Home » Products » Mechanical Testing » Universal Testing Systems » Instron Custom Universal Testing Machines

Creating the perfect engineered solution

Fit the mold of a standard frame

Instron Custom Universal Testing Machines

Special Solutions Engineered to Meet Your Unique Testing Needs

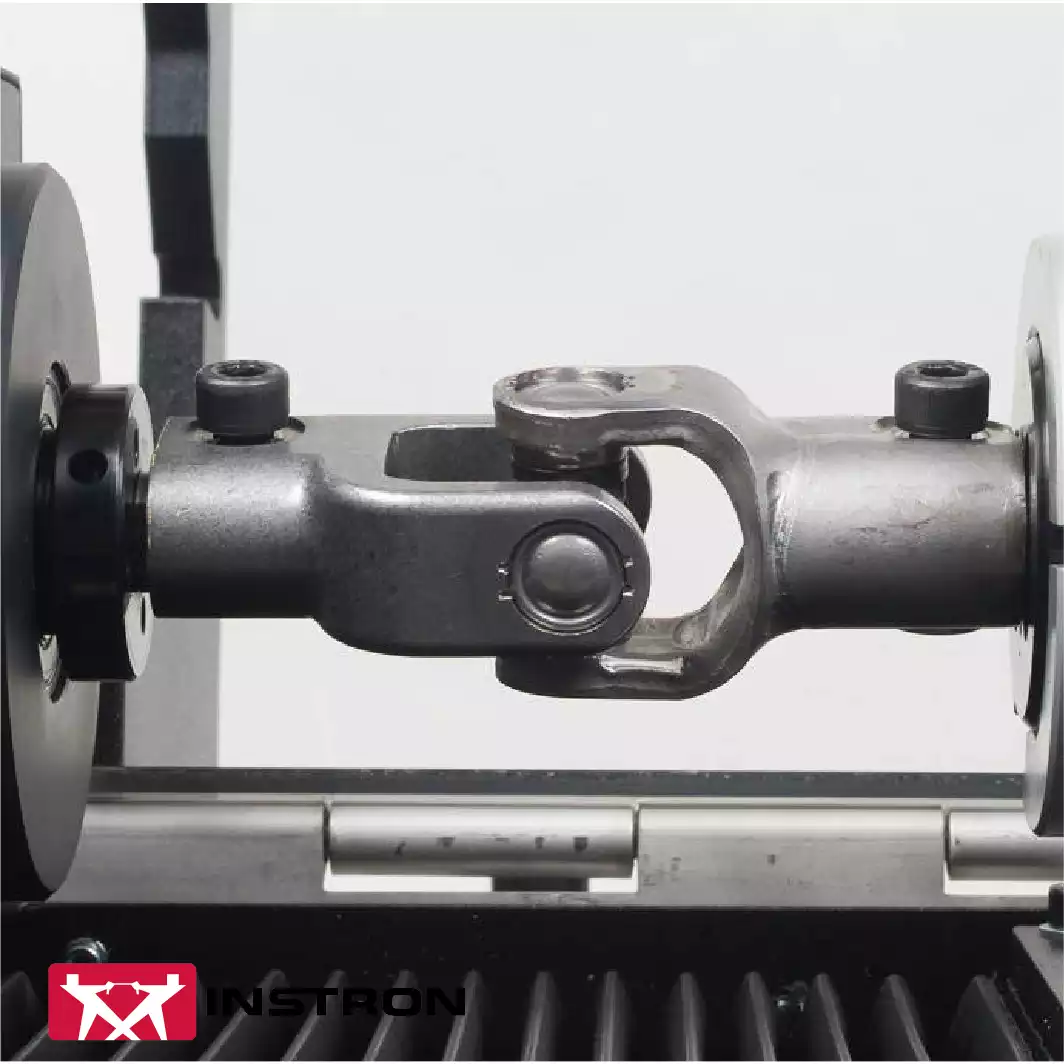

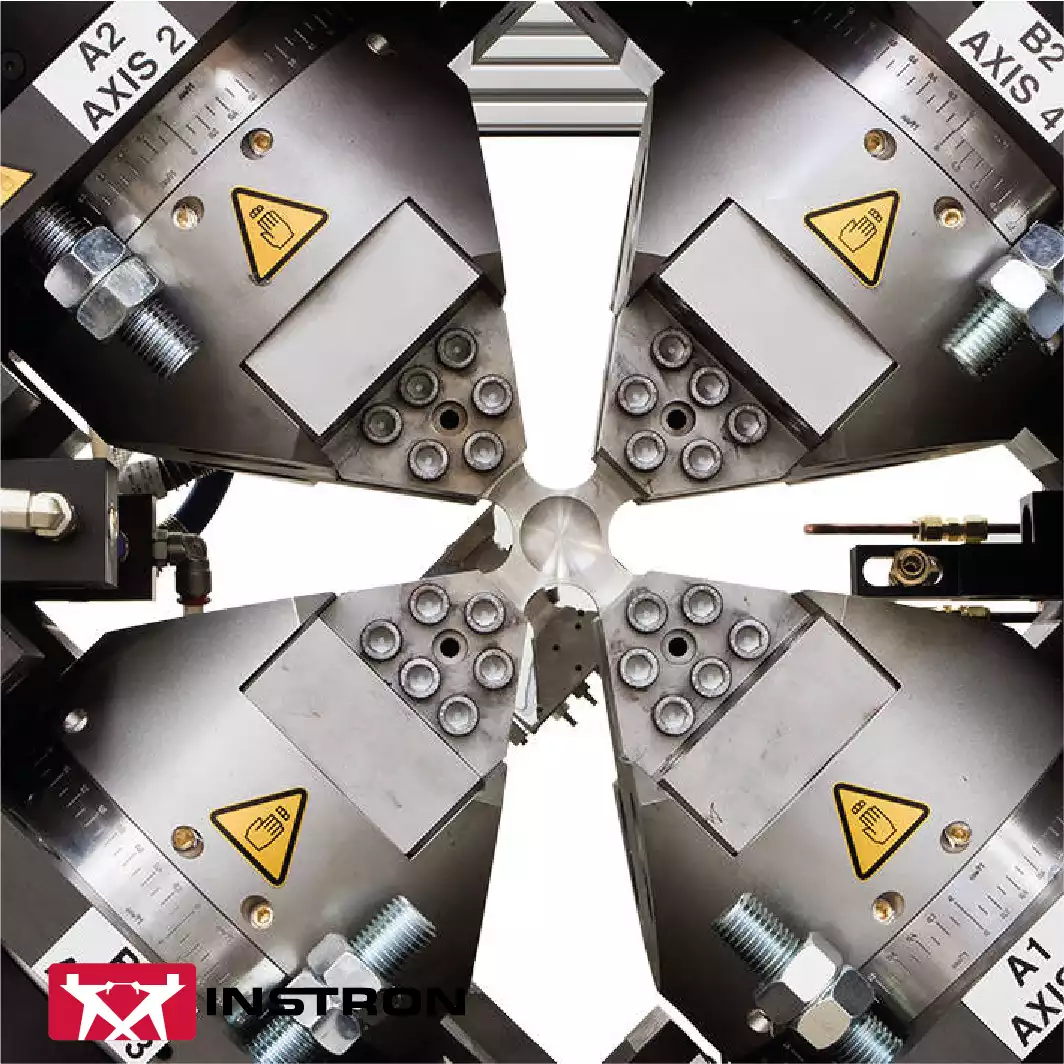

Custom Height and Width

Instron has a long history of working with customers to create specially sized frames. To accommodate industrial boxes, concrete components, and transmission pipeline, we have created frameworks that are both tall and wide. We will make every effort to learn about your needs as a new or existing customer and to fulfill those needs completely.

Custom Safety

For decades, Instron has been producing one-of-a-kind security answers for our customers. We can assist you in making your laboratory as secure as possible, which is of paramount importance in laboratories everywhere. We will put in the time and effort necessary to learn about your needs and make sure your shield, light curtain, etc. works with your present setup or your new one.

Custom High Speed Frames

Instron has spent decades creating tailor-made frames for our customers. If your specimen is extremely flexible, a high-speed frame is the way to go. No matter how quickly your frame needs to be built, we will work hard to learn your specifications and meet or surpass your expectations.

