GC Systems

The Next Industry Standard

Shimadzu GC Systems

Modern Shimadzu GC platforms are technically optimized for the digital laboratory era, utilizing IoT capabilities and smart sensors to maximize instrument uptime. The systems feature self-diagnostic functions that monitor column health, septum usage, and carrier gas pressures in real-time. This proactive approach to maintenance prevents unscheduled downtime and ensures that analytical results are always obtained under optimal conditions.

Furthermore, the software-driven "FlowPilot" technology prevents column damage by gradually increasing the oven temperature while managing gas flow, ensuring a long lifespan for expensive stationary phases. These technical advancements provide a robust framework for high-precision quantitation and qualitative identification across a broad spectrum of volatile analytes.

High-Sensitivity Detection Technology

Shimadzu GC systems are technically distinguished by their wide array of high-sensitivity detectors, including the Flame Ionization Detector (FID), Thermal Conductivity Detector (TCD), and specialized Barrier Discharge Ionization Detectors (BID). These sensors are engineered to provide a wide dynamic range and ultra-low detection limits. The BID, in particular, uses a unique helium plasma technology to detect trace-level organic and inorganic compounds that are difficult to analyze with conventional detectors, providing a versatile solution for complex gas analysis.

Advanced Flow Control and Precision Inlets

Precision in gas chromatography depends heavily on the stability of carrier gas flow. Shimadzu utilizes advanced Electronic Flow Controllers (EFC) that maintain constant pressure or flow regardless of oven temperature fluctuations. The systems support multiple inlet types, including split/splitless, on-column, and programmed temperature vaporization (PTV) inlets. This technical flexibility allows for the analysis of samples with varying concentrations and volatilities while minimizing sample degradation and maximizing peak symmetry.

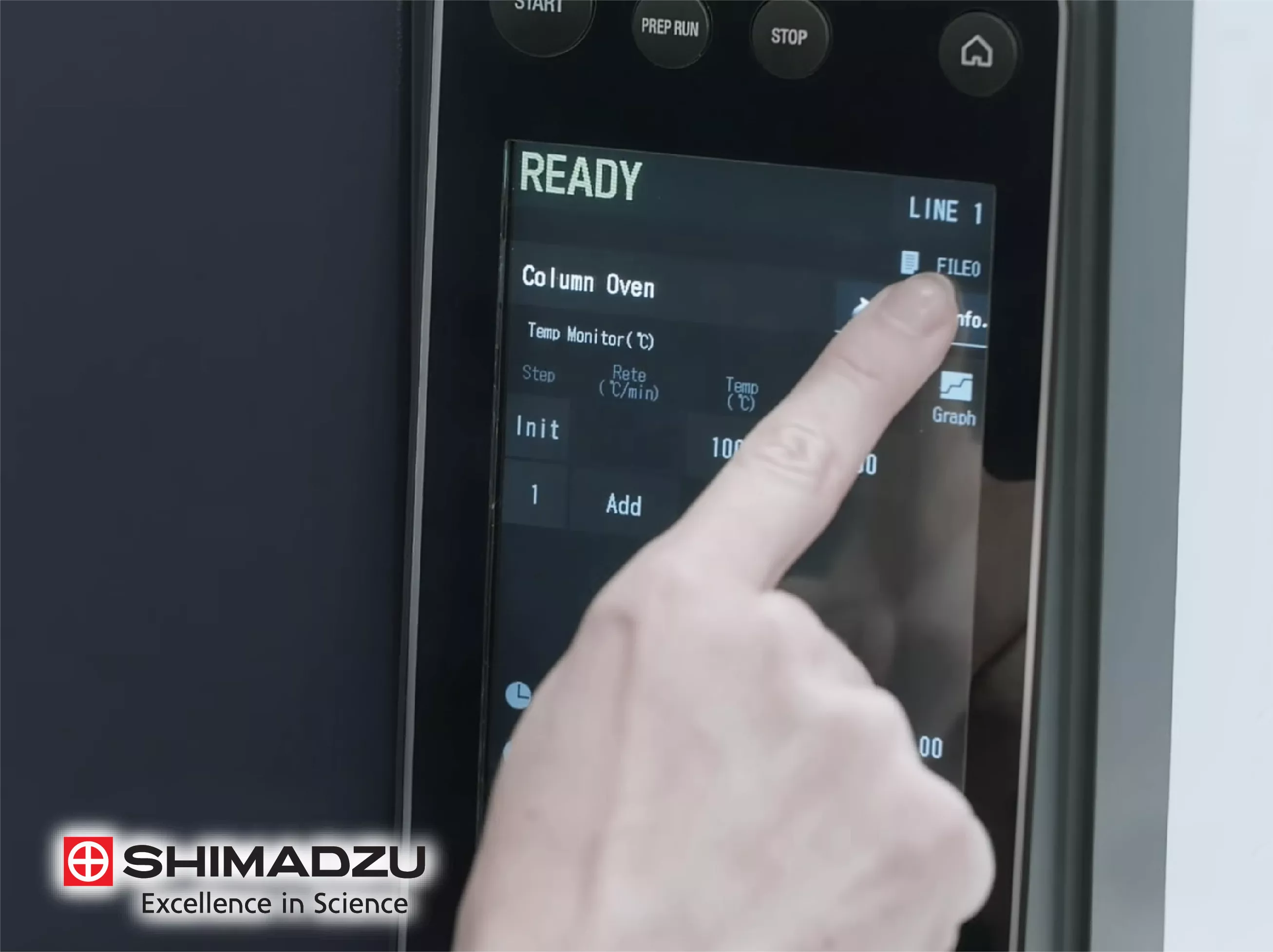

Analytical Intelligence and Automated Startup

The "Analytical Intelligence" framework automates the entire analytical sequence, from system check to final report. Technically, the system can perform an automated leak check before starting an analysis to prevent data loss or column oxidation. The "FlowPilot" function manages the startup of the GC and oven, ensuring that the column is adequately purged before heating. This automation reduces the technical burden on laboratory personnel and ensures consistent performance across different shifts.

