Nexis GC-2030

The Next Industry Standard

Shimadzu Nexis GC-2030

The Nexis GC-2030 features Analytical Intelligence to help achieve these goals. Clean Pilot, a system conformity test, and LabSolutions™ can provide an automated workflow together with remote operation and monitoring from instrument startup to analysis completion. Automated workflows incorporate the work-style habits of experienced analysts. The result is reliable data collected over extended periods and higher productivity.

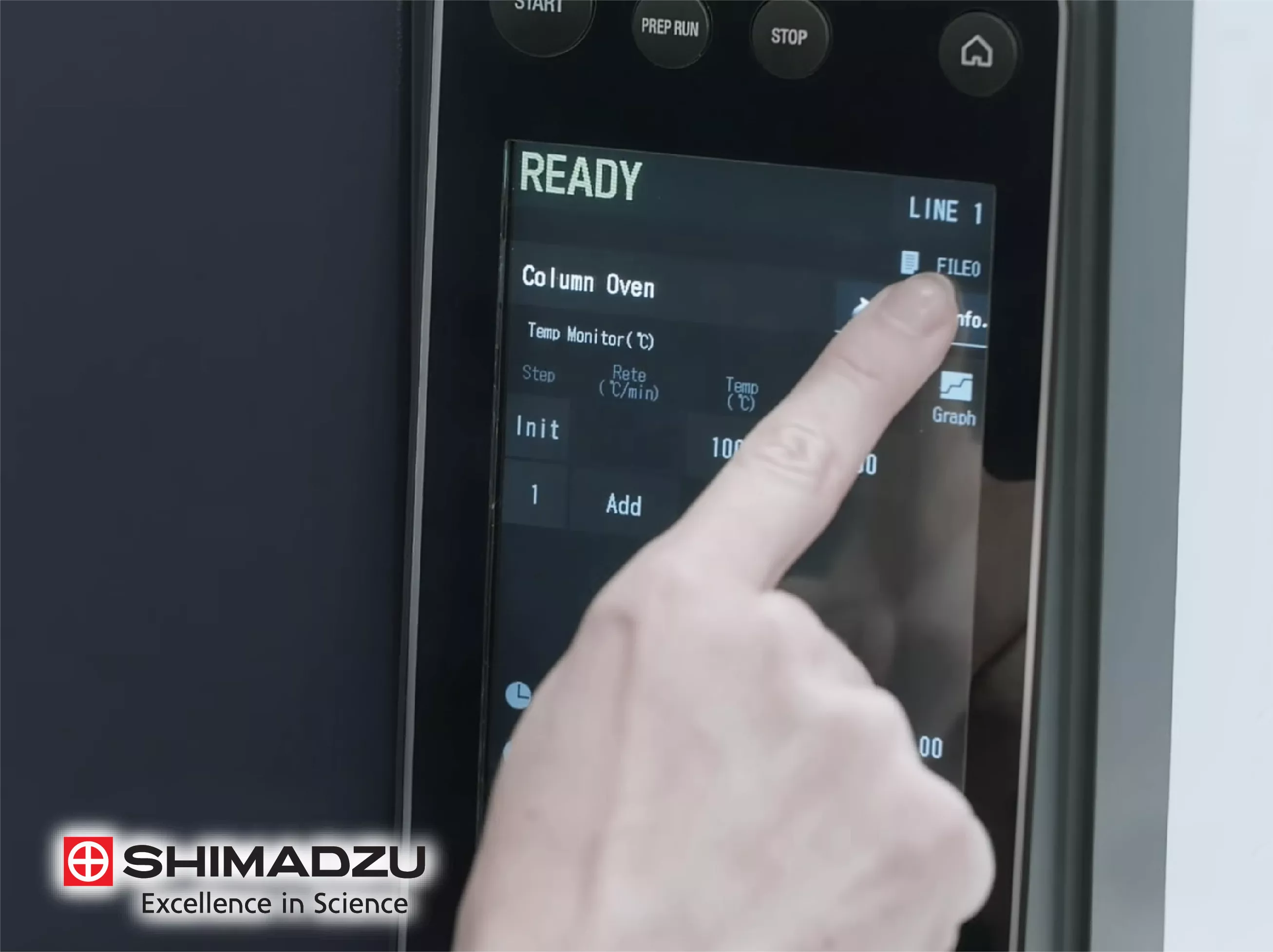

Analysts will benefit from the touch panel interface, which features clear graphics that display information instantly whenever needed. The user-friendly interface leaves the operator free to focus on obtaining optimal analytical results.

Reading a 2D code shown on the touch panel directs the user to a website with instructional videos on maintenance. This feature helps improve system availability and increases efficiency.

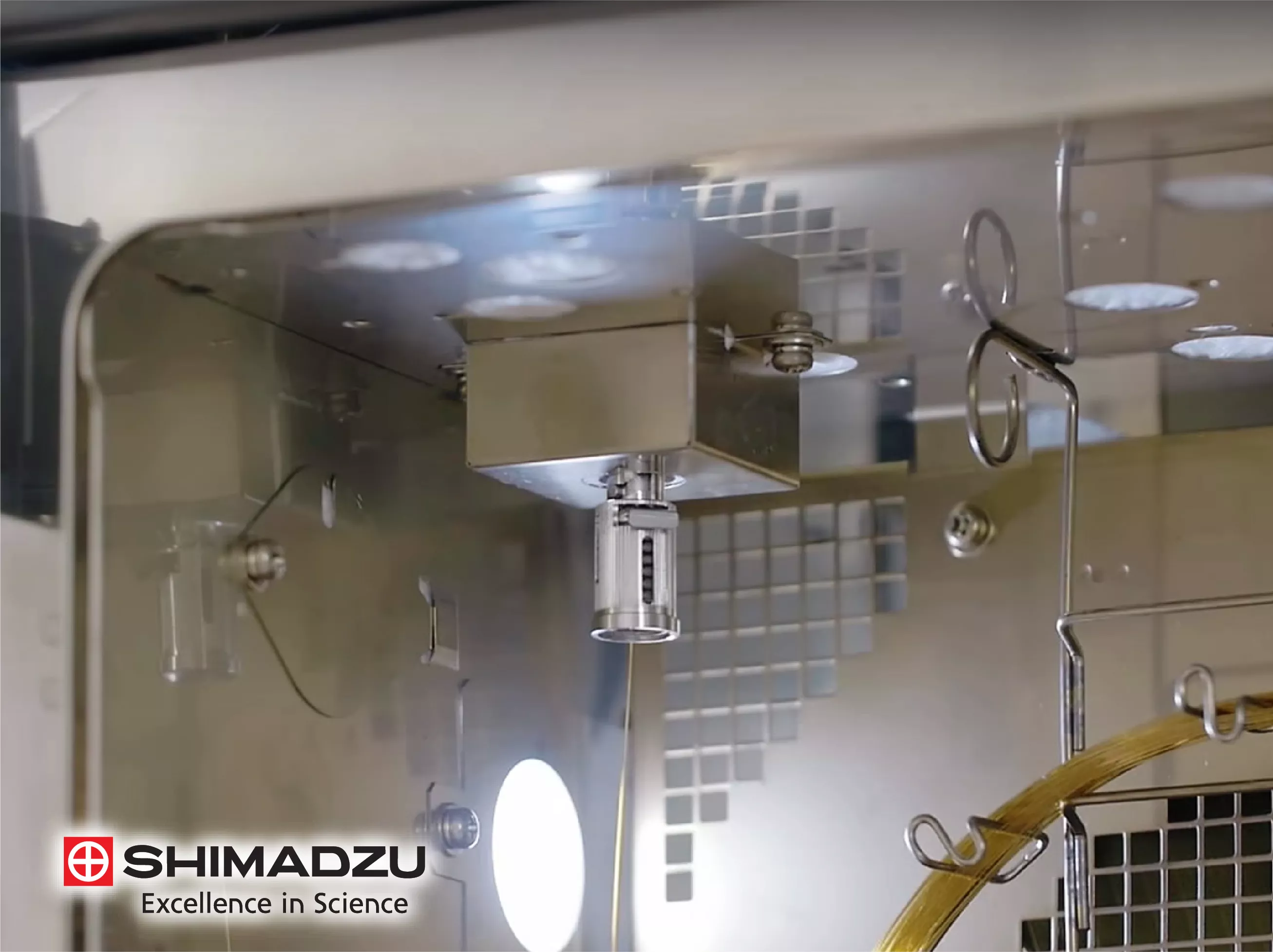

ClickTek™ connectors* make tool-free column installation a snap. The click sensation felt when finished attaching the column provides a more reliable connection and ensures a better seal under all operating conditions. In addition, a light has been installed inside the oven to brightly illuminate the area at hand, easing the burden on the operator when attaching columns.

During typical GC startup and batch analyses, in order to dispose of impurities remaining within the column, the operator has to implement conditioning by manually raising the oven temperature. Using the Clean Pilot function, conditioning is performed automatically, leading to more stable analytical results while easing the burden of lab work.

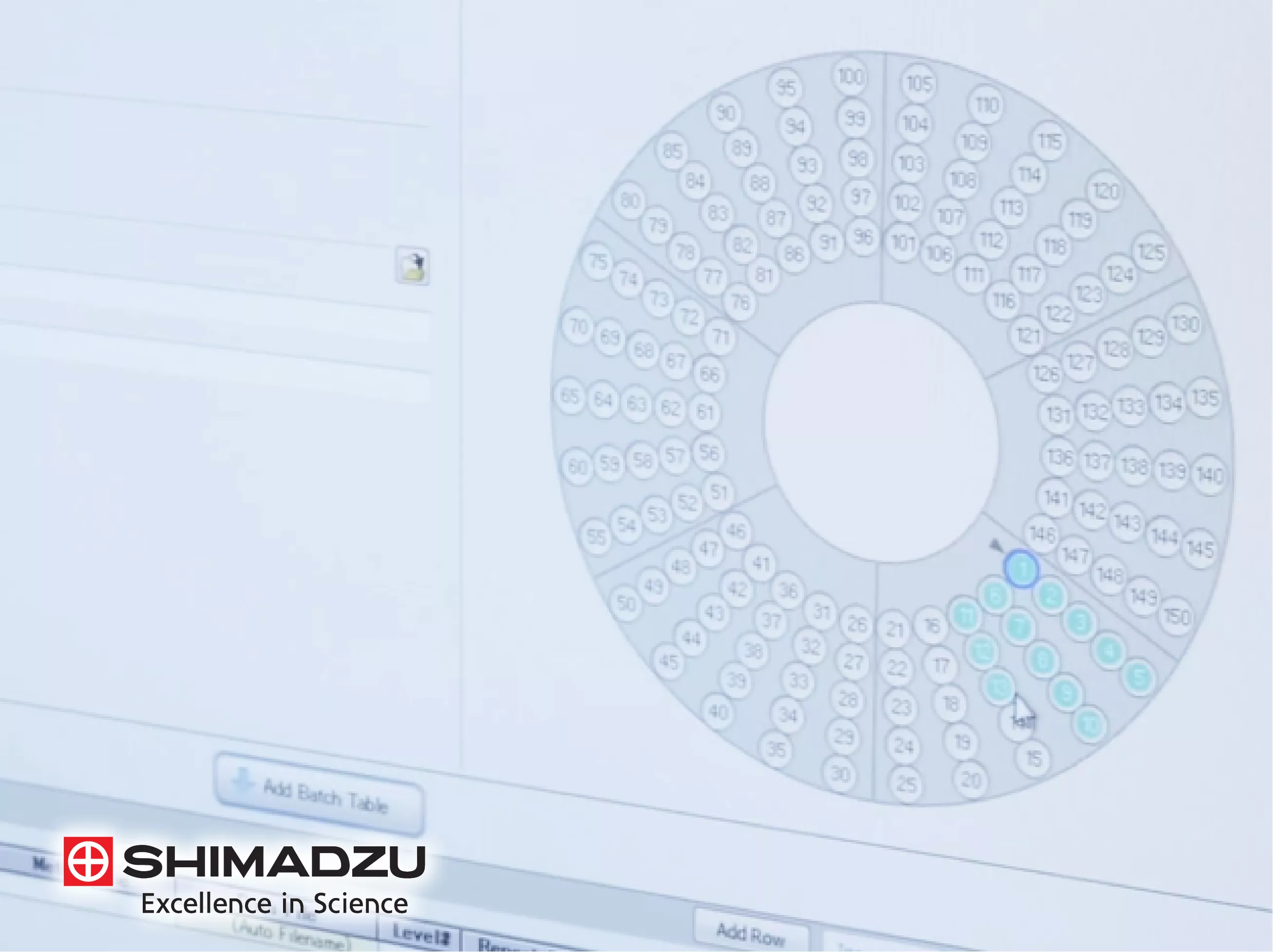

LabSolutions Direct is a remote access tool used to control or monitor GC systems via a simple user interface on a commercially available smartphone or tablet. Consequently, analyses can be performed while monitoring the status of instruments from locations away from the laboratory.

Read more about Shimadzu Nexis GC-2030