Home » Products » Scanning Electron Microscopy » Electron microscopy coating and cryogenic preparation » Quorum Glow Discharge for TEM and Surface Modification

Glow Discharge

for TEM and Surface Modification

Quorum Glow Discharge for TEM and Surface Modification

Quorum glow discharge systems are specialized instruments designed primarily for the surface modification of transmission electron microscopy (TEM) support films. In their natural state, the carbon support films used on TEM grids are often hydrophobic, which prevents aqueous solutions of biological specimens or nanoparticles from spreading evenly across the grid surface. Glow discharge treatment uses a low-pressure gas plasma to alter the surface energy of these films, making them hydrophilic. This process is essential for achieving a uniform distribution of the specimen, ensuring that the liquid film is thin and consistent, which is a prerequisite for high-quality, high-resolution imaging and successful cryo-electron microscopy.

Beyond simple hydrophilization, these systems provide a controlled environment for the removal of adsorbed organic contaminants. By subjecting the grids to a plasma in a vacuum chamber, hydrocarbon molecules are broken down and evacuated, resulting in a chemically clean surface. The systems are engineered to offer high reproducibility through precise control of vacuum levels, plasma current, and processing time. With the ability to introduce specific gases or vapors, users can further fine-tune the surface characteristics, such as introducing positive or negative charges to enhance the adherence of specific types of macromolecules or particles based on their intrinsic electrostatic properties.

Fundamental Principles of Glow Discharge Surface Alteration

The technical efficacy of glow discharge rests on the creation of a glow-zone plasma under vacuum conditions. When a high voltage is applied between two electrodes in a low-pressure gas environment, the gas molecules become ionized. These ions and electrons interact with the surface of the TEM grid, breaking chemical bonds and introducing new functional groups. This interaction significantly increases the surface free energy of the carbon film, transitioning it from a hydrophobic state to a hydrophilic one. This physical transformation is what allows aqueous samples to wet the surface effectively rather than bead up.

Hydrophilization and Sample Spreading Dynamics

Hydrophilization is the primary application for TEM grid preparation. Without this treatment, liquid samples applied to a carbon film will form isolated droplets due to high surface tension. Glow discharge reduces the contact angle of these droplets, forcing the liquid to spread into a thin, uniform layer across the grid. This uniformity is critical for electron transparency; if the sample is too thick or unevenly distributed, the electron beam cannot penetrate effectively, leading to poor contrast and loss of structural detail in the resulting micrographs.

Plasma Cleaning for Hydrocarbon Contamination Removal

Organic contaminants, primarily hydrocarbons, naturally accumulate on the surfaces of TEM grids and specimens over time. During electron microscopy, these contaminants can migrate and polymerize under the electron beam, forming a "contamination layer" that obscures fine details. Glow discharge systems act as plasma cleaners by oxidizing these organic residues into volatile components like CO2 and H2O, which are then removed by the vacuum system. This ensures that the imaging environment remains as pristine as possible, maximizing the signal-to-noise ratio.

Surface Charge Modification and Functionalization

Technical flexibility is a hallmark of these systems, allowing for the introduction of specific surface charges. Depending on the gas used during the discharge—such as air, oxygen, or specific chemical vapors like amylamine—the surface of the grid can be made negatively or positively charged. This is particularly important when working with proteins, nucleic acids, or viruses, which often carry their own net charges. By matching or opposing these charges, researchers can encourage better specimen adherence and prevent the loss of precious samples during the washing or staining steps.

Advanced Vacuum Control and Process Reproducibility

Precision in vacuum management is essential for consistent surface modification. Quorum systems utilize integrated vacuum sensors and automated valves to maintain a stable pressure throughout the treatment cycle. This prevents fluctuations in the plasma density, ensuring that the intensity of the surface treatment is identical from one session to the next. The ability to save and recall specific vacuum and current parameters allows for standardized protocols, which is vital for laboratories performing high-throughput sample preparation for structural biology.

Atmospheric Flexibility and Specialized Gas Integration

While ambient air is commonly used for standard hydrophilization, certain advanced applications require specialized gas environments. These systems are equipped with inlets that allow for the introduction of argon, oxygen, or other process gases. Argon plasma is often used for gentle cleaning without altering chemical functionality, while oxygen-rich plasma is highly effective for aggressive hydrocarbon removal. The technical design of the gas delivery system ensures that the flow is laminar and controlled, preventing turbulence that could disturb fragile TEM grids within the chamber.

