Home » Products » Material Preparation, Analysis, and Testing » Hardness Testing Systems » Buehler Brinell

High-Load Indentation Testing

Brinell Hardness for Bulk Materials

Buehler Brinell

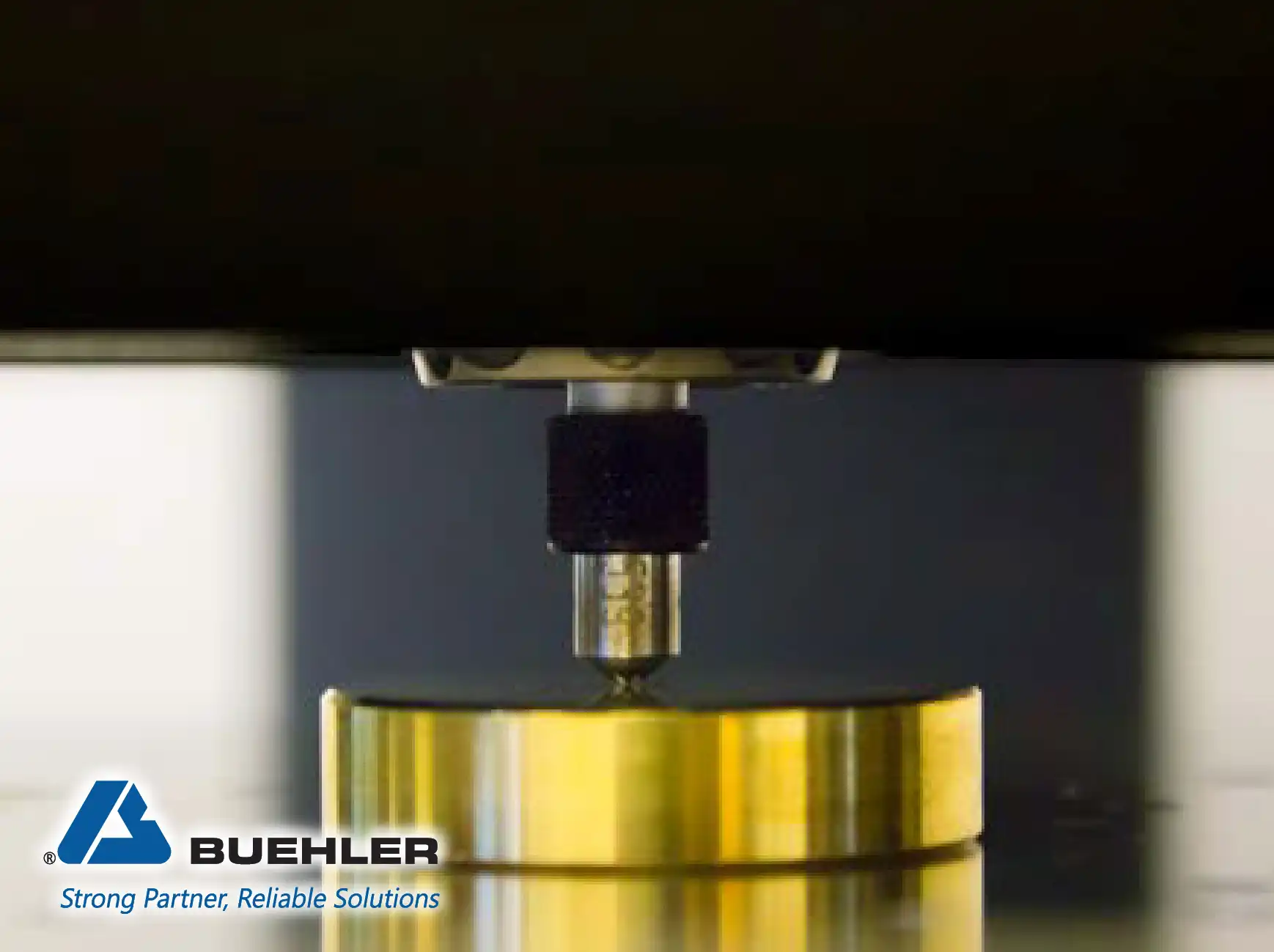

The Brinell hardness test is characterized by the use of a large, spherical tungsten carbide ball indenter and the application of very high test loads, typically ranging up to 3000 kgf. This methodology is uniquely suited for testing materials with coarse grain structures, such as engine castings and large-diameter piping, where the resulting indentation diameter must be large enough to average the hardness over multiple microstructural features.

