LC Software

Laboratory Data Management and Network Architecture

Shimadzu LC Software

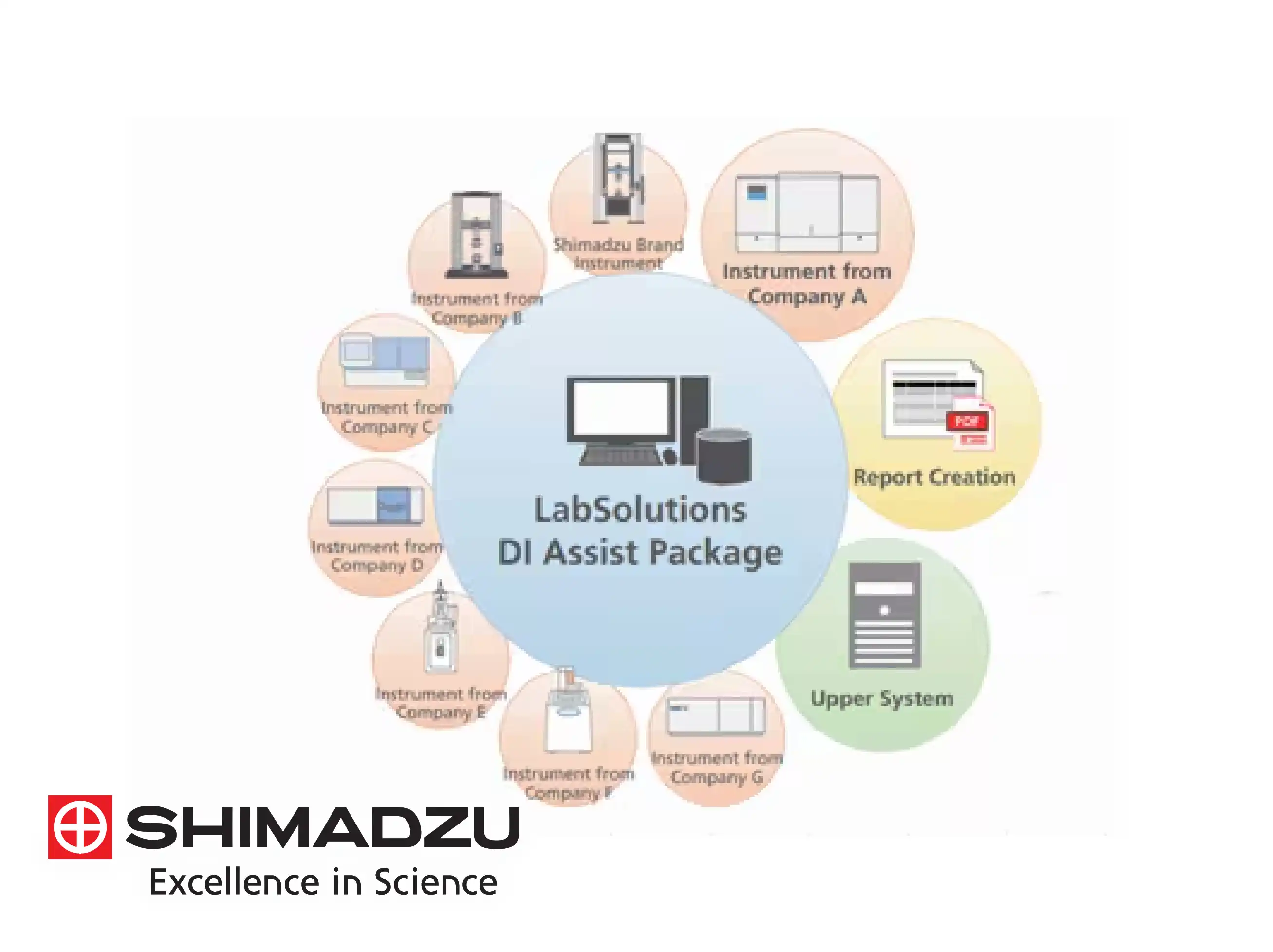

The integration of sophisticated LC software into a laboratory's ecosystem is critical for achieving high-throughput productivity and maintaining rigorous data standards. These software packages are designed with modularity in mind, allowing them to scale from a single workstation to a global network environment. Technically, they support multi-vendor instrument control, which allows researchers to manage diverse hardware through a single, familiar interface.

