.webp)

Cap Torque Testing

Precision Torque Measurement Solutions by Sure Torque

SureTorque Cap Torque Testing

Sure Torque specializes in the design and manufacturing of high-precision instruments for measuring the torque of threaded closures on containers. These technical systems are essential for evaluating the performance of capping machines and ensuring that products are sealed according to industry standards. The instruments are capable of measuring both application torque (the force used to close a cap) and removal torque (the force required to open it). By providing accurate, repeatable data, Sure Torque helps manufacturers avoid issues such as leakage, product degradation, or consumer difficulty in opening the packaging.

The technical core of Sure Torque technology lies in its advanced sensors and electronic processing units, which capture torque data at high sampling rates. These systems are designed to handle a wide variety of container shapes and closure types, including child-resistant caps that require simultaneous downward pressure and rotation. The integration of specialized software allows for real-time data visualization, statistical analysis, and the generation of comprehensive quality control reports.

High-Resolution Torque Sensing and Signal Processing

Sure Torque instruments utilize advanced strain gauge technology to achieve high-resolution torque measurements. The sensors are technically engineered to minimize non-linearity and hysteresis, ensuring that even the slightest variations in torque are captured accurately. The signals from these sensors are processed through high-speed analog-to-digital converters, allowing the system to record peak torque values and continuous torque profiles. This level of technical precision is vital for identifying mechanical inconsistencies in the capping process or defects in the closure threads.

Automated Testing for Increased Repeatability

Automated torque testers from Sure Torque eliminate the variability associated with manual testing. By using motorized drive systems to apply or remove closures, the instruments ensure a constant speed and a uniform application of force. This technical automation is crucial for achieving high repeatability and reproducibility (R&R) in quality control labs. Automated systems can be programmed to perform various test cycles, such as "strip tests" to determine the failure point of the closure or "re-torque tests" to measure the effectiveness of the initial seal.

Comprehensive Child-Resistant Closure (CRC) Analysis

Testing child-resistant closures requires a specialized technical approach because these caps require a dual-action force: top-load pressure and rotational torque. Sure Torque systems feature integrated load cells that measure the downward vertical force while simultaneously recording the rotational torque. This multi-axial sensing allows for the detailed analysis of the CRC mechanism, ensuring that the closure requires the correct amount of force to engage or disengage, thus maintaining child safety while remaining accessible to adults.

Real-Time Data Acquisition and Statistical Process Control

The integration of proprietary software with Sure Torque instruments enables real-time data acquisition and advanced statistical analysis. Operators can monitor live torque curves, allowing for the immediate detection of anomalies during the testing process. The software automatically calculates key statistical parameters such as mean, standard deviation, and range. This technical capability supports Statistical Process Control (SPC), helping manufacturers identify trends in capping machine performance and make proactive adjustments to prevent out-of-specification batches.

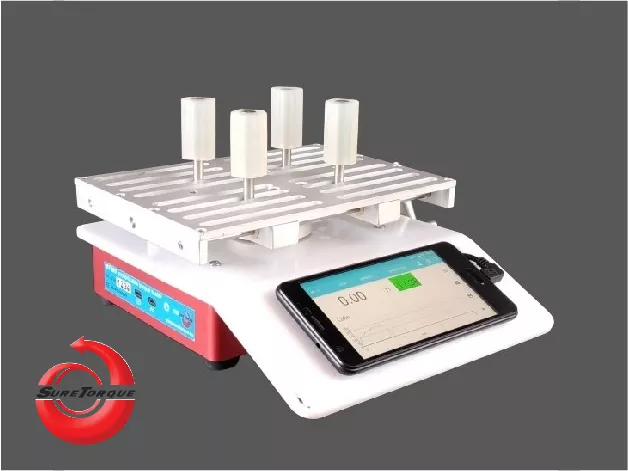

Multi-Station and High-Throughput System Design

For high-volume production environments, Sure Torque offers multi-station testing solutions. These systems can process multiple containers in a single cycle, significantly increasing testing throughput. Technically, each station operates with independent sensors and control logic, allowing for the simultaneous evaluation of different container sizes or closure types. This modular architecture is ideal for large-scale bottling plants and pharmaceutical manufacturers where efficiency and rapid data generation are critical for maintaining production schedules.

Specialized Gripping Systems for Diverse Container Geometries

One of the key technical challenges in torque testing is securely holding containers of various shapes—ranging from cylindrical bottles to flat-sided flasks—without deforming the container walls. Sure Torque addresses this through a range of universal and custom-designed gripping systems. These grippers utilize non-marring materials and adjustable clamping pressures to provide a stable base for the torque test. This ensures that the torque measured is purely the resistance of the closure and not influenced by container slippage or mechanical interference from the holding fixture.

In-Line and At-Line Quality Control Integration

Sure Torque provides technical solutions for both in-line and at-line quality control. At-line systems are positioned next to the production line for rapid periodic checks, while in-line systems are integrated directly into the conveyor system for 100% inspection of certain critical parameters. These systems are built with rugged housings to withstand industrial environments, featuring dust and moisture protection. This technical robustness ensures reliable operation in food and beverage plants where frequent washdowns and high humidity are common.

Calibration Standards and Regulatory Compliance

Maintaining the accuracy of torque measurement instruments requires regular calibration against traceable standards. Sure Torque systems are designed with built-in calibration routines and specialized calibration kits. This technical feature allows users to verify the performance of the sensors at multiple points along the measurement range. By ensuring that the instruments remain within specified tolerances, Sure Torque helps manufacturers comply with international quality standards such as ISO and FDA regulations, providing the documented proof of accuracy required for audits and certifications.

Read more about SureTorque Cap Torque Testing