Home » Products » Material Preparation, Analysis, and Testing » Mounting systems » Buehler Cold Mounting

Castable Mounting Solutions

Low Stress, Vacuum Amplification, Pore Infiltration

Buehler Cold Mounting

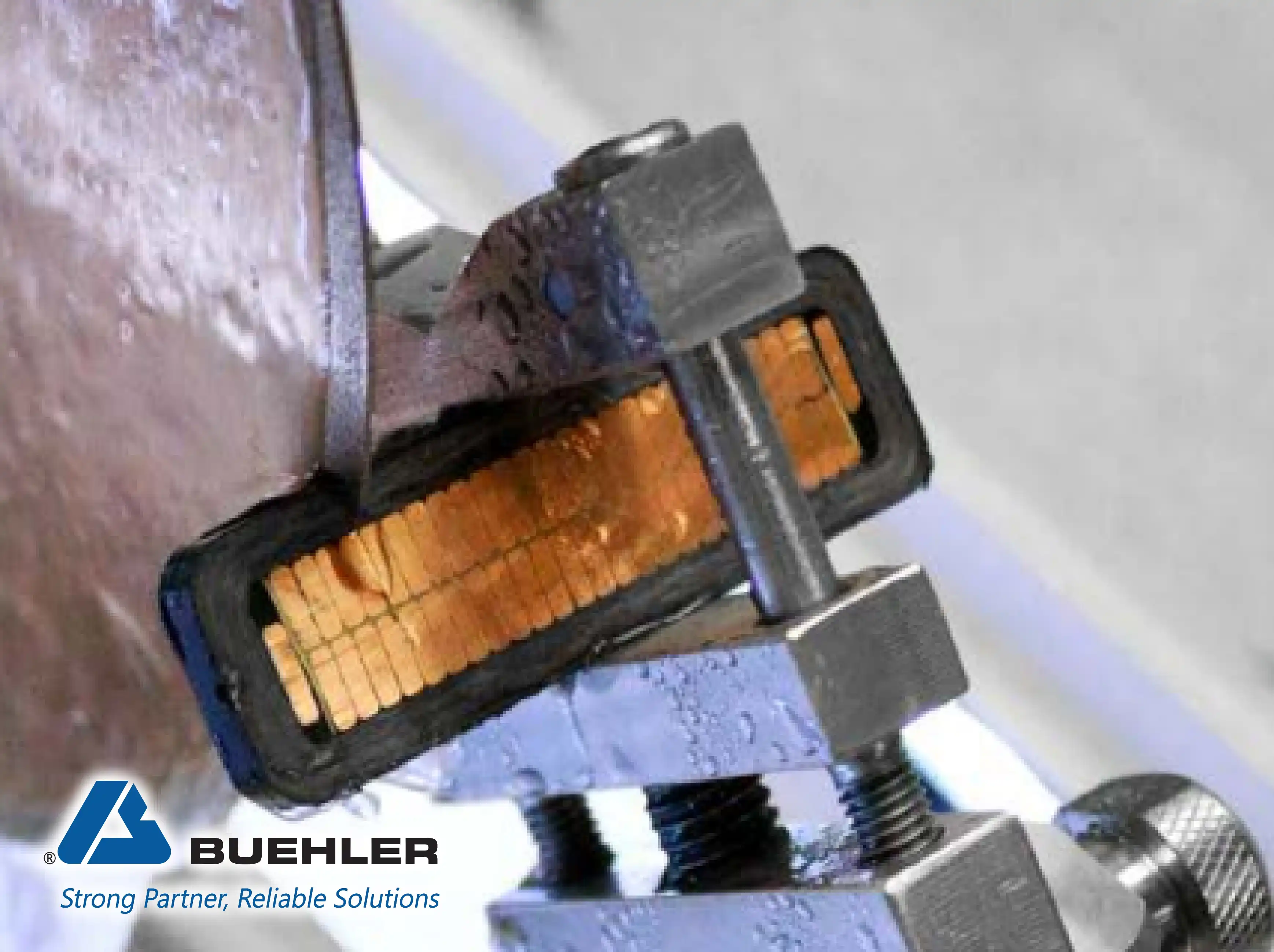

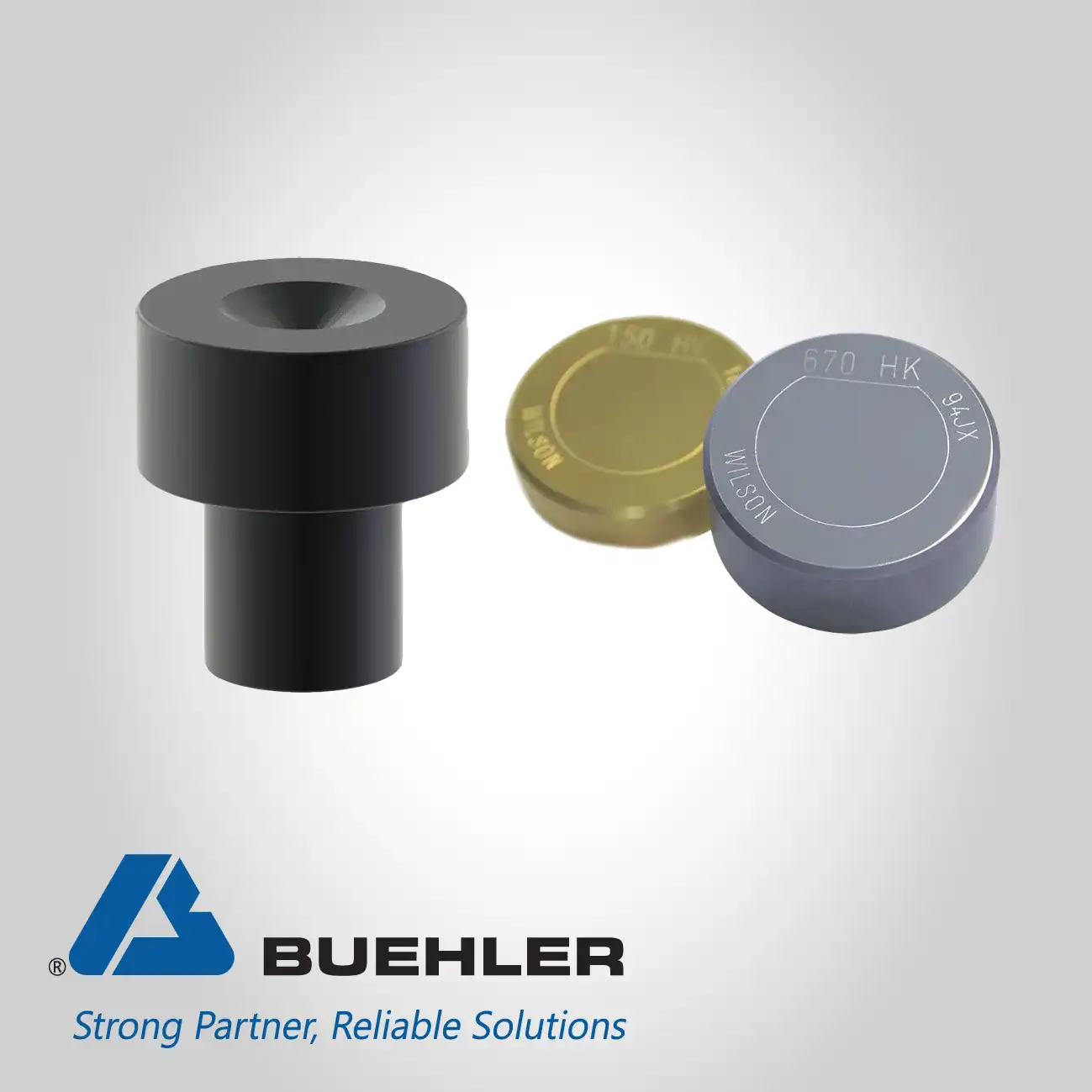

A significant customer pain in cold mounting is the lengthy cure time and the presence of micro-voids, which compromise mount quality. Acrylic mounting systems are the technical solution for simple geometry specimens, offering cure times as low as five minutes. This speed directly increases laboratory throughput. Conversely, epoxy systems, while potentially slower, provide excellent pore infiltration, which is technically necessary for materials with complex porosity or internal features that require full embedment to prevent damage during polishing.