This reduces the learning curve for operators and minimizes the risk of human error during method development and routine analysis. Furthermore, integrated diagnostic tools provide real-time feedback on instrument health, allowing for predictive maintenance and reducing unscheduled downtime in critical research and quality control settings.

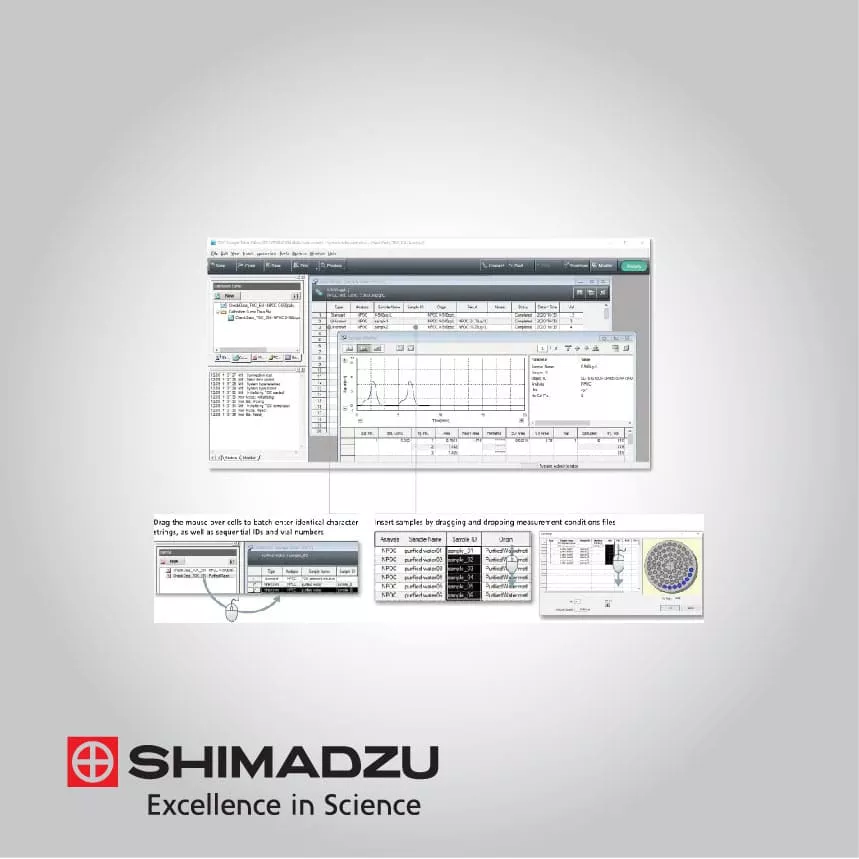

Unified Instrument Control and Management

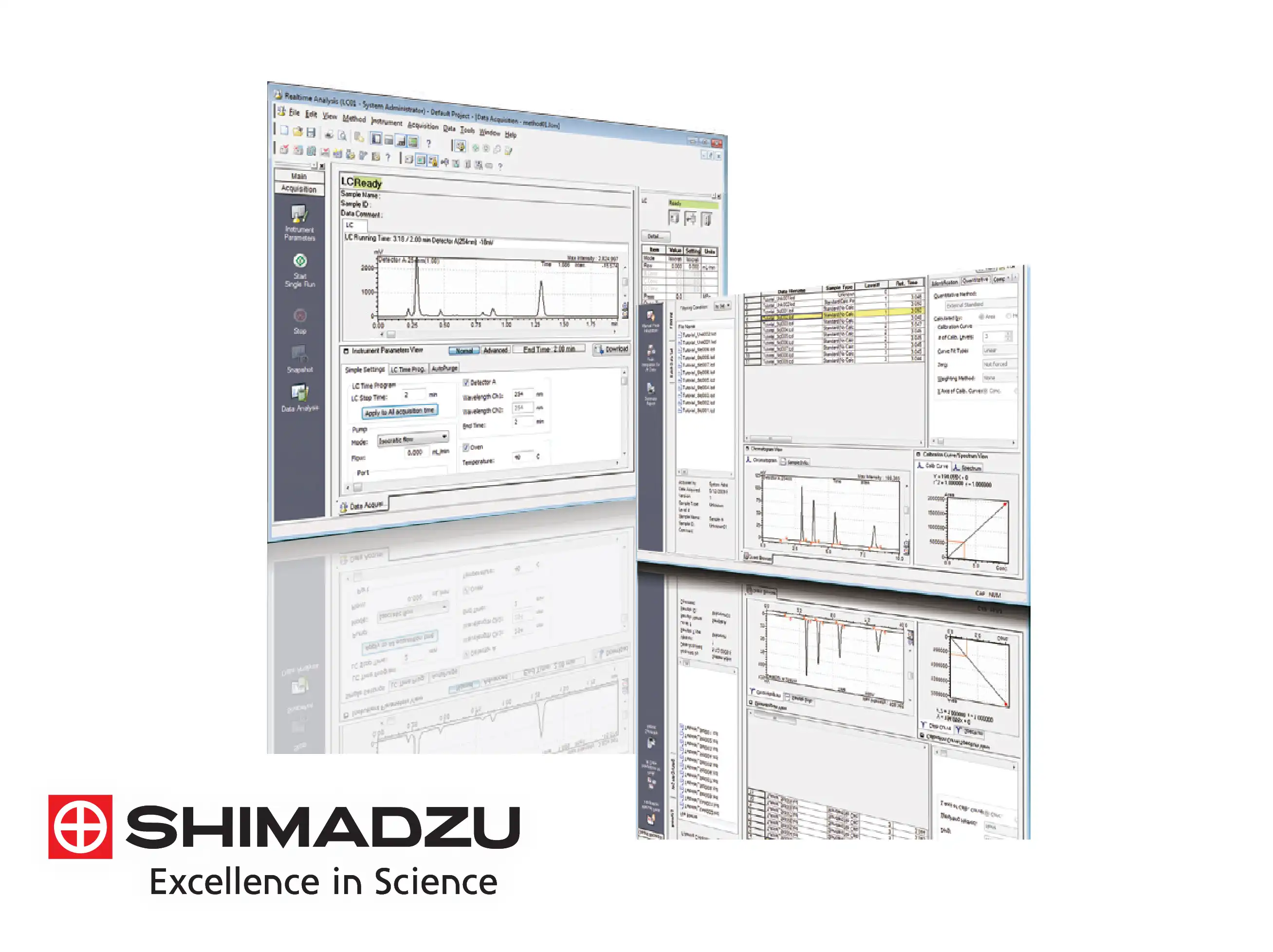

The primary technical function of LC software is to provide a centralized hub for instrument control. This allows for the precise programming of solvent gradients, temperature profiles for column ovens, and sampling sequences for autosamplers. By centralizing these controls, the software ensures that all system components operate in perfect synchrony, which is fundamental for achieving reproducible retention times and peak areas across multiple injections.

