Home » Products » Chromatography/Mass Spectrometry » Liquid Chromatograph-Mass Spectrometry » Shimadzu LC-MS Software

LC-MS Software

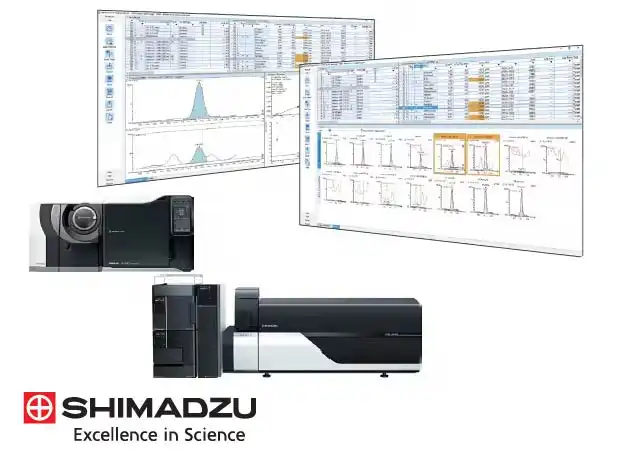

Intelligent Data Management and Automated Workflow for LC-MS

Shimadzu LC-MS Software

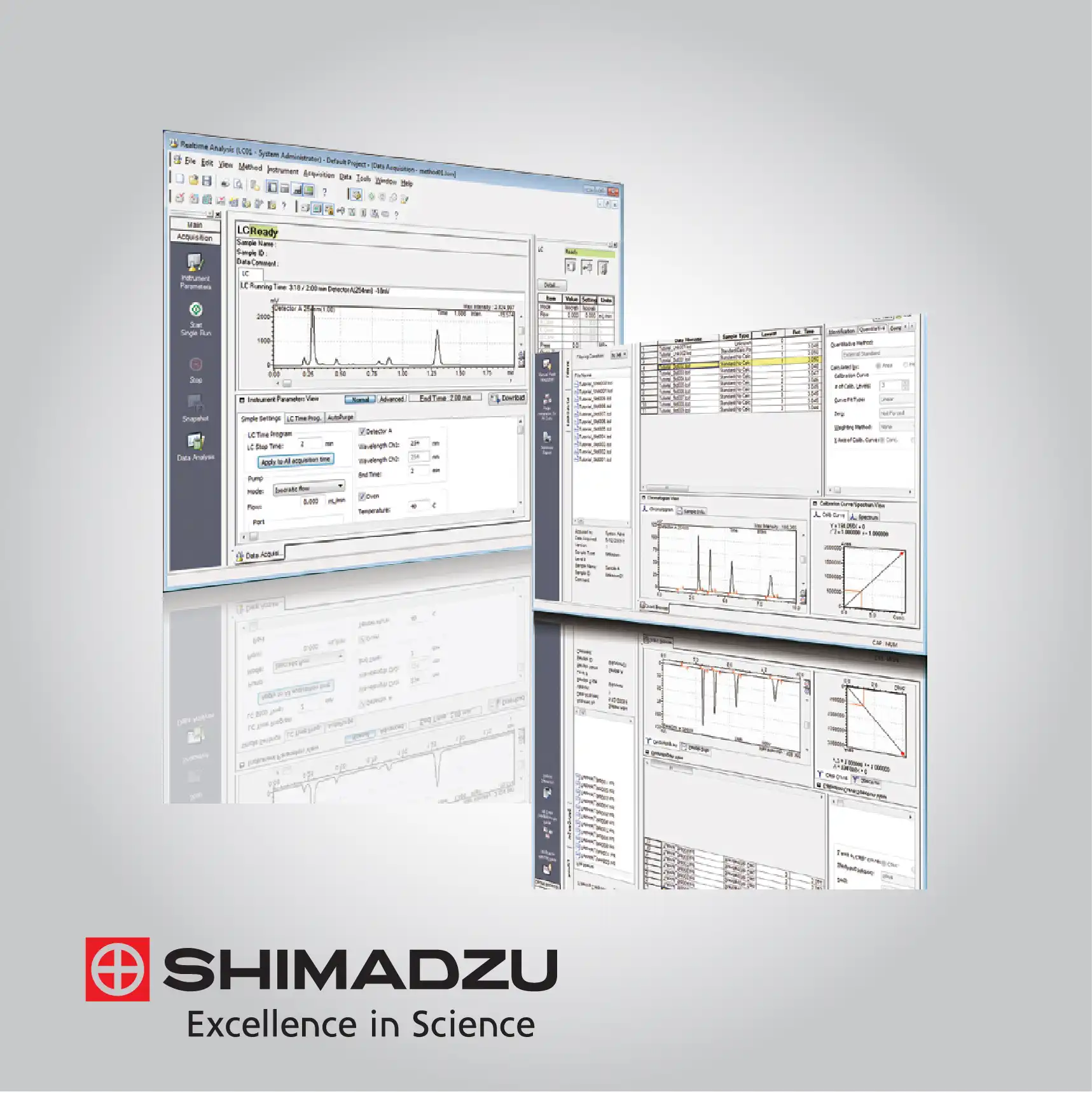

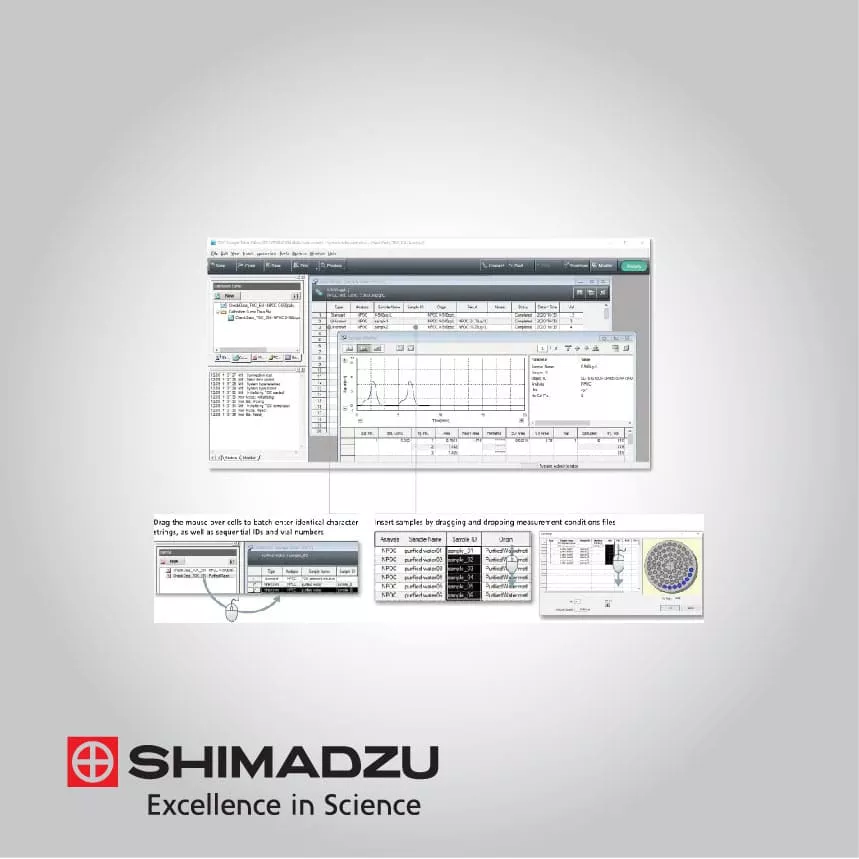

Shimadzu's LC-MS software environment is technically centered around the concept of "Analytical Intelligence," which transforms complex mass spectral data into actionable insights through automated workflows. This platform provides a unified control interface that synchronizes the high-pressure liquid chromatography front-end with the mass spectrometer's ion optics and vacuum systems. Technically, the software utilizes advanced data-processing algorithms to manage the massive data streams generated by high-speed scanning and Multiple Reaction Monitoring (MRM).

By incorporating smart features such as automated system checks and real-time peak monitoring, the software minimizes manual intervention and ensures that the system operates within peak performance parameters. This technical synergy is essential for laboratories that require high-throughput quantification and absolute data integrity in regulated industries.

