Home » Products » Material Preparation, Analysis, and Testing » Mounting systems » Buehler Hot Mounting

Compression Mounting Systems

High Pressure, Fast Cycle, Uniform Geometry

Buehler Hot Mounting

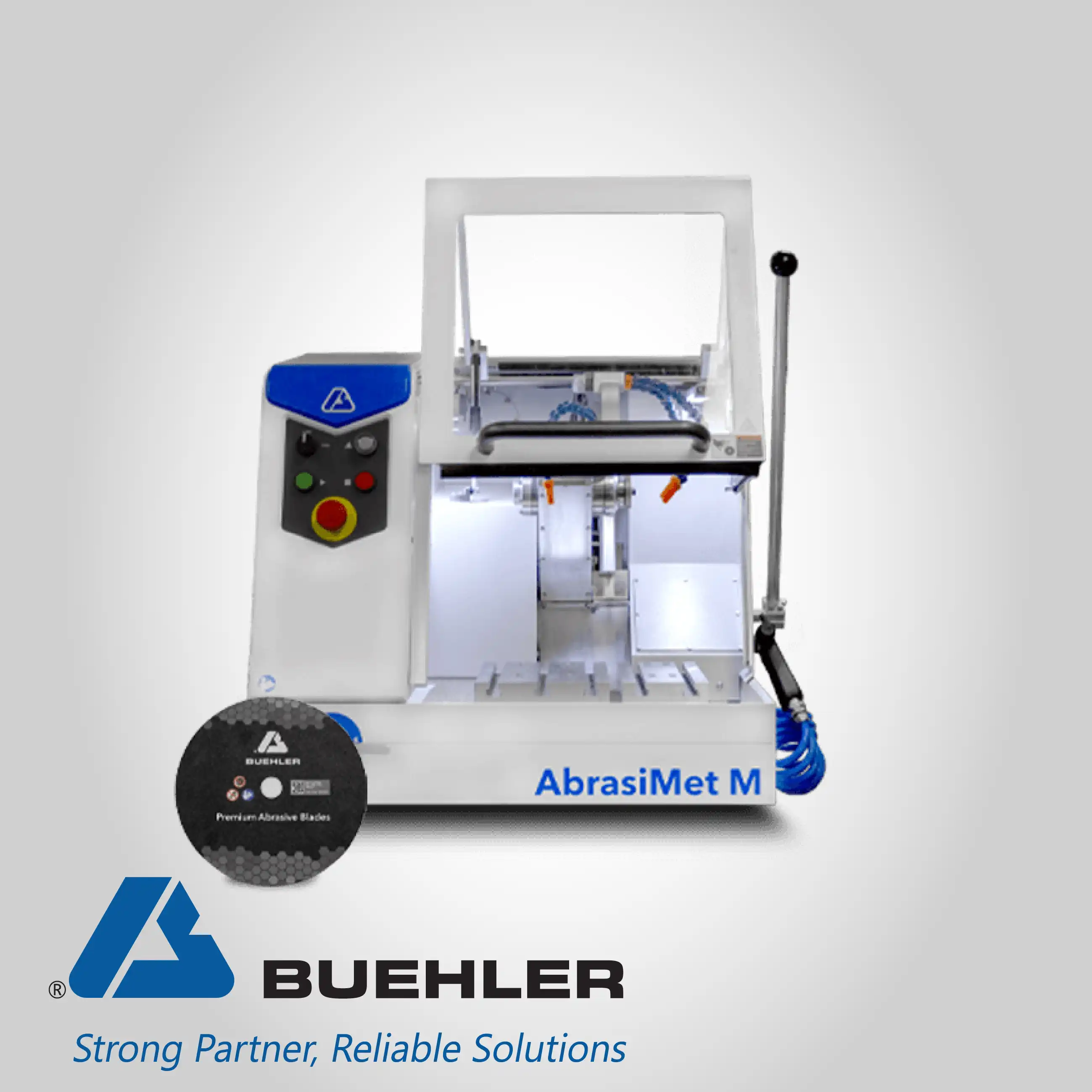

Compression mounting presses are technically characterized by their short cycle time, directly resolving the customer pain point of long processing bottlenecks. These systems are designed to maximize laboratory throughput by featuring the ability to process up to two samples per cycle, coupled with seven mount size options. This combination of speed and versatility ensures that high-volume laboratories can rapidly move from sample cutting to the mounting stage without sacrificing the necessary uniformity or quality required for microstructural analysis.

