Home » Products » Material Preparation, Analysis, and Testing » Image & Analysis Systems » Buehler OmniMet Modular Imaging System

Advanced Modular Imaging System

for Quantitative Metallographic Analysis

Buehler OmniMet Modular Imaging System

Unified Platform for Image Acquisition and Analysis The OmniMet Modular Imaging System functions as a central digital platform, engineered to seamlessly integrate disparate hardware components, including optical microscopes, digital cameras, and motorized stages, all accessed through a single intuitive interface. This convergence allows users to effortlessly capture images directly from calibrated microscopes or import standard format images for subsequent processing.

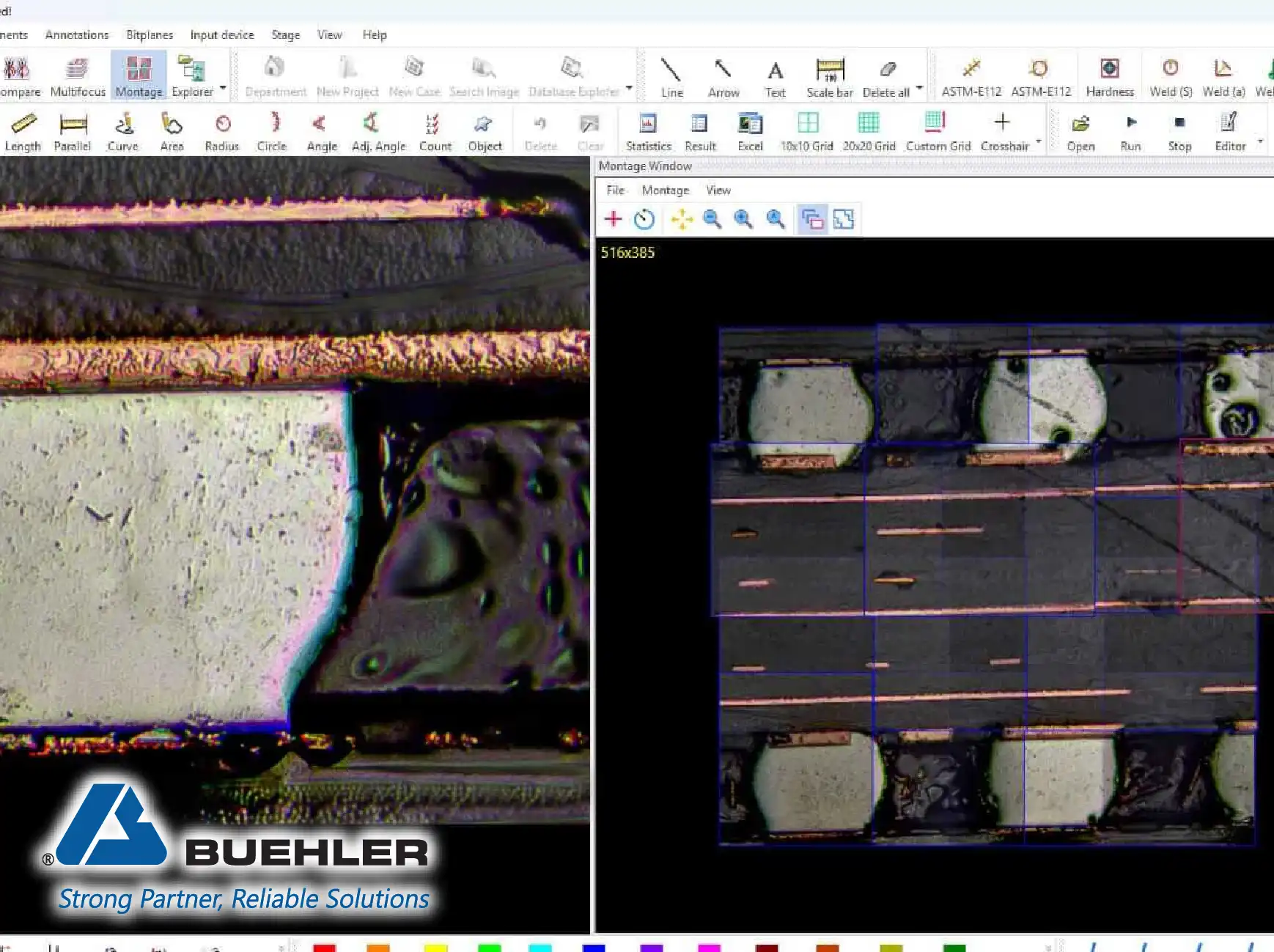

Scalable Modularity and Customization Designed with inherent flexibility, the software solution is offered across various functionality tiers, allowing laboratories to align their analytical power precisely with diverse metrology needs. The modular architecture supports extensive customization through the addition of specialized modules and pre-programmed analysis scripts for complex applications such as Multi-Focal Images, Mosaic Image Stitching, and specific material analyses like grain size support or Weld modules.

Overcoming Hardware Integration Complexity

The system provides seamless point-and-click integration with a multitude of industry-standard cameras, microscopes, and motorized stages. This capability eliminates the extensive configuration and compatibility issues typically associated with integrating disparate imaging components, ensuring a turnkey solution where image capture is standardized and immediately ready for calibration to the equipment's magnification level.

Eliminating Subjective Measurement Errors

The software directly addresses measurement subjectivity by offering intuitive point-and-click measurement possibilities for both simple and complex geometric evaluations, including length, area, radius, polygon, and adjustable angle tools. Further precision is achieved through advanced image processing utilizing Color Threshold functionality (based on size and intensity) and 16 Bitplanes for superior image segmentation, guaranteeing reliable and objective quantitative results.

Ensuring Process Reproducibility via Automation Scripts

The system enables Automated Imaging Analysis through the use of executable Scripts, either pre-programmed or user-defined. This functionality is engineered to eliminate repetitive steps and enforce the exact same process for every specimen, which critically improves quality control consistency. The top functionality tiers provide a ScriptEditor, granting the user complete control of analysis solutions by allowing them to write and edit complex automated routines.