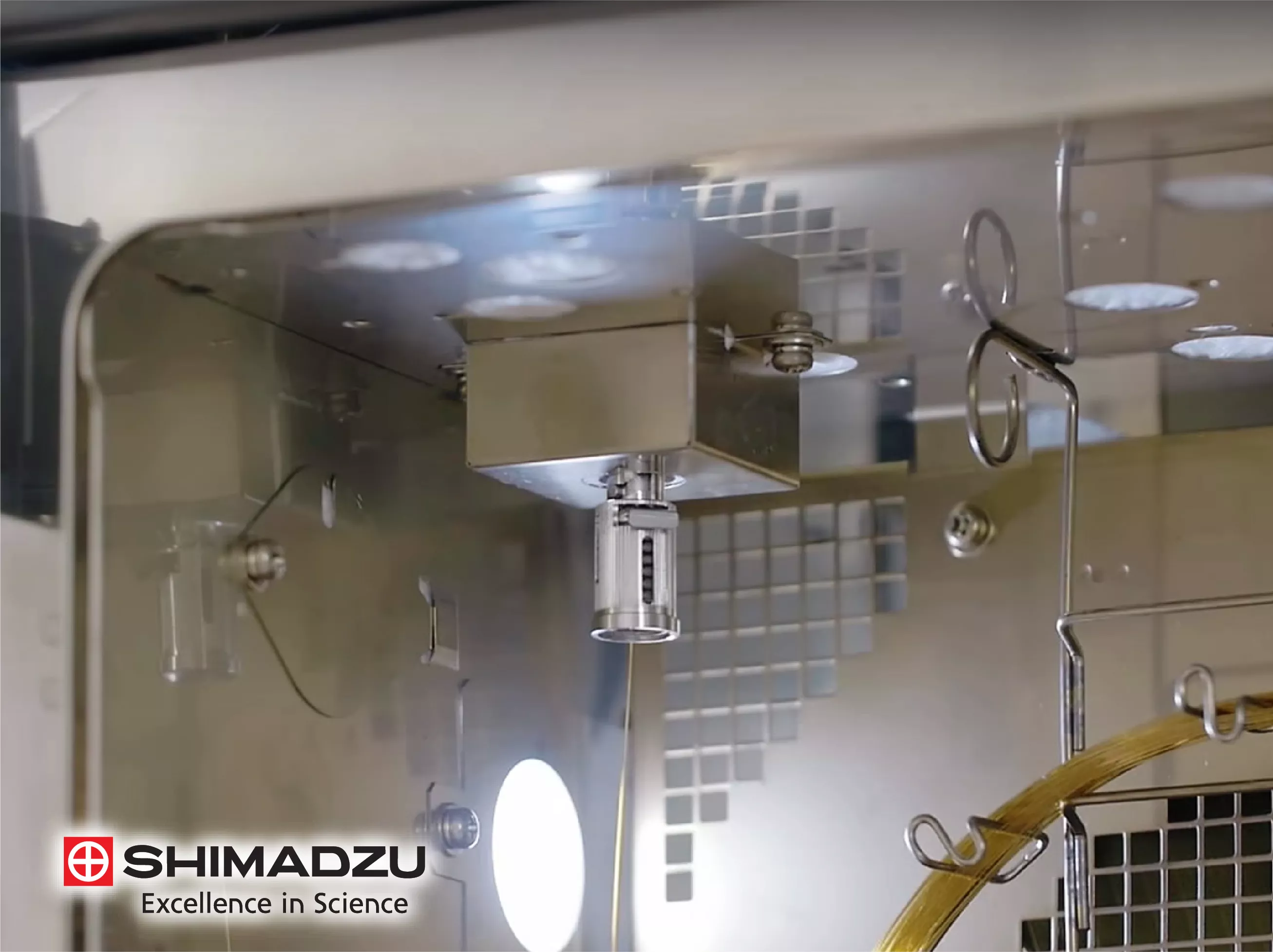

Smart Column Management and i-Column Technology

To enhance traceability and simplify maintenance, Shimadzu implements i-Column technology. This system uses smart tags on GC columns that store critical information such as injection counts, temperature history, and column dimensions. Technically, the GC reads this data automatically to set the correct flow parameters and alerts the user when the column is approaching the end of its lifespan. This prevents the use of degraded columns and ensures the integrity of the analytical data.

