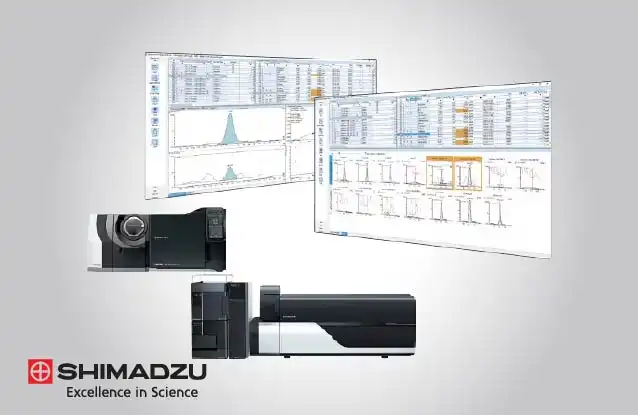

TOC Analysis Software

Operational Excellence and Digital Traceability

Shimadzu TOC Analysis Software

The software architecture is specifically designed to meet the rigorous technical requirements of regulated environments, including 21 CFR Part 11 and global Pharmacopeia standards. It incorporates multi-level user access controls, encrypted audit trails, and electronic signature capabilities to ensure that all analytical actions are traceable and unalterable. a review.

This centralized approach not only enhances operational security but also simplifies the validation process through automated system suitability calculations and comprehensive reporting tools that align with international water quality regulations.

