Home » Products » Testing Instruments » Pharmaceutical Testing Instruments » Pharma Test Tablet Dissolution Testing Instruments

Tablet Dissolution Testing Instruments

Proving the availability of API in their delivered form

Pharma Test Tablet Dissolution Testing Instruments

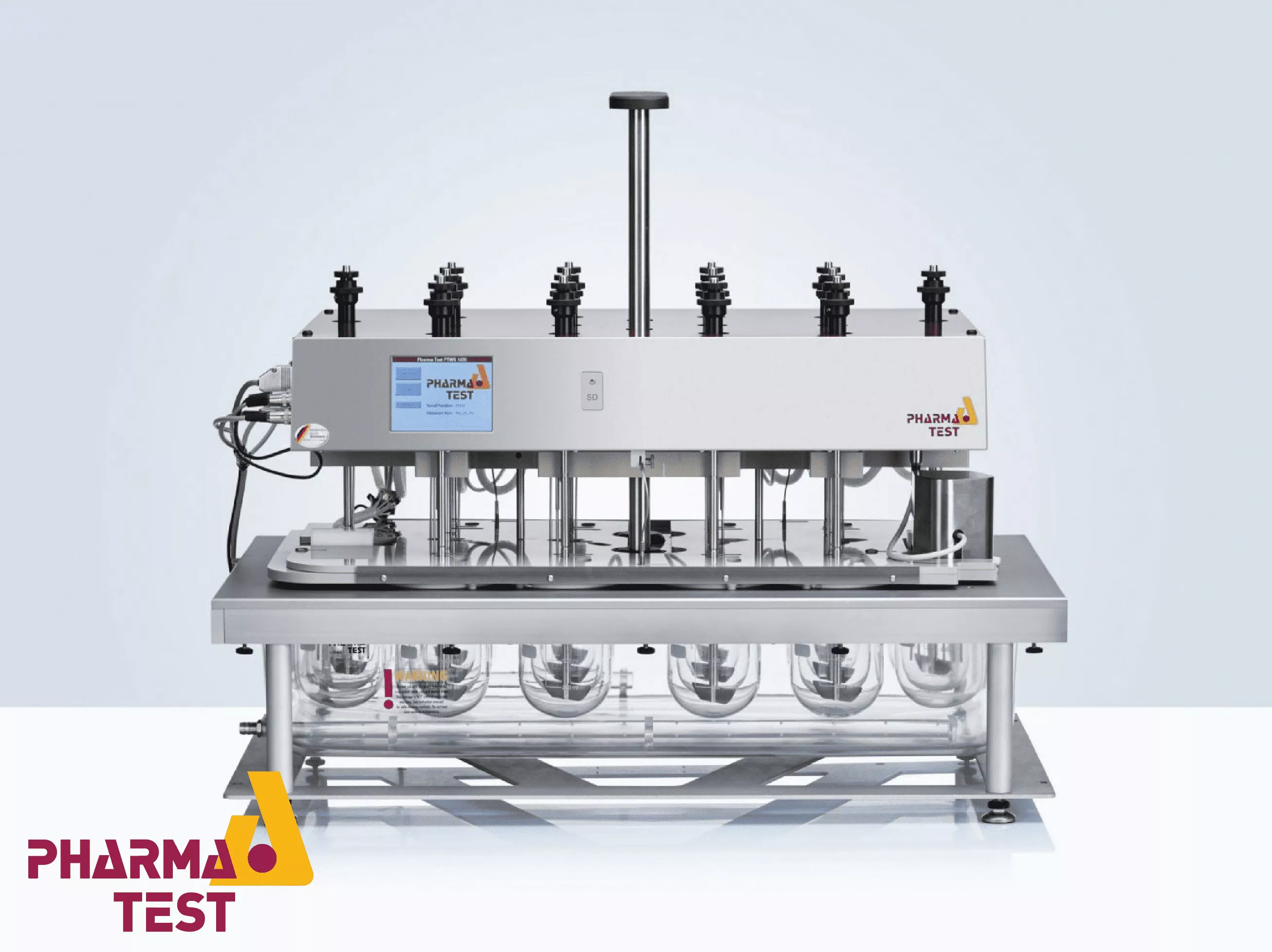

Pharma Test tablet dissolution testing instruments are technically engineered to determine the rate and extent of drug release from solid dosage forms, a critical requirement for ensuring the efficacy and safety of pharmaceutical products. These instruments are designed to strictly adhere to international pharmacopoeial standards, specifically supporting USP Apparatus 1 (Basket), Apparatus 2 (Paddle), Apparatus 5 (Paddle over Disk), and Apparatus 6 (Rotating Cylinder).

The technical architecture of these dissolution testers emphasizes mechanical precision and durability. Key features include automated tablet drop systems that ensure all dosage forms enter the media at the exact same time, and precise centering mechanisms for the dissolution vessels to minimize hydrodynamic variability. The drive systems are designed for ultra-quiet operation and precise speed control, typically ranging from 20 to 250 RPM.

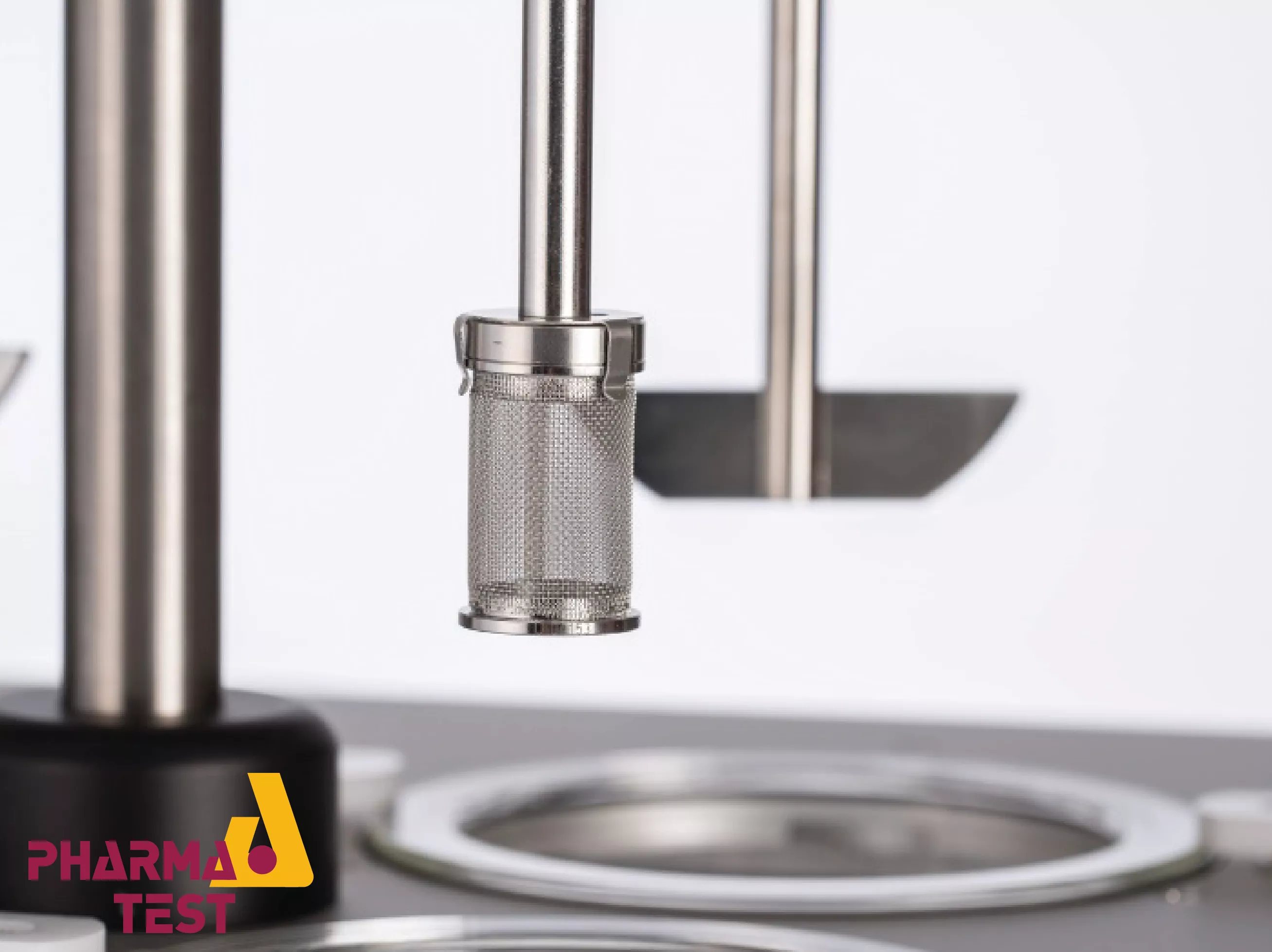

Compliance with USP and EP Apparatus Standards

Pharma Test dissolution instruments are designed to be fully compliant with the rigorous specifications of the United States Pharmacopoeia (USP) and the European Pharmacopoeia (EP). Technically, this means the instruments support various stirring elements, most commonly the USP Apparatus 1 (Rotating Basket) and Apparatus 2 (Paddle). The shafts and stirring elements are manufactured from high-grade, acid-resistant stainless steel or coated with inert materials to prevent chemical interactions with the dissolution media, ensuring the integrity of the drug release data.

High-Precision Water Bath and Thermal Management

A stable thermal environment is paramount for accurate dissolution testing. Pharma Test systems utilize high-clarity water baths combined with a powerful heating and circulation pump. The heating system is often decoupled from the main tester frame to minimize vibration, which is a critical technical requirement to avoid "vibration-induced" dissolution rate increases that could lead to false-positive results.

Automated Tablet Drop Systems

To ensure synchronized testing across multiple vessels, these instruments feature automated tablet drop systems. This technical mechanism allows the user to load tablets or capsules into a specialized tray, which then releases them simultaneously into the vessels at the start of the test. This eliminates the time delay associated with manual introduction.

Precision Vessel Centering and Hydrodynamics

The positioning of the dissolution vessel relative to the stirring shaft is a critical technical factor. Pharma Test instruments employ advanced centering mechanisms that ensure the vessel is perfectly aligned with the axis of rotation. Improper centering can cause wobbling or uneven flow patterns, significantly affecting the dissolution rate. By maintaining precise centering and verticality, these systems ensure reproducible hydrodynamics within each vessel, meeting the strict mechanical calibration requirements of global regulatory bodies.

Advanced Speed Control and Drive Systems

The drive systems in Pharma Test dissolution testers are engineered for precision and longevity. The speed is constantly monitored and displayed in real-time. This precise control is essential for testing various dosage forms, from fast-release tablets requiring low RPM to modified-release formulations that may require higher speeds or staggered intervals.

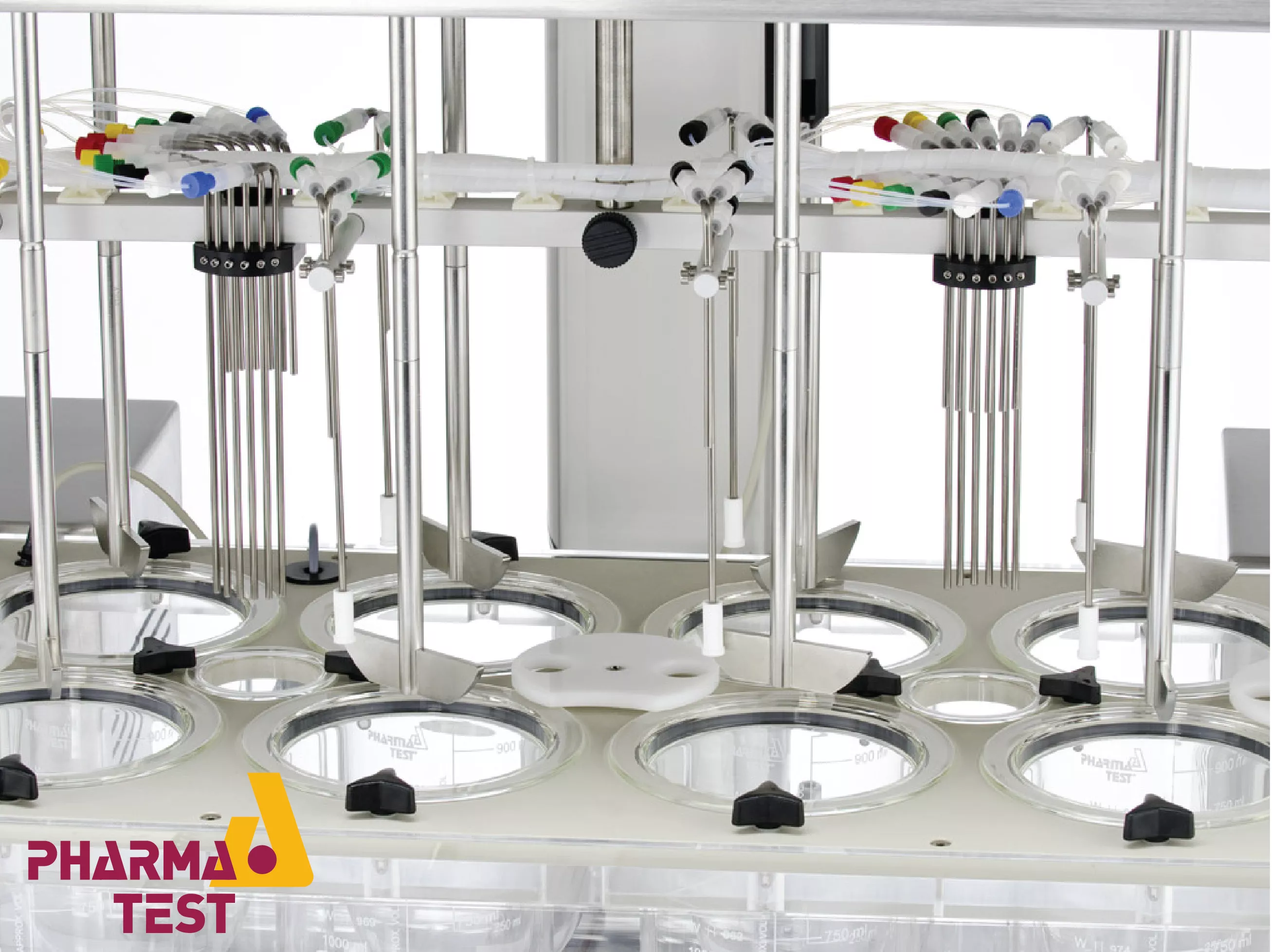

Sampling Interface and Probe Handling

For semi-automated and automated systems, the sampling interface is a key technical component. These instruments feature motorized manifolds that lower sampling probes into the media at pre-programmed intervals. The probes are positioned at the exact USP-specified sampling height—midway between the top of the stirring element and the media surface. To minimize hydrodynamic disturbance, the probes are often retracted from the vessels between sampling points, preventing any interference with the flow patterns.

Modular Design for Multi-Method Testing

The technical architecture of these testers allows for quick changes between different dissolution methods. Stirring elements (paddles, baskets, or cylinders) can be swapped easily using "quick-change" mechanisms that do not require re-adjustment of the height settings. This modularity enables a single instrument to be used for a wide variety of testing protocols, including those for transdermal patches (USP 5) or large-volume containers, making it a versatile tool for diverse pharmaceutical laboratories.

Software Integration and Data Integrity

Modern dissolution testing requires robust data management. Pharma Test instruments can be linked to dedicated dissolution software that automates the entire testing sequence, from method programming to final report generation. The software is technically designed to comply with 21 CFR Part 11, featuring secure user management, electronic signatures, and comprehensive audit trails. This ensures that all analytical results are traceable and tamper-proof, meeting the high standards required for pharmaceutical regulatory submissions.

Read more about Pharma Test Tablet Dissolution Testing Instruments