Modern Brinell systems are engineered for durability and high load capacity, making them ideal for challenging industrial environments. They incorporate closed-loop control technology to ensure the applied force is both quick and precise, eliminating the inaccuracies associated with traditional weight-based systems. These testers offer a wide load range, often spanning from 62.5 kgf up to the maximum 3000 kgf, providing exceptional versatility for diverse applications including the testing of aluminum, copper alloys, steels, and cast irons.

Ensuring Representative Testing for Large, Heterogeneous Components

When testing large parts or materials with local variations (e.g., castings, forgings), small indentations yield misleading data. Brinell testers address this by applying high loads (up to 3000 kgf) and using large ball indenters to create a large indentation diameter. This ensures the measured hardness number is a statistical average representative of the material's bulk properties and overcomes the challenge of local variations influencing the result.

Maintaining Accuracy Across a Broad Spectrum of Materials

The Brinell method requires maintaining a specific ratio between the load (P) and the square of the ball diameter (D²). To accurately test materials ranging from soft copper to hard steel while preserving this geometric similarity, the tester must offer a flexible and wide load range (62.5 kgf to 3000 kgf). This capability allows the operator to select the appropriate load for the material's hardness, ensuring that the test is compliant with the standard and the results are comparable across different material types.

Improving Readability and Precision for Large Indentations

Manually measuring the diameter of a large Brinell indentation can be challenging due to surface imperfections and the need for high accuracy. This is resolved by offering advanced reading accessories, such as a deep reading microscope option. This specialized optical tool enhances the precision and clarity of the diameter measurement, allowing operators to accurately determine the indentation size and, consequently, the correct Brinell Hardness Number (BHN).

Eliminating Inaccuracies from Uncontrolled Load Application

Variability in the test force application, common in open-loop or manual systems, introduces unacceptable errors in the final BHN calculation. High-performance Brinell testers use a closed-loop system which continuously monitors and adjusts the force throughout the testing cycle. This technology ensures the load is applied quickly and maintained precisely for the required dwell time, guaranteeing accurate and repeatable test results essential for certifying component quality.

Ensuring Stability and Safety for Testing Large Components

Testing heavy, large components in a production setting requires a robust mechanical solution to prevent movement during the high-load application. The machines are engineered with rugged construction and heavy-duty clamping devices. This robust mechanical design secures the oversized parts firmly against the anvil, ensuring specimen stability and preventing any motion that would compromise the geometric integrity of the indentation.

Simplifying the Calculation and Conversion Process

The necessity of manually calculating the Brinell Hardness Number from the measured diameter and performing conversions to other scales is time-consuming and prone to calculation error. Modern systems integrate automatic hardness calculations and conversions directly into the machine interface. This feature streamlines the process, providing the final BHN immediately and facilitating quick comparison with other established scales without manual interpolation or charting.

Maximizing Operational Up-time in Industrial Settings

Industrial testing environments often subject equipment to constant use and sometimes harsh conditions. The testers are designed with durability and protection as a priority, utilizing features that safeguard sensitive internal mechanisms. This focus on heavy-duty engineering minimizes the probability of mechanical failure, ensuring ease of set-up and maximizing the time the tester is available for production-critical tasks.