Sophisticated Peak Integration Algorithms

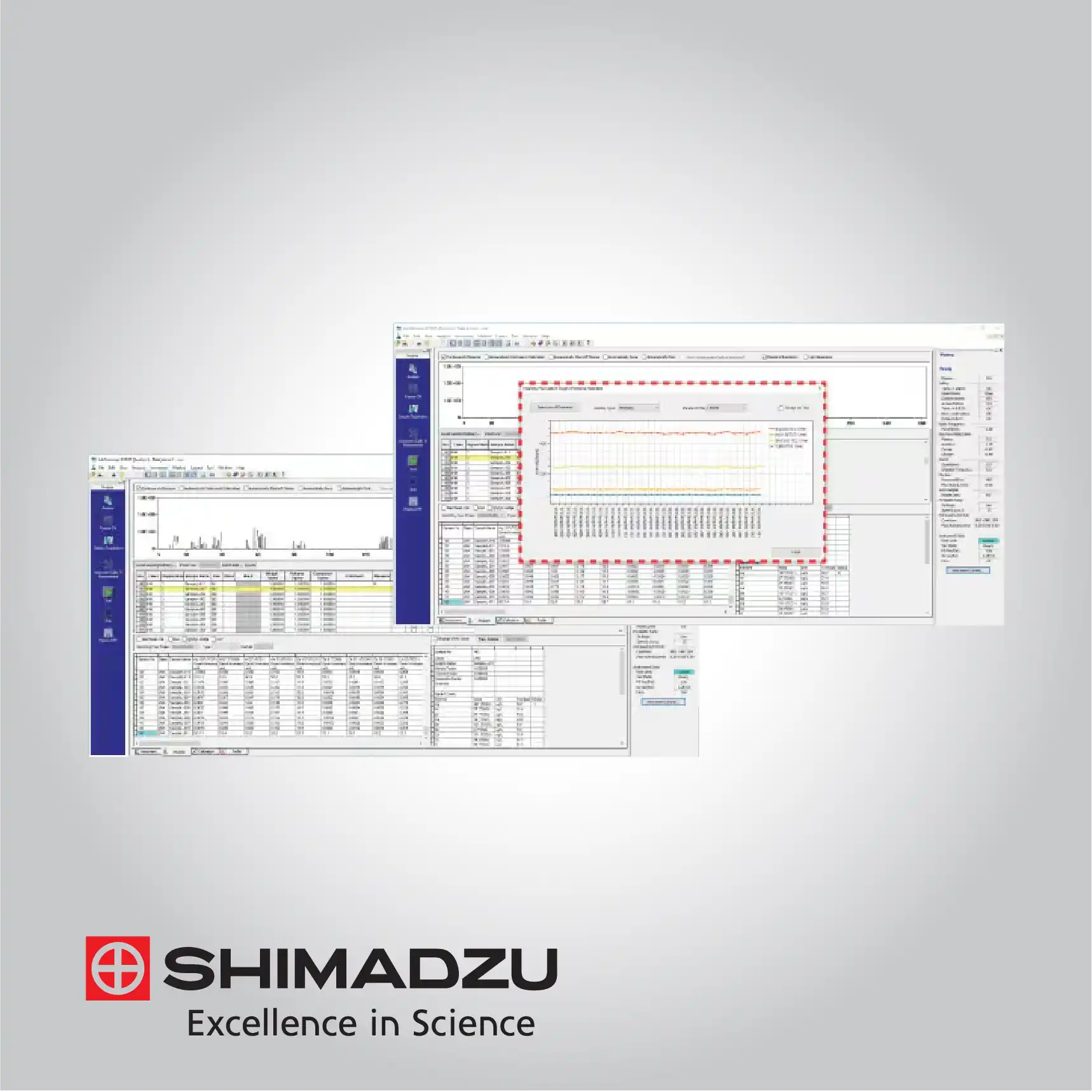

Accurate quantitation depends on the software's ability to precisely define peak boundaries. Advanced integration algorithms are employed to handle complex baselines, noise, and overlapping peaks. These tools allow for the automated detection of peaks even at low signal-to-noise ratios, reducing the need for manual re-integration and ensuring that quantitative results are both objective and consistent across different operators.

Automated Method Development and Optimization

Modern LC software includes technical tools that facilitate the rapid development of analytical methods. These features can automate the screening of different columns, mobile phase compositions, and gradient profiles. By systematically evaluating these variables, the software helps researchers identify the optimal conditions for separation in a fraction of the time required for manual trials, significantly improving laboratory efficiency.

Comprehensive Reporting and Data Visualization

Turning raw data into actionable information requires powerful visualization and reporting tools. LC software allows for the creation of customized report templates that automatically include chromatograms, calibration curves, and statistical summaries. Technically, these reports can be configured to highlight results that fall outside of pre-defined specifications, allowing for rapid quality control assessments and "management by exception."

Multi-Vendor Support and Connectivity

To accommodate diverse laboratory setups, high-level LC software provides the technical capability to control hardware from various manufacturers. This multi-vendor support is facilitated through standardized communication protocols, allowing labs to leverage a single software platform for their entire fleet of instruments. This interoperability simplifies data management and streamlines the training process for laboratory personnel.

Intelligent Troubleshooting and Diagnostics

Embedded diagnostic functions monitor the real-time performance of the LC system. The software can track parameters such as pump pressure pulsations, lamp intensity, and injection counts. When values deviate from the norm, the software provides technical alerts and troubleshooting guidance. This proactive approach to instrument maintenance helps prevent system failure and ensures that analytical results are always obtained from a system in peak operating condition.

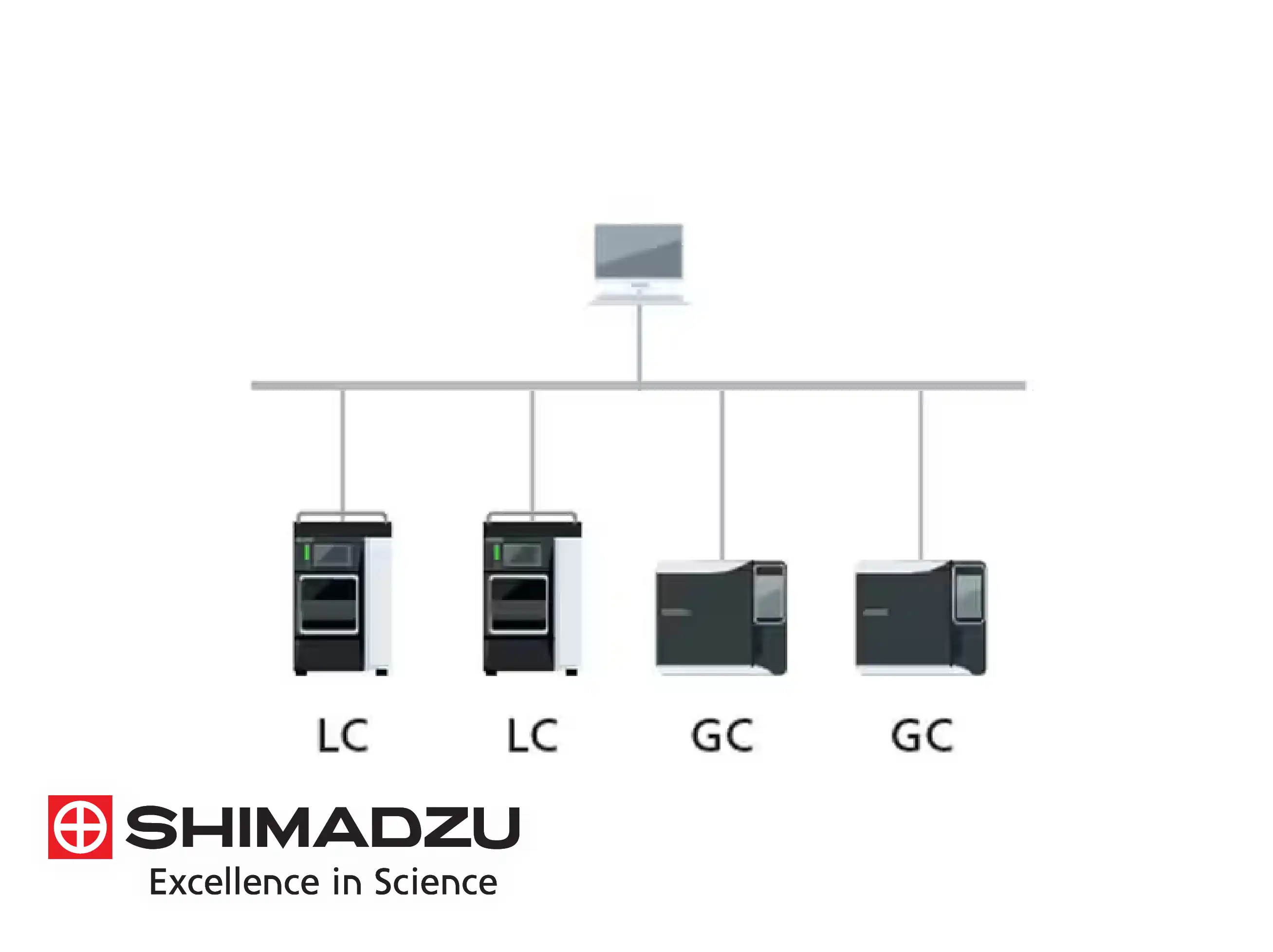

Scalable Network and Database Architecture

For large organizations, LC software is designed with a scalable network architecture. Data is stored in centralized databases that support high-speed retrieval and secure long-term archiving. This technical structure allows researchers to access results from any connected workstation, facilitating collaboration and ensuring that data is protected by robust backup and disaster recovery protocols.

Advanced Qualitative and Quantitative Analysis

Beyond simple area calculations, the software provides deep analytical capabilities for both qualitative and quantitative work. This includes spectral library searching for compound identification and advanced statistical tools for trend analysis. These technical features enable laboratories to perform complex characterizations and high-sensitivity quantitation, meeting the rigorous demands of pharmaceutical, environmental, and food safety testing.

Click here for more information about Shimadzu range of products

Related Products

Ask Us A Question

CONTACT US

Taawon for Laboratory & Scientific Supplies

Taawon Group © 2026 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience