Home » Products » Material Preparation, Analysis, and Testing » Hardness Testing Systems » Buehler Test Blocks and Accessories

Hardness Testing Calibration

Standards and Fixturing

Buehler Test Blocks and Accessories

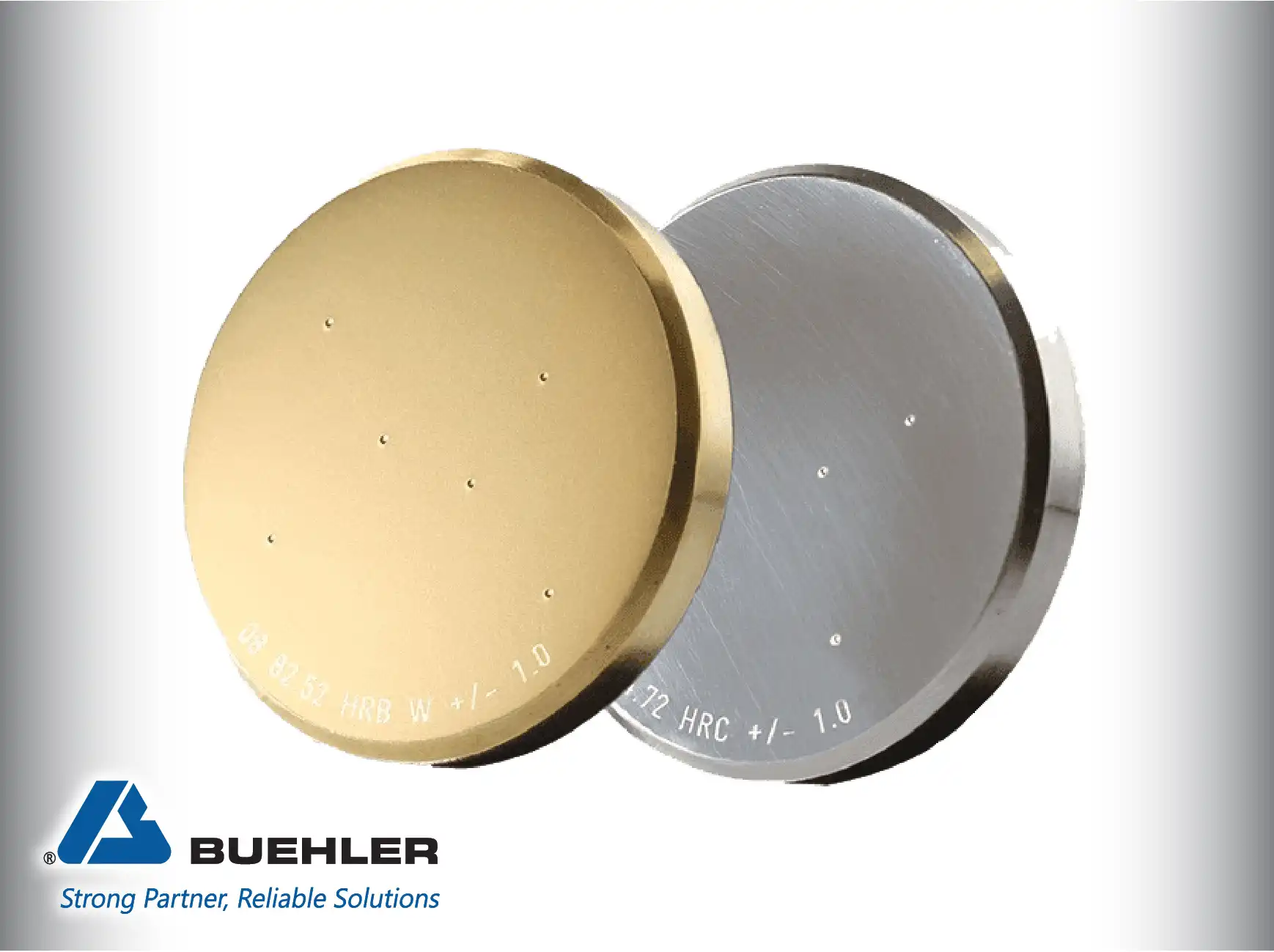

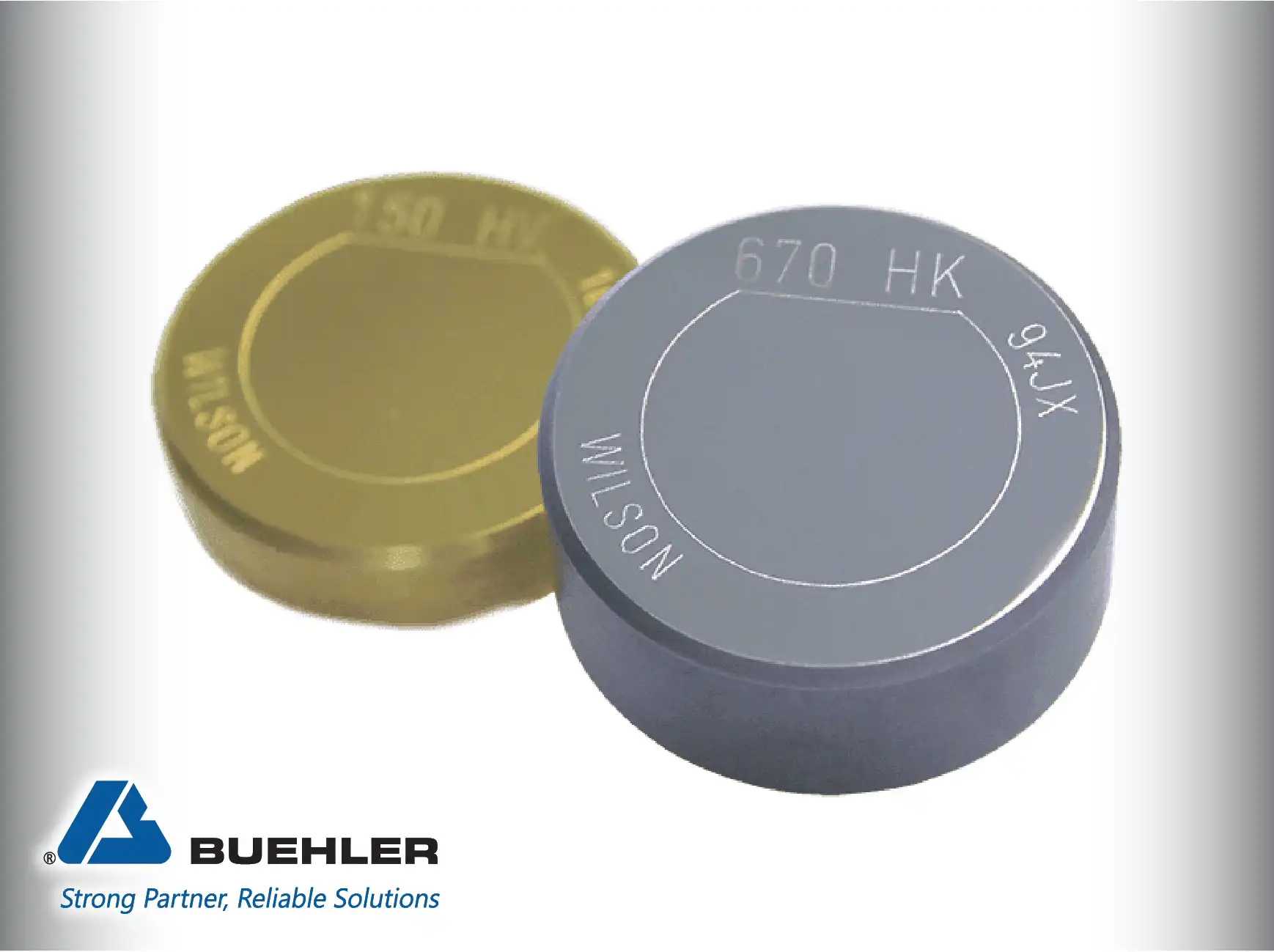

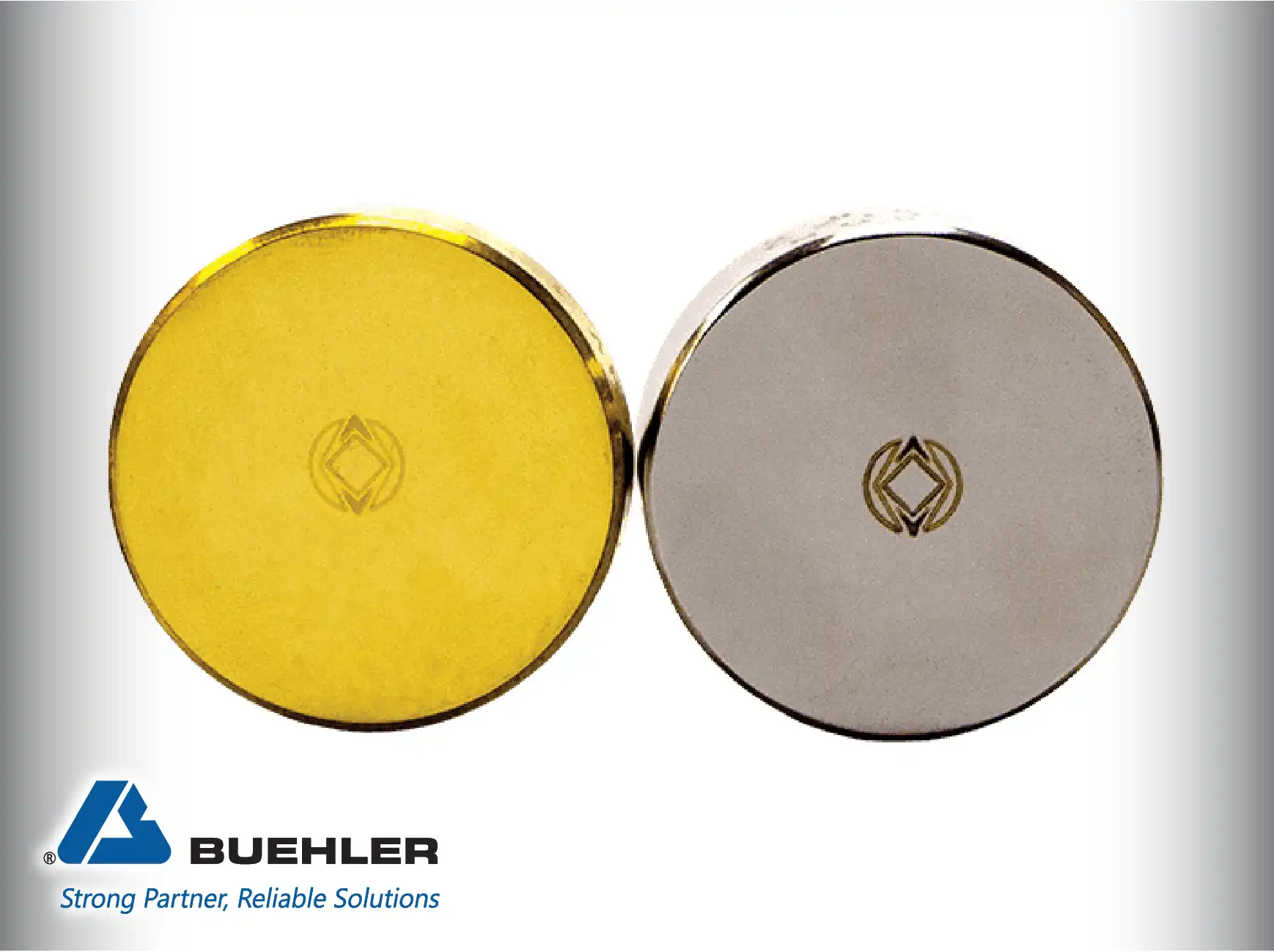

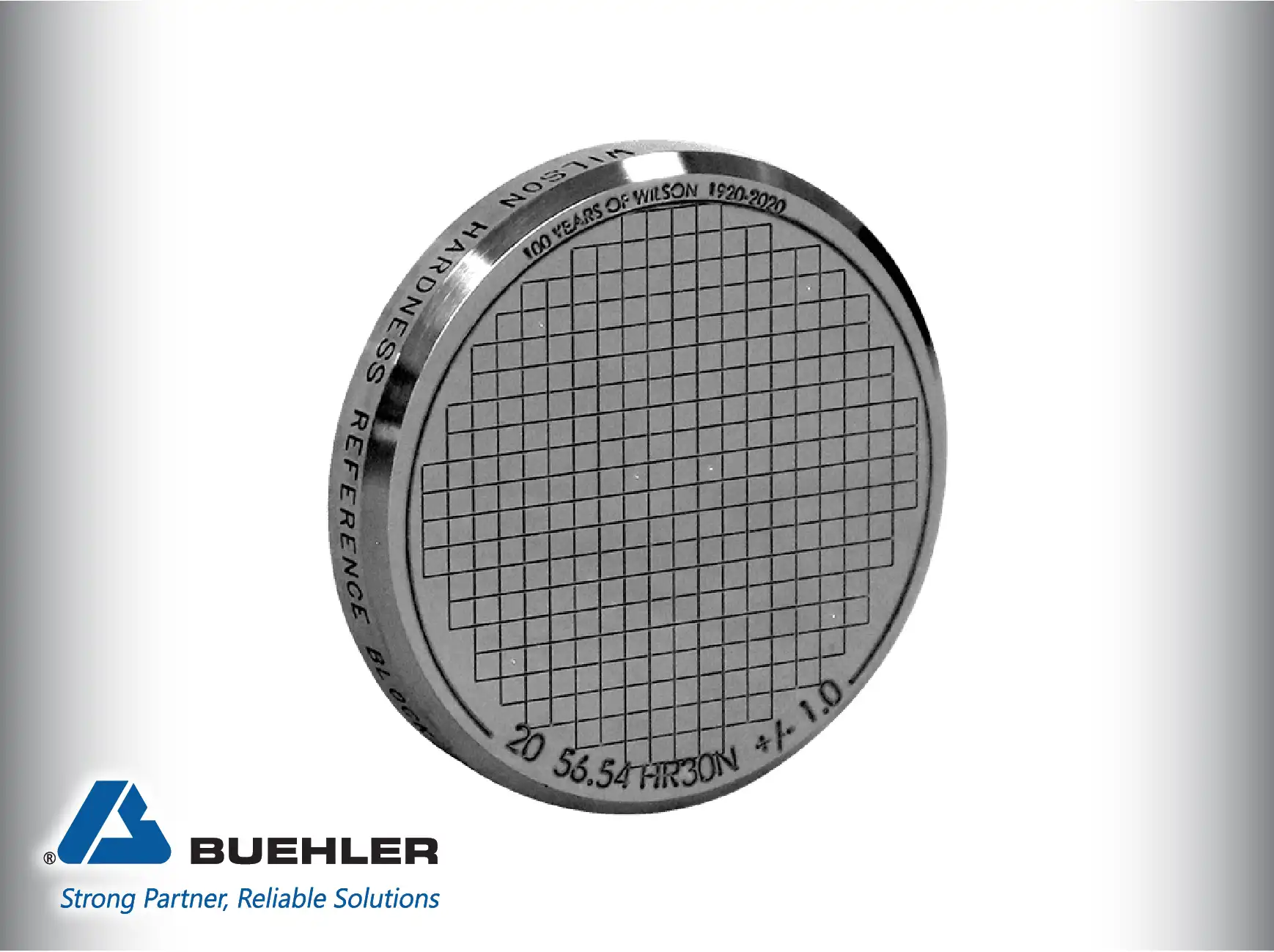

Hardness test blocks and accessories are foundational to maintaining the integrity and compliance of any hardness testing operation. Test blocks, specifically, serve as the industry standard reference for verifying the performance and accuracy of Rockwell, Brinell, Vickers, and Knoop testers. They are meticulously crafted from top-quality materials to ensure unmatched uniformity and repeatability, which is paramount for establishing the benchmark against which instrument performance is judged.

