Home » Products » Material Preparation, Analysis, and Testing » Hardness Testing Systems » Buehler Vickers & Knoop

Precision Indentation Hardness Testing

Vickers and Knoop

Buehler Vickers & Knoop

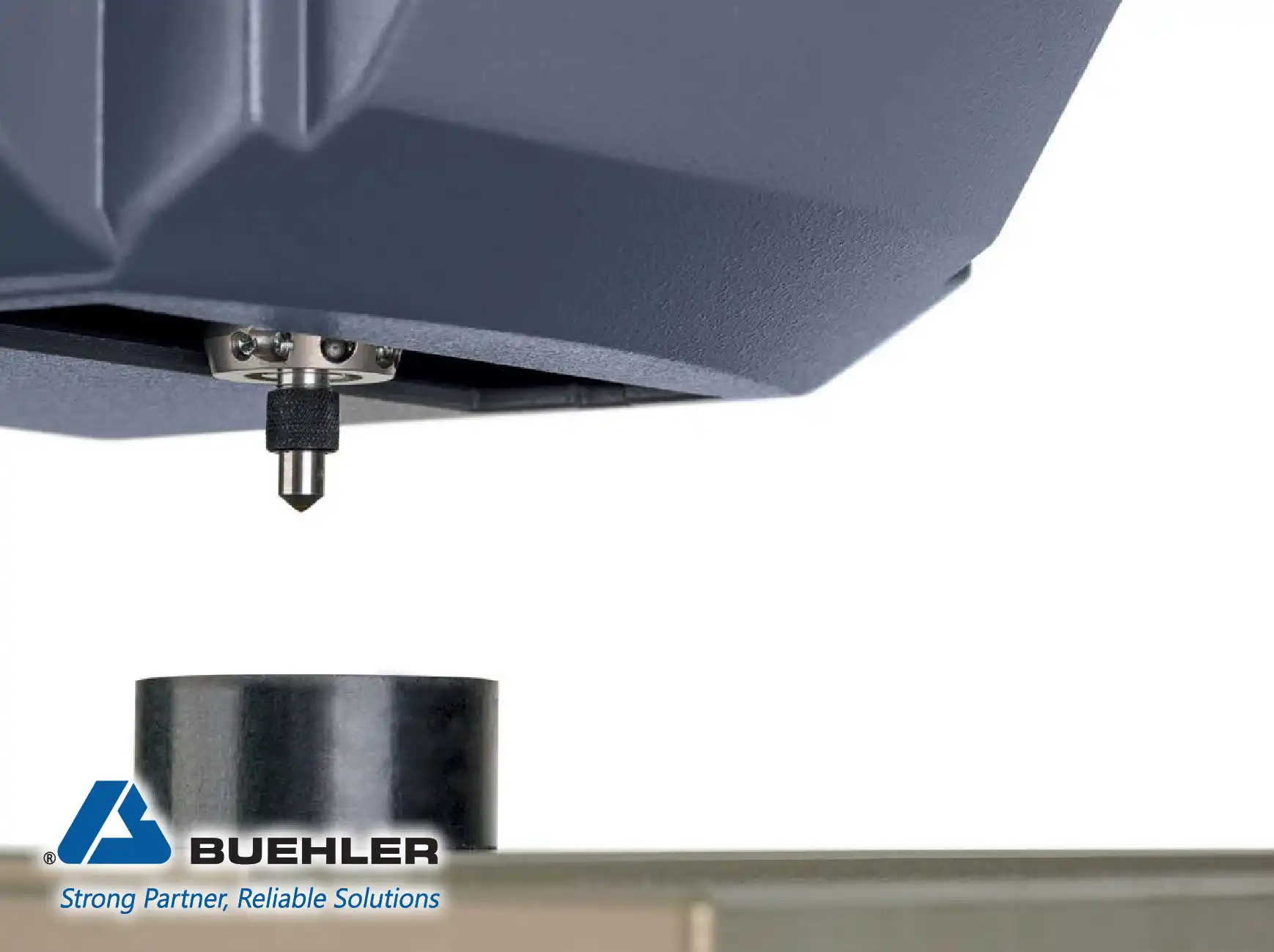

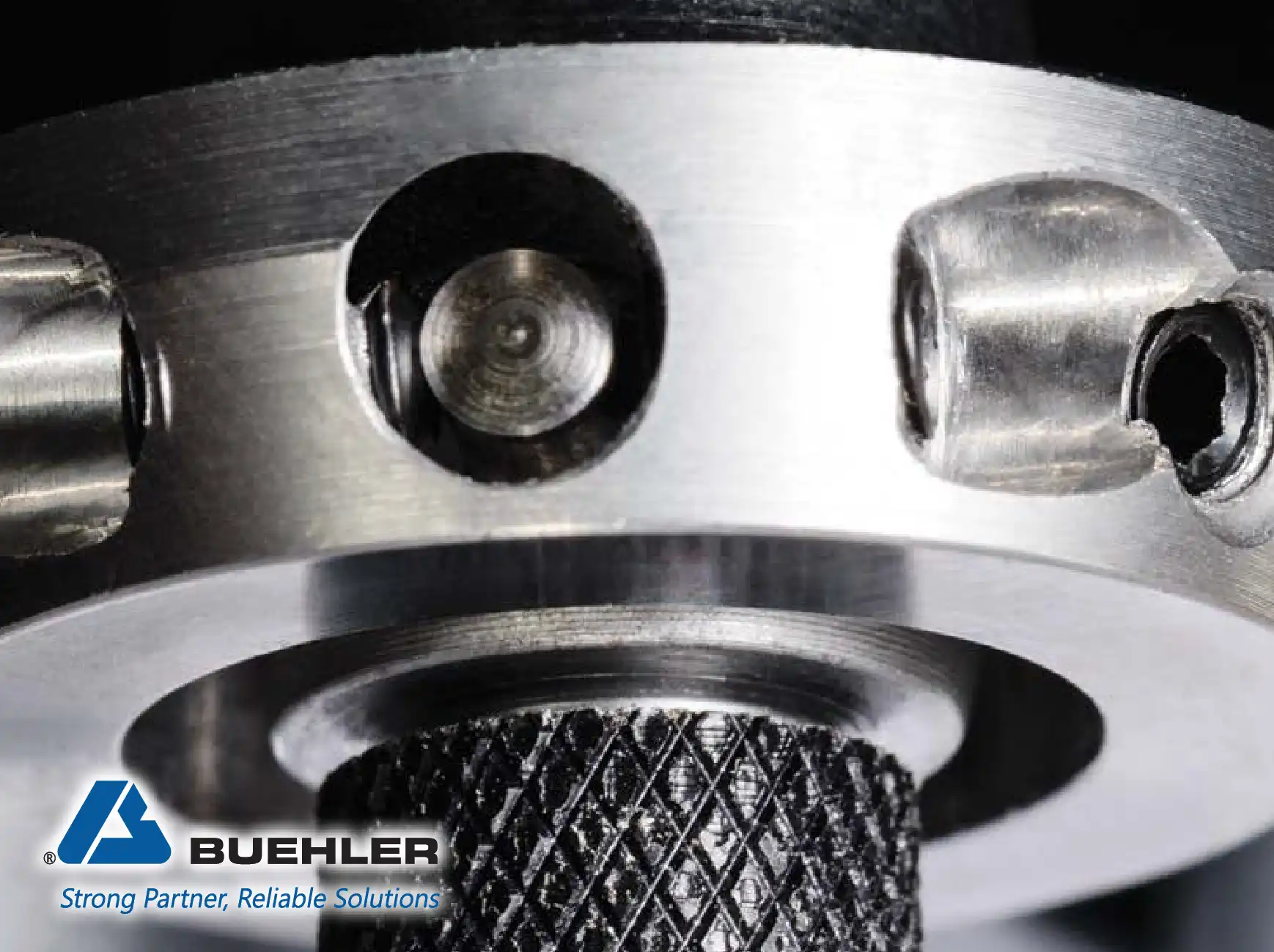

Vickers and Knoop hardness testing systems provide precise methods for determining a material’s resistance to plastic deformation under controlled loading conditions. These techniques utilize geometrically defined diamond indenters—a square-based pyramid for Vickers and a rhombic pyramid for Knoop—to create micro-indentations on the sample surface. The resulting diagonal lengths are then measured with high accuracy to calculate the respective hardness value.

The instruments supporting these methods are highly sophisticated, ranging from versatile systems capable of switching between both test types to dedicated machines optimized for macro- or micro-load ranges. Advanced capabilities, such as integrated imaging software and automated measurement routines, are critical for overcoming the challenges inherent in high-precision testing.

