High-Precision Flash Point Measurement

For Fuel and Chemical Safety

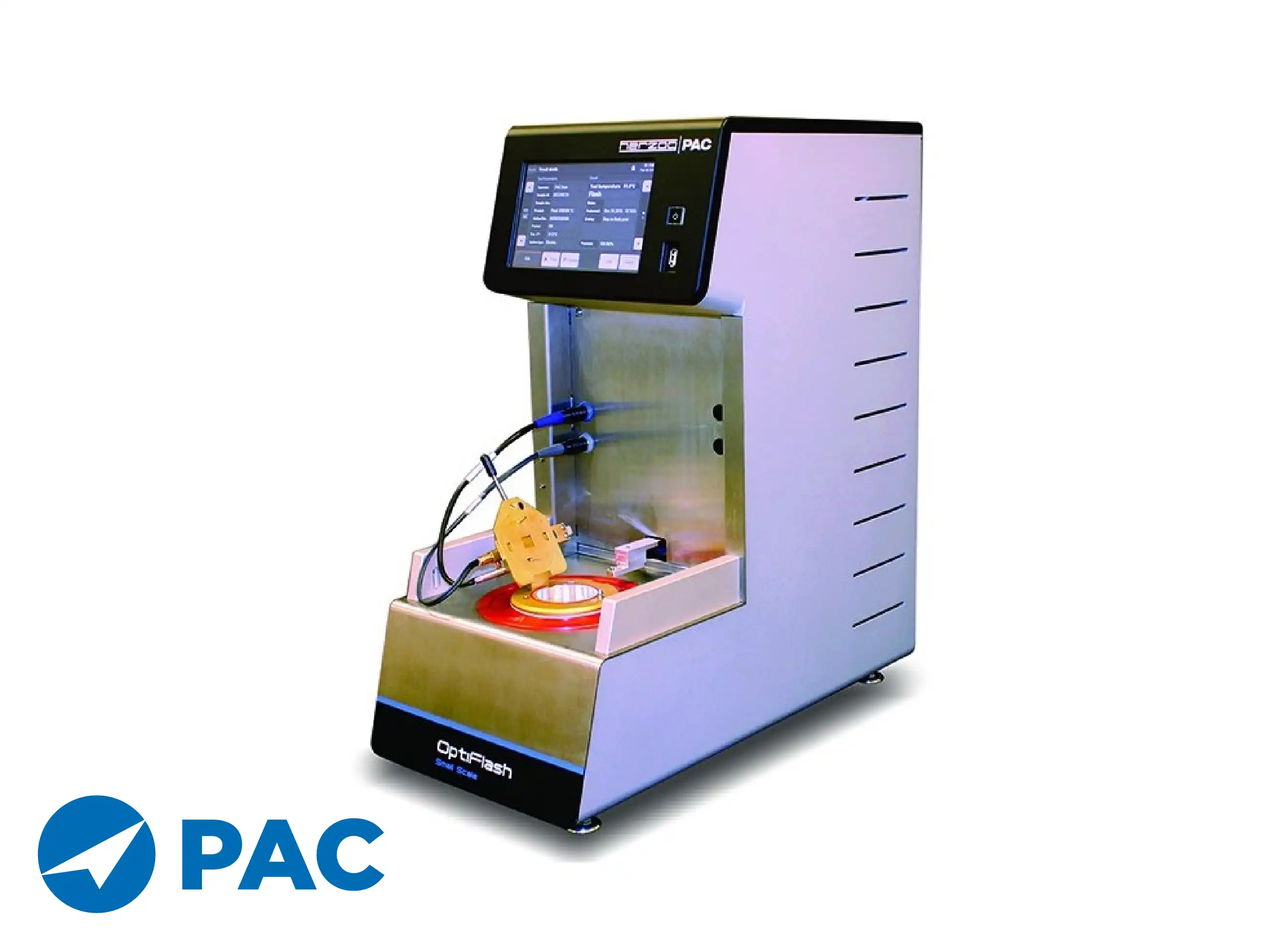

PAC Flash Point Determination

Flash Point analysis is a critical property determination for liquids, indicating the lowest temperature at which vapors above a sample ignite when exposed to an ignition source. Accurate flash point measurement is essential for evaluating flammability, transportation safety, and compliance with international fuel and chemical standards.