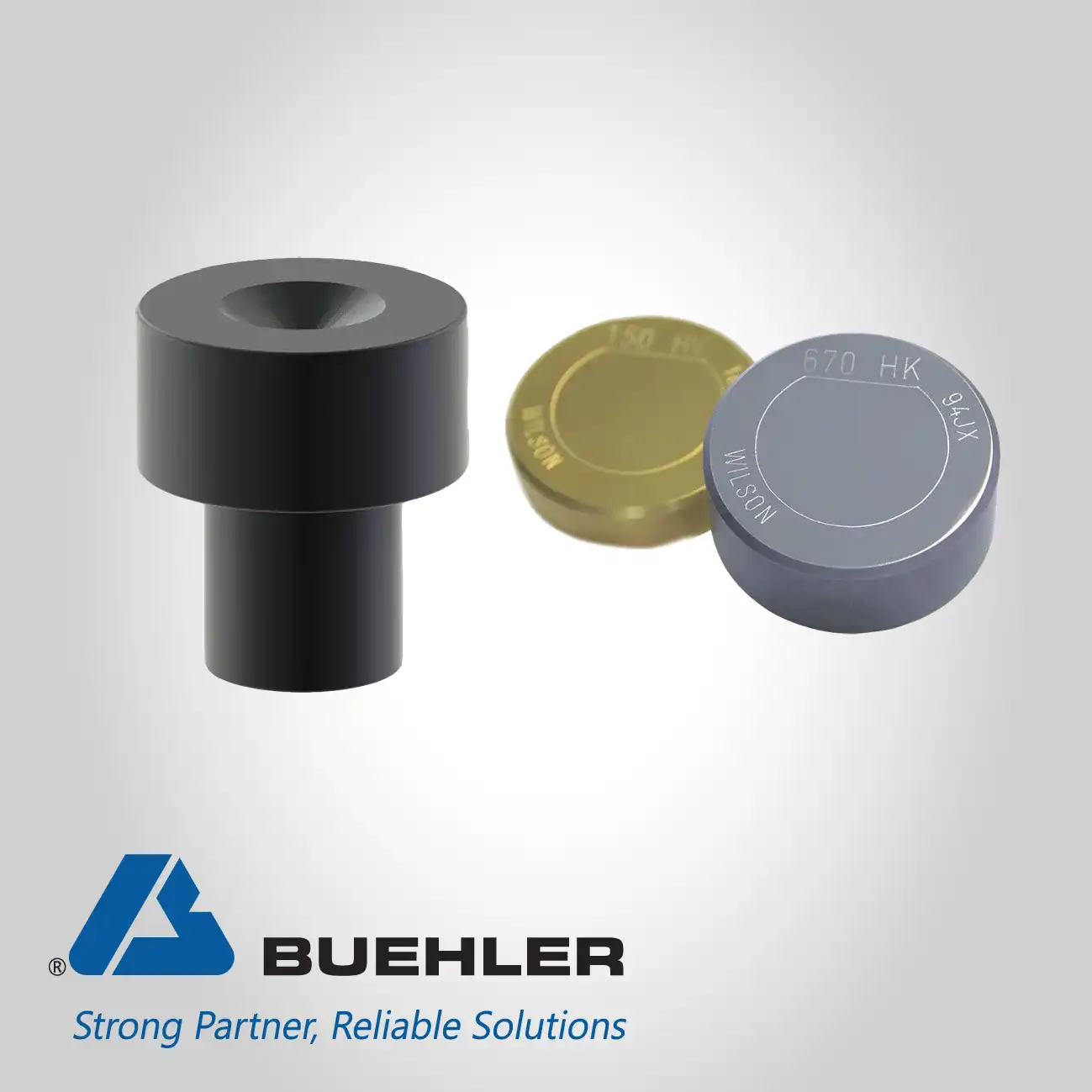

The technical performance of hot mounting compounds is engineered to specifically address the customer pain of shrinkage and sample compromise. These specialized compounds minimize shrinkage during the encapsulation process while simultaneously protecting and preserving the sample edges. Maintaining sharp and undamaged sample edges is a critical prerequisite for accurate metallographic analysis, as it prevents misleading data from the region of interest during hardness testing or microscopic examination.

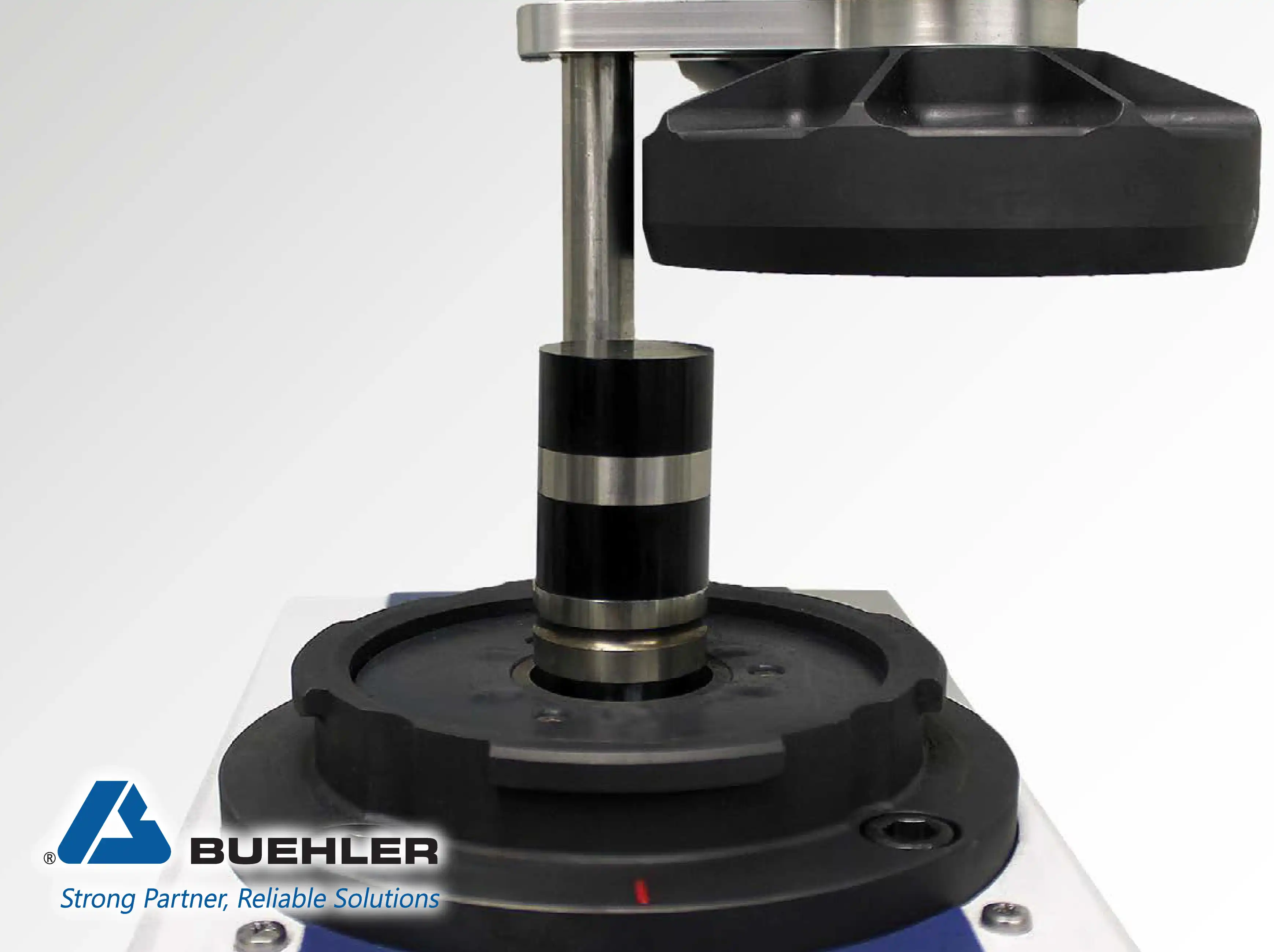

The challenge of achieving inconsistent sample shape and flatness is solved by the high-pressure mechanism of the compression mounting press. By forming the specimen under high mechanical force, the machine ensures a highly uniform, flat mount geometry. This technical rigor improves the ease of subsequent grinding and polishing processes, preventing preferential material removal that can skew analytical results.

For high-volume labs, the primary concern is slow preparation time. The short cycle time feature of the hot mounting machine directly mitigates this, offering a rapid turnaround for mounted samples. This technical efficiency ensures the mounting stage does not become a workflow bottleneck, thereby increasing overall laboratory throughput and maximizing the utilization of expensive analytical instruments.

The challenge associated with limited specimen size capacity is addressed by the machine's technical versatility, which supports up to seven different mount size options. This broad technical range allows operators to encapsulate specimens of varying dimensions using a single machine, reducing the need for multiple, specialized mounting units and maximizing the system's utility across different research or quality control requirements.

The issue of inconsistent results between batches is minimized by the machine's ability to process two samples per cycle. This technical capability ensures that two specimens are subjected to identical pressure and thermal profiles simultaneously, guaranteeing a high level of consistency in the physical properties of the resulting mounts.

A key challenge is the vulnerability of sample edges during the preparation stages, which compromises critical analysis zones. Hot mounting compounds are technically formulated to minimize shrinkage. This precise control over volumetric contraction ensures the mounting medium remains tightly bonded to the specimen, providing robust support and preservation of the edge integrity.

The potential for confusion in selecting the correct mounting medium is simplified. The process is technically defined by using hot mounting primarily for specimens that are known to withstand high heat and pressure. This technical constraint clearly outlines the appropriate application, reducing the risk of selecting an incorrect mounting method that could damage the material's microstructural characteristics.

The difficulty of maintaining varied mount geometry across different runs is mitigated by the machine's consistent and high-quality solution capabilities. The system's technical design ensures that the high pressure is applied uniformly, resulting in mounts that are reliable in shape, which is fundamental for automated grinding and polishing equipment.

The machine's inherent design, which focuses on providing a fast, consistent, and high-quality solution, directly targets the limitations of time-consuming manual processes. The technical automation of the pressure and heat cycles removes the subjectivity and potential for human error associated with attempting to manually replicate these critical parameters.

Click here to know more about Buehler products

.webp)