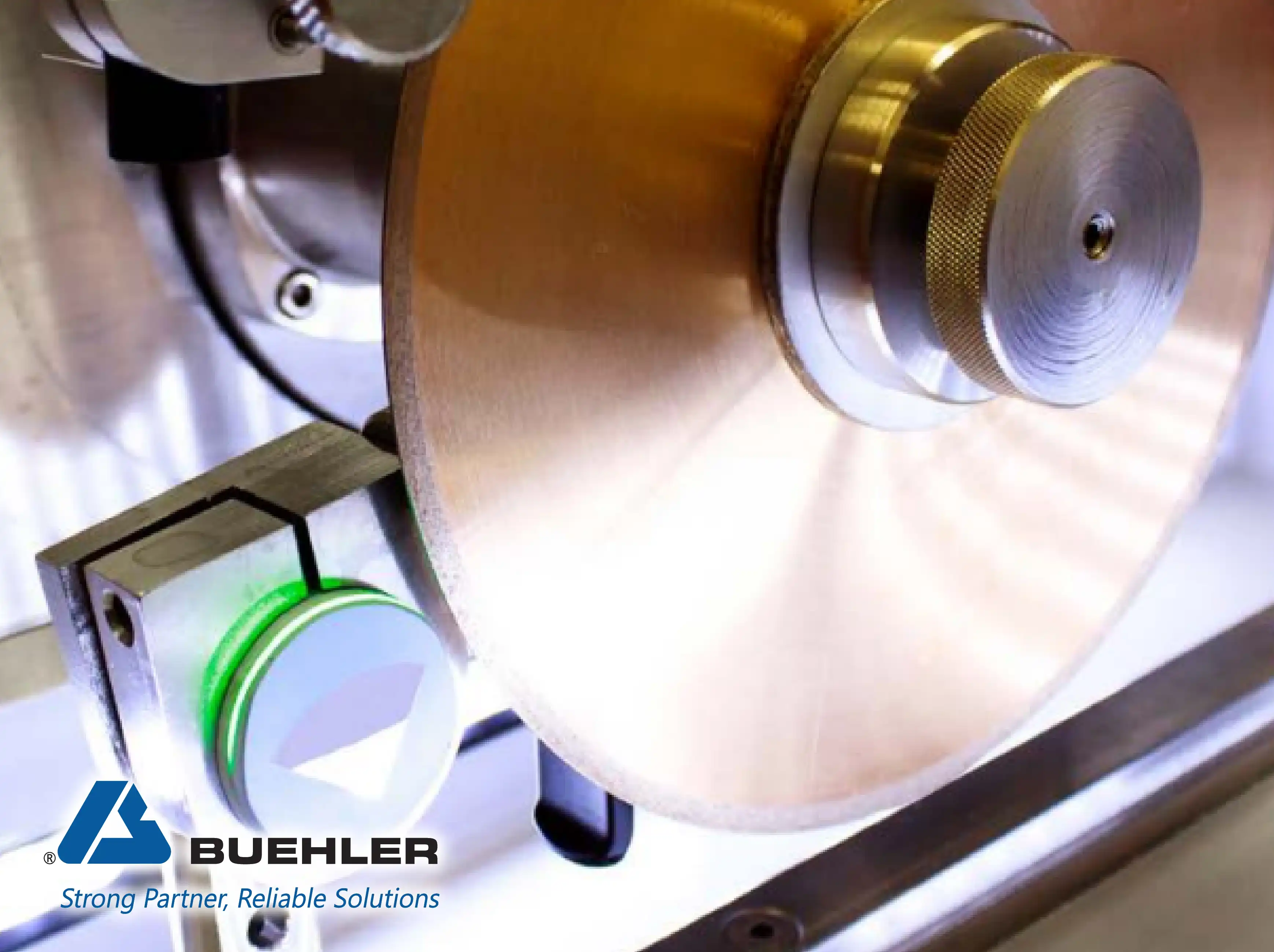

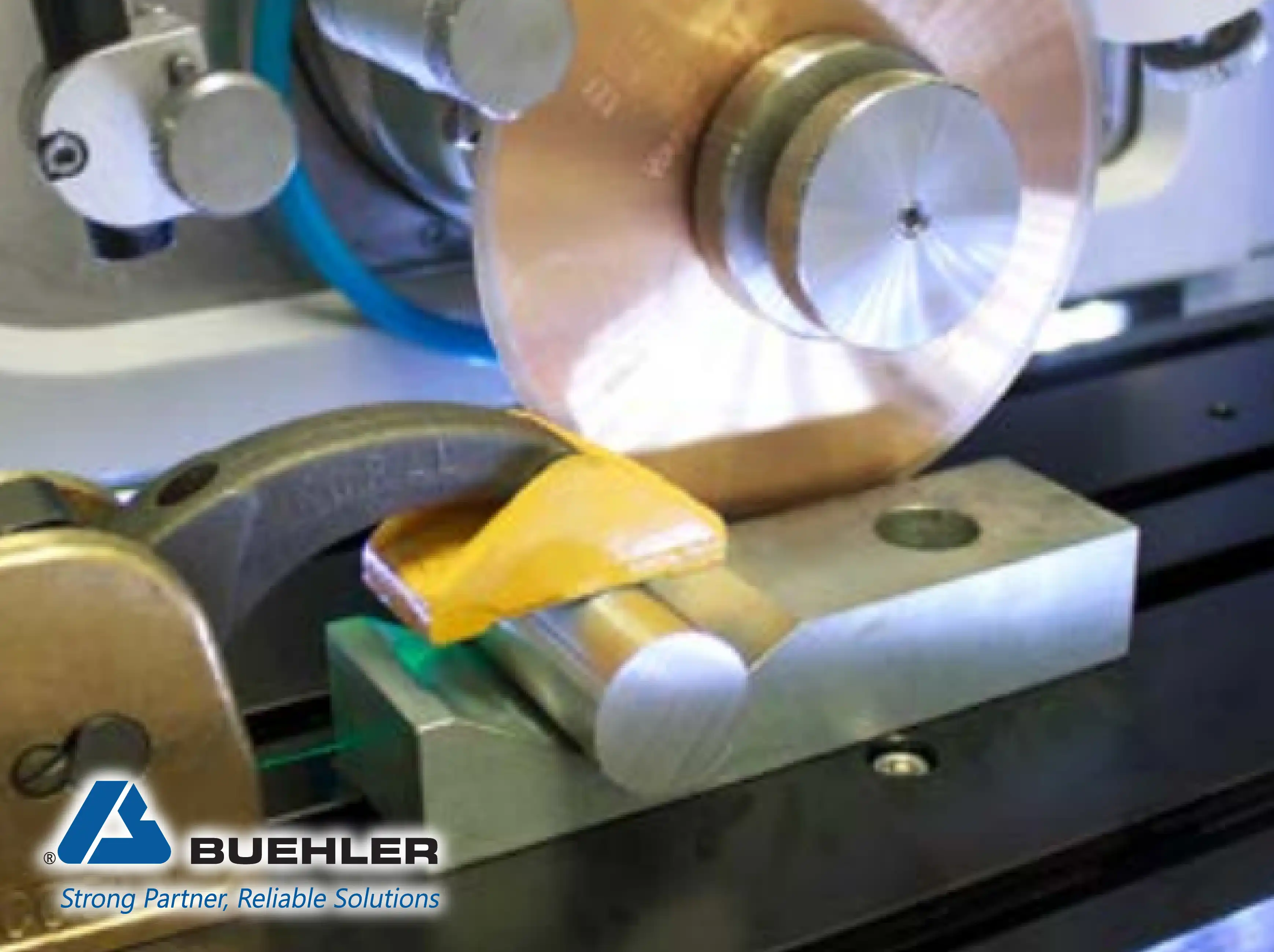

The technical efficacy of epoxy mounts is amplified by the use of a vacuum mounting system, which specifically targets the customer pain of entrapped air and voids at the sample interface. The system features an easy-to-use touchscreen interface allowing the operator to precisely control the vacuum pressure, cycle time, and the number of cycles. This technical control over the process parameters is crucial for ensuring maximum pore penetration and a dense, high-quality mount, especially in high-reliability applications where structural defects in the mount are unacceptable.