The system employs a closed-cup methodology, which minimizes vapor loss and external environmental influence while providing reliable results in compliance with international standards. Controlled heating ensures that the sample temperature increases at a consistent rate, while a sophisticated detection system monitors for the ignition event. This design reduces measurement variability, enhances repeatability, and ensures accurate flash point determination for highly volatile or thermally sensitive liquids.

Fundamental Safety in Flash Point Analysis

Flash point determination is a critical technical safety metric used to classify the flammability of liquids for transport, storage, and safety regulations. Technically, the flash point is the lowest temperature at which a liquid produces enough vapor to form an ignitable mixture in air. The PAC OptiFlash system is specifically engineered to handle this volatile process with maximum security. By automating the heating and ignition sequence, the instrument eliminates the risks associated with manual testing, ensuring that the precise moment of "flash" is captured safely and accurately.

Versatile Support for Multiple Test Methods

The OptiFlash platform is technically versatile, supporting a wide range of international standards including Pensky-Martens (ASTM D93), Cleveland Open Cup (ASTM D92), and Tag Closed Cup (ASTM D56). This flexibility allows laboratories to test various materials, from high-viscosity bitumen and lubricants to volatile solvents and chemicals. The system features exchangeable test cups and heads, allowing users to switch between different methodologies quickly while maintaining the specific thermal and mechanical requirements dictated by each global standard.

Innovative Electric Igniter Technology

A major technical advancement in the OptiFlash is its robust electric igniter. Traditional gas-flame igniters require constant fuel supply and manual adjustment, which can introduce variability. The PAC electric igniter provides a consistent and reliable heat source for vapor ignition. This technology is designed for long-term durability and precision, ensuring that the ignition source is applied at the exact intervals required by the test protocol. This shift to electric ignition improves repeatability and reduces the laboratory's dependence on flammable gas lines.

Advanced Fire Detection and Extinguishing System

Safety is integrated into the core technical design of the OptiFlash through an ultra-fast fire detection and extinguishing system. The instrument is equipped with sensors that monitor the test area for any signs of an uncontrolled fire beyond the standard flash. If a fire is detected, the system automatically triggers a built-in extinguisher that utilizes nitrogen or carbon dioxide to quench the flames immediately. This automated safety response protects the laboratory equipment and personnel, allowing for unattended operation during long temperature ramps.

Automated Lift and Sample Handling

The OptiFlash features a motorized lift system that automates the positioning of the test head and sensors. Technically, this ensures that the stirrer, temperature probe, and igniter are always placed at the exact depth and orientation required by the test method. This automation eliminates mechanical errors caused by improper manual setup. Once the test is finished, the lift automatically raises the head, allowing for a faster cooling cycle and easier cleaning, which significantly increases the sample throughput of the laboratory.

Precision Temperature and Pressure Regulation

Precise thermal management is essential for accurate flash point results. The OptiFlash utilizes high-resolution temperature sensors to monitor the sample and the heating block. The system also includes an integrated barometric pressure sensor that automatically corrects the final flash point result for atmospheric variations. This technical correction is vital because the concentration of vapors in the air changes with altitude and weather; by normalizing to standard pressure, the OptiFlash ensures that results are consistent across different geographic locations.

Intuitive User Interface and Data Management

The system is operated via a large, high-resolution touchscreen interface that provides real-time monitoring of the test progress. The software includes pre-programmed standard methods and allows for the creation of customized test profiles. Technically, the system stores all test data, including heating rates and flash detection curves, providing a comprehensive audit trail. This data can be exported to a Laboratory Information Management System (LIMS), supporting digital traceability and compliance with ISO quality standards.

Enhanced Durability and Ease of Maintenance

Designed for high-volume industrial environments, the OptiFlash is built with high-quality materials resistant to chemical corrosion and extreme heat. The technical layout emphasizes easy access for maintenance and cleaning. The test cups are designed for durability, and the sensors are protected from mechanical damage during handling. These design choices ensure a low total cost of ownership by reducing downtime and the frequency of spare part replacements, making it a reliable workhorse for refinery and independent testing laboratories.

Read More About PAC Products Here

.webp)

.webp)

.webp)

.webp)

.webp)