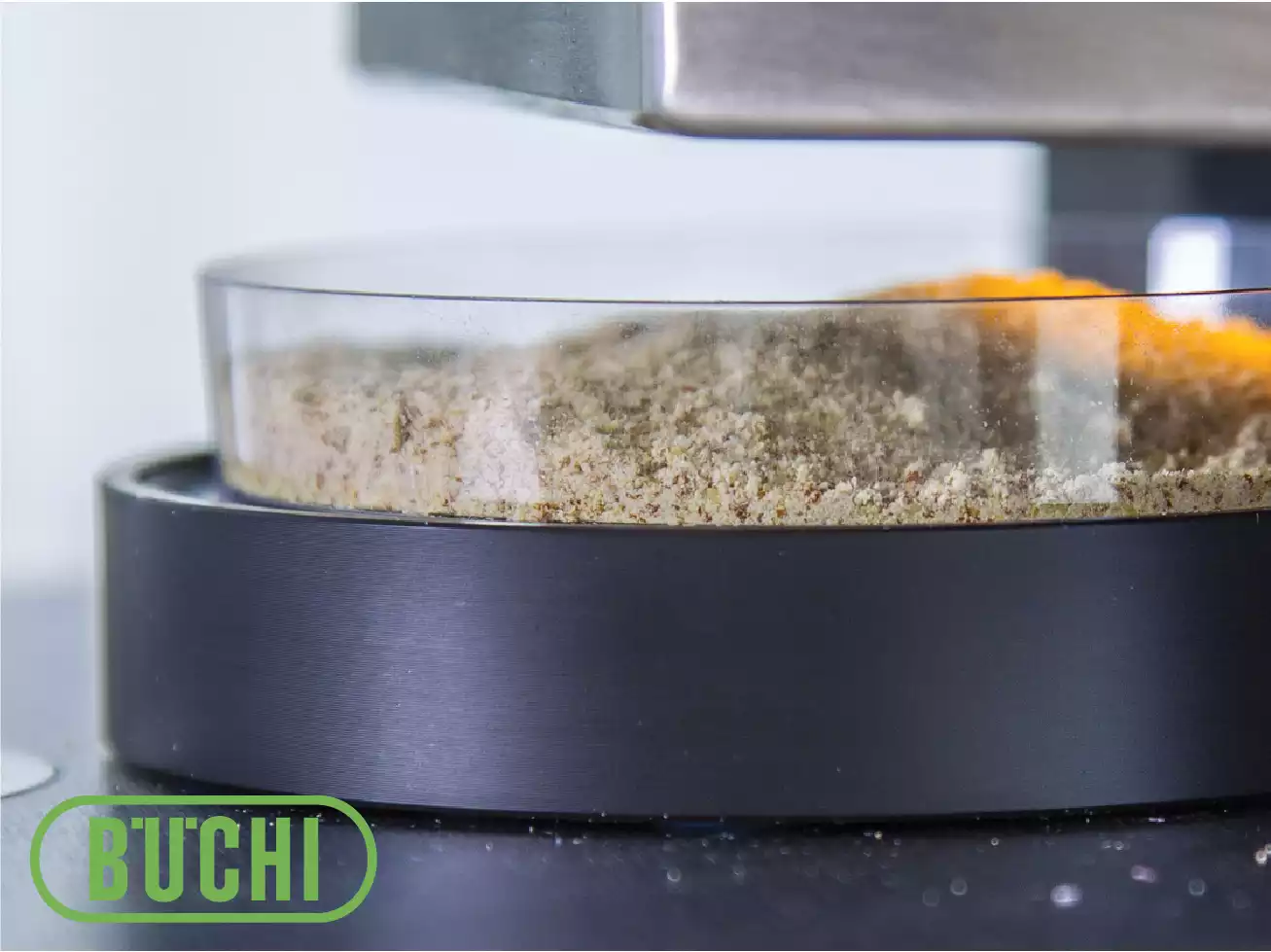

Dual-View Optical Configurations

To accommodate diverse sample types, the ProxiMate offers flexible optical setups including Up-View and Down-View configurations. The Up-View mode illuminates the sample through the bottom of a glass dish, providing a highly reproducible fixed sample plane ideal for liquids and fine powders. Conversely, the Down-View mode features a larger illumination spot size (30 mm) for non-contact measurement of coarse or inhomogeneous samples like whole grains or meat. This dual-capability ensures the best analytical performance regardless of the sample's physical state.

Integrated NIR and Visible Spectroscopy

Beyond compositional analysis, the ProxiMate can be equipped with a dual-sensor system combining NIR and Visible (VIS) light spectroscopy. This enables the instrument to measure color metrics such as L*, a*, and b* values or a "browning index" simultaneously with chemical constituents. Technically, the VIS signal can be mathematically integrated with NIR data to improve the detection limits for certain parameters, such as ash content in flour, providing a more comprehensive quality profile in a single measurement cycle.

Simplified Calibration with AutoCal

Calibration development is often a bottleneck in NIR spectroscopy, but the ProxiMate addresses this with the AutoCal function. This feature utilizes advanced algorithms to automatically optimize calibration models. Users simply select the samples with known reference values and press a button; the system then handles the complex mathematical modeling. This removes the need for in-house chemometric expertise, allowing production personnel to maintain and update calibrations easily as raw material profiles change over time.

Factory Standardization and Calibration Transfer

A significant technical advantage of the ProxiMate is that all units are factory standardized. This means that a calibration developed on one instrument can be copied and deployed to any other ProxiMate unit—whether in the same facility or a different global location—with identical results. This standardization is critical for large-scale operations requiring consistent quality control across multiple production lines, as it ensures that "product quality" is measured against the exact same digital standard everywhere.

Hygienic Design Endorsed by HALAG

Food safety is paramount, and the ProxiMate's hygienic design has been assessed and endorsed by the food hygiene agency HALAG. The instrument features smooth surfaces with no sharp edges, voids, or dead zones where food particles could accumulate and encourage bacterial growth. This design philosophy facilitates easy and effective sanitation, ensuring that the presence of the instrument on the factory floor does not compromise the microbiological integrity of the production environment.

High-Speed Multi-Parameter Analysis

Speed is essential in at-line testing to minimize process deviations. The ProxiMate provides analysis results in approximately 15 to 50 seconds, depending on the configuration. During this short window, it simultaneously determines multiple parameters such as moisture, fat, protein, fiber, and starch. This rapid feedback allows production operators to make real-time adjustments to formulations or processes, such as optimizing a blender batch or deciding on grain classification, thereby reducing waste and maximizing yield.

Versatile Sample Presentation and Accessories

The ProxiMate supports a wide variety of sample presentation options through interchangeable carriers and adapters. For liquids, a transflectance adapter can be used in the Up-View mode, while solid samples can be rotated using a magnetic drive unit to ensure a representative scan of the entire sample surface. From petri dishes and robust cups to large carriers for inhomogeneous materials, these accessories ensure the instrument can handle everything from meat and cheese to edible oils and compound feeds with high precision.

Read More About Buchi Products Here.

.webp)

.webp)

.webp)

.webp)