Home » Products » Chromatography/Mass Spectrometry » Liquid Chromatography » Shimadzu Preparative HPLC Systems

Preparative HPLC Systems

Refine high-purity target compounds

Shimadzu Preparative HPLC Systems

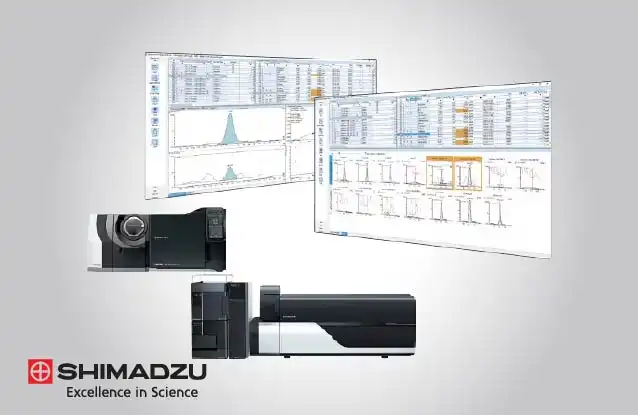

High-purity target chemicals are separated and refined using HPLC from a mixed solution following a synthetic step or from natural extracts. A SFC system uses carbon dioxide as the mobile phase and reveals a number of benefits over conventional HPLC systems, including a reduction in the amount of organic solvent used in the mobile phase of almost 70%, the elimination of the need to evaporate the collected fractions, and enhanced isomer separation abilities.

A preparative system (HPLC or SFC) is used to separate and collect high-purity compounds and in some cases, large quantities of compounds required for subsequent evaluation, analysis, and processing in the shortest possible time.

High-Performance Liquid Delivery Pumps

Shimadzu’s preparative pumps are designed for high-pressure durability and precision flow control. They utilize a parallel double-plunger design that ensures pulse-free solvent delivery, which is essential for maintaining a stable baseline in preparative chromatography. These pumps can handle a wide range of flow rates, from analytical levels up to 150 mL/min or higher, depending on the system configuration, enabling efficient purification across different column internal diameters.

Wide Dynamic Range Detection Systems

To effectively monitor preparative runs where sample concentrations are high, Shimadzu employs detectors with a wide dynamic range. These sensors are technically optimized to prevent signal saturation, allowing the software to accurately track both large main peaks and small impurity peaks simultaneously. Specialized flow cells with shorter path lengths are often utilized to manage the high absorbance of preparative-scale samples, ensuring precise fraction triggering.

Advanced Solvent Recovery Systems

In large-scale purification, solvent consumption can be significant. Shimadzu incorporates solvent recycling valves that automatically divert pure mobile phase back to the reservoir when no peaks are detected. This technical feature not only reduces the cost of operation but also lessens the environmental impact by minimizing chemical waste. The system is programmed to distinguish between baseline noise and actual peaks to ensure that target compounds are never accidentally recycled.

Versatile Injection Strategies and Auto-Samplers

Shimadzu preparative HPLC systems offer multiple injection options, including large-volume loops and direct-on-column injection via a dedicated pump. The automated samplers are designed to handle high-pressure environments and can be equipped with wash functions to eliminate carryover between different purification runs. This versatility allows researchers to process large volumes of dilute samples or high concentrations of crude mixtures with equal efficiency.

Multi-Column Tracking and Method Management

The systems support multi-column configurations where the software tracks the usage history and performance of each preparative column. Integrated column switching valves allow for automated screening of different stationary phases, enabling the rapid identification of the best separation conditions for a specific mixture. This technical capability streamlines method development and ensures that columns are used within their specified pressure and flow limits.

Logic-Based Peak Discrimination and Fractioning

The fractionation software employs advanced logic to differentiate between the target compound and impurities. By using a combination of "Level" (threshold) and "Slope" (rate of change) detection, the system can precisely cut peaks even in complex chromatograms with overlapping components. This high-precision switching ensures that the collected fractions have the highest possible purity and that the recovery rate is maximized for high-value compounds.

Integrated Preparative SFC Options

In addition to standard HPLC, Shimadzu provides Supercritical Fluid Chromatography (SFC) systems for preparative use. These systems utilize liquid CO2 as a mobile phase, which offers high diffusion coefficients and low viscosity. Technically, this allows for much faster separation times and simplified sample recovery, as the CO2 evaporates upon collection, leaving the purified compound in a small volume of organic modifier.

