Home » Products » Material Preparation, Analysis, and Testing » Sectioning & Cutting Systems » Buehler Abrasive Cutters

Abrasive Sectioning Systems

High-Throughput and Advanced Cut Cycles

Buehler Abrasive Cutters

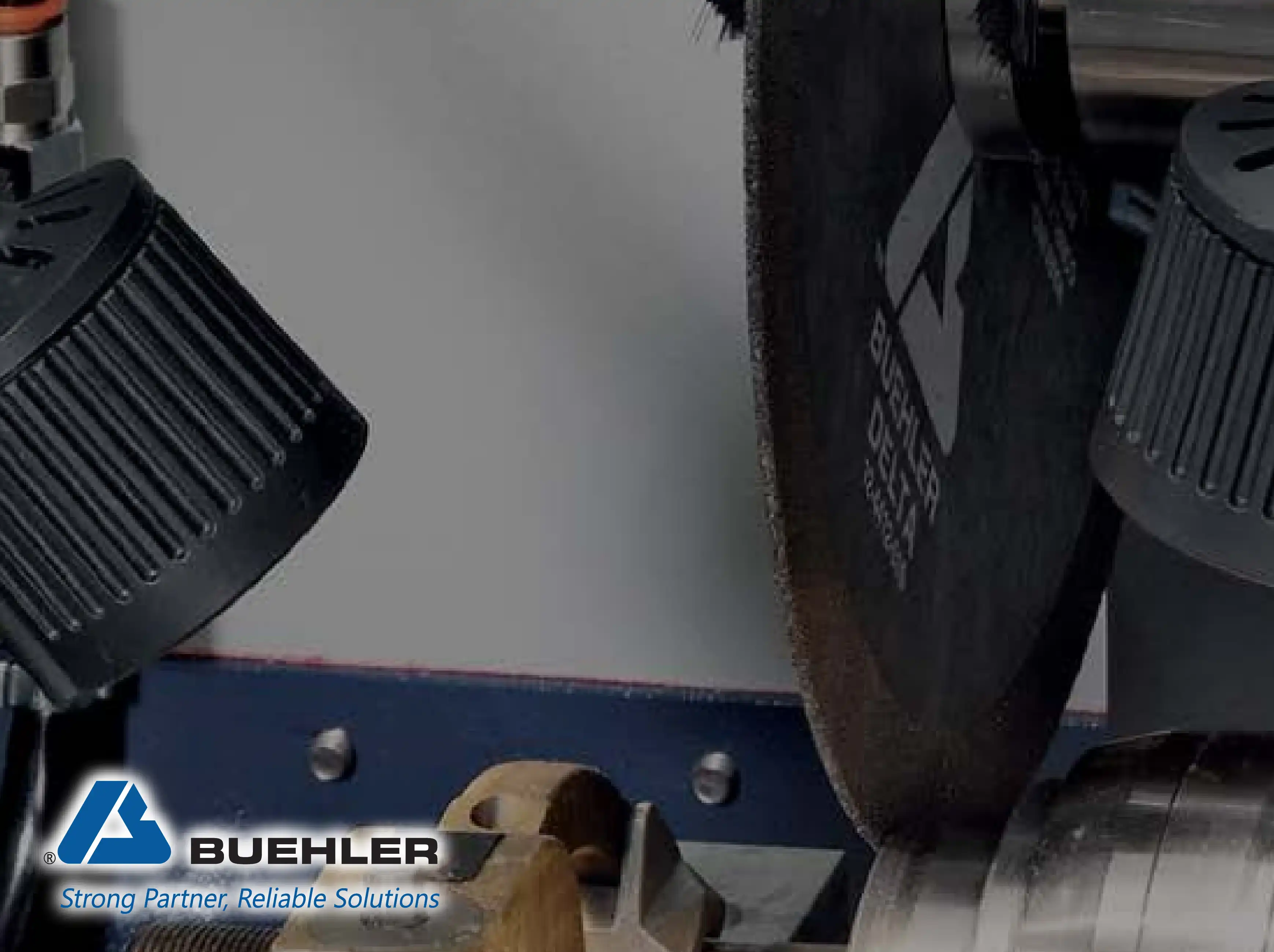

The greatest technical challenge in abrasive sectioning is managing the heat generated during the high-speed material removal process, as thermal damage is a major customer pain point leading to sample alteration. Advanced automated systems utilize methods like Chop Cutting with Pulsing or Y Feed Cut with Pulsing. These techniques are technically crucial because the intermittent pausing action allows the coolant sufficient time to wash away abrasive swarf and effectively dissipate localized heat, thereby preventing microstructural artifacts and ensuring a substantially better surface quality from the initial cut.

For users who frequently section varying sample sizes, the customer pain often centers on machine flexibility and capacity limitations. High-end automated abrasive cutters resolve this by offering fully automatic movement in all three axes, coupled with large chambers capable of accommodating massive workpieces up to the 18-inch blade diameter maximum. This feature, combined with automated chamber cleaning, reduces the time spent on setup, aligning the cut, and maintenance, allowing users to focus on other tasks during the cycle and directly increasing laboratory efficiency and throughput.

Cut quality

The primary challenge addressed by automated abrasive systems is the inconsistency of cut quality inherent in manual operation. Technical programmable interfaces allow for precise input of cutting parameters, ensuring that the critical first step in material preparation is perfectly repeatable across all shifts and operators. The ability of the machine to control the feed rate, force, and axis movement automatically removes subjective human error, preventing poor surface finishes that necessitate extensive and costly rework during the subsequent grinding stages.

Fatigue and strain

Manual abrasive machines, while robust, present operator fatigue and strain challenge during high-volume processing. The technical design of these machines focuses on minimal cutting effort and high visibility within the chamber. This approach, while simple, allows for fast and efficient cuts on non-delicate samples, enabling the laboratory to quickly move through the materialographic workflow without the bottleneck of physically demanding cutting processes, maximizing the utility of technician time.