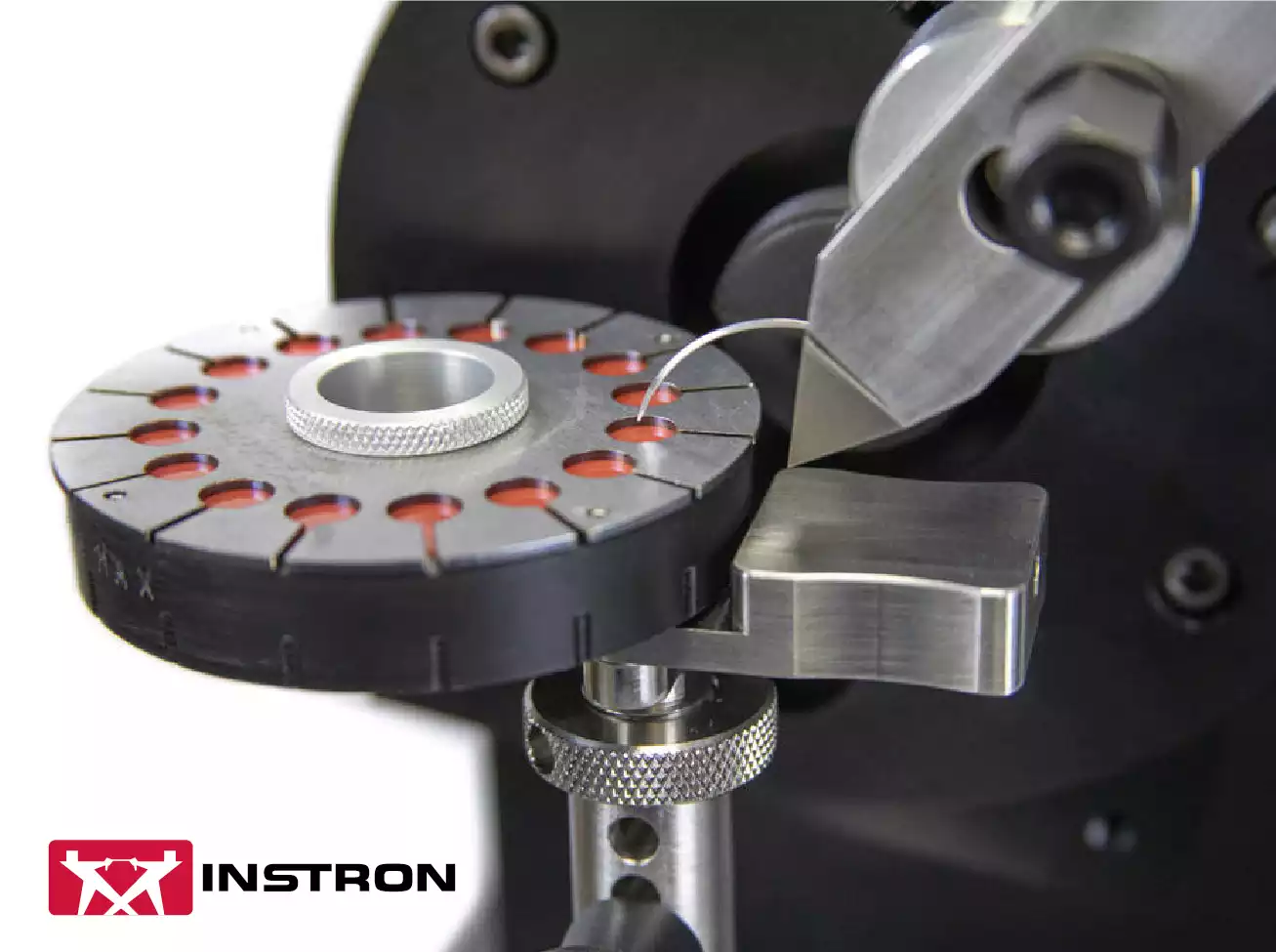

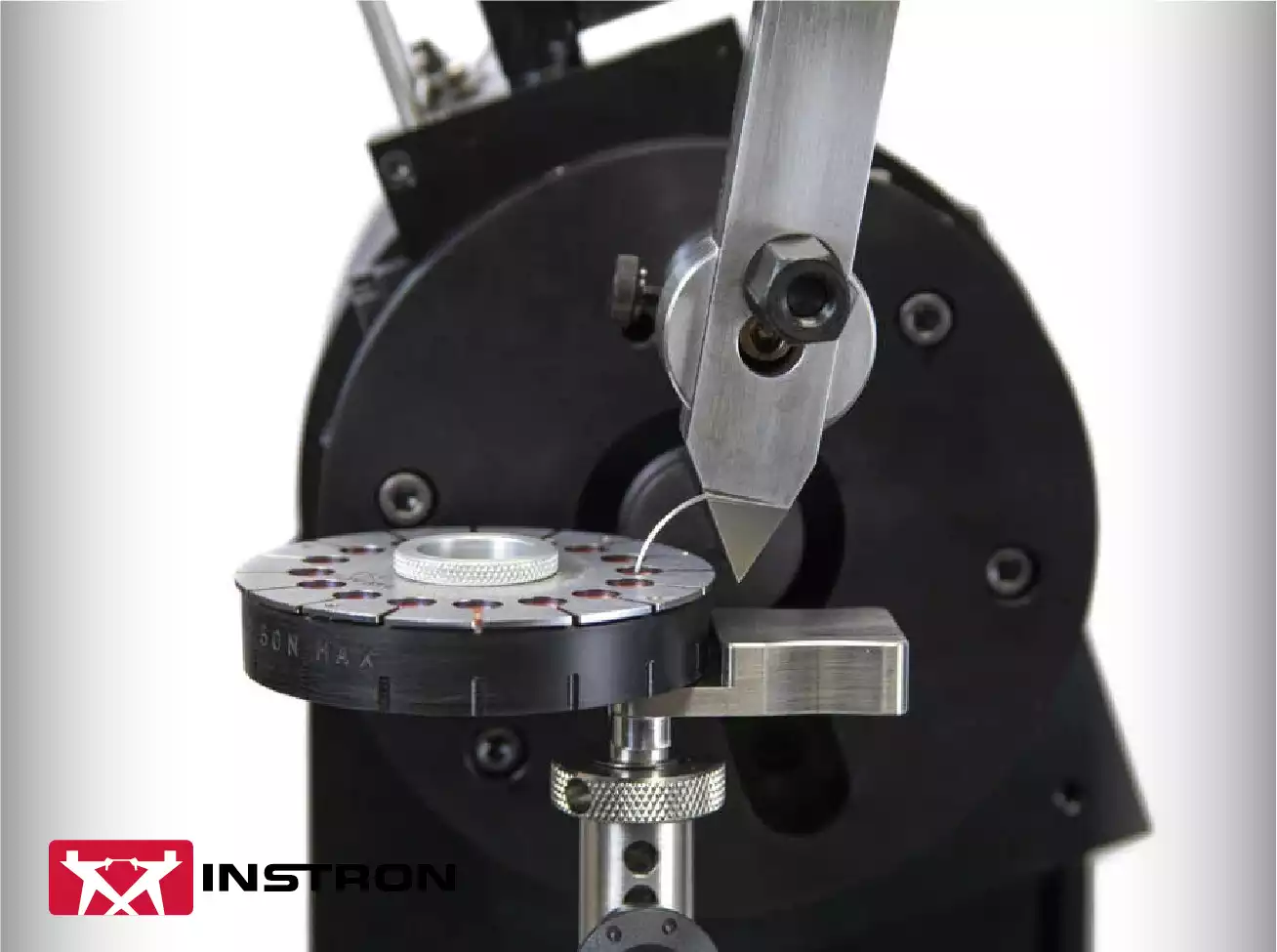

Curved Needle Test Systems

Needles used in wound closure or surgery can be put to the test using the Instron® Curved Needle Testing System. This setup serves as a foundation for two distinct needle testing methods: the ASTM F3014-compliant curved needle puncture test and the more general cantilever bend test. Needle sharpness and coating durability can be assessed with the curved needle puncture testing equipment, while flexural qualities can be measured with the needle bend testing fixture. The Curved Needle Testing System is compact and won't take up much room on your lab bench because of its tabletop design. Bluehill® Universal software, which is used by the testing system, provides test control, data collecting, test results, reports, and a sizable library of computations.

