Thermomechanical Analysis

TMA

Thermomechanical Analysis (TMA) from Mettler Toledo

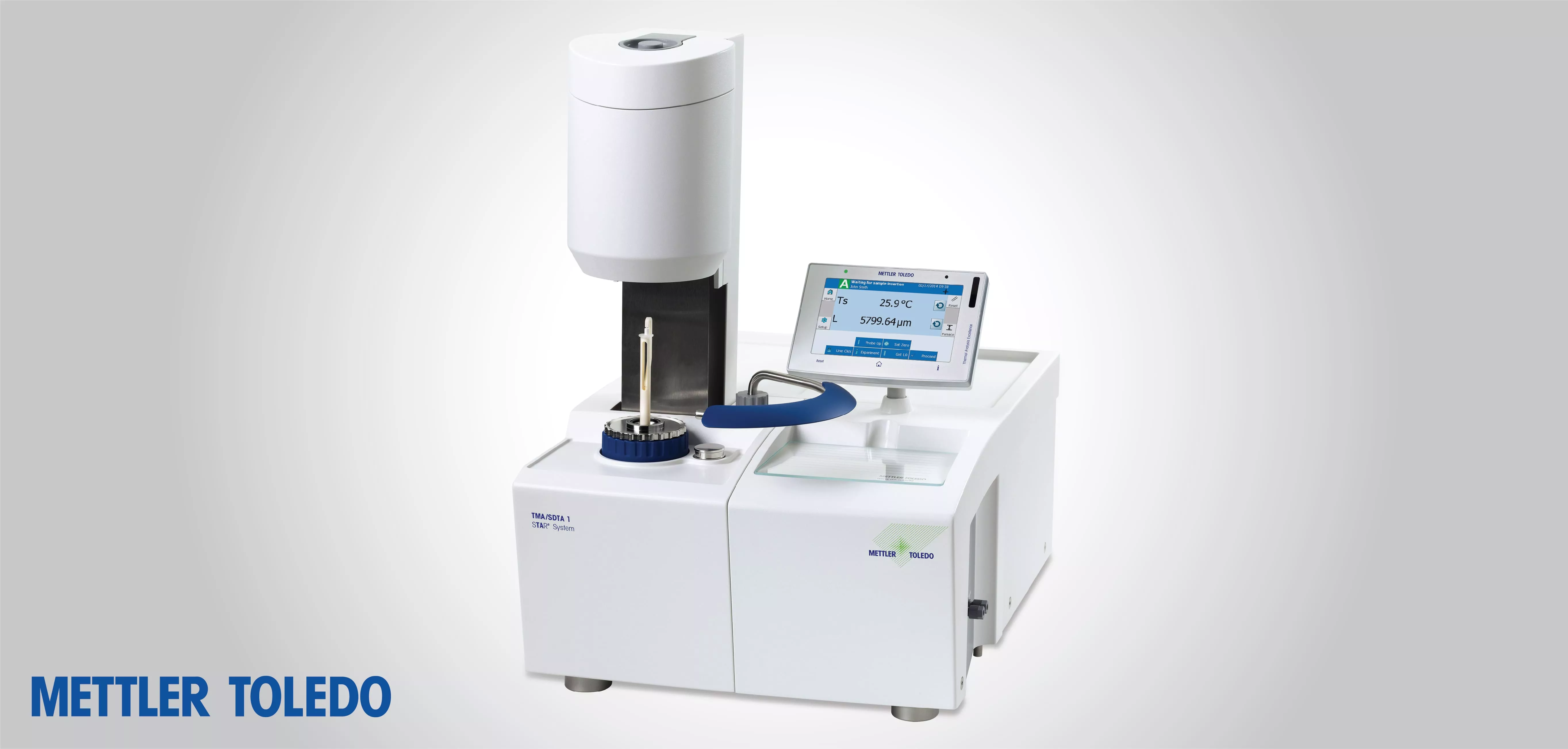

Thermomechanical analysis (TMA) is used to measure dimensional changes of a material as a function of temperature. Thermal expansion and effects such as crystallization, softening, and solid-solid transitions determine the potential applications of a material and deliver important information about its composition. Viscoelastic behavior can be studied by varying the applied force (DLTMA mode). The TMA/SDTA 2+ incorporates Swiss precision mechanics and is available in four versions with furnace systems optimized for measurements between –150 and 1600 °C.

The TMA/SDTA 2+ from Mettler Toledo is the only instrument on the market that measures the sample temperature very close to the sample in all operating modes. This allows temperature adjustment to be carried out using reference substances (such as the melting points of pure metals) or through a change in length.

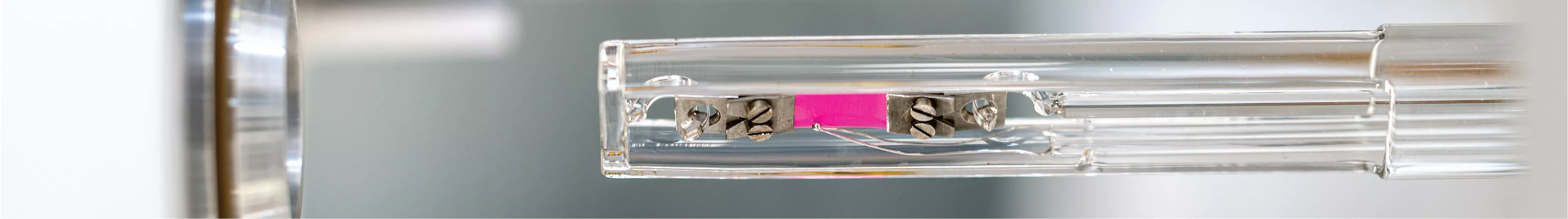

The sampling area is easily accessible for installing the sample holder and measuring probe. Such operations are performed quickly and easily. An indentation ensures that the sample holder can be installed in one position only. The measuring probe is firmly attached to the length sensor (LVDT) by means of a magnet and can easily be changed. Various sample holders and measuring probes are available for each measuring mode. This lets you choose the best configuration for each application.

A complete thermal analysis system involves four different measurement techniques. Each characterizes the sample in its own specific way. The combination of all the results gives the whole picture and simplifies interpretation. DMA measures the mechanical modulus, DSC and Flash DSC the heat flow, TGA the weight curve, and TMA the length change. All these quantities change as a function of temperature.

The touchscreen terminal for the TMA/SDTA 2+ – with One Click™ technology. The touch-sensitive color terminal for the TMA/ SDTA 2+ presents clear and precise information and is easily seen from a distance.

Features and benefits:

- Wide temperature range – from –150 to 1600 °C

- SDTA – for the simultaneous measurement of thermal effects

- One Click™ – provides efficient sample measurement

- Nanometer resolution – allows very small dimensional changes to be measured

- Dynamic load TMA (DLTMA mode) – measures weak transitions and elasticity

- Wide measurement range – for small and large samples

- Modular design – allows future expansion to meet new requirements

- Hyphenated techniques – for Evolved Gas Analysis using MS, GC-MS, or FTIR