Home » Products » Material Preparation, Analysis, and Testing » Hardness Testing Systems » Buehler Rockwell

Depth-Sensing Hardness Testing

Rockwell Regular and Superficial

Buehler Rockwell

The Rockwell hardness test is fundamentally a depth measurement method, contrasting sharply with optical-based techniques like Vickers and Knoop. The principle involves measuring the difference in the depth of penetration of an indenter (either a diamond cone or a tungsten carbide ball) under the application of a minor (preload) and a major (main) load. This differential depth is directly converted into a hardness number, providing a rapid, direct reading that makes the technique highly favored in production and quality control environments.

Modern Rockwell testing instruments are engineered for durability and high-volume operations, designed to function reliably on production floors and within research facilities worldwide. They are built to comply with rigorous international standards, including ASTM E18 and ISO 6508. Key technical features include a high-precision depth measurement system, motorized test cycles, and advanced data handling capabilities such as integrated USB ports for direct data transfer.

Mitigating Inaccuracy from Manual Load Application

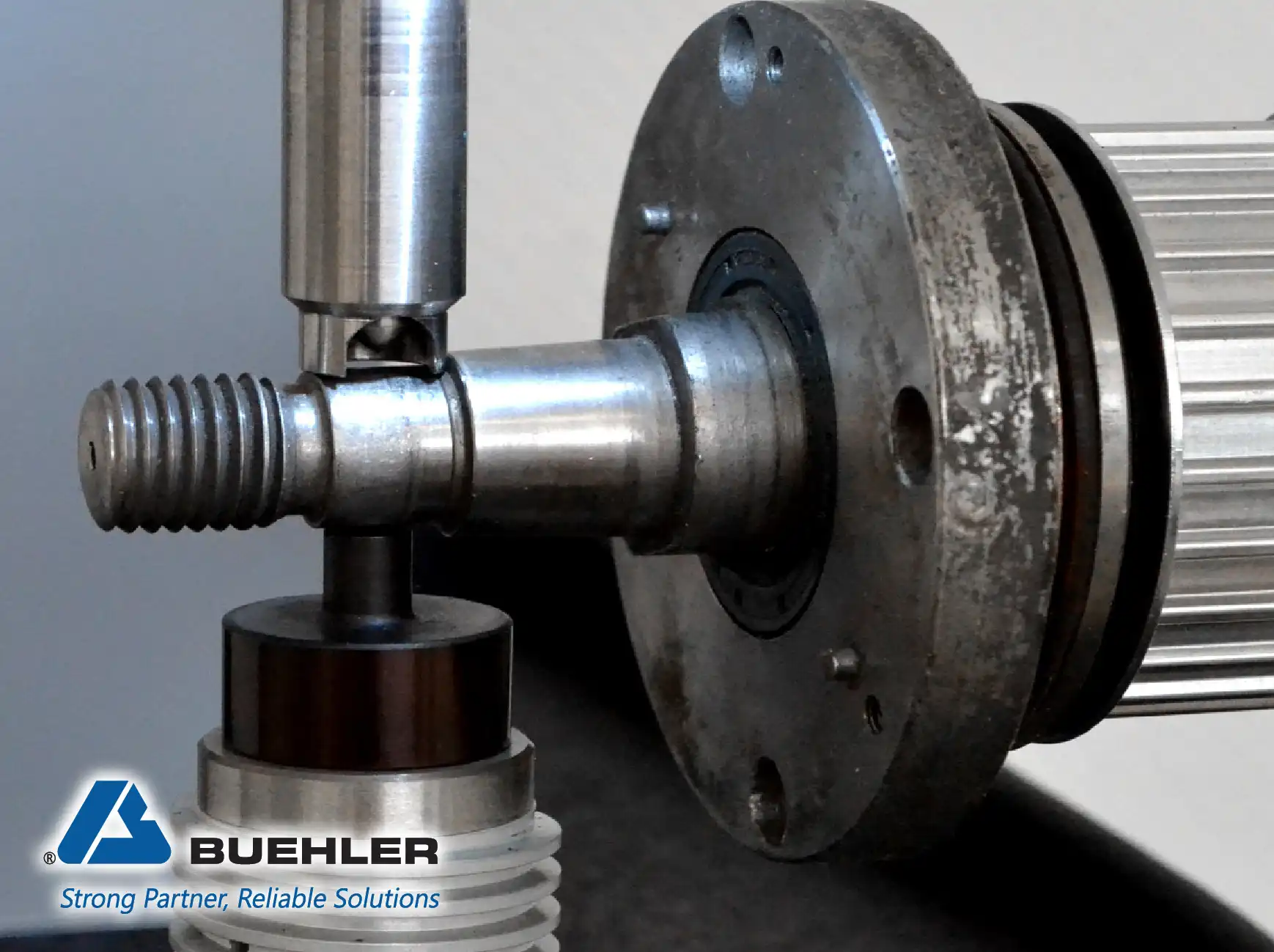

Traditional hardness testers often rely on manual mechanisms for load sequencing, which can introduce inconsistency, especially in the critical main load phase. Advanced Rockwell systems address this by featuring a fully automated main load test cycle coupled with an auto preload brake. This ensures the precise and immediate application and removal of the load according to the strict timing requirements of the test standards, significantly enhancing the accuracy and repeatability of the depth measurement.

Solving the Need for Versatility in Material Thickness

Materials requiring hardness assessment can vary significantly in thickness, from thin case-hardened layers to bulk components. Relying solely on Regular Rockwell scales risks penetrating the substrate on thin parts. Testers offering Regular and Superficial Twin Scale models resolve this by allowing the operator to select the appropriate force combination (e.g., 15N, 30N, 45N for Superficial) and indenter size, ensuring the test is confined to the specific layer of interest while adhering to the standard’s penetration depth limits.

Achieving Superior Consistency in Production Testing