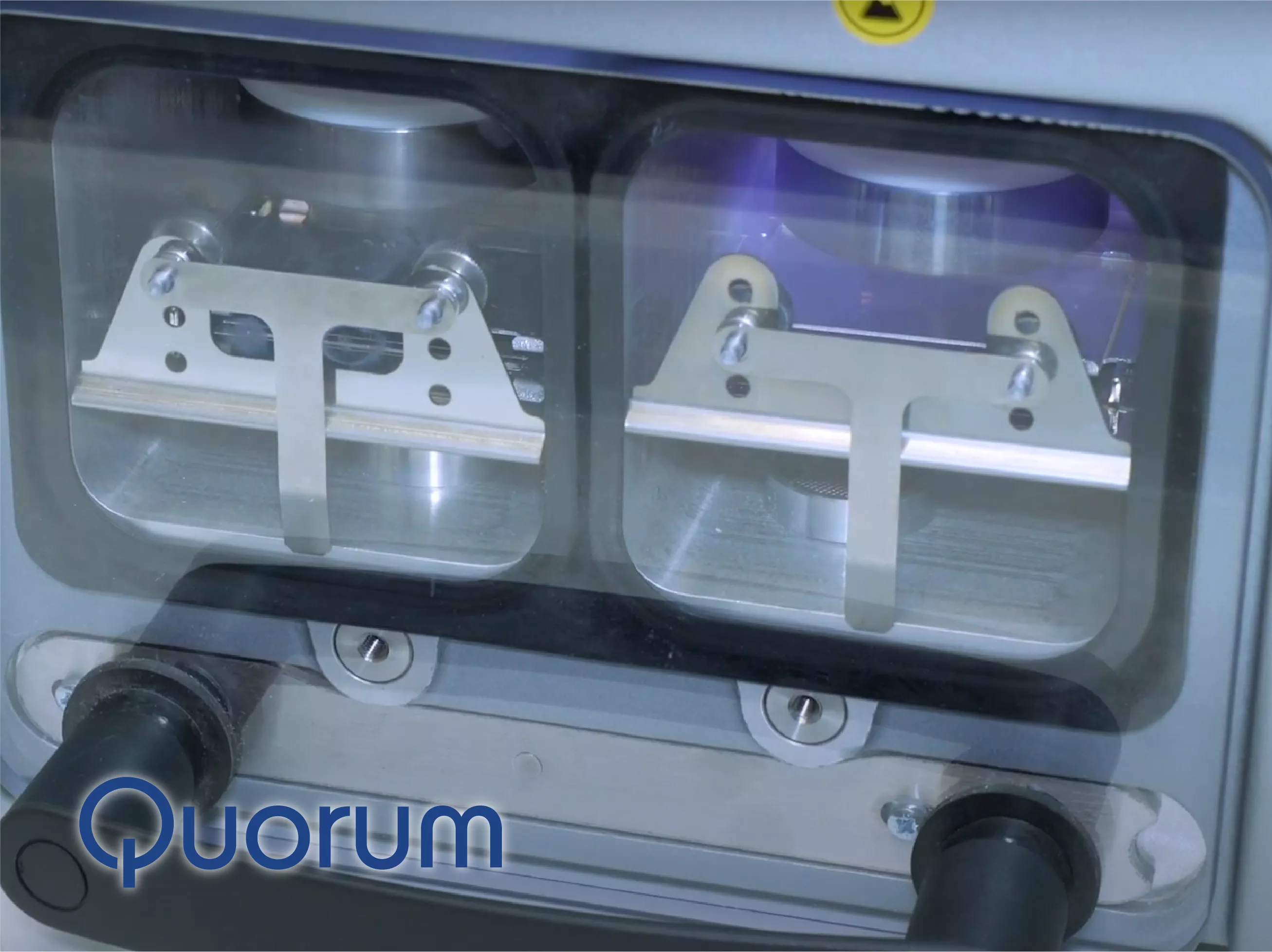

Dual-Chamber Configurations for Specialized Workflows

In multi-user facilities, the risk of cross-contamination between different chemical treatments is a significant concern. Technical solutions include dual-chamber configurations where one chamber can be dedicated to standard air/oxygen hydrophilization and the second to specialized chemical vapor treatments (such as alkylamines). This physical separation ensures that residual vapors from one process do not interfere with the plasma chemistry of the other, maintaining the purity of the surface modification and extending the intervals between maintenance cycles.