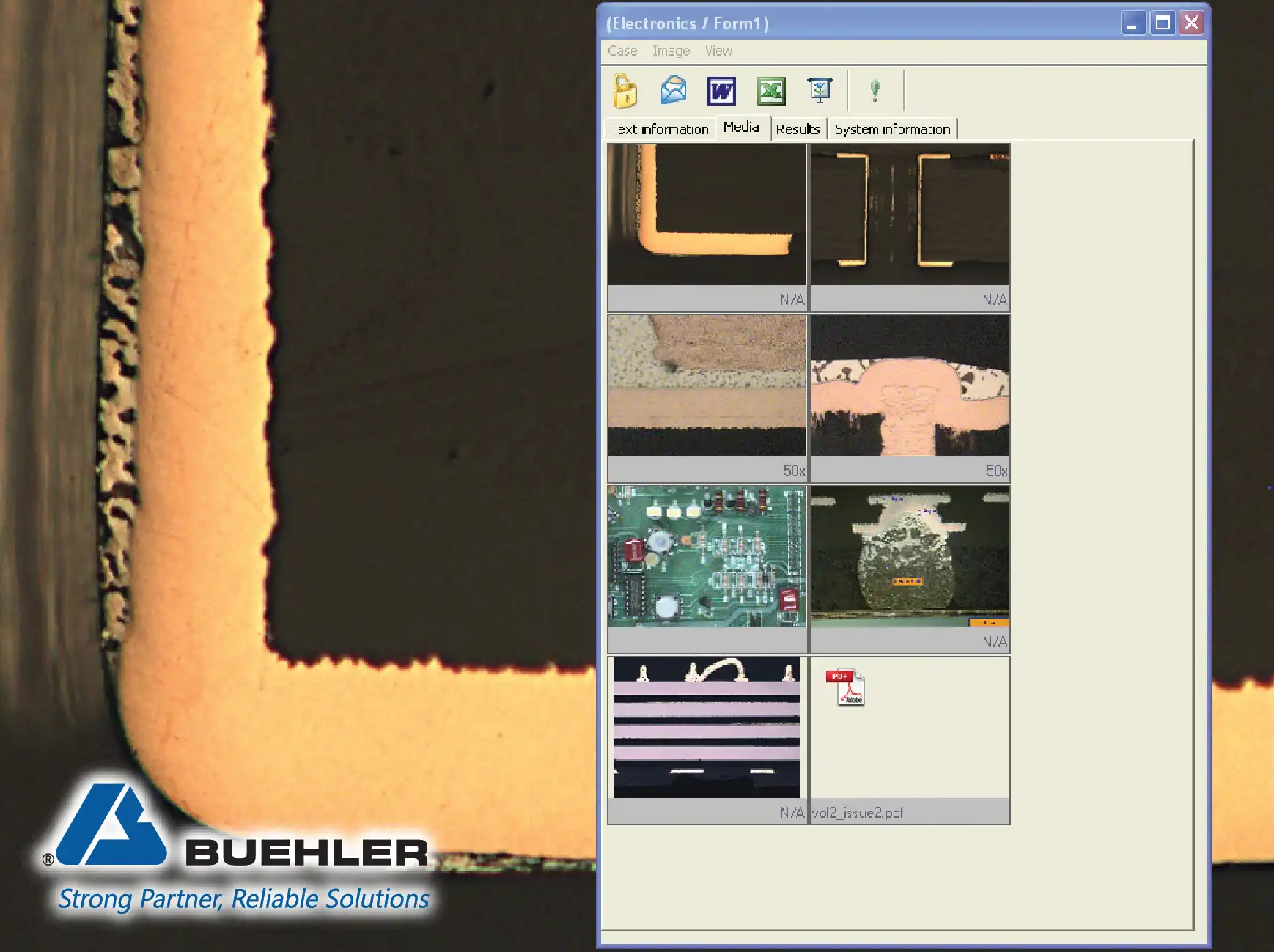

Comprehensive Data Archiving and Security

The platform delivers flexible database functionality for both archiving and administration. It supports the creation and secure management of a centralized database, allowing networked users to reliably view and modify images and information. Furthermore, the inclusion of individual user accounts with administrative security protocols ensures controlled access to all functions and sensitive data, upholding rigorous traceability standards required in regulated industries.

Standardizing Complex Analysis and Reporting

The platform includes application-specific Modules and pre-programmed Scripts, such as those for grain size support and Weld modules, which significantly reduce analysis steps. It can automatically export analyzed data and integrated images to standard external report templates, ensuring compliance to national standards with minimal interaction. The real-time update of Results and Statistics windows ensures immediate data review and reporting accuracy.

Addressing Non-Standard Specimen Imaging

Specialized optional Capture Modules are available to manage challenging specimens. These include capabilities for Multi-Focal Images to address depth-of-field issues on uneven surfaces, and Mosaic Image Stitching to create a single, high-resolution panoramic view of a large area from multiple fields of view. This automation minimizes the manual effort required for acquiring representative images of non-standard samples.

Providing Tailored Functional Access

The software is strategically offered in six different Editions across varying levels of functionality, allowing users to select their required level of automation and feature access. This tiered approach ensures laboratories do not pay for unused functionality. Furthermore, the system is designed to allow users to upgrade functionality from one software level to another at any time, providing seamless scalability as analytical needs evolve.

Optimizing User Experience and Tool

Access Navigation within the system is designed to be simple and easy with a clean layout utilizing simple and intuitive gestures. The platform's customizable toolbars and overall layout give users quick access to the tools they need without clutter. This focus on an optimized user experience (UX) ensures that the powerful tools are simple and smart to work with, thereby speeding up daily operations and improving user competency.

Click here to know more about Buehler products

.webp)