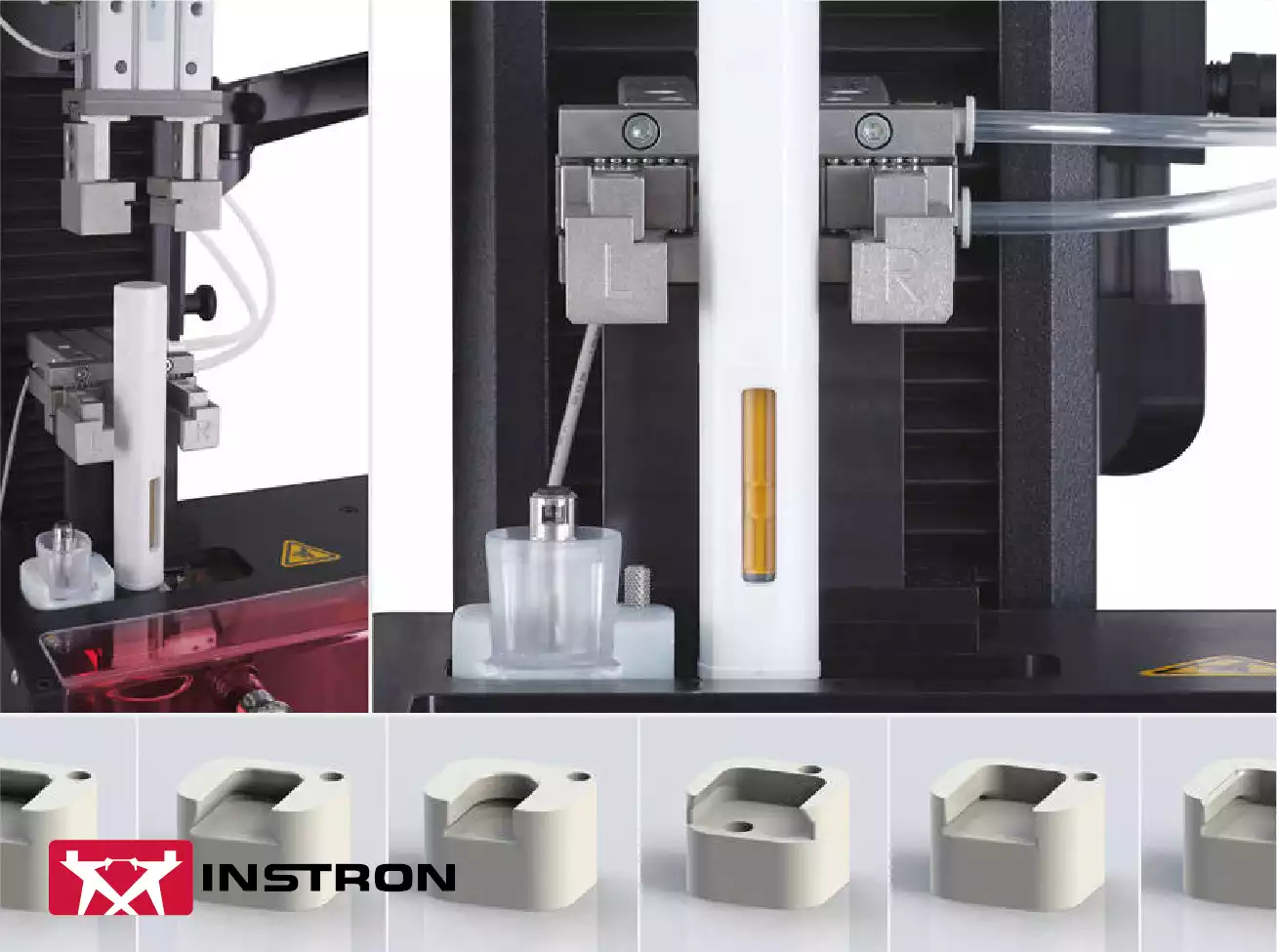

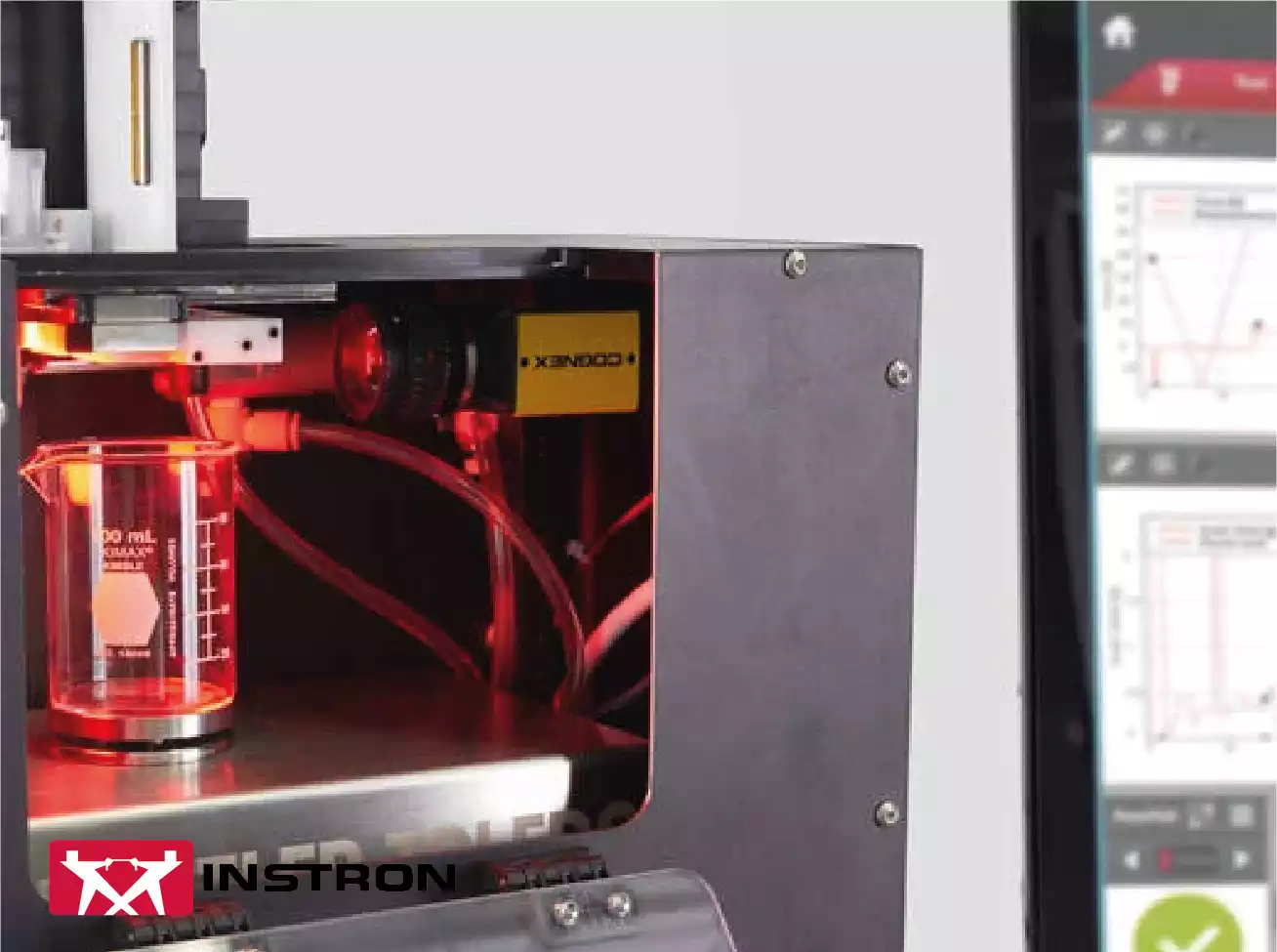

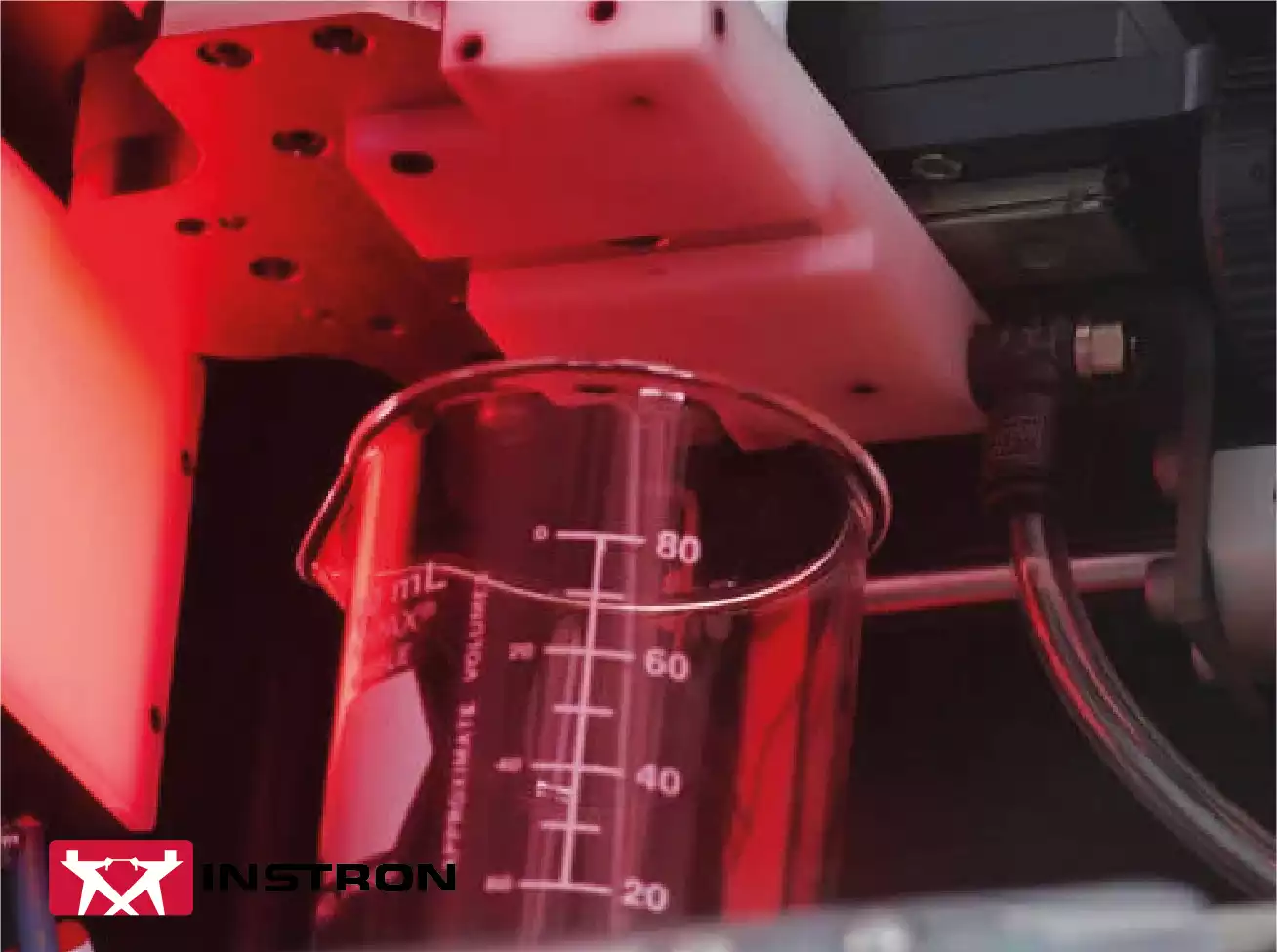

Auto-Injector Testing System

All of the necessary testing of injectable devices can be performed with only one test using the Instron® Auto-Injector Test System, a semi-automated approach. Cap removal force, activation force, injection time, injection mass/volume, and lock out force of the needle shield may all be measured in a single test using this device designed to suit a wide range of pen and auto-injector geometries. If you already own a universal testing system from either the 6800 Series or the 5900 Series and are using Bluehill® Universal software and the TestProfiler module, you can add the Auto-Injector Test System to it. More information, such as the injection's click and the needle's length after it's been withdrawn, can be recorded with the addition of sensors and cameras.