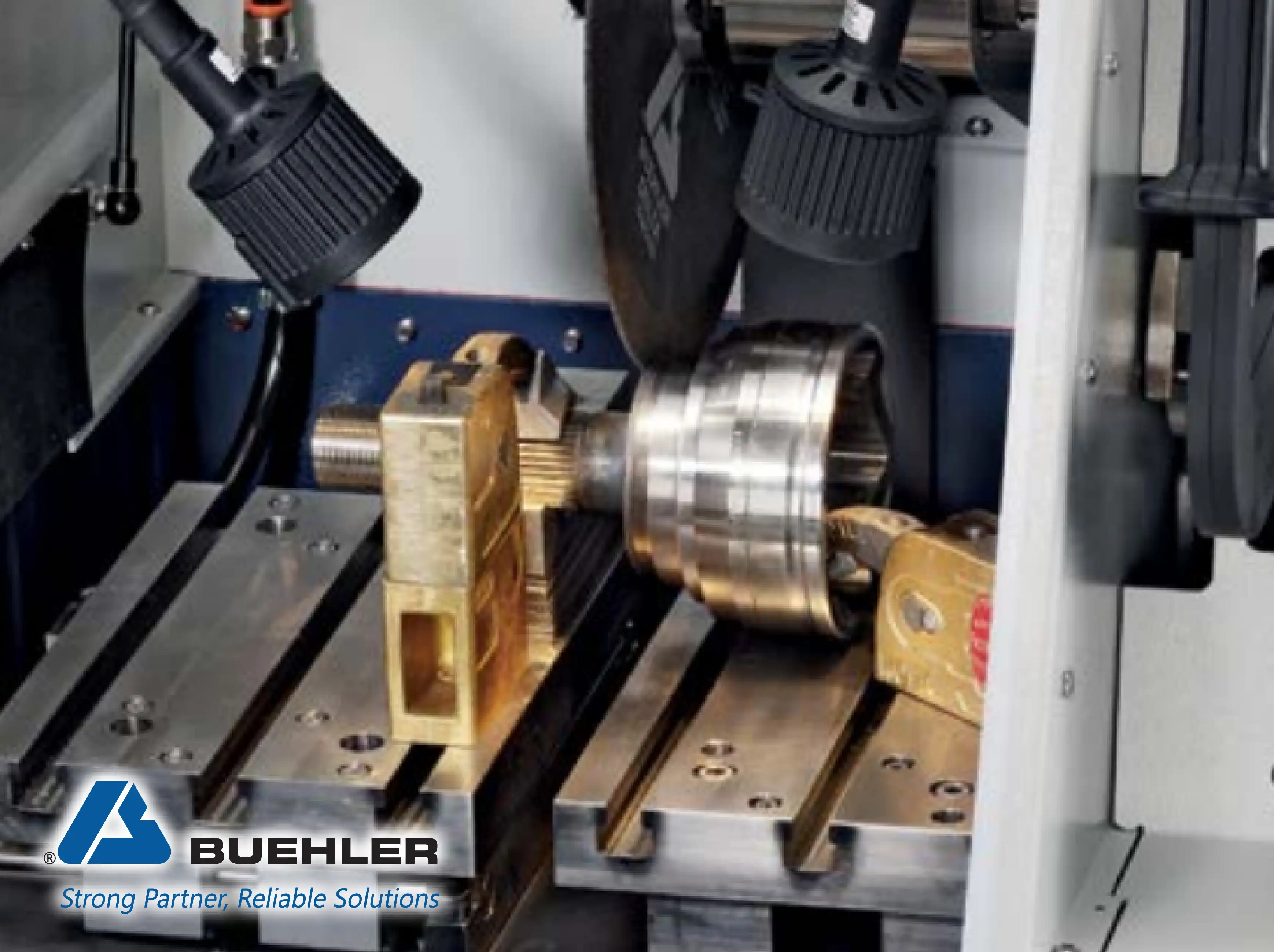

Difficult-to-cut samples

For facilities dealing with large or difficult-to-cut samples, the limitation of traditional chop cutting due to the wide arc of wheel contact, causing a struggle with oversized parts. The technical inclusion of fully automatic three-axis movement allows for advanced cutting styles like Planar Cut, where the wheel contact arc is governed by the height of each successive vertical step, not the total height of the sample. This technique significantly reduces the heat and load on the blade, successfully sectioning parts previously deemed too challenging.

Contamination

Swarf buildup and coolant contamination are common technical frustrations by requiring frequent manual cleaning. Modern abrasive cutters address this by integrating automated chamber cleaning features. This technical capability maintains a clean cutting environment automatically, ensuring that recirculating coolant remains effective for heat dissipation and that the visibility for the operator is maximized, thereby increasing non-productive maintenance downtime.