A primary objective in manufacturing quality control is minimizing Gauge Repeatability and Reproducibility (GR&R) errors among different operators and test cycles. The fundamental design of high-quality Rockwell testers, featuring a deadweight, closed-loop (implied by high GR&R) control system and robust construction, delivers best-in-class GR&R. This technical focus on mechanical stability and depth-sensing precision ensures that the results are consistent and reliable across the production line, minimizing material classification errors.

Simplifying Data Handling and Reporting in High-Volume Labs

Converting numerous test results into actionable quality reports is a manual, error-prone process. This challenge is overcome by integrating user-friendly, built-in USB ports for rapid data transfer. This feature allows seamless integration with common spreadsheet software or dedicated hardness testing software, enabling fast, error-free analysis, storage, and report generation without the need for manual transcription, thus maximizing sample throughput.

Ensuring Sample Stability and Protection During Testing

Testing large or uniquely shaped production components can lead to instability under the main load, which compromises the depth measurement accuracy. High-capacity testers (offering up to 14-inch vertical capacity) address this by incorporating robust fixtures, such as an auto-stop clamping device. This mechanism secures the specimen firmly prior to load application, preventing any movement during the critical indentation phase, thereby protecting the integrity of the depth measurement system and the test result.

Maintaining System Durability in Harsh Production Environments

Production floors are often characterized by airborne debris, temperature fluctuations, and continuous operation, which can degrade sensitive testing components. The engineering solution is a proven robust design featuring durable components, a protective sheet metal casing, and load cell protection. This rugged construction is specifically tailored for continuous, high-volume efforts, ensuring the instrument maintains its calibration and up-time in demanding operational conditions.

Improving Testing Flexibility for Specialized Components

Accessing complex or recessed areas of a component with a standard indenter can be difficult or impossible. Specialized testers anticipate this by offering features like optional indenter extensions and wide vertical capacity. This allows the system to accommodate non-standard geometries and larger parts, increasing the range of components that can be certified for hardness without requiring destructive sectioning or complex fixturing.

