Home » Products » Analytical Solutions » Pipettes & Liquid Handling » Mettler Toledo Multichannel Electronic Pipettes

E4 XLS+

Quantitative analysis in fewer steps

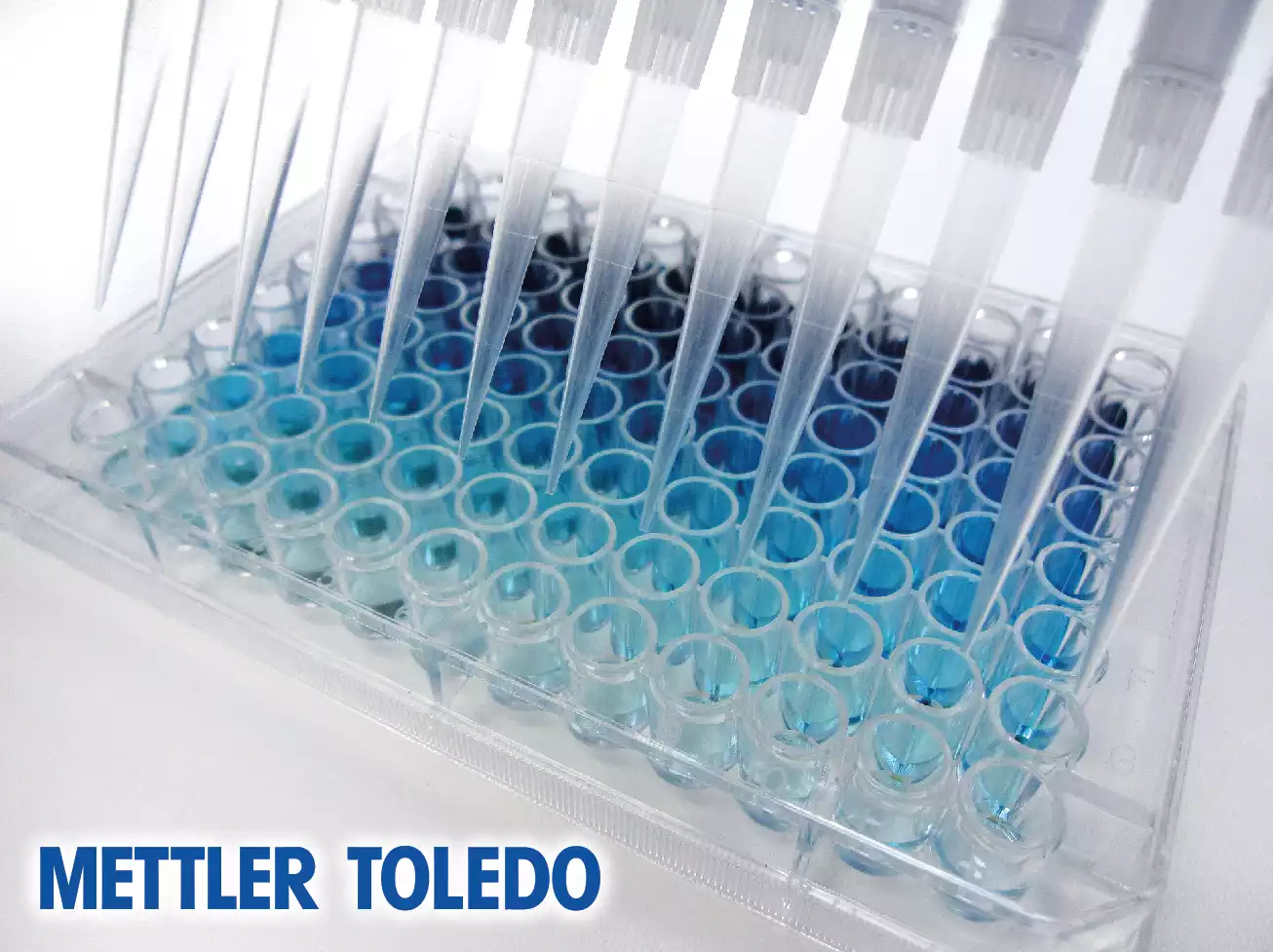

Mettler Toledo Multichannel Electronic Pipettes

Mettler Toledo’s Rainin E4 XLS+ multichannel electronic pipettes are engineered for high-throughput liquid handling, offering a technical solution for complex plate-based workflows. These instruments utilize a high-precision stepper motor to govern piston movement, ensuring that every channel—whether in an 8 or 12-channel configuration—aspirates and dispenses identical volumes with absolute synchronicity.

By automating the mechanical action of pipetting, the E4 XLS+ eliminates the variability associated with manual force, providing a standardized performance that is critical for sensitive genomic and proteomic assays. The integration of advanced microprocessor control allows for diverse operational modes, such as multi-dispensing and automated mixing, which significantly accelerate the processing of 96-well and 384-well plates while maintaining rigorous volumetric accuracy.

High-Precision Stepper Motor Control

The technical core of the E4 XLS+ multichannel pipette is its advanced stepper motor, which replaces manual plunger activation. This motor moves the pistons at a constant, electronically controlled velocity, ensuring that the aspiration and dispensing rates are identical across all channels. This level of mechanical consistency is impossible to achieve with manual pipettes and is vital for maintaining low coefficients of variation (CV) when filling 96-well plates. The motor's precision allows for extremely small increments in volume adjustment, providing high resolution for delicate liquid handling tasks.

Simultaneous Multichannel Synchronicity

In high-throughput environments, the synchronicity of liquid movement across all 8 or 12 channels is paramount. The E4 XLS+ is engineered to ensure that air displacement and piston stroke are perfectly aligned within the manifold. This ensures that every well in a row or column receives the exact same volume at the exact same time. This technical uniformity is essential for assays where incubation times must be strictly controlled across the entire plate, preventing "edge effects" and ensuring the reproducibility of experimental data.

Patented LiteTouch System (LTS) for Manifold Integrity

A significant technical challenge for multichannel pipettes is ensuring a consistent seal across all nozzles. Mettler Toledo addresses this with the patented LiteTouch System (LTS). The LTS design utilizes a cylindrical nozzle and a thin sealing ring with a positive stop. This ensures that each tip is loaded with the same minimal force and sits at the same depth, creating a perfect, leak-proof seal across the entire manifold. This system also features extremely low tip ejection forces, protecting the internal mechanics of the multichannel head during high-frequency use.

Advanced Multi-Dispensing and Aliquoting

The E4 XLS+ features a sophisticated "Multi-dispense" mode, which technically automates the process of aliquoting a large volume into multiple smaller portions. The microprocessor calculates the total volume required, including an automatic compensation for the "dead volume" to maintain accuracy in the final aliquot. This mode is a major productivity driver for plate filling, as it allows a researcher to fill a 96-well plate with fewer aspiration cycles, reducing both time and mechanical wear on the instrument.

Programmable Protocols and Workflow Standardization

To ensure compliance and consistency in regulated laboratories, the E4 XLS+ allows for the creation and storage of complex, multi-step protocols. Users can program specific sequences of aspiration, mixing, and dispensing, which the pipette then executes with digital precision. This technical capability ensures that every operator follows the exact same liquid handling steps, effectively standardizing the workflow and minimizing human error. Protocols can be password-protected to prevent unauthorized changes to validated laboratory methods.

Dynamic Speed Control for Challenging Fluids

Handling viscous or volatile liquids with a multichannel pipette requires precise control over aspiration and dispensing speeds. The E4 XLS+ allows the operator to adjust the motor speed for both the uptake and delivery phases. By slowing down the aspiration speed, the pipette allows viscous fluids to reach equilibrium within the tips, preventing air bubbles and volume inaccuracies. Conversely, for volatile solvents, the electronic control can minimize evaporation by managing the stroke speed, providing technical flexibility for diverse chemical and biological reagents.

Integrated RFID for Calibration and Compliance

Each Rainin E4 XLS+ multichannel pipette contains an embedded RFID (Radio Frequency Identification) chip. This chip serves as a digital passport, storing the tool’s serial number, manufacture date, and comprehensive service and calibration records. When interfaced with an RFID reader and software, this allows for the automated tracking of the pipette’s compliance status. This technical feature is indispensable for labs operating under GLP/GMP standards, as it ensures that only calibrated instruments are used for critical multichannel plate assays.

Ergonomic Optimization for Extended High-Throughput Use

The E4 XLS+ is technically designed to provide maximum performance with minimal physical effort. Because the piston movement is entirely motor-driven, the force required to operate the trigger is negligible. The tool is perfectly balanced and features a contoured finger hook, allowing for a relaxed grip. These ergonomic refinements are critical in multichannel pipetting, where the weight of the manifold and the frequency of use can otherwise lead to repetitive strain injuries. The digital joystick control further simplifies navigation, making high-throughput tasks less physically demanding.

Read more about Mettler Toledo Multichannel Electronic Pipettes