High-speed conditions

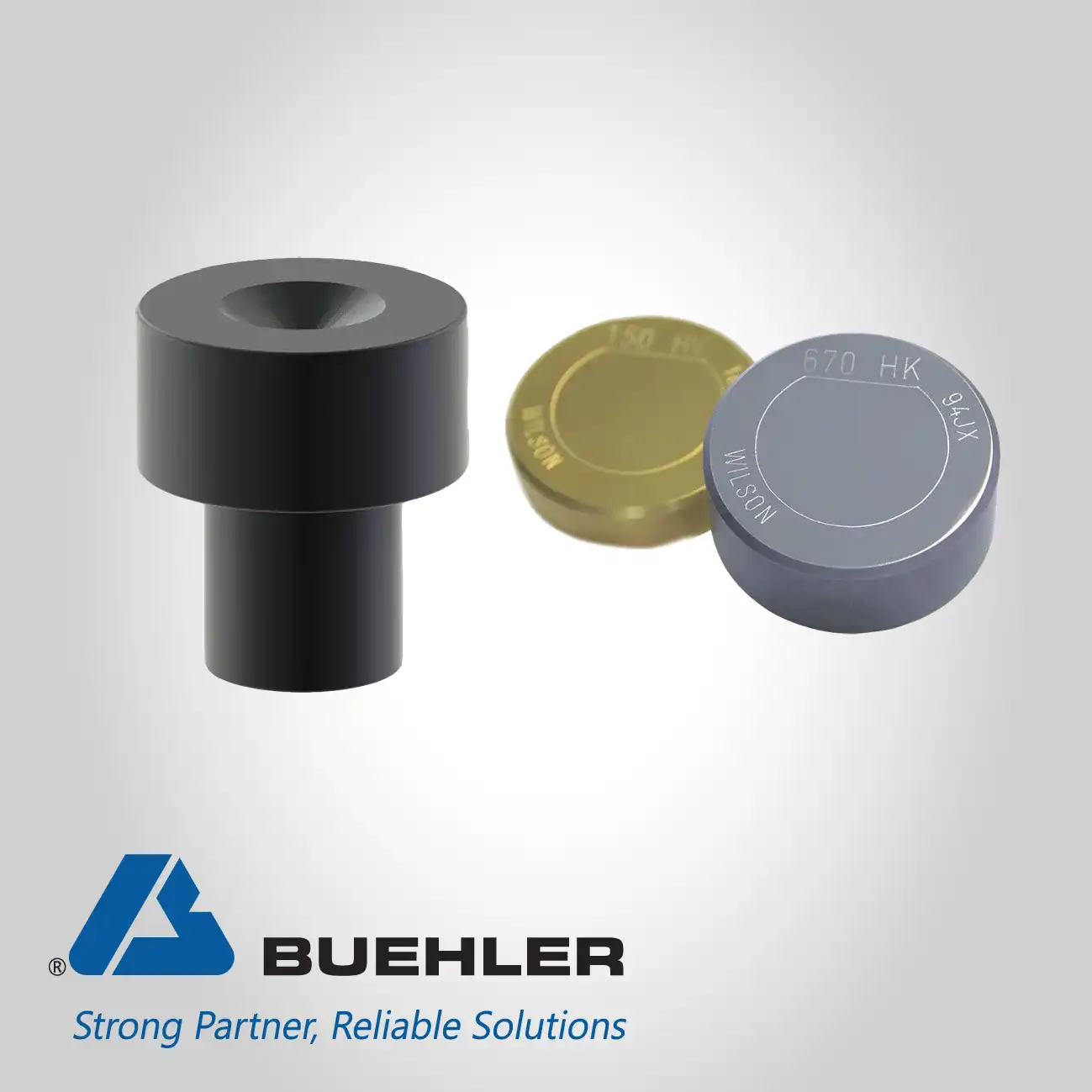

Achieving adequate cut quality under high-speed conditions is mitigated by the technical options for abrasive blades. Performance-proven abrasive blades, available in rubber and resin bonded formulations, are specifically engineered for efficient cutting, extended lifetime, and most importantly, minimal surface deformation. Selecting the correct bonded blade type ensures the aggressive material removal necessary for throughput does not compromise the microstructural integrity near the cut surface.