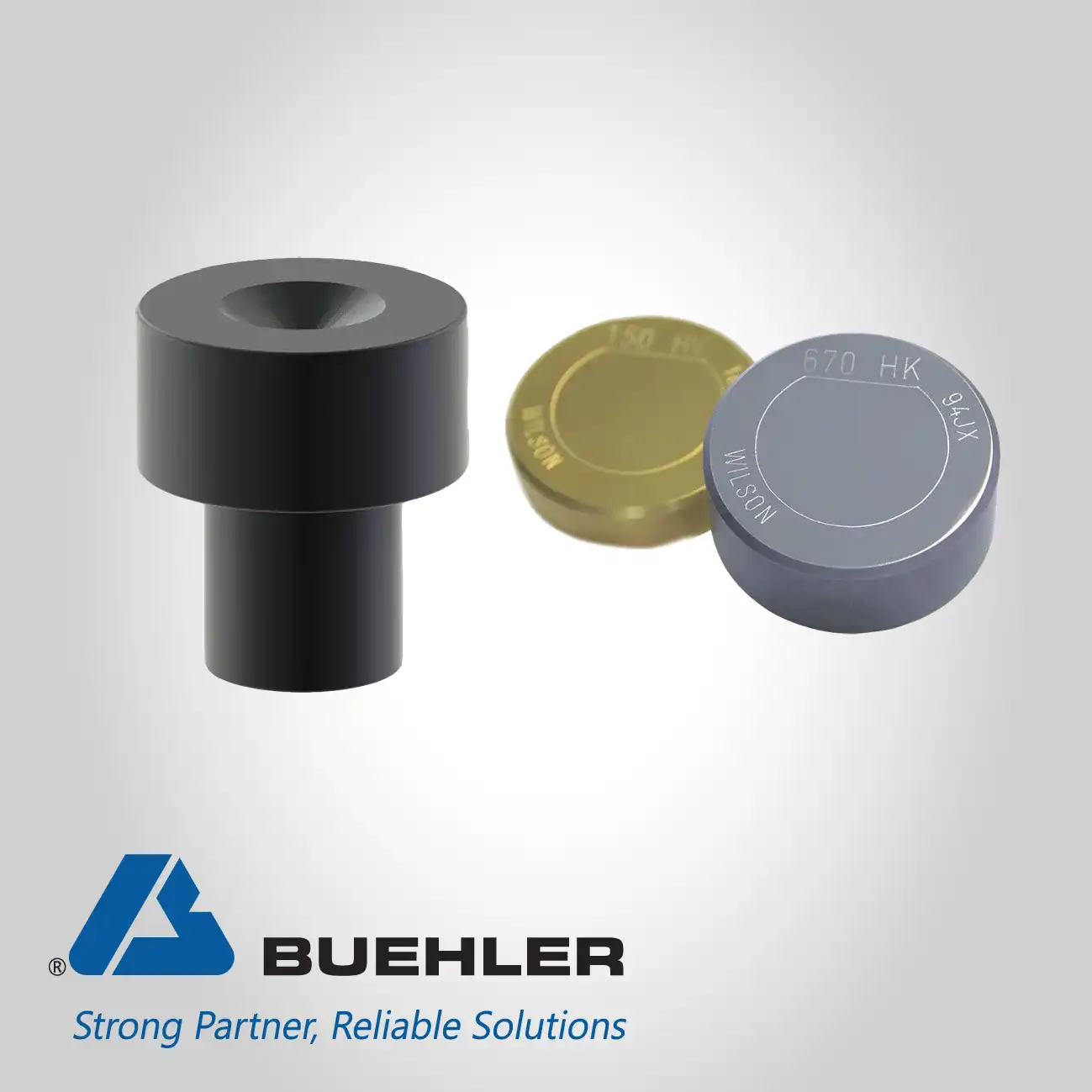

Guaranteeing Accuracy Through Traceable Calibration

The accuracy of the depth-sensing mechanism is critically dependent on calibration standards. The use of precisely manufactured test blocks and calibration sets is essential. These blocks are manufactured from top-quality materials under stringent control to ensure uniformity, flatness, and parallelism and are calibrated in an accredited ISO-IEC 17025 lab, ensuring the reference standards meet or exceed the requirements of ASTM E18 and ISO 6508 for ultimate measurement confidence.

Click here to know more about Buehler products

.webp)