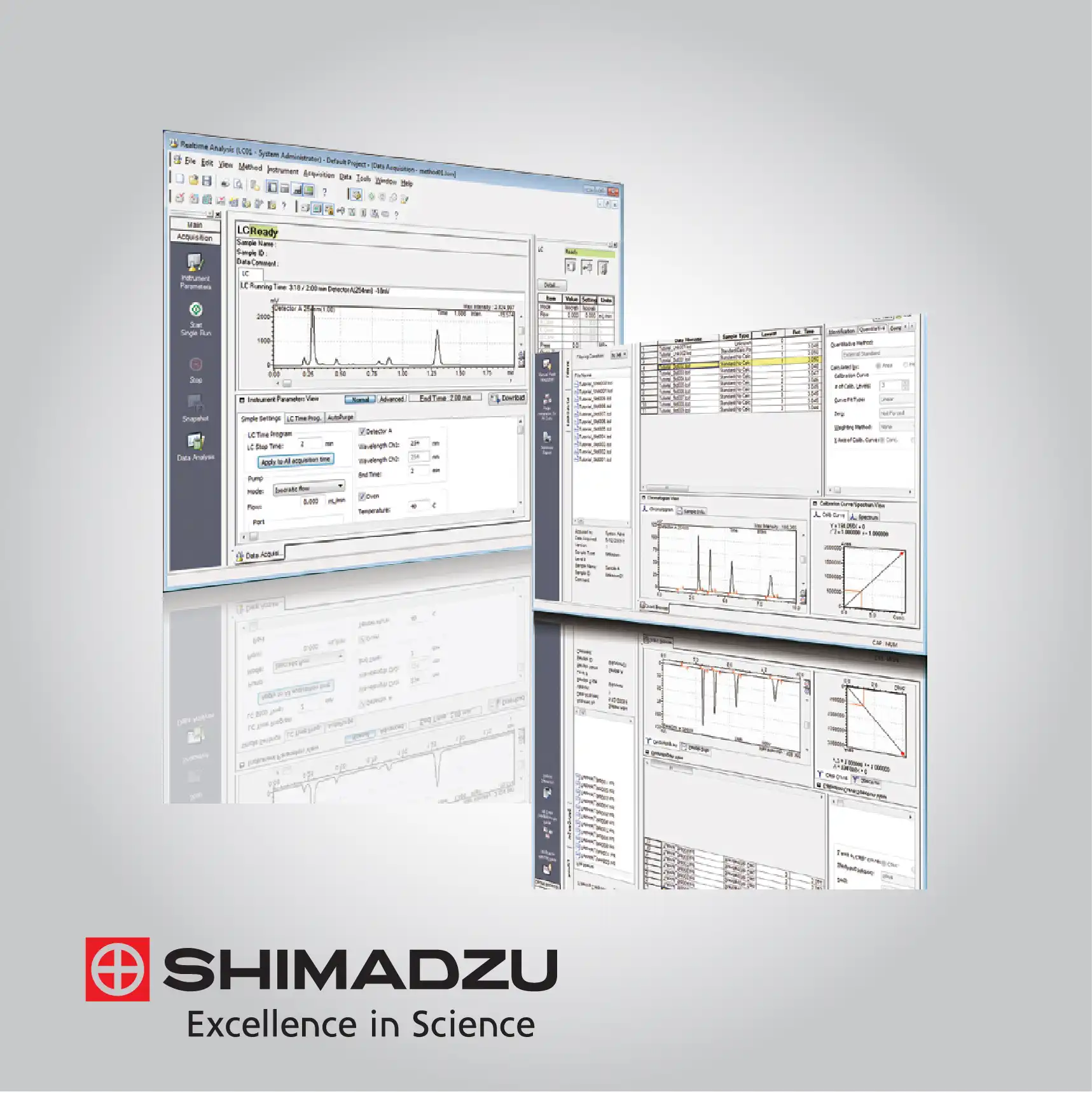

Robust Software for Data Integrity and Compliance

All preparative workflows are managed by a centralized software platform that ensures data integrity and traceability. The software records every parameter of the purification run, including pressure profiles, gradient curves, and fraction locations. For laboratories operating in regulated environments, the system supports full audit trails and user access management, ensuring that all purification processes are documented and compliant with international standards.

Read more about Shimadzu Preparative HPLC Systems here

Related Products

CONTACT US

CONTACT US

Taawon for Laboratory & Scientific Supplies

Taawon Group © 2026 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience