.webp)

High-Precision Cetane Ignition Delay

Analysis for Diesel Fuel Characterization

PAC Cetane Ignition Delay

Cetane Ignition Delay analysis is an essential method for evaluating the ignition quality of diesel fuels and related hydrocarbon products, providing laboratories with highly accurate and reproducible measurements. It measures the precise time interval between the fuel injection into the combustion chamber and the onset of combustion, a period commonly referred to as ignition delay. This parameter is crucial because it directly affects diesel engine performance, combustion efficiency, emissions characteristics, and overall fuel quality.

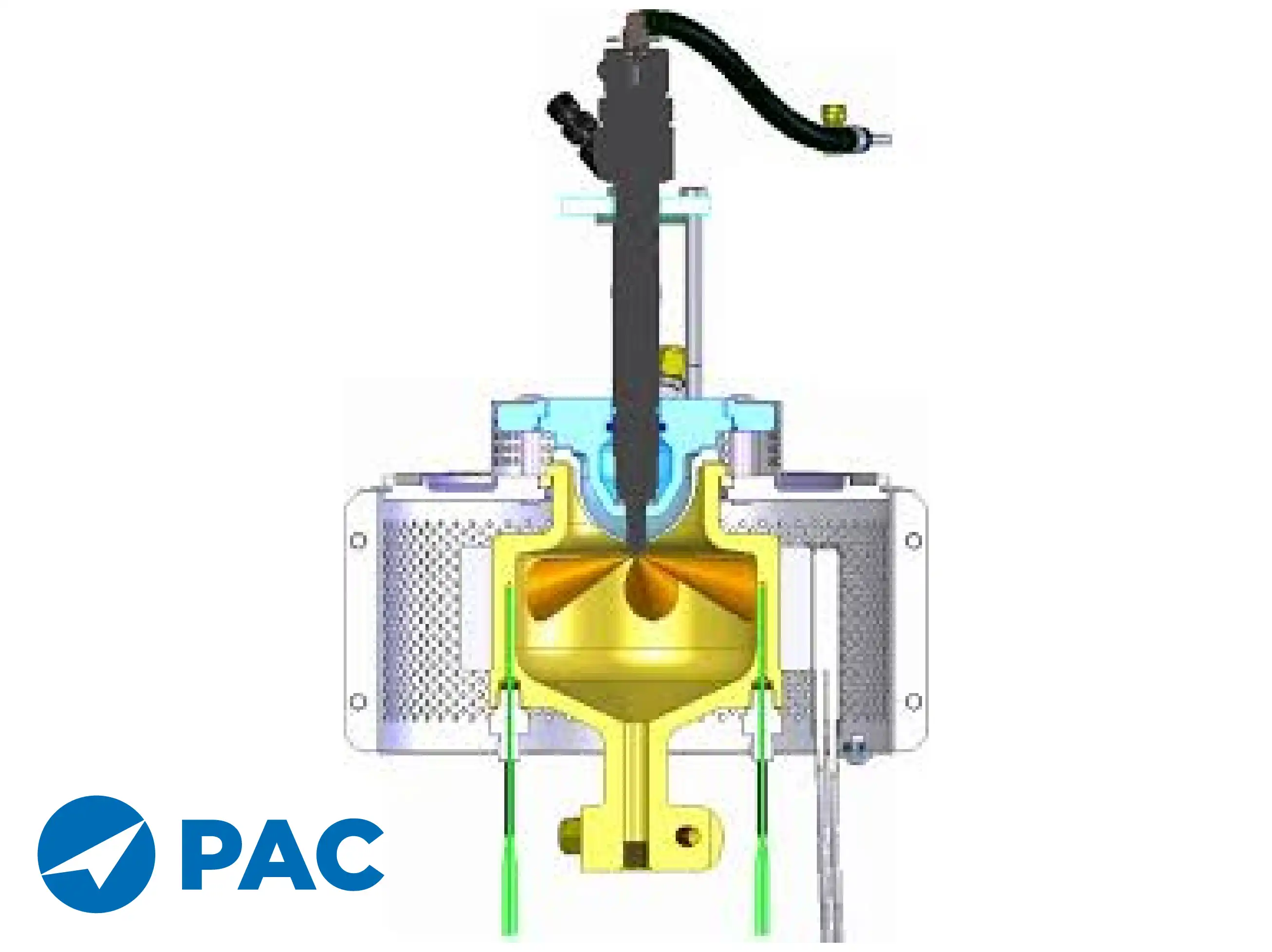

The system operates by introducing a small, controlled quantity of fuel into a high-pressure and high-temperature combustion chamber designed to mimic real diesel combustion conditions. Advanced sensors and automated data acquisition systems detect the exact ignition point with microsecond precision, capturing the delay time accurately. This measured delay is then mathematically converted into a calculated cetane number, which serves as a direct indicator of the fuel’s ignition properties.

Temperature and Pressure Control

Temperature and pressure are critical for accurate cetane analysis, with the system maintaining both parameters at precise levels throughout the measurement cycle. Chamber temperature is stabilized and continuously monitored, while pressure control ensures the fuel experiences consistent combustion conditions. This stability prevents variations in ignition delay measurements due to environmental or sample differences and allows different fuels to be tested under standardized conditions for reliable and comparable results.

Detector Performance

Detector performance is optimized to capture the earliest moments of fuel ignition, ensuring even small variations in delay times are accurately recorded. High-speed data acquisition allows precise determination of ignition behavior, which is critical for evaluating marginal cetane fuels or comparing different diesel formulations, including conventional, biodiesel, and alternative fuels.

Fuel Compatibility

The system is designed to handle a wide range of diesel fuels, including conventional petroleum diesel, biodiesel blends, and alternative fuels such as synthetic or renewable diesel. Its combustion chamber and fuel injection system are engineered for long-term reliability, durability, and minimal maintenance, ensuring uninterrupted performance in laboratory and industrial environments.

Automated Calibration

Automated calibration and verification routines maintain precision and traceability across multiple tests. The system monitors critical parameters like chamber temperature, pressure, and ignition delay, applying real-time corrections as needed, improving efficiency and reducing operator errors.

Integrated Data Management

The integrated data management system provides real-time monitoring, analysis, and documentation. Ignition delay curves, cetane number calculations, and reproducibility statistics are automatically generated and stored, enabling quick evaluation, batch comparison, and standardized reporting for quality control or regulatory purposes.

Accuracy and Efficiency

The system offers a complete solution for measuring diesel fuel ignition properties with unmatched accuracy, repeatability, and efficiency. It combines precise thermal and pressure control, sensitive detection, automated calibration, and intelligent data processing to optimize combustion behavior.

Performance Optimization

The system supports laboratories and fuel producers in optimizing engine performance, complying with stringent fuel quality specifications, and reducing emissions. It is a vital tool for quality control, R&D, and regulatory compliance in modern diesel fuel production and testing.

Broad Applicability

The system can be applied to all types of diesel fuels, blends, and alternatives, offering great flexibility in testing and comparison across a wide range of chemical and physical fuel samples.

Read More About PAC Products Here

.webp)

.webp)

.webp)

.webp)