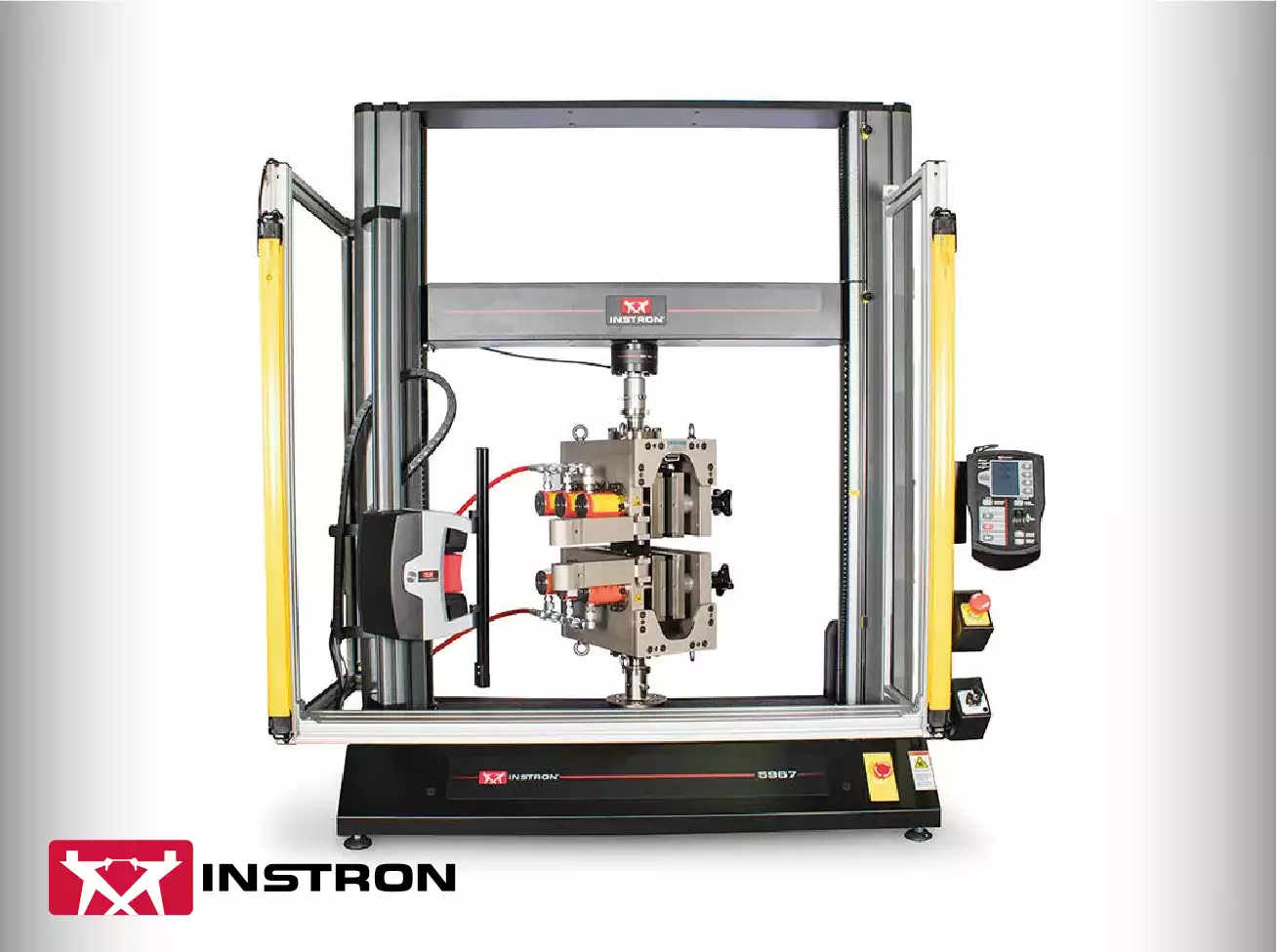

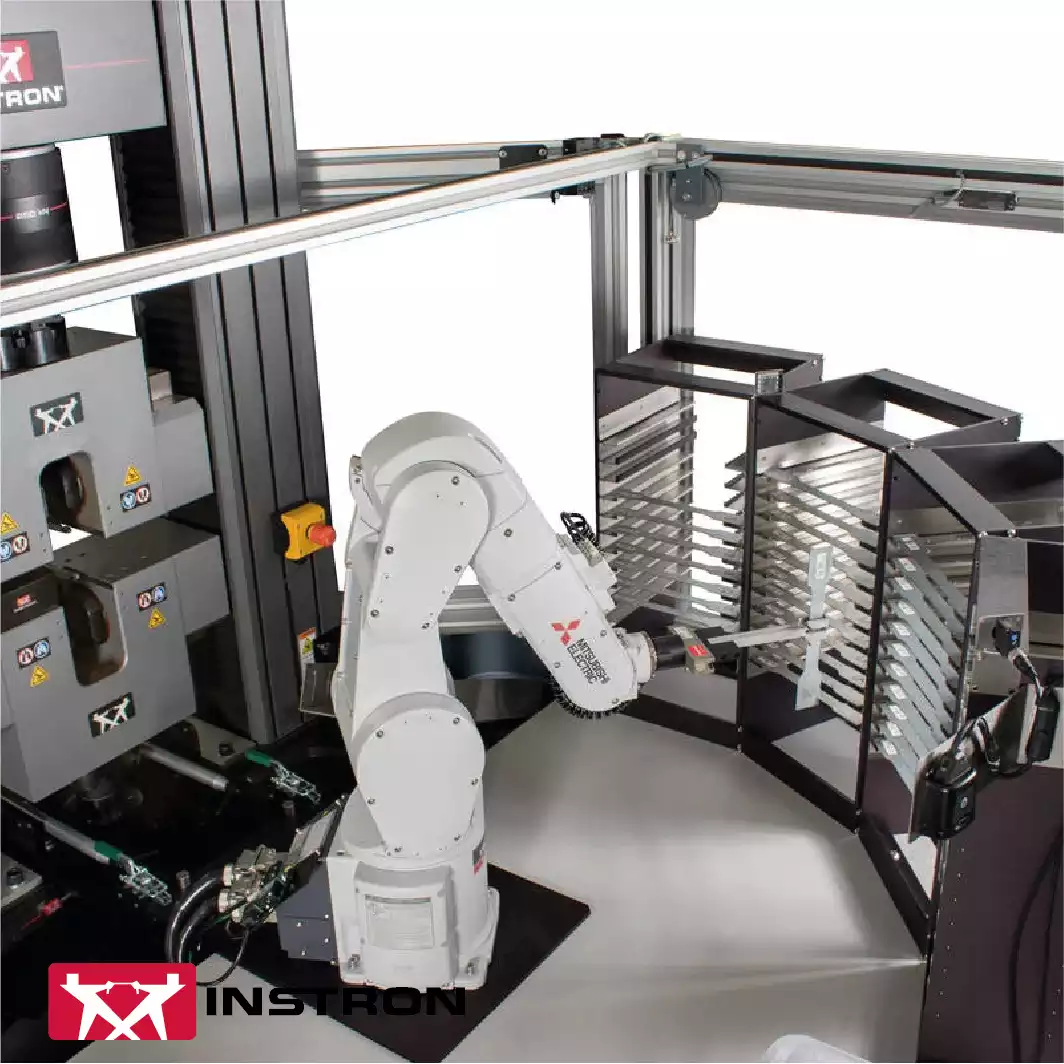

Automation

(AUTOMATED TESTING SYSTEMS page)

Automated testing systems from Instron allow laboratories to boost productivity, consistency, and safety, while freeing up trained personnel for more strategic endeavors. The flexible control and handling capacity required to test a wide range of applications is available as either a complete turnkey system or as modules added to existing Instron testing instruments, depending on your program's needs. Tensile, flex, and compression testing systems for polymers, thin films, metals, and components are standardized.

Read more about Instron Custom Universal Testing Machines here

Related Products

Ask Us A Question

Subscribe to our Newsletter

Receive all our promotions, updates, news and much more...

CONTACT US

Taawon for Laboratory & Scientific Supplies

Taawon Group © 2024 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience

.webp)