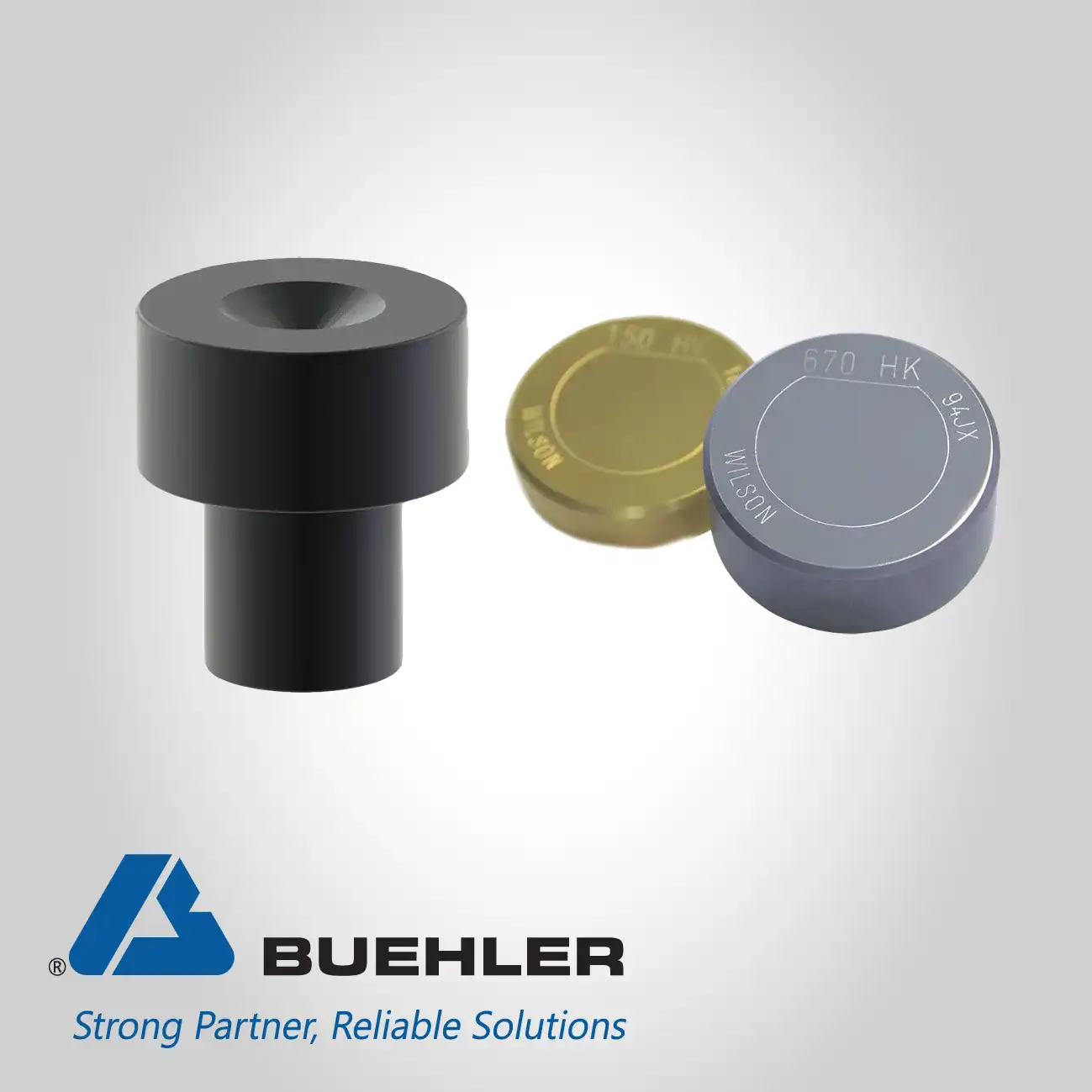

Ensuring Calibration Traceability and Compliance

The foundation of reliable Brinell testing rests on the use of certified reference standards. The systems rely on high-quality Brinell Hardness Test Blocks which are specifically manufactured and calibrated for various loads (e.g., up to 250 kgf). These blocks comply with international standards such as ASTM E10 and ISO 6508, providing a guaranteed, traceable standard against which the performance of the testing machine can be verified and maintained.

Click here to know more about Buehler products

.webp)