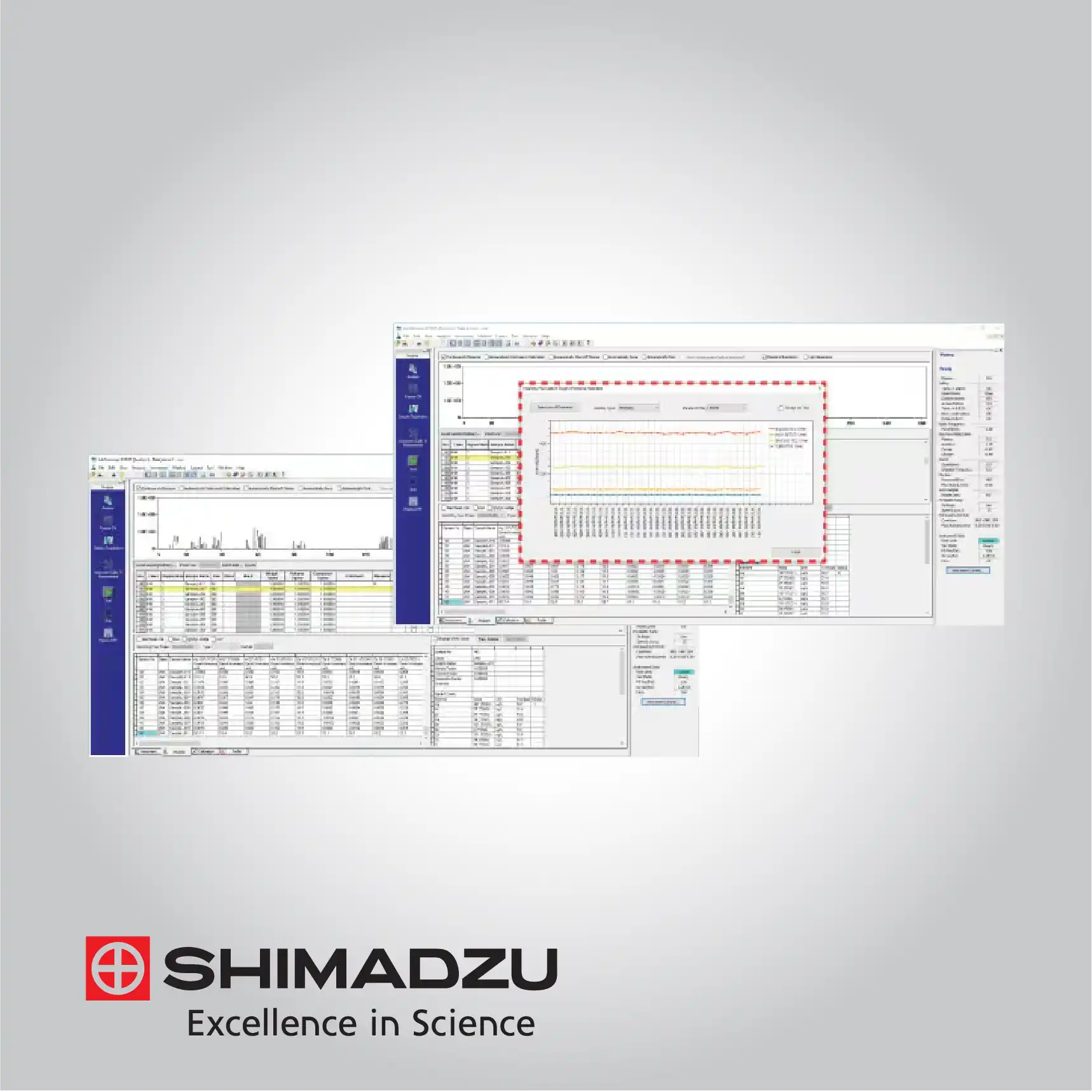

Automated MRM Optimization and Scheduling

For quantitative analysis using triple quadrupole systems, the software technically automates the Multiple Reaction Monitoring (MRM) optimization process. It determines the most sensitive precursor-to-product ion transitions and the ideal collision energy for each target analyte. Technically, the software can schedule these transitions based on retention time windows, ensuring that the mass spectrometer spends maximum dwell time on the expected analytes, thereby improving the signal-to-noise ratio and detection limits.

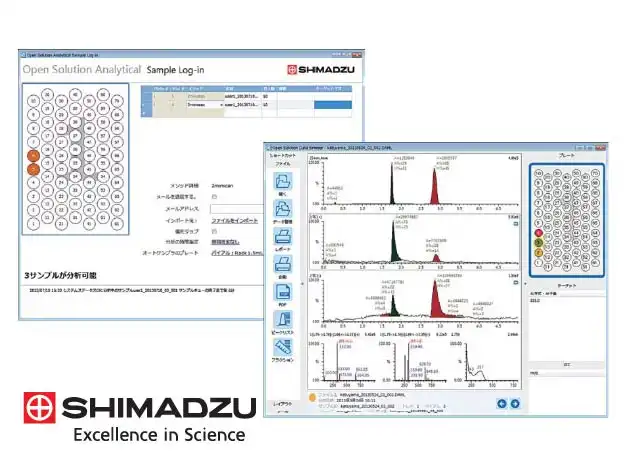

Advanced Algorithms for Deconvolution and Peak Integration

The software utilizes sophisticated technical algorithms for spectral deconvolution, which is essential for identifying co-eluting compounds in complex matrices. By analyzing the unique mass signatures within a single chromatographic peak, the software can technically resolve individual components that would otherwise be indistinguishable. This is coupled with intelligent peak integration tools that adapt to varying baseline conditions, ensuring accurate area calculation for both high-concentration and trace-level components.

Real-Time Instrument Health and Vacuum Monitoring

Technically, the software provides a continuous diagnostic link to the LC-MS hardware. It monitors critical parameters such as the vacuum pressure in the ion source and collision cell, the temperature of the desolvation line, and the voltages of the ion guides. If any parameter drifts outside of the specified technical tolerance, the software triggers an automated alert or pauses the analytical sequence. This proactive monitoring protects the hardware and prevents the acquisition of invalid data.

LabSolutions Network for Total Data Traceability

The software is technically integrated into the LabSolutions network architecture, providing a centralized database for all analytical records. This ensures that every raw data file is linked to its specific method parameters, calibration curves, and audit trails. Technically, this centralized management facilitates compliance with global data integrity standards, such as 21 CFR Part 11, by preventing unauthorized data modification and ensuring that all actions are fully documented and searchable.

Intelligent Library Searching and Compound Identification

For qualitative screening, the software technically leverages high-fidelity spectral libraries. It compares the measured mass spectra and isotopic patterns against thousands of entries in databases like NIST or Wiley. Technically, the software calculates a "match factor" based on mass accuracy and fragment intensity ratios, providing a statistical probability for compound identification. This is essential in forensic and environmental applications where the identification of unknown substances must be defensible.

Smart Dynamic Range Management and Saturation Prevention

In high-sensitivity analysis, the software technically manages the detector's dynamic range to prevent ion saturation. If the signal intensity exceeds a predefined threshold, the software can automatically adjust the gain or utilize specific pulse-counting algorithms to maintain linearity. This technical capability ensures that laboratories can quantify analytes across several orders of magnitude in a single injection, reducing the need for sample re-analysis or manual dilution.

Automated Validation and System Suitability Testing (SST)

The software technically simplifies the validation process through automated System Suitability Testing (SST). Before a sample batch begins, the software can run a standard solution and automatically calculate parameters such as peak resolution, tailing factor, and mass accuracy. Technically, if the system fails to meet the pre-defined performance criteria, it can perform automated troubleshooting or shutdown routines, ensuring that only high-quality data is generated.

Data Reprocessing and Quantitative Summary Tools

For high-throughput environments, the software provides technical tools for rapid data reprocessing. Large batches of data can be re-integrated or re-quantified using updated calibration curves in a single operation. Technically, the software generates comprehensive summary tables that highlight out-of-specification results or ion ratio failures, allowing analysts to quickly identify and address potential issues in large-scale quantitative studies.

Click here for more information about Shimadzu range of products

Related Products

CONTACT US

CONTACT US

Taawon for Laboratory & Scientific Supplies

Taawon Group © 2026 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience