.webp)

Home » Products » Chromatography/Mass Spectrometry » Elemental Analysis » Shimadzu Energy Dispersive X-ray Fluorescence Spectroscopy

Energy Dispersive X-ray Fluorescence Spectroscopy

Analytical Integrity and Non-Destructive Precision

Shimadzu Energy Dispersive X-ray Fluorescence Spectroscopy

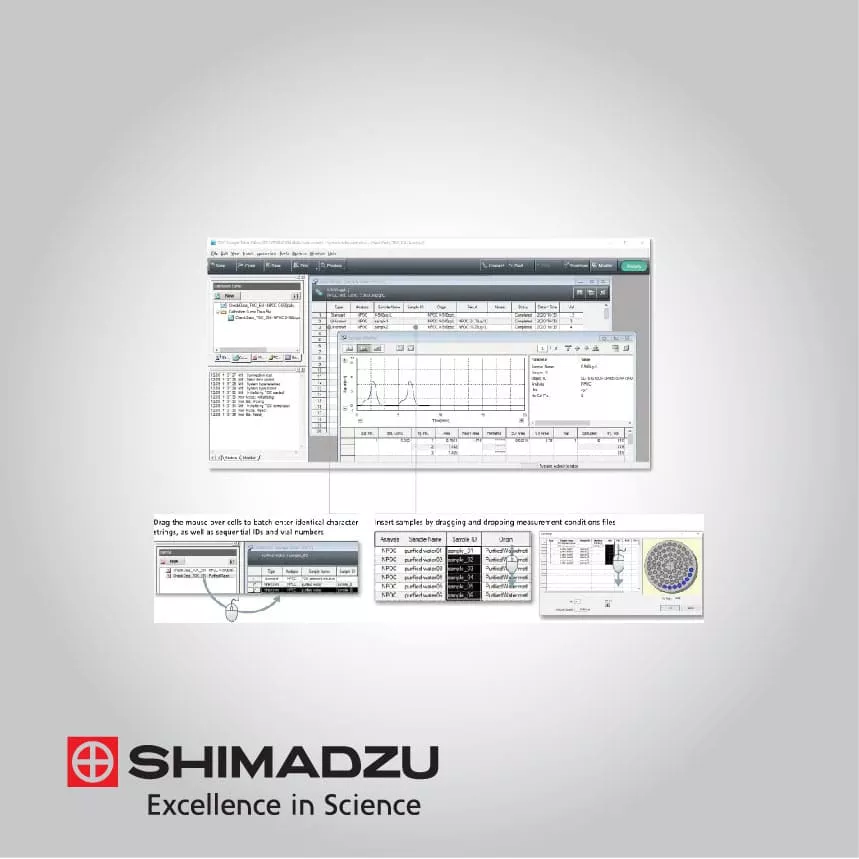

The technical architecture of these EDXRF solutions is specifically optimized for high-throughput screening and compliance with international regulations such as RoHS/ELV. The software integrates automated "pass/fail" judgment functions that compare detected concentrations against pre-defined regulatory limits. Technically, the systems utilize primary filters to improve the signal-to-noise ratio for specific trace elements like Lead, Cadmium, and Mercury.

Combined with a large sample chamber and automated turret options, the technology enables the simultaneous analysis of multiple samples, providing detailed elemental mapping and thickness measurements for plating and thin films in a secure, traceable data environment.