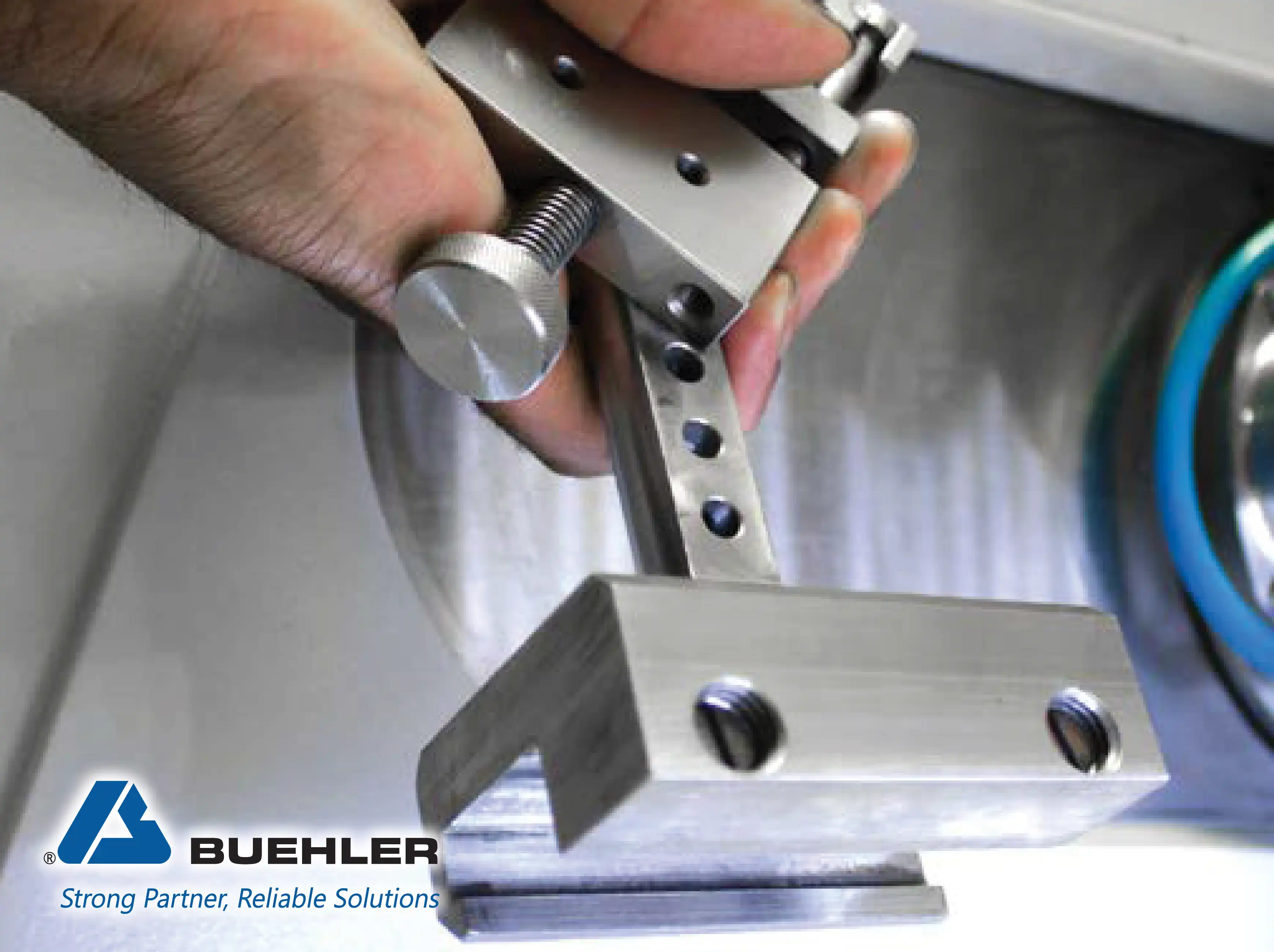

The core challenge of damaging delicate samples with heat and pressure is resolved by the fundamental castable mounting technique. The process is inherently low-temperature and low-stress, making it the technical ideal for specimens, such as biological materials or sensitive electronic components, that would otherwise experience microstructural or thermal distortion.

For porous materials, the challenge is the incomplete infiltration of the mounting medium, leaving voids that compromise edge retention. Epoxy mounting systems provide the technical solution by offering excellent pore infiltration, ensuring the resin flows into fine details and surfaces, which is critical for supporting the material during subsequent mechanical preparation.

The issue of trapped air bubbles and voids in epoxy mounts is eliminated by the vacuum mounting system. Technically, the system draws a vacuum using controlled pressure and time, removing gases that would otherwise remain as defects. This ensures a fully dense mount structure, which is vital for high-magnification analysis where these voids can obscure critical features.

The lengthy curing time associated with traditional epoxies presents a significant limitation. Acrylic mounting systems are the technical countermeasure, offering cure times as fast as five minutes. This acceleration increases the daily sample throughput, making acrylics the ideal choice for simple geometry specimens in high-speed quality control environments.

The technical requirement for reliable and consistent cold mounting is addressed by the vacuum system's touchscreen control. This interface allows the operator to pre-program and replicate exact vacuum pressure, cycle time, and number of cycles. This technical repeatability removes guesswork and subjectivity, guaranteeing consistent mount properties regardless of the operator.

The risk of surface damage from excessive exothermic heat generated during curing is a risk with some castable systems. The specialized formulation of mounting media is the technical defense, providing stable curing profiles that minimize temperature spikes, thus protecting the microstructural integrity of temperature-sensitive samples.

For specimens that are sensitive to high pressure and high temperature, cold mounting is technically positioned as the ideal solution. It avoids the mechanical stress of compression, preventing deformation. This inherent low-stress processing directly solves the problem of sample destruction that is often unavoidable when dealing with brittle or delicate components under hot mounting conditions.

The technical benefit of reducing the curing time in epoxy systems is achieved by combining them with the vacuum mounting machine. The vacuum action effectively accelerates the pore penetration and allows the epoxy to achieve its final strength faster, thus mitigating the long waiting periods before the sample can proceed to the next preparation step.

Click here to know more about Buehler products

.webp)