Home » Products » Material Preparation, Analysis, and Testing » Sectioning & Cutting Systems » Buehler Precision Cutters

Low-Force Precision Sectioning

for Delicate and High-Value Materials

Buehler Precision Cutters

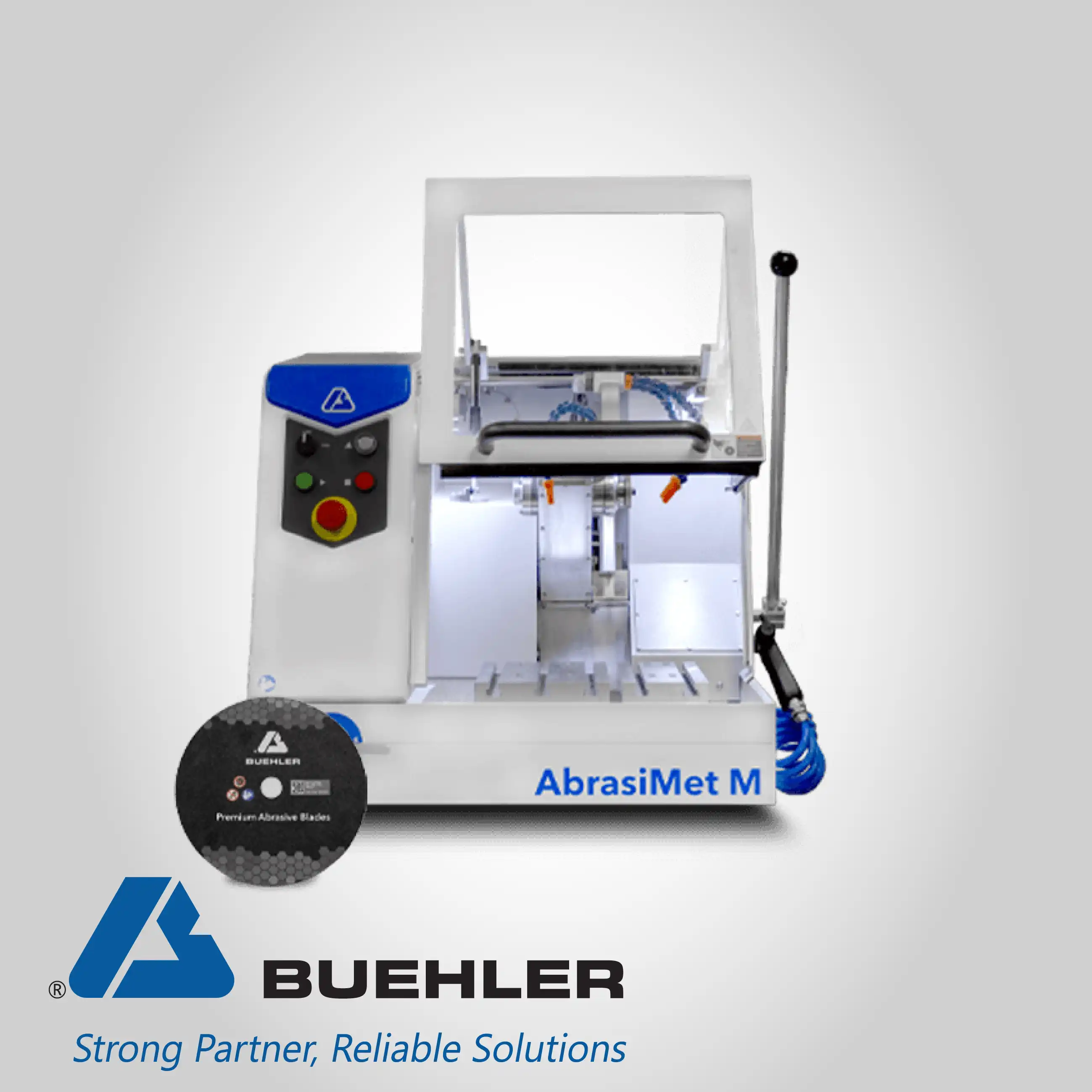

The core technical advantage of precision sectioning is its focus on surface quality over speed, directly addressing the customer pain of lengthy and error-prone pre-grinding steps. Manual precision cutters, often gravity-fed, utilize low kinetic energy and slow feed rates to yield highly smooth cut surfaces. Contrastingly, fully automatic precision systems incorporate three-axis movement and automated blade dressing, which are technical features designed to ensure positional consistency and blade sharpness, thereby accelerating the transition from sectioning to the subsequent analytical stages.

Specialized precision cutters are developed to resolve the customer pain associated with preparing unique material types that require ultra-thin sections, such as ceramics, concrete, or bone. Machines designed for thin sectioning perform a technically specific function, preparing samples for high magnification analysis. This specialized equipment necessitates precise fixtures to bond the samples to slides, ensuring the critical positional accuracy and minimal thickness variation required for polarized light microscopy or other advanced structural characterization techniques.

Delicate materials

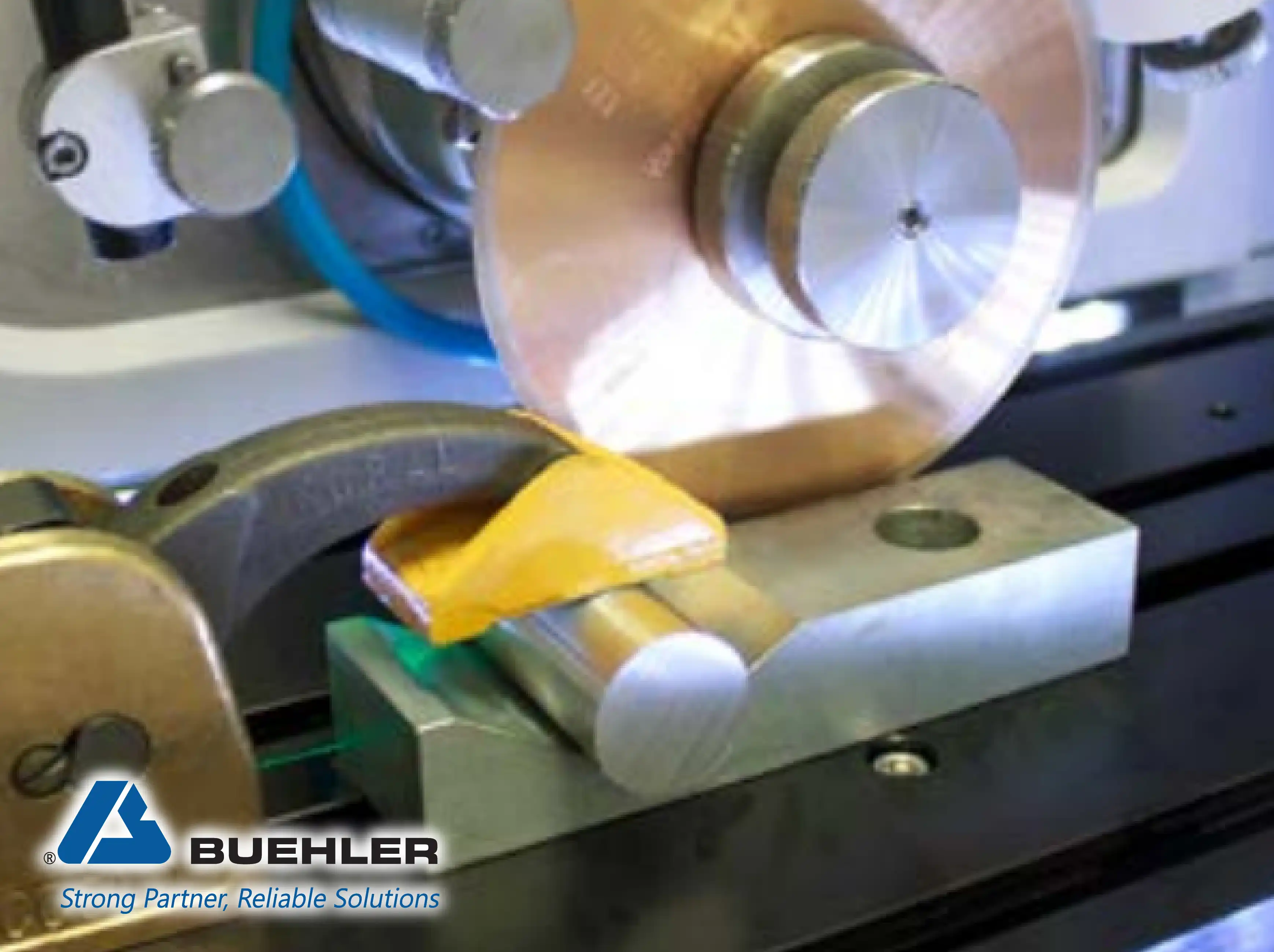

The foremost challenge of delicate materials is the destruction or tearing of the sample during cutting due to high mechanical stress. Precision cutters overcome this by technical reliance on low-speed, low-force operation and gravity feed mechanisms. These principles minimize the cutting force applied to the specimen, preserving the integrity of fragile internal components—a necessity for electronic components or composites where structural damage renders the sample useless for subsequent analysis.

Alignment consistency

The lack of alignment consistency, leading to non-parallel cuts that waste material during subsequent grinding. Fully automatic precision systems alleviate this through three-axis movement of the blade or sample, guaranteeing exceptional positioning accuracy. This technical control ensures the cut is executed precisely along the intended plane, maximizing usable sample volume, which is critical for expensive or scarce materials.