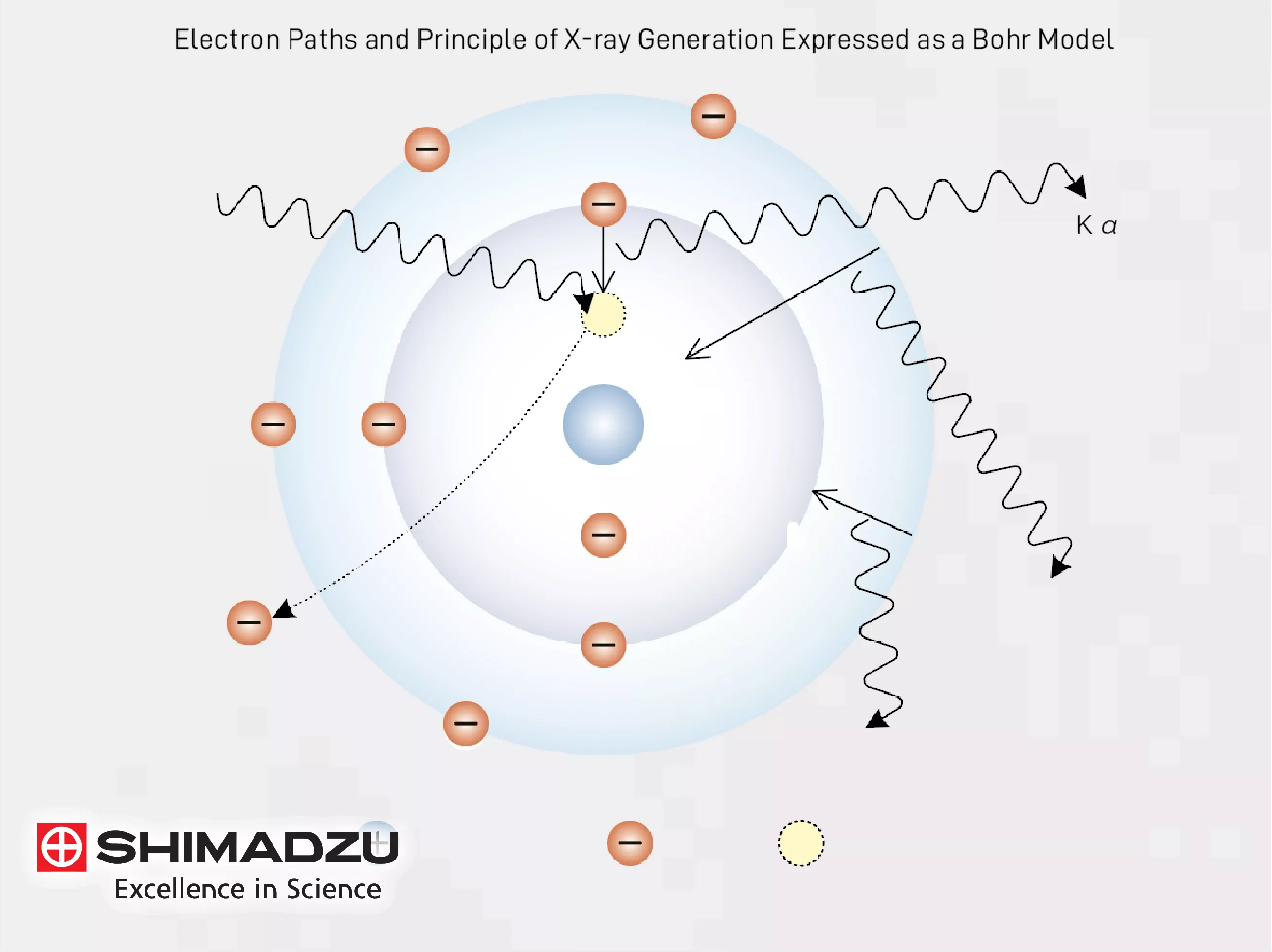

High-Resolution Silicon Drift Detector (SDD) Performance

The core of the EDXRF system is the high-performance Silicon Drift Detector (SDD). Technically, the SDD is designed to handle extremely high count rates while maintaining superior energy resolution. This allows the system to distinguish between closely spaced fluorescent peaks, which is essential for accurate qualitative analysis in samples containing complex mixtures of heavy metals. The detector's high sensitivity also enables shorter measurement times, significantly increasing laboratory throughput.

Primary X-ray Filters for Signal Enhancement

To improve the detection limits of specific elements, the system utilizes an automated primary filter changer. Technically, these filters are placed between the X-ray tube and the sample to suppress background scatter or enhance the excitation of particular target elements. For example, using a specific filter can significantly improve the sensitivity for trace amounts of Cadmium or Lead by reducing the interference from the X-ray tube's characteristic lines.

Vacuum and Helium Atmosphere Options

For the analysis of light elements such as Sodium, Magnesium, and Aluminum, the system provides vacuum or helium atmosphere options. Technically, atmospheric air absorbs the low-energy fluorescent X-rays emitted by light elements, making them difficult to detect. By evacuating the sample chamber or purging it with helium, the X-ray path is cleared of absorbing gases, dramatically enhancing the sensitivity and precision for light element quantification in both solid and liquid samples.

Large Sample Chamber and Automated Turret

The technical design features a spacious sample chamber capable of accommodating large or irregularly shaped objects without the need for cutting or destructive sampling. For high-throughput requirements, an automated turret or sample changer can be integrated. This allows for the sequential analysis of multiple samples unattended, where the software manages the positioning and measurement parameters for each individual sample, ensuring consistent results across large batches.

Non-Destructive Thin Film and Plating Analysis

Beyond elemental concentration, EDXRF is technically capable of non-destructive plating thickness measurements. By analyzing the intensity of X-rays from both the coating and the substrate, the software calculates the thickness and composition of thin films. This is a critical technical application in the electronics and automotive industries, where the integrity of multi-layer coatings must be verified without damaging the finished component.

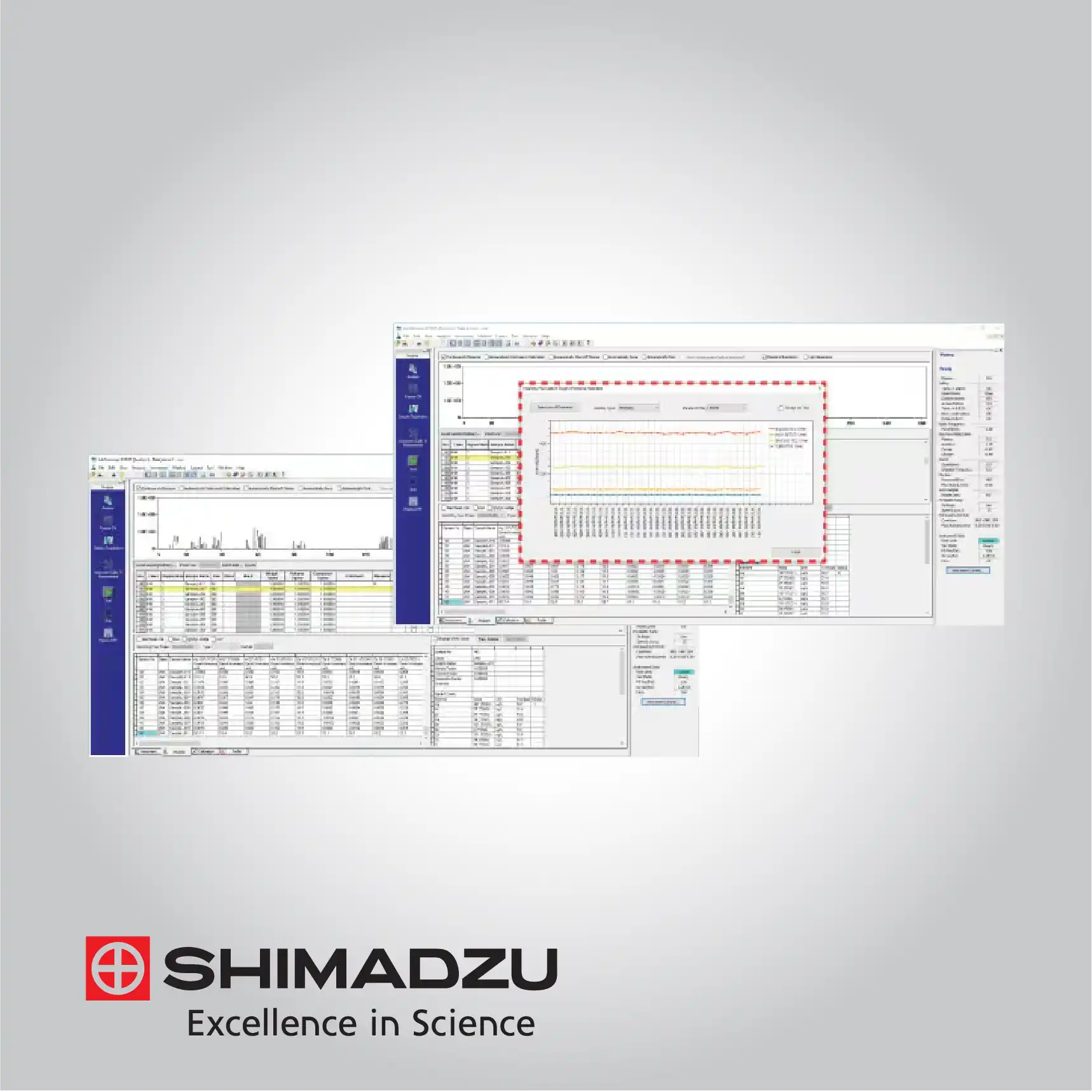

Automated RoHS/ELV Screening Functions

The software includes specialized modules for RoHS/ELV screening, technically designed to automate compliance testing. Users can set threshold values for regulated substances, and the system provides an immediate "Pass," "Fail," or "Gray" (manual review required) judgment after the analysis. This automated logic includes internal standard corrections and matrix matching, ensuring that the results are reliable even when testing diverse plastic or metal components.

Background Independent Fundamental Parameter (FP) Method

For quantitative analysis without the need for numerous standard samples, the system employs the Background Independent Fundamental Parameter (FP) method. Technically, this algorithm uses theoretical physical equations to calculate concentrations based on the measured X-ray intensities. It accounts for matrix effects such as absorption and secondary excitation between elements, providing accurate quantitative results for unknown samples where matching standards are unavailable.

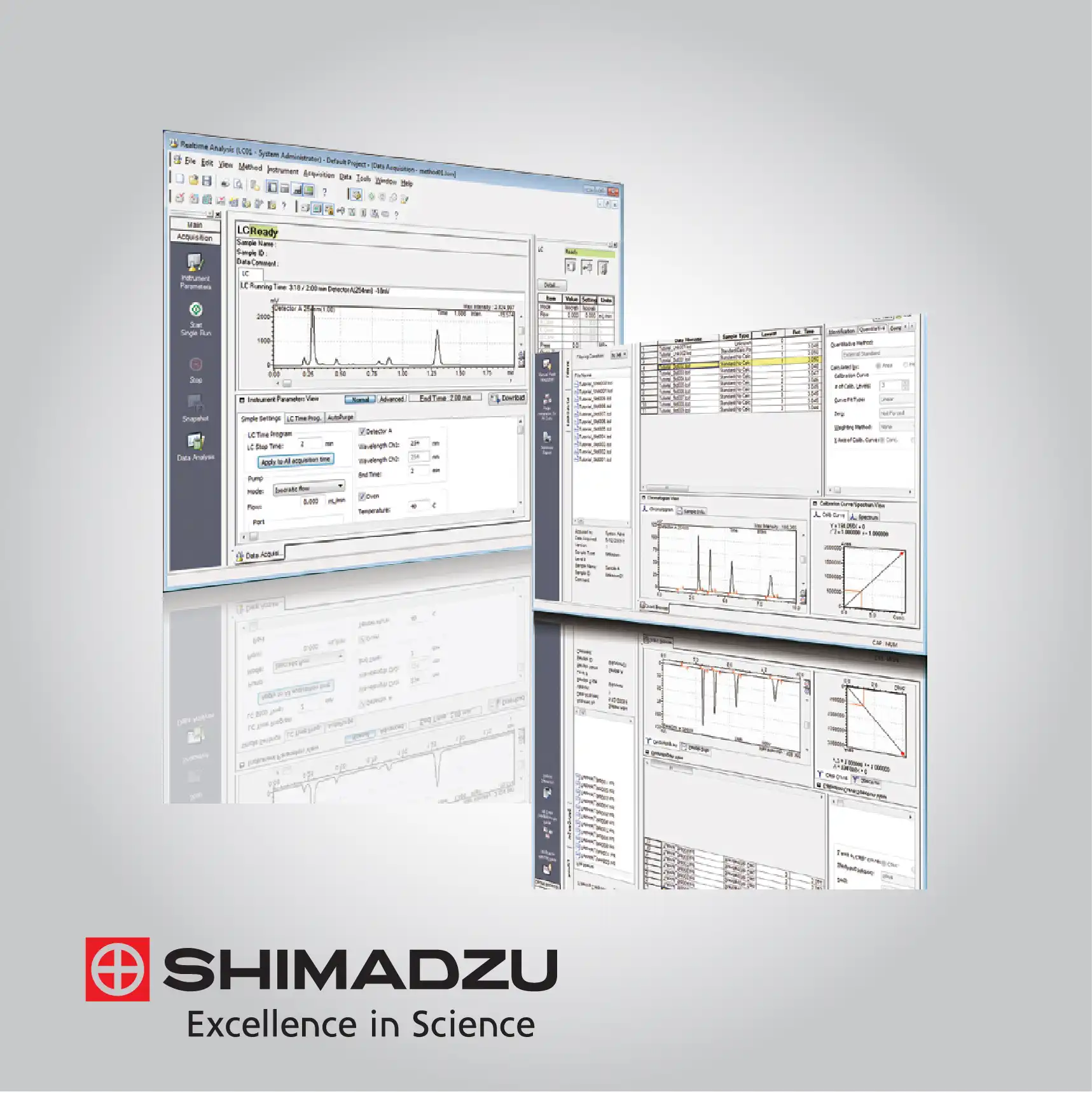

Integrated CCD Camera for Precise Spot Analysis

To ensure accurate measurement of small areas or specific features on a sample, the systems are equipped with a high-resolution CCD camera. Technically, this allows the operator to visually identify the analysis point and align the X-ray beam using automated collimators. This capability is essential for analyzing small electronic parts, inclusions in minerals, or specific areas of forensic evidence, providing a clear correlation between visual morphology and elemental composition.

Click here for more information about Shimadzu range of products

Related Products

CONTACT US

CONTACT US

Taawon for Laboratory & Scientific Supplies

Taawon Group © 2026 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience