.webp)

Coverslippers

Increased turnover and high reproducibility

Slee Coverslippers

The primary technical function is the application of a coverslipping film with great precision and accuracy onto the prepared slides. This process supports laboratory personnel by automating a critical and often repetitive step, maintaining the structural integrity of the thin specimen sections. The operation is characterized by its high speed and efficiency, enabling laboratories to manage significant slide volumes quickly while adhering to stringent quality benchmarks, which is fundamental for reliable diagnostic preparation.

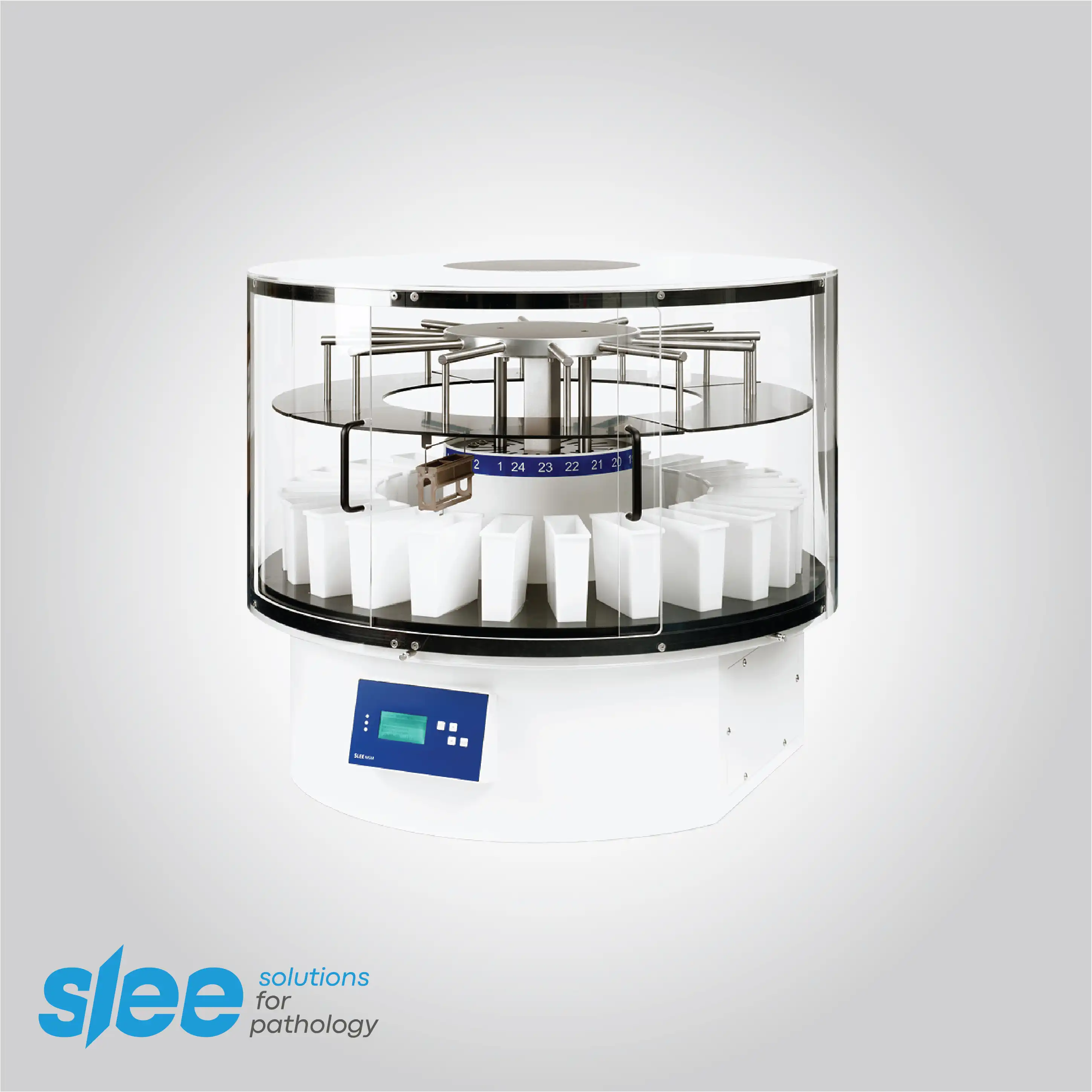

Certain systems are developed with a modular design, allowing for flexible integration into existing laboratory setups, even when operating under budget constraints. This architecture facilitates the seamless automation of the laboratory, utilizing minimal physical space. A key technical feature of some advanced units is the capability for direct, integrated connection to a compatible automated stainer, which dramatically simplifies operational workflows by combining the staining and coverslipping processes into one continuous, streamlined procedure.