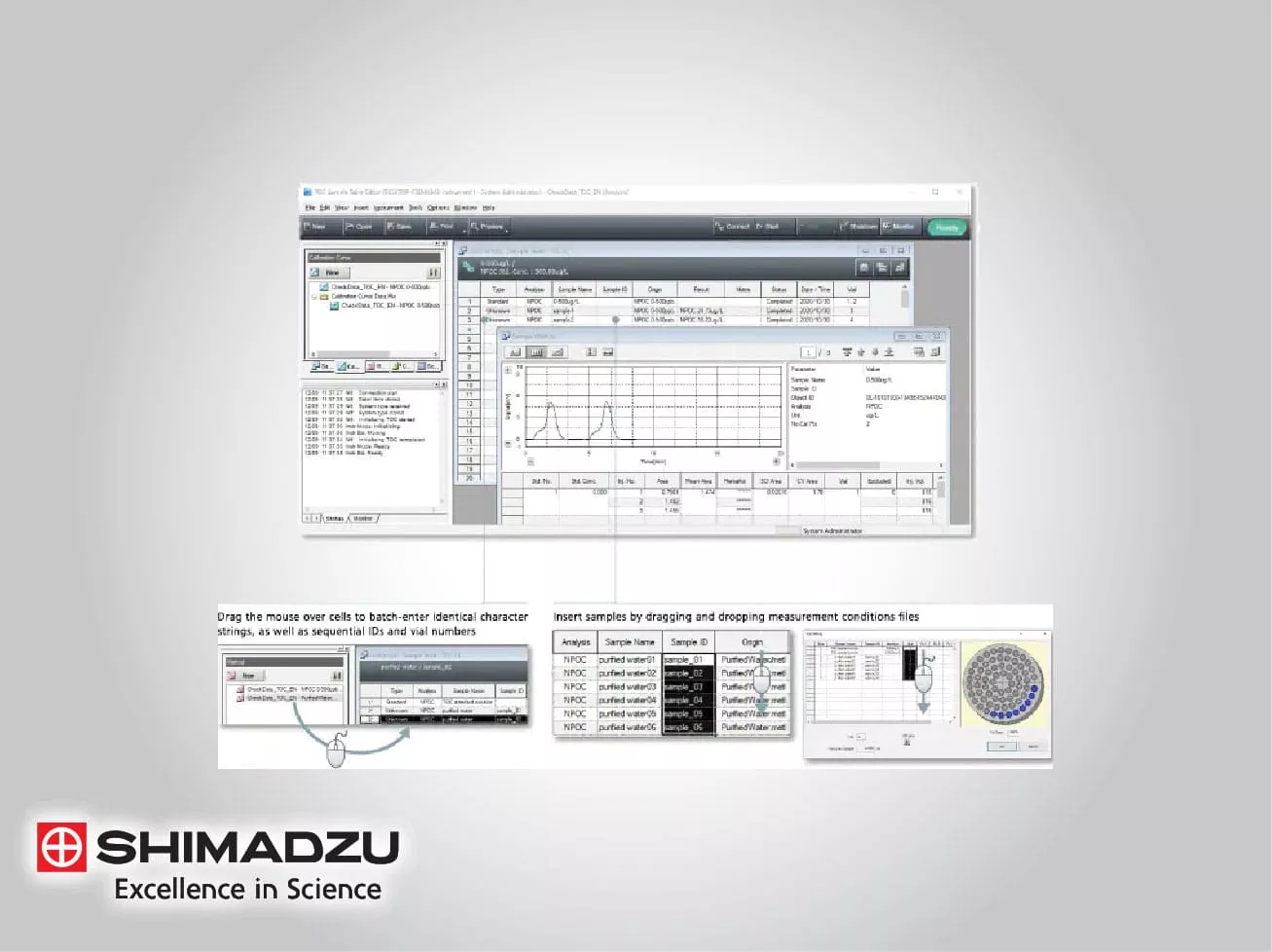

Integration with LabSolutions Database Architecture

Shimadzu’s TOC software is technically built upon the LabSolutions database architecture, which ensures that all analytical data is stored in a secure, centralized environment. This structure prevents the accidental deletion or overwriting of files, a common risk in standalone systems. By linking methods, schedules, and raw data within a relational database, the software provides a robust technical framework for laboratories that require high-level data management and rapid retrieval of historical analysis results.

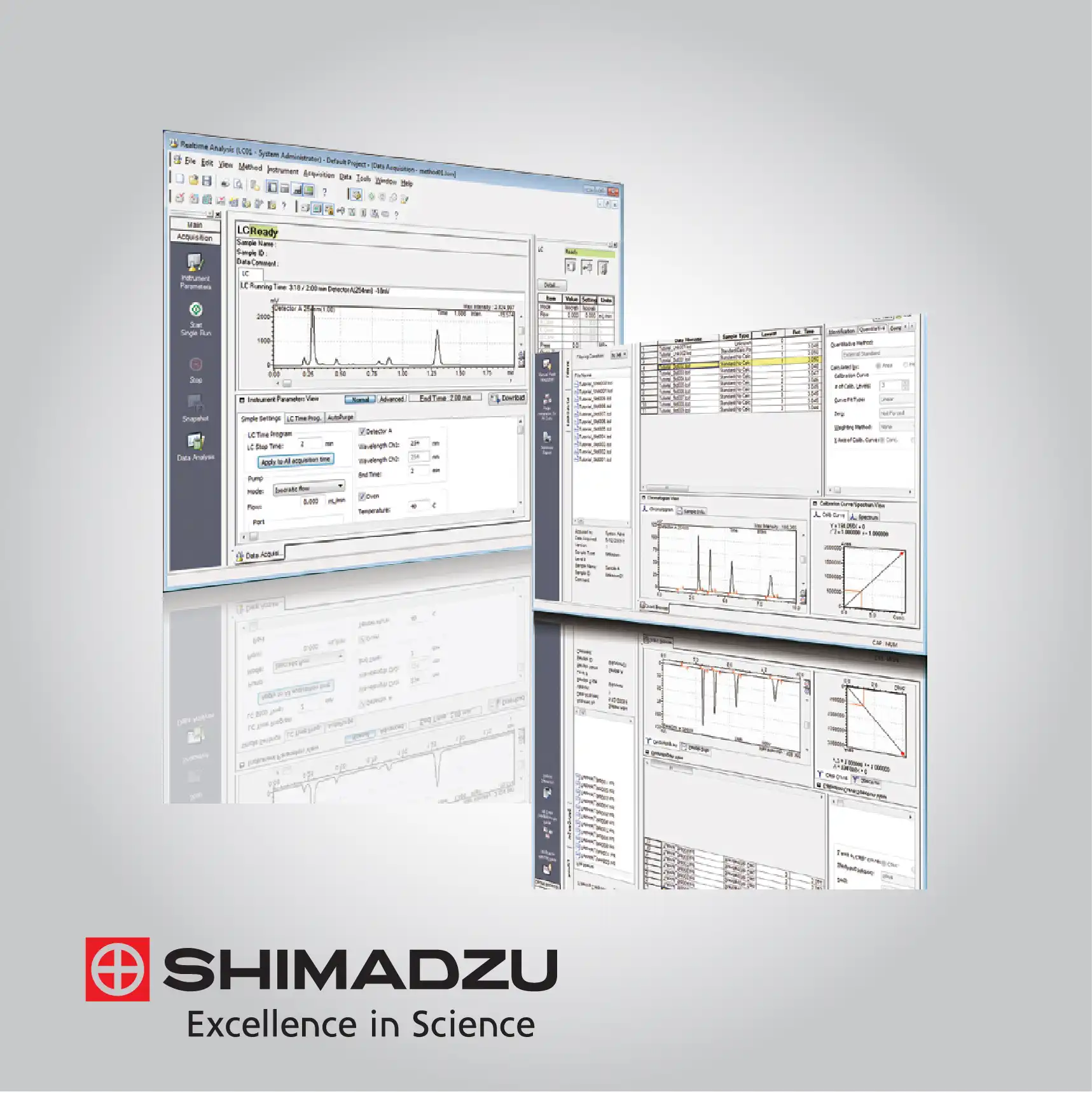

Analytical Intelligence for Smart Instrument Preparation

The software incorporates "Analytical Intelligence" to automate the complex technical steps required for instrument startup. It monitors the baseline stability and ensures that the combustion furnace or UV lamp has reached the required operational temperature before allowing any injections. Technically, this feature eliminates the variability of manual checks, ensuring that every sample is analyzed under identical, optimized conditions to maintain peak sensitivity and accuracy.

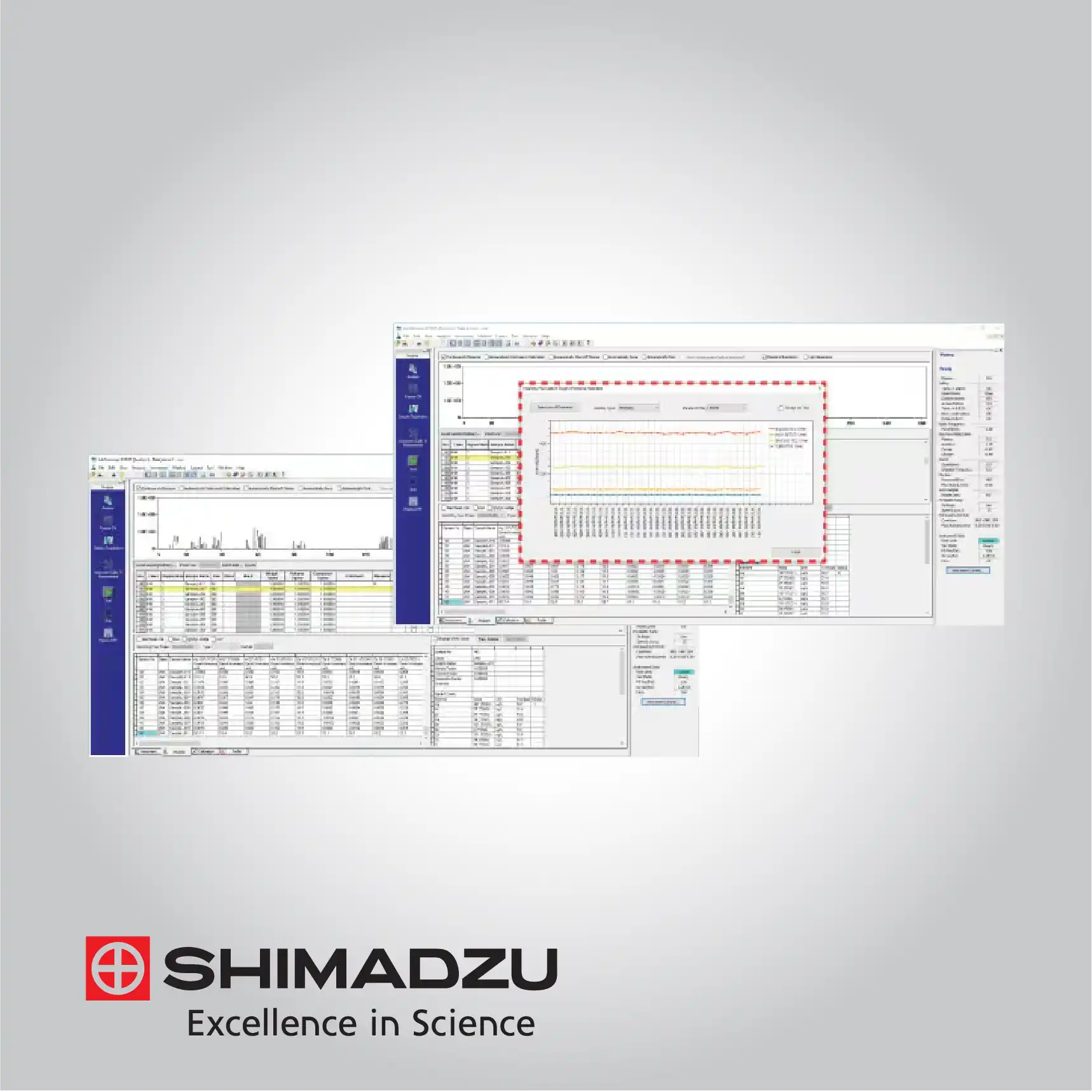

Automated System Suitability Testing (SST) Protocols

For pharmaceutical laboratories, the software provides a technical module dedicated to System Suitability Testing (SST). It guides users through the specific requirements of the USP, EP, and JP pharmacopeias, such as calculating the response efficiency of sucrose versus 1,4-benzoquinone. The software automatically evaluates the results against regulatory limits and provides a definitive "Pass" or "Fail" status, ensuring that the system is fully validated for use.

Multi-Level User Access and Security Management

Technically, the software environment is secured through multi-level user access controls. Administrators can define specific roles and permissions, restricting sensitive functions—such as calibration curve modification or data deletion—to authorized personnel only. This hierarchical security model is essential for maintaining a controlled analytical environment and preventing unauthorized changes that could compromise the integrity of the water quality data.

Comprehensive Audit Trail and Change Logs

Every action performed within the software is technically recorded in a comprehensive audit trail. This includes the "who, what, when, and why" of every modification made to methods or data sets. The audit trail is encrypted and stored alongside the analytical data, providing a transparent and unalterable history of the instrument's operation. This level of technical documentation is vital for meeting global data integrity standards and passing regulatory inspections.

Dynamic Real-Time Peak Monitoring and Re-Processing

During an analytical sequence, the software offers a dynamic display of peak profiles in real-time. Technically, this allows operators to observe the oxidation process as it happens. After acquisition, the software provides advanced peak re-processing tools that allow for manual integration or baseline adjustments if necessary. Every re-processing action is automatically logged in the audit trail, ensuring that the final calculated TOC values remain fully traceable.

Automated Maintenance and Consumable Tracking

The software features a technical diagnostic module that monitors the lifespan of critical consumables, such as the catalyst, halogen scrubber, and reagents. By tracking the number of injections and the total carbon load, the software provides proactive maintenance alerts. This prevents the degradation of analytical performance due to exhausted consumables and allows laboratories to schedule maintenance during planned downtime, maximizing instrument availability.

Network-Based Centralized Control and Reporting

The technical architecture of the software supports full network integration, allowing one workstation to control multiple TOC analyzers. This enables the synchronization of analytical methods across different units and the generation of consolidated reports. Technically, this network capability streamlines the management of large-scale water monitoring projects, where data from various sources must be compiled into a standardized, compliance-ready format.

Click here for more information about Shimadzu range of products

Related Products

CONTACT US

CONTACT US

Taawon for Laboratory & Scientific Supplies

Taawon Group © 2026 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience