Home » Products » Material Preparation, Analysis, and Testing » Hardness Testing Systems » Buehler Universal Hardness Testing

Hardness Testing Platform

Comprehensive and Multi-Method

Buehler Universal Hardness Testing

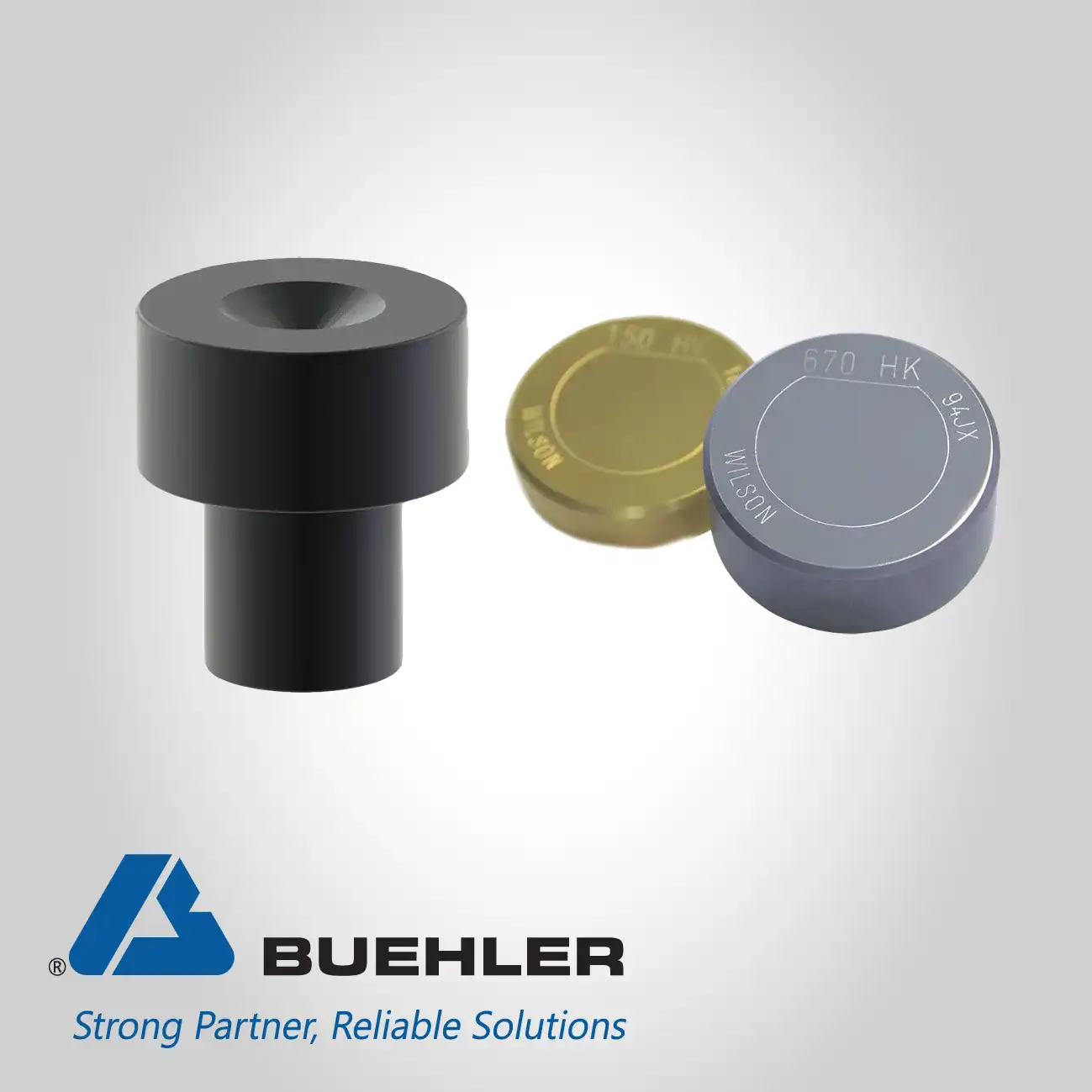

Universal hardness testers represent the pinnacle of flexibility in material characterization, integrating the capabilities of multiple distinct hardness methods—Rockwell, Vickers, Knoop, and Brinell—into a single, unified platform. This all-in-one approach is specifically built to address the highly varied testing demands encountered in both high-volume production floors and advanced research laboratories where different samples necessitate different test methods based on material composition, geometry, and thickness.

