.webp)

Home » Products » Separation & NIR Solutions » NIR Spectroscopy » Buchi NIR-Online Process Analyzers

NIR-Online Process Analyzers

Real time process control

Buchi NIR-Online Process Analyzers

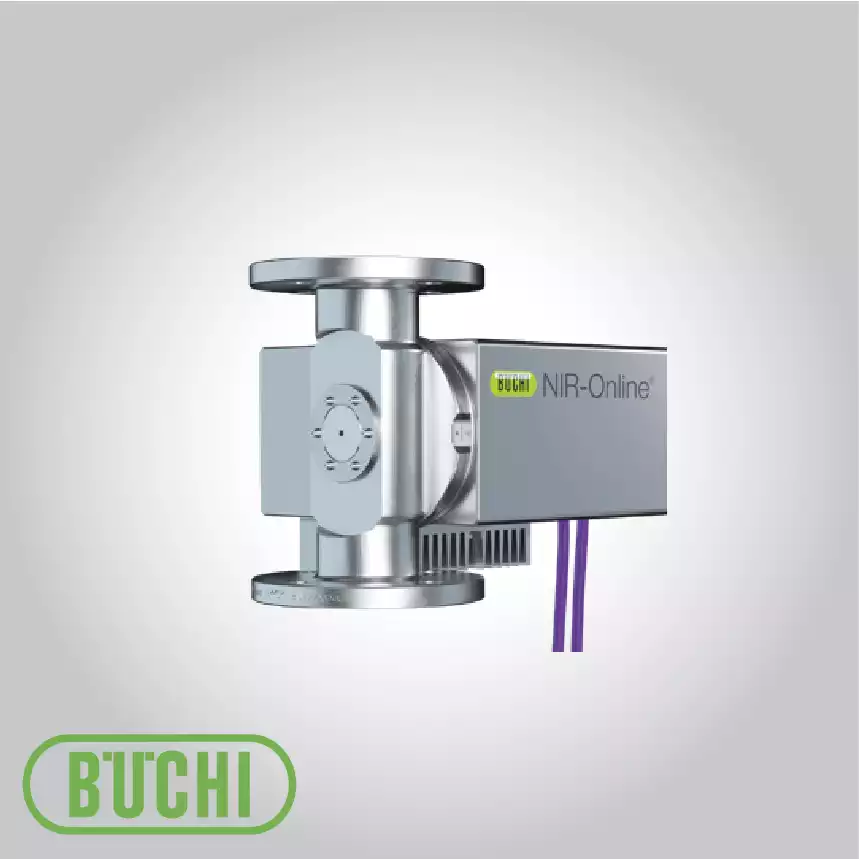

Buchi NIR-Online Process Analyzers are engineered for seamless integration into industrial production environments, providing continuous and non-destructive monitoring of critical quality parameters. Utilizing advanced diode array technology, these sensors deliver exceptionally fast measurements, capturing spectral data in milliseconds. This real-time data stream allows manufacturers to monitor constituents such as moisture, fat, protein, ash, and starch directly in the process flow, whether on conveyor belts, in pipes, or within bypass systems.

The technical architecture of these systems is distinguished by the inclusion of an integrated high-resolution camera, which provides a unique visual window into the production process. This feature allows operators to observe the physical state of the product simultaneously with the chemical analysis, facilitating the identification of process irregularities such as blockages or product inhomogeneities. Designed for durability, the analyzers feature robust housings with high ingress protection (IP) ratings, making them suitable for the demanding conditions of food, feed, and chemical processing plants.

Diode Array Technology for Ultra-Fast Acquisition

The core of the analyzer is its high-performance diode array sensor, which allows for simultaneous data acquisition across the entire spectral range. Unlike scanning spectrometers, this technology has no moving parts, ensuring high reliability and the ability to capture thousands of data points in a single second. This high speed is crucial for monitoring fast-moving products on conveyor belts or high-velocity flows in pipelines, ensuring that every significant change in product composition is detected without delay.

Integrated Process Visualization via High-Resolution Camera

A standout technical feature is the internal high-resolution camera integrated within the sensor head. This allows for real-time visualization of the sample surface as it passes the measurement window. By combining spectral data with visual images, operators can correlate chemical spikes with physical events, such as a change in grain size or the presence of foreign materials. This visual feedback is essential for troubleshooting and ensuring that the sensor is measuring representative product.

Automated Calibration and Maintenance with AutoCal

To ensure long-term accuracy without constant manual intervention, the system features AutoCal functionality. This software tool automatically integrates laboratory reference values into the existing calibration models. By streamlining the transfer of lab data to the online sensor, the system minimizes the need for expert chemometricians and ensures that the calibration remains robust against seasonal variations or changes in raw material origin.