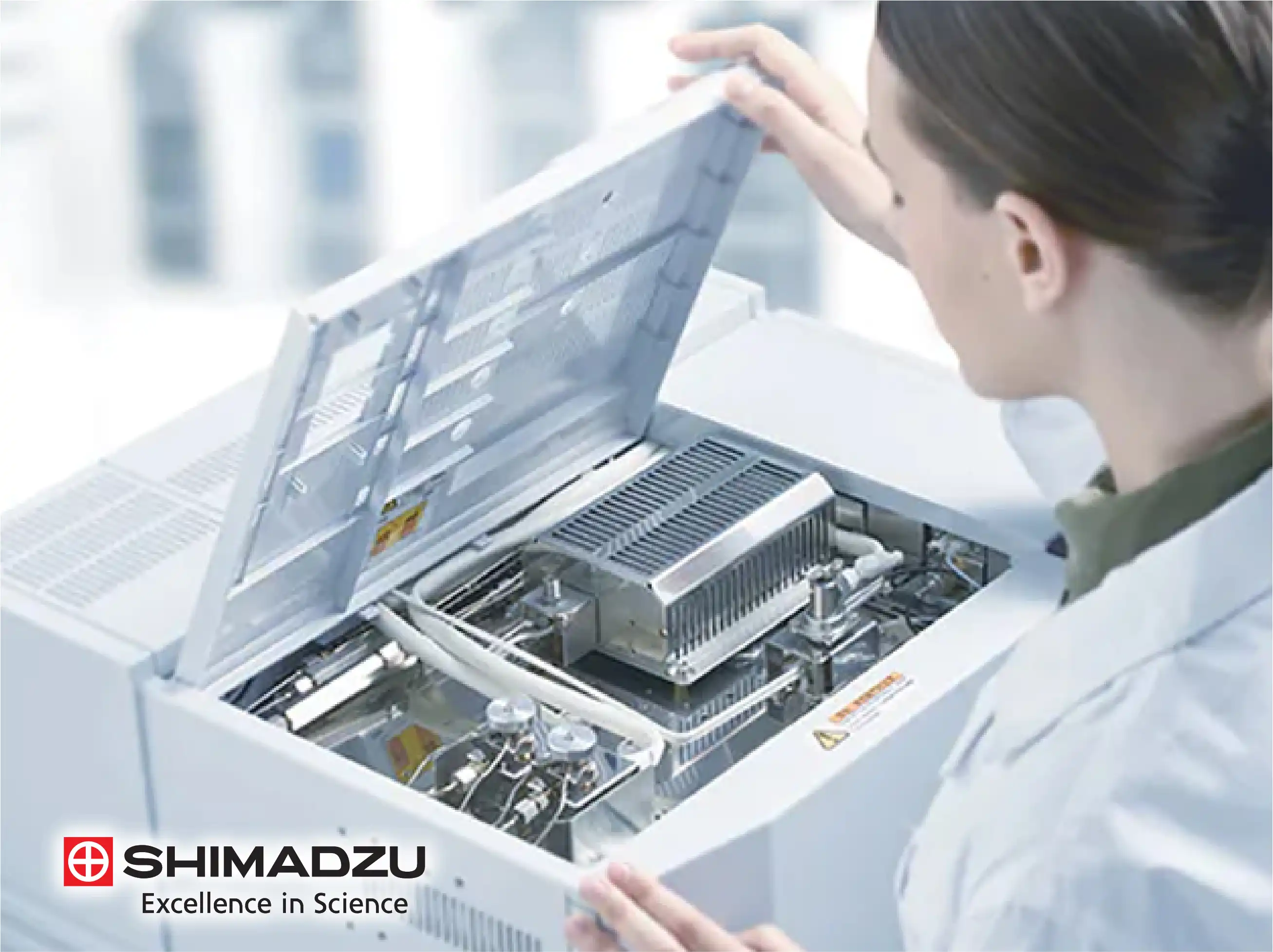

High-Efficiency Oven Design for Rapid Cooling

The GC oven is technically designed for exceptional thermal stability and rapid heating/cooling cycles. By utilizing a high-efficiency fan and specialized insulation, the oven can cool down from $450^{\circ}\text{C}$ to $50^{\circ}\text{C}$ in a fraction of the time required by conventional systems. This rapid cycle time is essential for high-throughput laboratories, as it significantly reduces the time between injections and increases the total number of samples that can be processed in a single workday.

Versatile Sampling and Autosampler Integration

Shimadzu GC systems are designed for seamless integration with a variety of automated sampling units, including liquid autosamplers, headspace samplers, and thermal desorption units. Technically, the communication between the GC and the sampler is synchronized through a unified software interface. This allow for the processing of hundreds of samples with different injection techniques, such as sandwich injections or internal standard addition, without manual intervention, enhancing both precision and throughput.

Specialized Detectors for Trace Element Analysis

For applications requiring specific element detection, Shimadzu provides specialized detectors such as the Flame Photometric Detector (FPD) for sulfur and phosphorus, and the Electron Capture Detector (ECD) for halogenated compounds. These detectors are technically optimized for high selectivity, allowing researchers to quantify trace-level contaminants in complex matrices like food extracts or petrochemicals without interference from the main sample components.

Remote Monitoring and Cloud Connectivity

With built-in network capabilities, Shimadzu GC systems support remote monitoring via web browsers. Users can check the current status of the analysis, view chromatograms in real-time, and receive alerts on their mobile devices. Technically, this allows laboratory managers to oversee multiple instruments from a central location. The data can be automatically uploaded to a secure database, supporting 21 CFR Part 11 compliance and ensuring that all analytical records are archived with full traceability.

Click here for more information about Shimadzu range of products