These systems are engineered to provide complete test flexibility, often featuring a multi-position turret (e.g., an 8-position turret) to accommodate the various indenters and optics required for each standard (ASTM and ISO). Crucially, the internal construction, typically featuring a durable steel casting, is designed to sustain continuous operation and withstand the high loads associated with methods like Brinell, minimizing service costs and increasing operational up-time.

Overcoming the Need for Multiple Dedicated Testing Units

Laboratories often face the challenge of needing four distinct hardness testers (Rockwell, Brinell, Vickers, Knoop) to satisfy a diverse range of standards and material types, leading to high capital expenditure and space constraints. Universal testers resolve this by consolidating the entire range of standard indentation methods onto a single machine. This flexibility is achieved through an 8-position turret which accommodates all necessary indenters and objectives, making the unit inherently versatile.

Managing Complex Test Parameters and Operator Error

Switching between hardness methods requires precise changes in indenter, load, and measurement technique, which is prone to manual error and setup delay. The Universal tester addresses this by being entirely controlled through DiaMet software. This centralization enables the system to handle the complexity, automatically selecting the correct parameters, performing load applications, and calculating results, ensuring a fast and simple operation even when maintaining the complexity required by expert users.

Ensuring Accuracy and Repeatability Across All Load Ranges

Combining micro-loads (Vickers/Knoop) with very high loads (Brinell up to 3000 kgf) requires an extremely robust and precise load application system. These testers utilize advanced mechanics (inferred from the Universal nature) to accurately deliver forces across the full spectrum. This critical control over force application guarantees the precision and stability needed for reliable results, regardless of the test scale being performed.

Standardizing Data Management and Reporting

Running tests on multiple dedicated machines often results in fragmented data stored across various platforms, complicating reporting and traceability. The Universal system’s integration with DiaMet software provides a centralized hub for all test results—Rockwell, Brinell, Vickers, and Knoop. This allows for seamless data storage, analysis, and the generation of complete, customizable reports, streamlining the quality documentation process.