Accessories, encompassing items such as anvils, indenters, and specialized fixtures, are equally crucial components that ensure the test is conducted under ideal conditions. Proper sample holders and anvils are required to guarantee that the specimen remains stationary and is supported correctly throughout the application of the test load, preventing measurement errors caused by movement.

Ensuring Traceability and Verification of Instrument Accuracy

Without reliable reference standards, the validity of any measured hardness value is compromised. Test blocks resolve this by being the benchmark for consistency and reproducibility. They are precisely manufactured and calibrated in an accredited ISO-IEC 17025 lab, ensuring full traceability and providing the definitive standard against which the performance of the testing machine is verified.

Addressing Measurement Inaccuracy Due to Substandard Reference Surfaces

If a test block surface is not perfectly uniform, the verification test itself becomes unreliable. Test blocks are guaranteed through 100% inspection for compliance in terms of thickness, flatness, parallelism, and surface roughness. This strict control over dimensional and surface integrity ensures that the indentation geometry is perfect and the measured hardness number reflects the true reference value.

Maintaining Indenter Geometry and Compliance

The geometric precision of the indenter is fundamental to all hardness testing methods. Using non-certified or worn indenters directly corrupts the test results. This challenge is mitigated by providing a selection of ISO & ASTM certified indenters (diamond cones, carbide balls). Using certified indenters ensures that the critical parameters, such as the cone angle or ball diameter, meet the precise requirements of the standard (e.g., ASTM E18, ISO 6508).

Preventing Sample Movement and Instability During Load Application

Inadequate support or fixturing can allow the test specimen to shift or rock during the application of the major load, causing an inaccurate indentation or faulty depth measurement. This operational flaw is countered by supplying a wide range of sample holders and anvils. These accessories provide the correct support required to ensure the specimen remains absolutely stationary, which is vital for maintaining the integrity of the test geometry.