Setup time

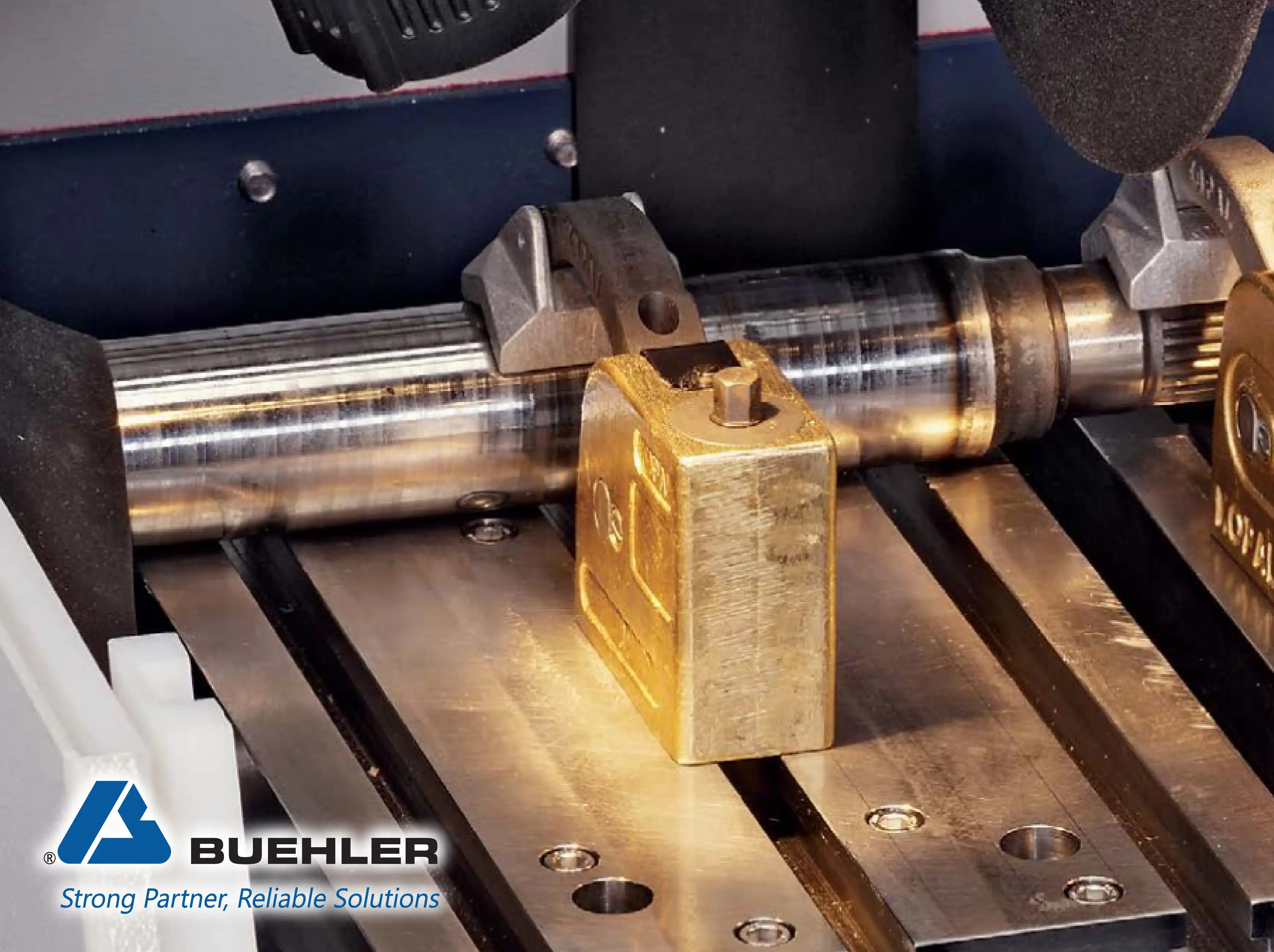

Setup time is a significant non-productive challenge, especially when frequent vising changes are required. The technical solution lies in the versatility of the abrasive vising accessories offered, including small, medium, and large options. This broad range ensures that technicians can quickly select the appropriate vise to clamp samples of diverse geometries perfectly, making setup fast and flexible and reducing the overall material preparation cycle time.

Blade wear

Dealing with difficult parts often results in the excessive blade wear due to uneven contact stress. Technical innovations in automated cutters, such as the ability to perform Y Feed Cut, where the cutting table moves forward while the wheel is stationary, ensure that the wheel contact arc is governed by the sample height. This optimized interaction minimizes undue stress on the blade, maximizing its operational life and reducing the consumable cost and frequency of replacement.

Heat-sensitive materials

The risk of heat-related cracking or phase changes in heat-sensitive materials is a critical, hidden customer pain. The technical defense against this involves utilizing dedicated sectioning coolants—either water-miscible or oil-based—specifically formulated for effective heat transfer and lubrication. The constant flow of the appropriate coolant is essential in preventing the high friction at the cut interface from altering the sample's microstructural integrity before it can be analyzed.

Click here to know more about Buehler products

.webp)