Subsurface deformation

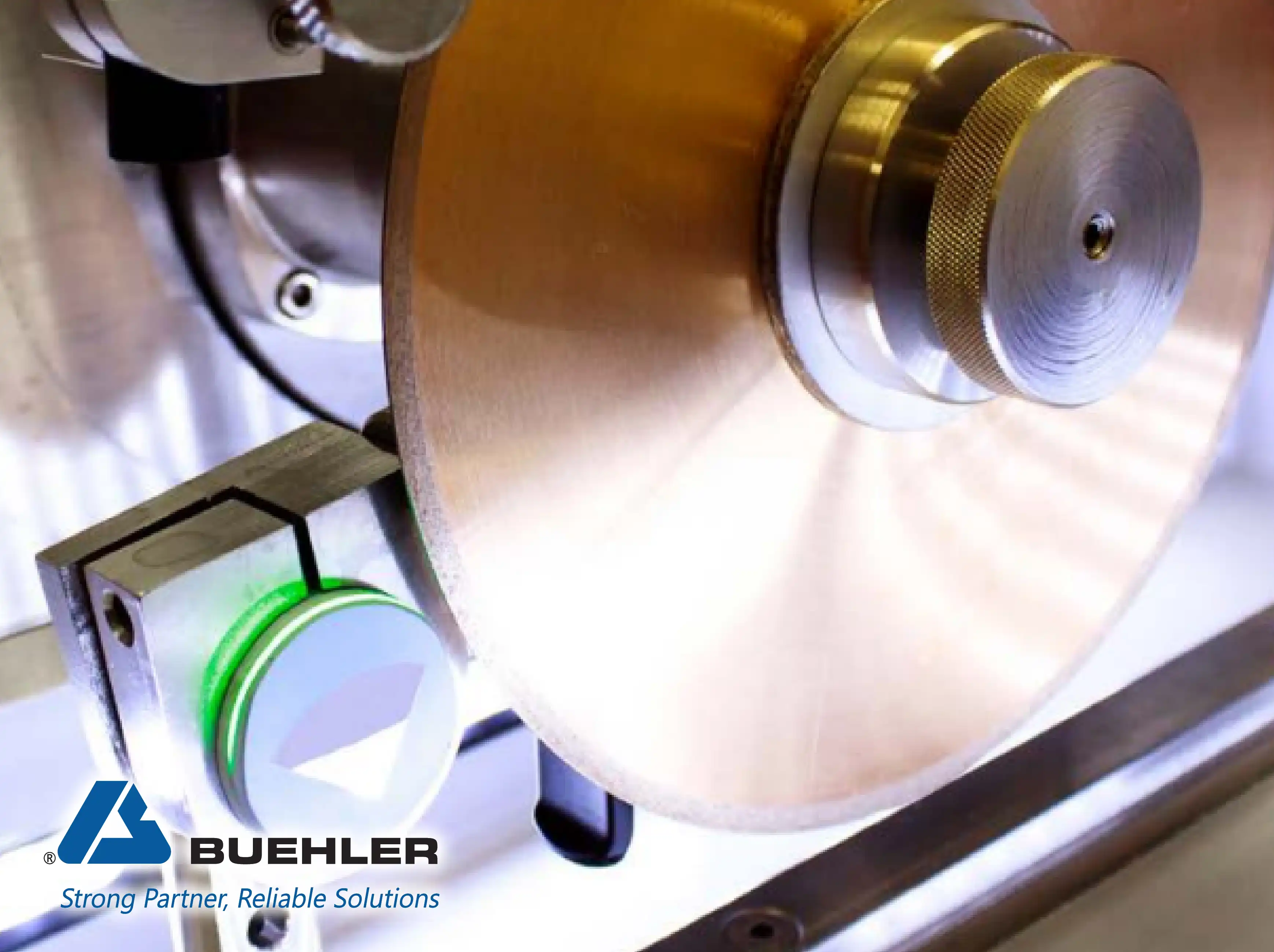

The rapid dulling of cutting blades causes subsurface deformation and requiring frequent, time-consuming blade changes. The technical solution integrated into automated precision cutters is automatic blade dressing. This feature maintains a sharp cutting edge, optimizing the cutting efficiency and, most critically, ensuring the finished surface quality remains high throughout the operational cycle, accelerating the workflow by reducing the need for manual maintenance.

Microscopic analysis

Preparing ultra-thin sections for petrography or bone analysis is crucial for microscopic analysis. Specialized thin sectioning machines are technically designed to provide the necessary rigidity and precise control over material removal required for this specific application, delivering the high quality and consistency of thin section preparation demanded by high magnification techniques.

