Home » Products » Analytical Solutions » Automated Reactors & IN SITU » Mettler Toledo Automated Synthesis & Process Development

Automated Lab Reactors

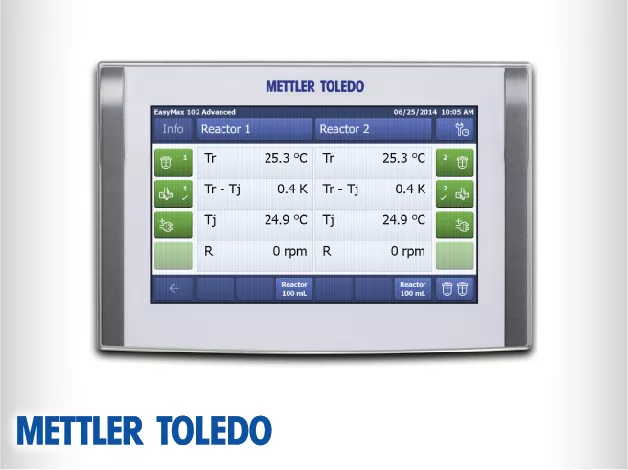

Control and record all reaction parameters

Mettler Toledo Automated Synthesis & Process Development

The innovative chemical synthesis reactors, EasyMax and OptiMax, are easy-to-use platforms that accurately and precisely control reaction parameters and execute recipes, thus enabling every chemist to perform reactions reproducibly. Experiment procedures can be run unattended, around the clock, all data is automatically recorded, and ready to be instantly shared and reported.

Chemical reactors reinvent the way scientists work, enabling their ability to generate more information per experiment, and accelerate the delivery of life-changing products. Automated chemical synthesis reactors are well established in chemical and pharmaceutical industry, and are essential to speed up time-to-market cycles at lower R&D costs.

High-Precision Parameter Control and Execution

The core technical advantage of automated synthesis workstations like EasyMax and OptiMax is their ability to control reaction parameters with extreme precision. Unlike manual setups, these systems utilize advanced thermostats and sensors to maintain temperatures within a range of -80°C to 180°C without the need for ice baths or heating mantles. The integrated control systems execute complex multi-step recipes, managing dosing rates and stirring speeds automatically. This level of control eliminates human variability and ensures that every chemical transformation is performed under identical conditions, which is vital for studying kinetics and identifying optimal reaction pathways.

Scalability and Process Characterization (0.5 mL to 1000 mL)

Mettler Toledo reactors are engineered to support the entire development lifecycle, from small-scale discovery to liter-scale optimization. The systems accommodate various vessel sizes, ranging from 0.5 mL tubes to 1000 mL jacketed vessels. This scalability allows researchers to characterize and optimize chemical reactions at a representative scale before moving to pilot plants or manufacturing. By identifying heat and mass transfer requirements under process-like conditions, the OptiMax system helps in making informed "go/no-go" decisions for scale-up, ensuring that processes are robust and safe when transitioned to larger reactors.

Integrated Reaction Calorimetry and Thermal Safety

The EasyMax HFCal and OptiMax HFCal systems combine synthesis capabilities with heat flow calorimetry. This technical integration allows scientists to measure the heat released during a reaction Delta H and identify the enthalpy and heat capacity of the mixture in real-time. Understanding the thermal profile is critical for assessing process safety, especially for exothermic reactions. By calculating the potential adiabatic temperature rise, engineers can design cooling strategies and dosing protocols that prevent thermal runaway, thereby ensuring that the chemistry is safe for large-scale production.

24/7 Unattended Operation and Lab Productivity

The automated nature of these lab reactors enables unattended operation 24 hours a day. Pre-programmed experimental sequences and safety limits allow reactions to run safely overnight, effectively doubling or tripling lab productivity. The system's "walk-up" interface is designed to minimize bottlenecks, allowing chemists to focus on data analysis rather than manual adjustments. This continuous operation is supported by automated data logging, which captures all sensor inputs and instrument events without manual intervention, creating a comprehensive digital record of every experiment.

Seamless Integration with In Situ PAT Tools

A defining technical feature of Mettler Toledo workstations is their "Plug-and-Play" compatibility with Process Analytical Technology (PAT) tools. Instruments like ReactIR (FTIR), ReactRaman, and ParticleTrack (FBRM) can be inserted directly into the reactor vessel. The control software synchronizes data from these probes with the reactor's physical parameters (T, P, pH). This allows scientists to correlate molecular-level changes, such as the disappearance of a reactant or the growth of a crystal, directly with the reaction conditions, providing a deep mechanistic understanding that is impossible with offline sampling.

Automated Sampling and Representative Data

For reactions that require offline analysis, the systems can be integrated with EasySampler for automated, representative sampling. This is particularly useful for reactions that are air-sensitive, toxic, or held at high pressures. The sampler captures a fixed volume at specific time intervals or reaction triggers and quenches it immediately, ensuring the sample is truly representative of the reaction state at that moment. This automated approach eliminates the inaccuracies and safety risks associated with manual sampling, providing high-quality data for HPLC or GC analysis.

Advanced Software for Analysis and Reporting

The iC Software Suite serves as the digital command center for automated synthesis. It provides powerful tools for data visualization, allowing researchers to overlay multiple reaction trends and identify key events such as the onset of a reaction or the end of a dosing step. The software automatically merges data from the reactor, sensors, and PAT instruments into a single timeline. Automated reporting tools then transform this raw technical data into smart reports, facilitating better communication within research teams and supporting regulatory compliance through detailed audit trails and history logs.

Versatility for Complex Chemistries (Lithiation to Hydrogenation)

These workstations are technically versatile enough to handle a wide range of challenging chemistries. The EasyMax LowTemp, for example, is specifically designed for sub-ambient conditions, providing precise control down to -90°C, which is ideal for organometallic reactions like lithiation and metalation. The reactors can also be configured for high-pressure applications, vacuum environments, or specialized particle engineering through controlled (re)crystallization. This technical flexibility ensures that the automated synthesis platform can adapt to evolving research needs across the pharmaceutical, specialty chemical, and polymer industries.

Read more about Mettler Toledo Automated Synthesis & Process Development

.webp)