Achieving Versatility Across Different Material Structures

A common operational challenge arises from the need to characterize materials requiring fundamentally different indentation profiles. Standardized instruments that combine both Vickers and Knoop capabilities are essential to mitigate this. The Vickers test, utilizing its uniform indentation geometry, offers a robust hardness number applicable across the entire sample area, ideal for bulk assessment. Conversely, the Knoop test, with its shallow penetration and elongated shape, is crucial for measuring the hardness of highly brittle materials or thin surface layers where excessive penetration would compromise the measurement integrity or penetrate the substrate. The ability to switch seamlessly between these indenter types on a single platform eliminates the necessity for multiple dedicated machines.

Eliminating Variability from Manual Indentation Measurement

The high magnification required to accurately read the small diagonals produced by micro-indentation tests introduces a significant source of measurement uncertainty stemming from operator subjectivity. The visual alignment of crosshairs with the indentation tips is prone to human error, particularly when dealing with poor-contrast materials or slightly rounded edges. Modern testers resolve this by incorporating high-resolution digital cameras and automatic image analysis software. This technology processes the image of the indentation, applies proprietary edge-detection algorithms, and calculates the hardness value digitally, thereby guaranteeing consistent measurement criteria independent of the individual conducting the test.

Addressing Requirements for Testing Ultra-Fine Microstructures

The hardness measurement of individual grains, specific phases, or extremely thin surface coatings, such as PVD or CVD films, requires testing at ultra-low forces (Micro and sometimes Nano levels). The difficulty lies in controlling the minute applied force with sufficient accuracy and maintaining the precision of the resulting minuscule indentation. Dedicated microhardness testers are designed with specialized, highly sensitive load application mechanisms to ensure the load is consistently delivered and withdrawn. This focus on controlled, low-load application is vital for obtaining valid hardness measurements on features that are often only microns in size.

Ensuring Representativeness in Coarse or Heterogeneous Materials

Conversely, when characterizing materials with a coarse grain structure, large inclusion phases, or significant local variations, utilizing insufficient test loads can lead to a hardness value that is not representative of the material's bulk behavior. This necessitates the application of Macro Vickers loads. These systems are designed to accommodate higher forces and utilize larger indenters, producing an indentation area large enough to span multiple grains or features. This ensures the resulting hardness number reflects a statistically relevant average of the material's overall properties, mitigating the issue of local sampling bias.

Maintaining Absolute Load Accuracy and Precision Control

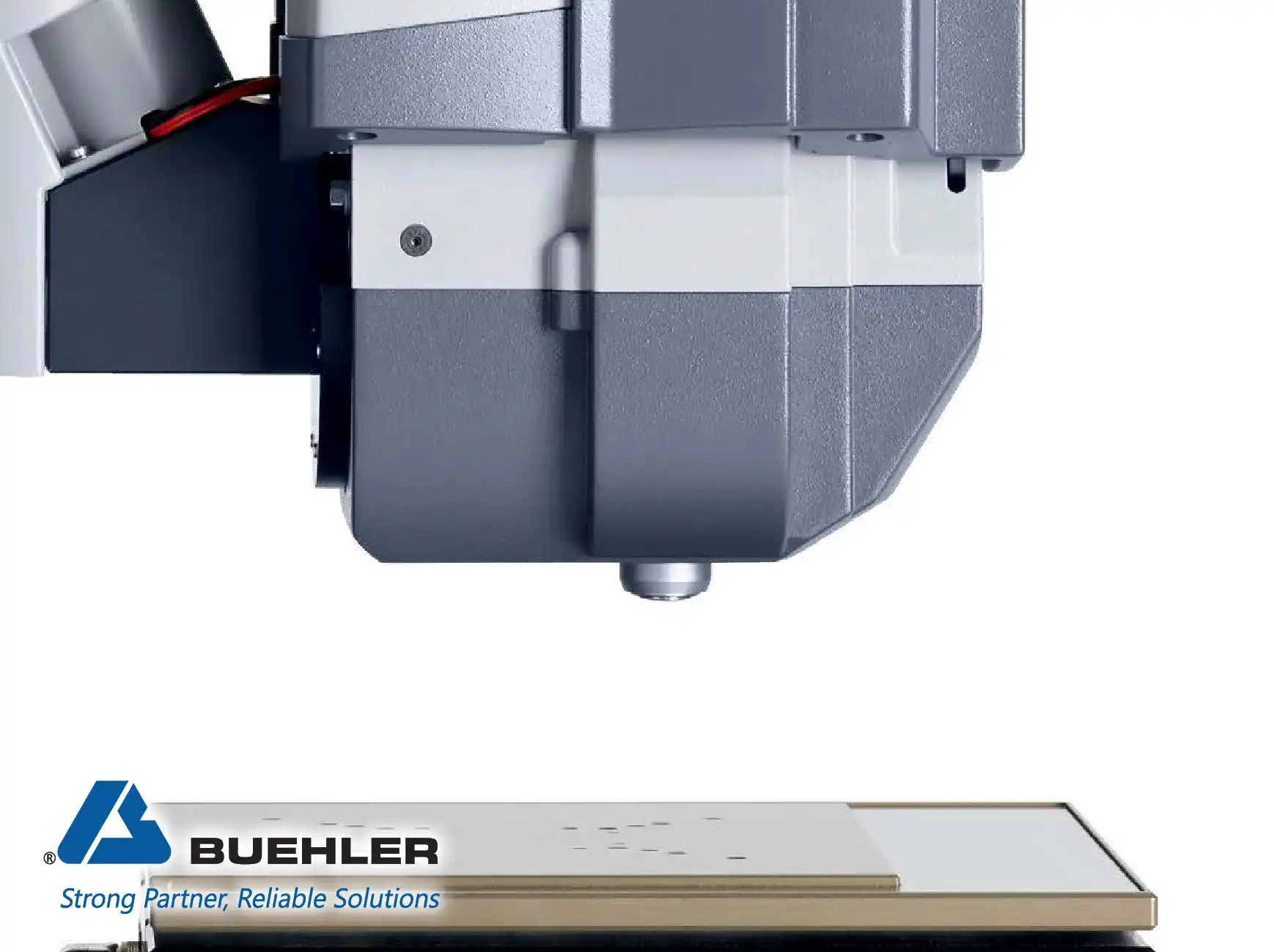

Ensuring that the test force is applied accurately is paramount, particularly in controlled environments where traceability is mandatory. Traditional deadweight systems can be subject to mechanical friction or inertia. Advanced testers utilize closed-loop force application systems. This technology continuously monitors and adjusts the applied force via a load cell throughout the entire indentation cycle. This dynamic feedback loop guarantees that the test load remains within the required tolerance specified by international standards, offering far superior precision and stability compared to open-loop systems, especially during prolonged testing campaigns.

Standardizing and Streamlining the Reporting Process

Converting raw diagonal measurements into final, certified hardness values and comprehensive test reports is a laborious, multi-step process that is vulnerable to calculation and transcription errors. Modern testing platforms eliminate this workflow deficiency by integrating the measurement, conversion, and reporting functions. The system automatically handles complex conversions between different hardness scales, applies necessary geometric corrections, and generates complete, customizable data reports. This centralization of data management ensures seamless traceability and significantly reduces the time and potential for error between data acquisition and final documentation.

Automating High-Volume Testing for Production Environments

In quality control or high-volume production settings, the time required for manual sample indexing, focusing, and testing for large batches creates a significant bottleneck and raises operational complexity. Automated systems are deployed to address this by providing multi-axis, motorized stage control combined with predefined test patterns. The operator can program a sequence of hundreds of test points, and the machine executes the entire process—including stage movement, indentation, focusing, and measurement—unattended. This automation is essential for maximizing throughput and guaranteeing that the testing frequency meets stringent production quality targets.

Correcting Errors Related to Sample Preparation Quality

Imperfections in sample preparation, such as surface roughness or slight deviations from perfect planarity, can introduce reading errors or skew the geometry of the indentation, compromising data integrity. The instruments must therefore be equipped with high-definition optics and illumination control to overcome these challenges. Features like multi-light settings (e.g., brightfield, darkfield) and high numerical aperture objectives allow the operator or the automatic software to clearly delineate the edges of the indentation even on poorly prepared or low-contrast surfaces, ensuring that the measurement diagonal is taken from the true, undistorted contact points.

Click here to know more about Buehler products

.webp)