Sample fixturing and rotation

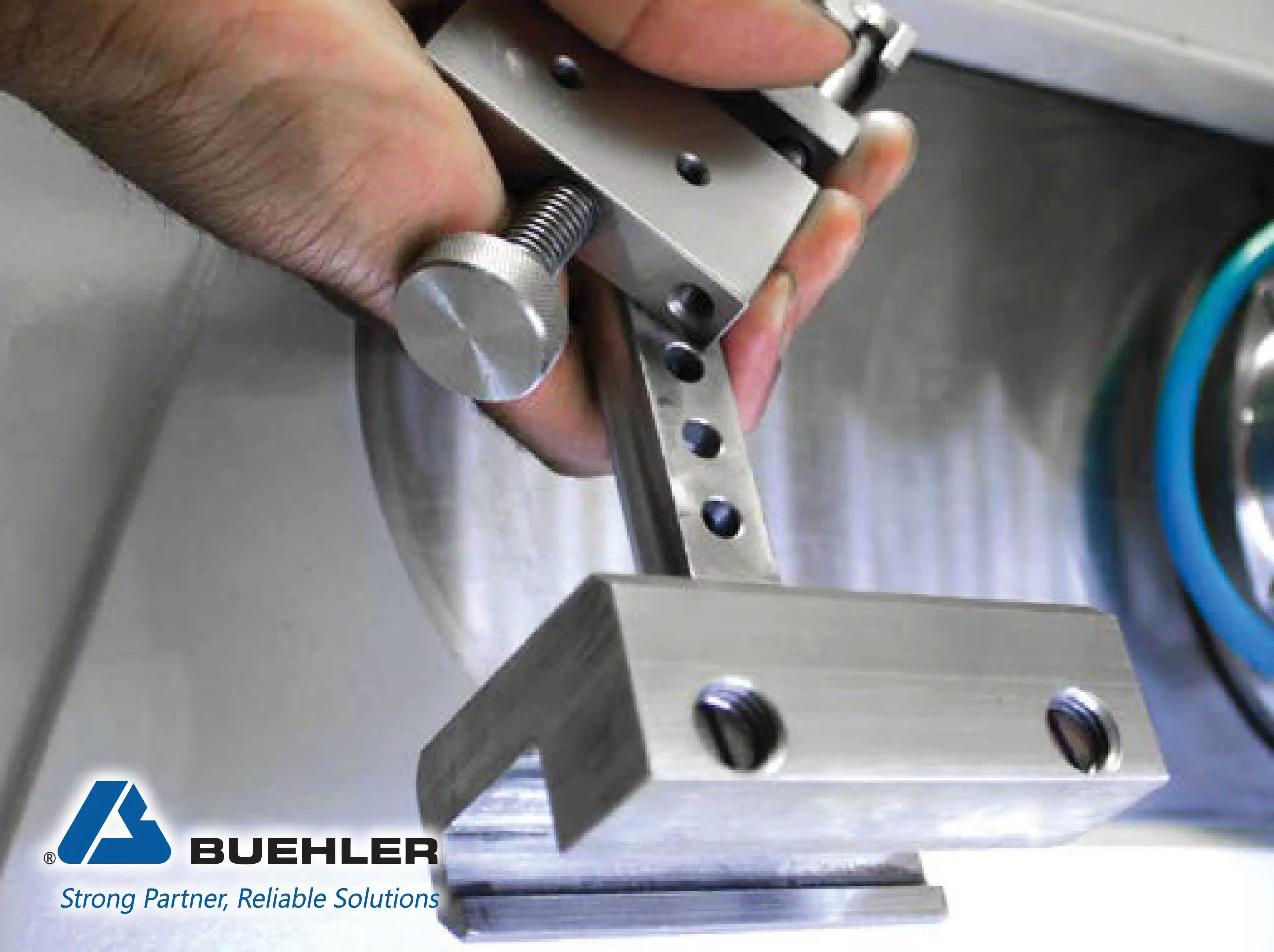

When sectioning samples for specific orientation analysis, the difficulty in precise sample fixturing and rotation is the real challenge. Precision cutting accessories, such as chucks and vises, are technically designed to hold samples securely while allowing for repeatable angular positioning. This capability is paramount for ensuring that the crystallographic or structural features of interest are cut along the correct plane for later X-ray or micro-analysis.

Subsurface damage

Utilizing the wrong type of blade for delicate work results in the subsurface damage and smearing. Precision cutters mitigate this by utilizing blades made from advanced materials like diamond and CBN. These technical materials are selected for their superb cutting properties and ability to achieve a superior surface quality on a wide range of materials, effectively eliminating the need to use inappropriate tooling that compromises sample integrity.

Simultaneous multiple thin sections

The necessity of preparing multiple thin sections simultaneously presents a technical workflow pain. This is addressed by accessories like the thin section bonding fixture, which can accommodate several samples affixed to glass slides. This fixture ensures uniform preparation of specimens before the final thinning process, guaranteeing that the critical bonding interface is consistent and repeatable across all samples.

Accidental damage

For technicians transitioning to automatic precision cutting, the initial learning curve and fear of accidental damage represent customer pain. Automatic precision systems feature easy-to-use interfaces that simplify setup and cycle execution. The integration of technology to make precise sectioning simple and intuitive ensures that even complex, delicate cuts can be performed reliably, increasing user confidence and minimizing the risk of costly errors.

Click here to know more about Buehler products

.webp)