Streamlining Workflow Between Preparation and Testing

The transfer of prepared metallographic samples from a grinding/polishing machine to the hardness tester often involves manual handling, leading to potential damage or orientation errors. Specialized accessories, like the GP-HDT Sample Fixture, solve this by allowing direct movement from grinding and polishing to hardness testing without the need to unload and reload samples. This eliminates handling errors and significantly increases throughput.

Guaranteeing Consistency in Material Composition for Reference Standards

The reliability of a test block relies on the inherent consistency of the material being used. The manufacturing process addresses this by collaborating directly with mills to specify the chemical composition. Furthermore, all machining processes are performed in-house, ensuring an unbroken chain of quality control from raw material to final product, thereby guaranteeing uniformity across all supplied test blocks.

Providing Complete Calibration Solutions for Specific Scales

The need to verify testers across multiple regular and superficial Rockwell scales can be complex. Rockwell calibration sets are available, providing a comprehensive, coordinated set of reference blocks. These sets ensure the ultimate accuracy and performance verification necessary for regulatory compliance and robust Gauge Repeatability and Reproducibility (GR&R).

Enabling Specialized Testing Requirements

Beyond standard indenter support, labs often require specific fixtures to handle unique sample shapes or testing configurations. A variety of additional accessories are available to enhance the machine and meet tailored application requirements. This flexibility ensures that the testing system can be adapted to almost any component geometry, extending the utility of the hardness tester.

Click here to know more about Buehler products

.webp)