High-Speed Throughput Capability

The core technical performance metric of these systems is their high-speed throughput, essential for maintaining efficiency in high-volume pathology settings. Specific apparatuses are designed to achieve a remarkable processing speed, handling slides at a rate of approximately 3 seconds per slide. This results in an overall capacity to safely process up to 1,200 slides within one hour. This exceptional speed and throughput capability is instrumental in reducing turnaround times and significantly elevating the productivity of the laboratory, ensuring quick and safe handling of all processed specimens.

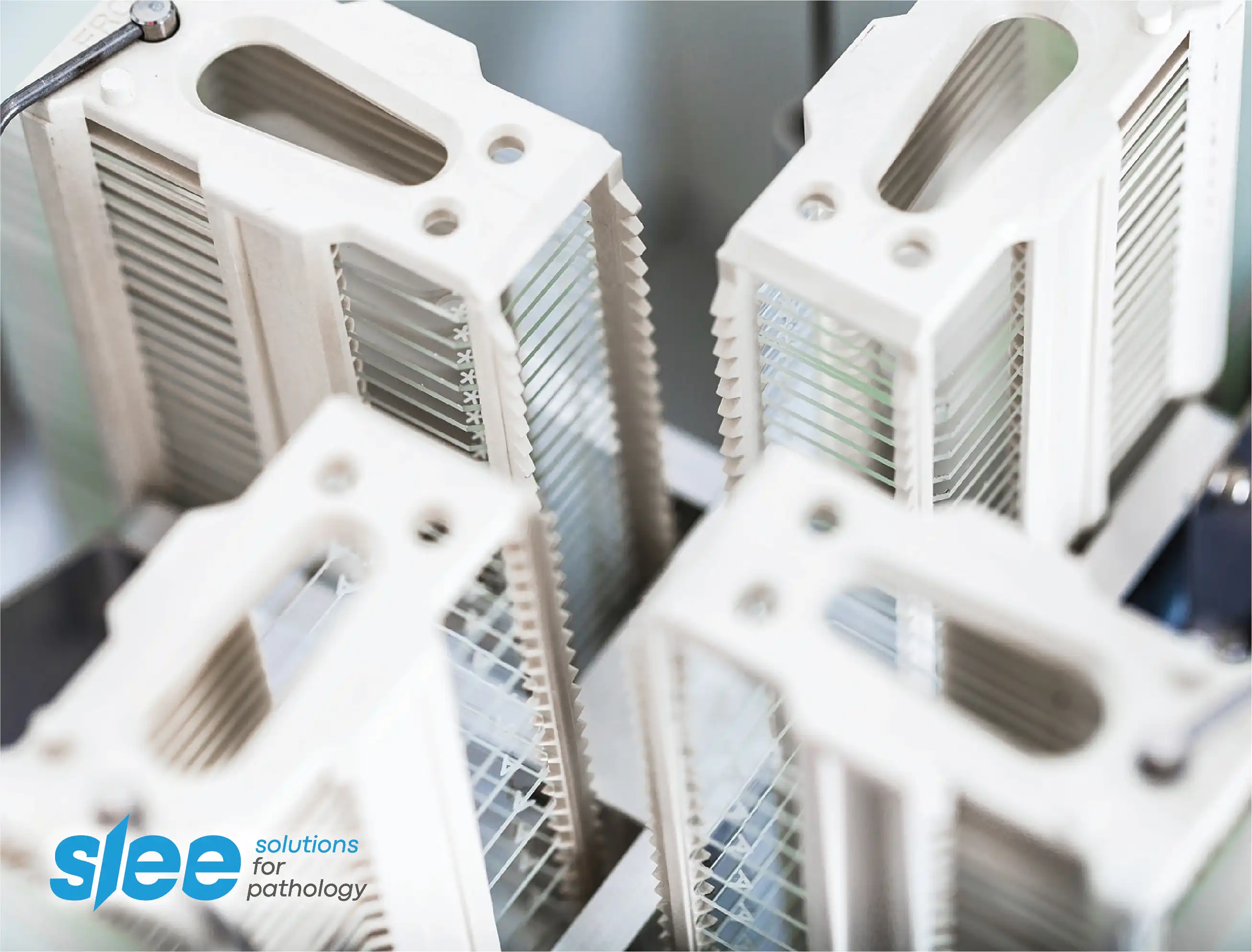

Coverslipping Film Application

The technical mechanism involves the efficient and careful placement of a coverslipping film onto the prepared microscope slides, specifically covering the thin section of the specimen. The use of a film, as opposed to liquid mounting media and glass coverslips, ensures consistency and eliminates issues associated with bubbles or uneven application. The system's engineering guarantees this operation is executed with great precision and accuracy, which is paramount for the subsequent microscopic examination and long-term preservation of the slide, thereby supporting the technical integrity of the diagnostic sample.

Integration with Staining Systems

A significant technical advancement in workflow management is the capacity for certain coverslipping units to be directly connected to compatible automated stainers. This hardwired connection allows for the seamless, one-step execution of staining and coverslipping. By combining these two distinct processes into a unified workflow, the system eliminates the need for manual transfer steps between devices, thereby reducing handling errors, minimizing processing gaps, and fundamentally streamlining the entire post-sectioning procedure to enhance overall laboratory automation.

Modular Design for Laboratory Flexibility

The system employs a modular design which provides inherent flexibility in laboratory configuration. This technical approach allows the coverslipper to be easily integrated into various physical laboratory layouts, maximizing space efficiency and minimizing installation complexity. The modularity also supports laboratories with restricted financial resources or small physical footprints by offering an efficient and adaptable solution for automation. This design choice ensures that high-quality, automated coverslipping is accessible across diverse operational scales and budget parameters.

Compatibility with Standard Slide Baskets

Technical compatibility is maintained through the use of 30 standard slide baskets that are identical to those utilized in compatible automated staining apparatuses. This feature is crucial for maintaining a smooth, uninterrupted workflow. By employing a common standard for slide carriers, the system eliminates the need for manual transfer or re-racking of slides between the staining and coverslipping stages, significantly contributing to the automation and efficiency of the overall process and reducing the potential for specimen mix-ups.

Support for Laboratory Personnel

The automated functionality is engineered to provide substantial technical support to laboratory personnel. By undertaking the highly repetitive and time-sensitive task of coverslipping with great precision and accuracy, the system frees up skilled technicians. This optimization allows staff to concentrate on tasks that require higher levels of cognitive engagement and expertise, such as analysis or protocol development. The system's reliability ensures that the consistency and speed of the final slide preparation are maintained independently of operator fatigue.

Highest Quality Standards Operation

The systems are explicitly stated to operate according to the highest quality standards. Technically, this implies a mechanism that ensures optimal application of the coverslipping film, guaranteeing bubble-free adhesion, uniform coverage, and minimal deviation in placement. This commitment to quality is crucial as the coverslipped slide represents the final, archival form of the diagnostic specimen. The precision engineering supports long-term slide stability and ensures that the prepared slide is immediately suitable for high-resolution microscopic imaging and pathological review.

Automation and Operational Economy

The automation offered by these systems represents a strategic investment in operational economy. By providing a reliable device for high-throughput processing, even in environments characterized by small budgets, the technology maximizes the efficiency of resource utilization. The rapid slide processing rate and the potential for integrated workflow (staining and coverslipping in one step) minimize labor costs and reagent waste, directly translating technical performance into economic benefits. The automation is positioned as a reliable pathway for laboratory modernization and cost-effective operation.

Read more about Slee Products Here