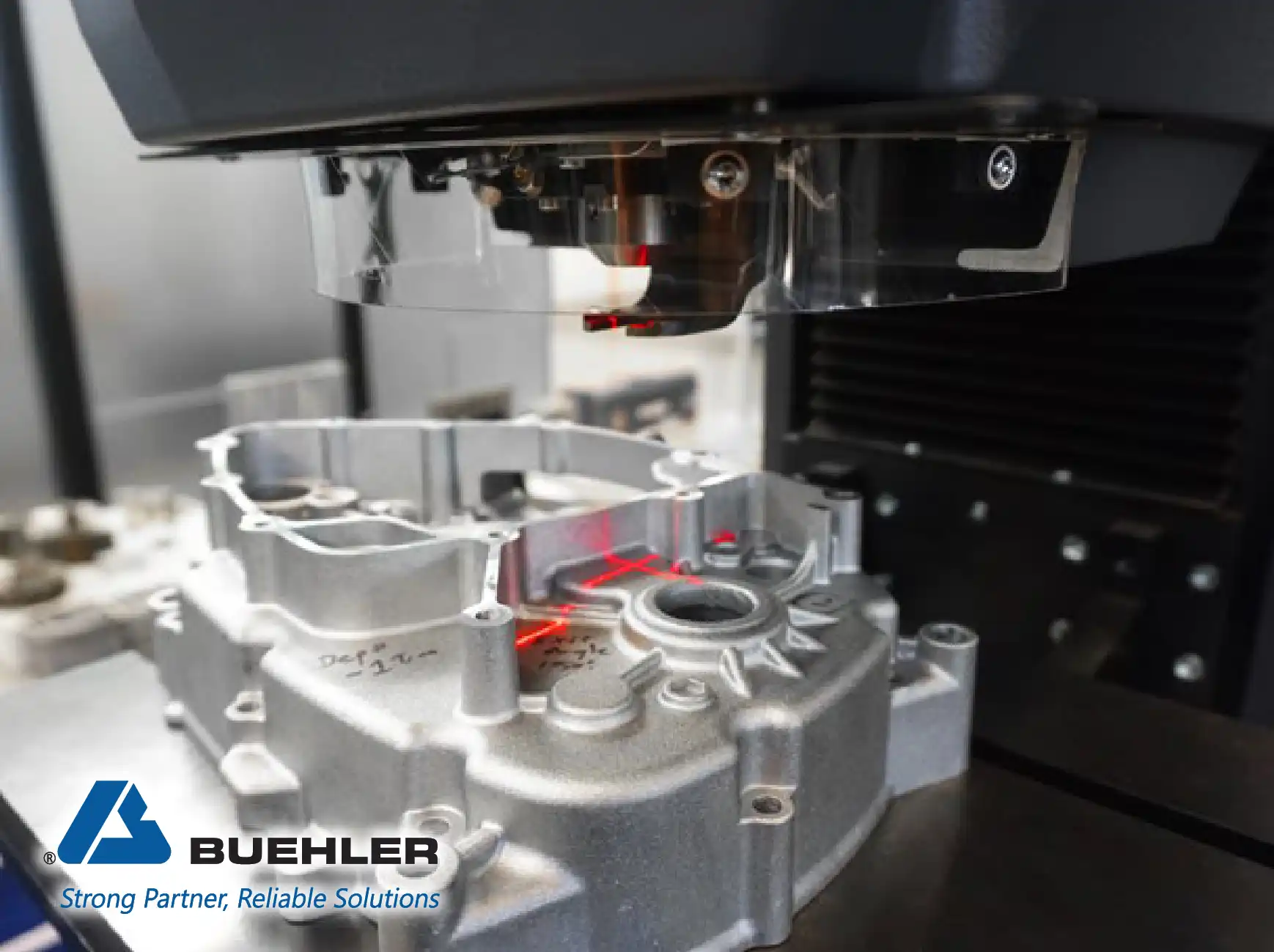

Achieving Precise Targeting and Measurement on Large or Complex Samples

Accurately placing an indentation, especially a Brinell ball on a large component, can be difficult. Universal testers enhance targeting by including a laser for precise targeting and a ring light for accurate Brinell measurements. These features guide the operator to the exact test location and ensure optimal illumination for optical measurement, even on challenging or rough surfaces.

Maximizing Operational Up-time and Minimizing Maintenance Costs

Continuous high-volume testing, especially involving macro-loads, places high stress on the machine's frame and mechanical components. The Universal tester is built with a steel casting structure, which provides durability and inherent stability. This robust construction is essential for minimizing long-term wear and tear, which directly reduces service costs and maintains high up-time in demanding production environments.

Ensuring Sample Stability During High-Load Testing

The application of heavy Brinell loads requires the sample to be rigidly held to prevent movement, which would compromise the indentation geometry. To counter this, Universal testers offer an optional clamping tool for stability. This specialized fixturing secures the sample firmly prior to the test cycle, guaranteeing that the geometry of the indentation is preserved, leading to accurate and valid results.

Meeting the Needs of Both Novice and Expert Operators

Instruments that are highly capable are often overly complex for new users, leading to high training costs and potential misuse. The design of these systems focuses on fast and simple operation for novices while simultaneously maintaining the complexity of features required by experts. This intuitive workflow, controlled by the software interface, significantly reduces the barrier to entry and ensures the machine can be utilized effectively by a wide range of laboratory personnel.

Click here to know more about Buehler products

.webp)