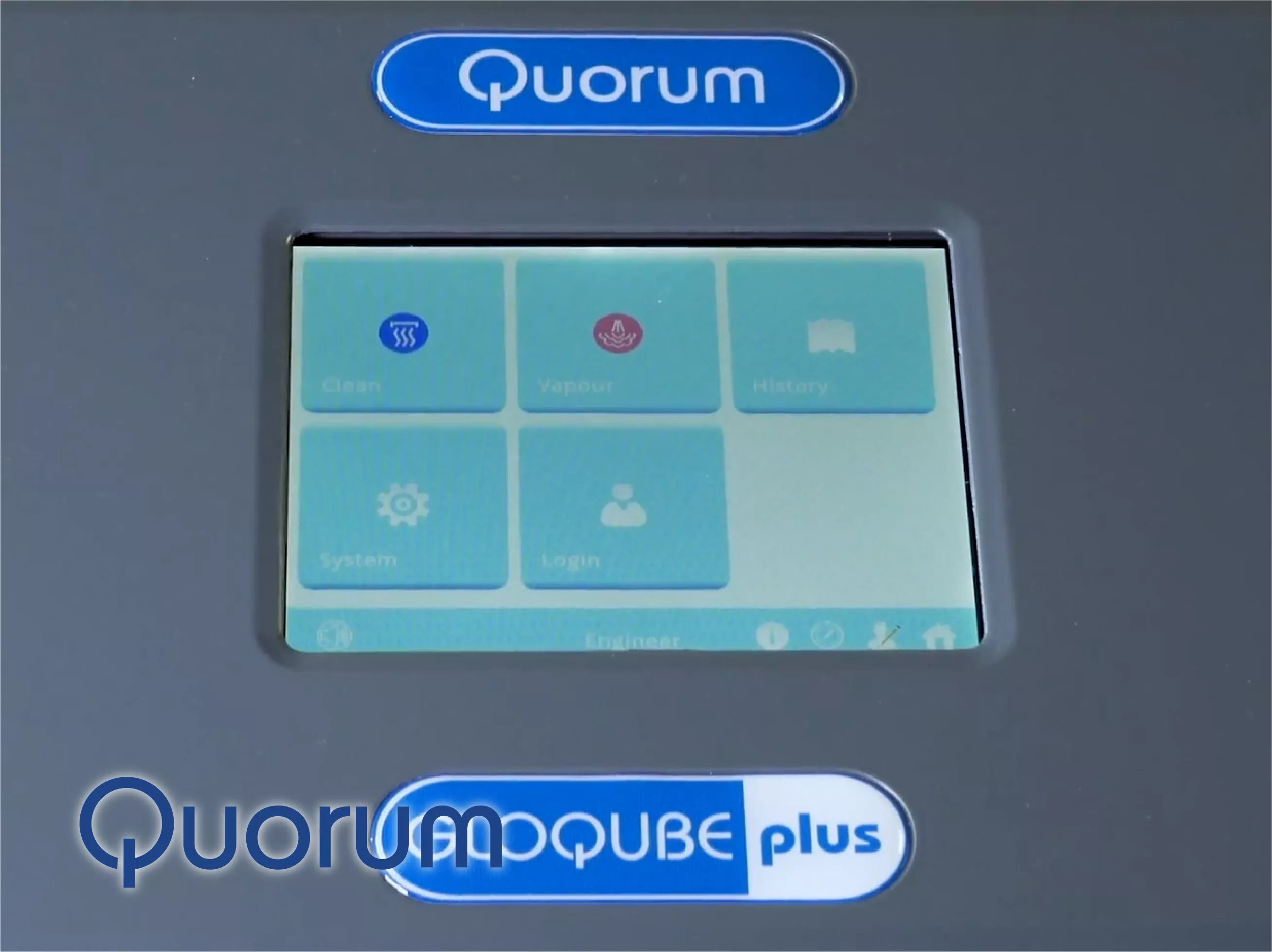

User Interface and Automated Safety Protocols

The technical operation is facilitated through intuitive touch-screen interfaces that provide real-time feedback on the plasma status. Safety protocols are integrated into the system's firmware to protect both the user and the delicate samples. For example, the system will not initiate the glow discharge until a stable vacuum is achieved, and it automatically vents the chamber slowly to prevent the "blowing" of grids. These automated features reduce the potential for human error and ensure that the delicate carbon support films are not physically damaged by sudden pressure changes.

Read more about Quorum Glow Discharge for TEM and Surface Modification

.webp)

.webp)