Versatile Mounting and Process Interface Options

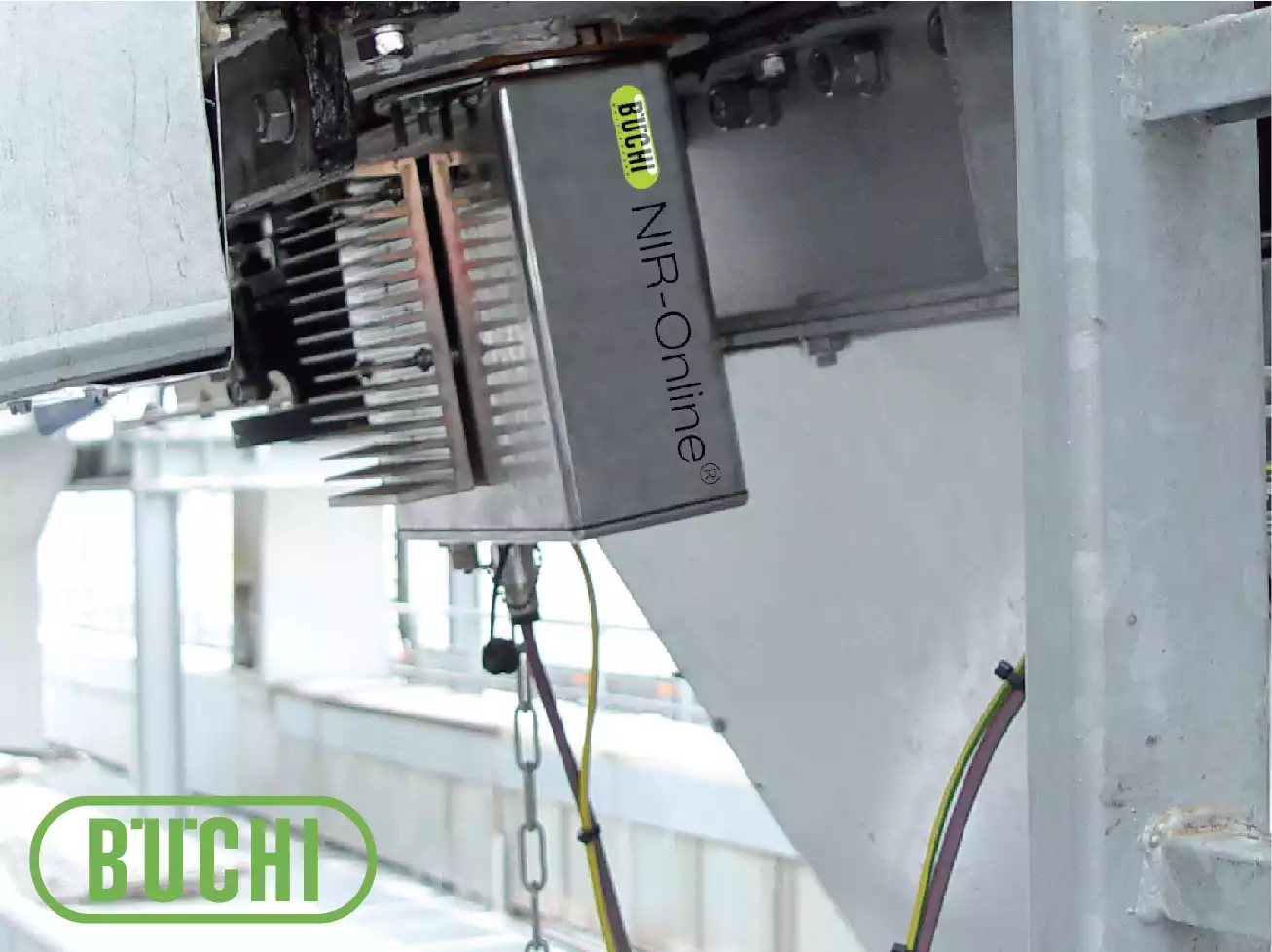

The analyzer is designed for maximum installation flexibility. It can be mounted using various process interfaces, including flanges, bypass systems, and specialized mounting frames for conveyor belts. This versatility ensures that the sensor can be placed at the most critical points of the production chain, such as at the intake of raw materials, after a dryer, or before final packaging, providing a complete map of the production process.

Robust Ingress Protection for Harsh Environments

Engineered for industrial longevity, the analyzer is housed in a stainless steel casing with protection ratings reaching up to IP65 or IP66. This technical specification ensures that the device is completely dust-tight and resistant to water jets, which is critical in food and feed industries where high-pressure washdowns are standard. The robust construction also includes vibration resistance, ensuring stable measurements even when mounted on heavy machinery.

Simultaneous Multi-Parameter Analysis

In a single measurement cycle, the analyzer determines multiple chemical and physical properties simultaneously. By analyzing the absorption of near-infrared light, it provides data for moisture, fat, protein, fiber, and ash content. This multi-parameter capability provides a comprehensive overview of the product quality in real-time, allowing for the optimization of formulations and the reduction of expensive ingredient giveaway.

Direct Integration with PLC and Control Systems

For true automated process control, the system features diverse communication protocols for integration with PLC and SCADA systems. Measurement results are transmitted via industry-standard interfaces, enabling the control system to make autonomous adjustments to production parameters, such as dryer temperature or blender speeds. This creates a closed-loop control system that stabilizes product quality and maximizes operational efficiency.

Hygienic Design and Food Safety Compliance

Technical focus is placed on maintaining food safety and hygiene. The measurement window is typically made of sapphire glass, which is scratch-resistant and avoids the risk of glass breakage in the production line. The smooth surfaces and specialized gaskets ensure that there are no "dead zones" where product can accumulate, meeting the strict requirements of hygienic design necessary for dairy, milling, and meat processing applications.

Read More About Buchi Products Here.