Home » Products » Chromatography/Mass Spectrometry » Gas Chromatography » Shimadzu GC Components & Accessories

GC Components & Accessories

Analytical Versatility and System Modularization

Shimadzu GC Components & Accessories

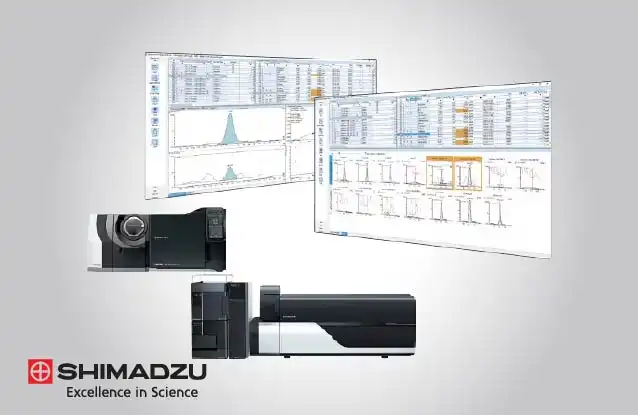

The technical architecture of Shimadzu GC components emphasizes modularity, allowing laboratories to configure systems that meet specific analytical demands through the integration of specialized detectors and sample introduction units. Technically, the seamless communication between the Electronic Flow Controllers (EFC) and the main processor ensures that every accessory, from a headspace sampler to a methanizer, operates in perfect synchronization.

This modular approach is supported by advanced diagnostic software that monitors the health of the gas supply and detector stability in real-time. By utilizing high-precision components designed for thermal resilience and chemical inertness, Shimadzu ensures that the GC system remains a stable platform for both routine quality control and complex research.

High-Performance Flame Ionization Detector (FID)

The FID is technically engineered for the universal detection of organic compounds with a wide linear dynamic range. Utilizing a hydrogen/air flame, it pyrolyzes carbon-containing compounds to form ions, which are then collected by an electrode to generate a current. Technically, the FID’s jet and collector are designed to minimize noise and prevent the accumulation of silica or carbon deposits, ensuring long-term sensitivity and minimal maintenance during high-throughput carbon analysis.

Thermal Conductivity Detector (TCD) Stability

For the analysis of inorganic gases and permanent gases like H2, $O2, and N2, the TCD provides a technical solution based on the measurement of thermal conductivity differences. The detector features a micro-volume cell and a precision filament bridge. Technically, this configuration ensures high sensitivity even for small sample volumes while maintaining exceptional thermal stability, allowing for the quantification of components that cannot be detected by ionizing detectors.

Programmable Temperature Vaporization (PTV) Injection

The PTV injection unit is a sophisticated technical component used for the analysis of thermally labile or high-boiling point compounds. Unlike standard split/splitless inlets, the PTV can be cooled during sample introduction and then rapidly heated to vaporize the analytes. This technical control prevents the "needle discrimination" effect and protects sensitive molecules from thermal degradation, ensuring that the sample reaches the column in its original chemical state.

Automated Headspace Analysis for Volatiles

Headspace accessories are technically vital for analyzing volatile organic compounds (VOCs) in difficult matrices like soil or polymers. The system heats the sample vial to establish a gas-liquid equilibrium, then extracts a precise volume of the vapor phase. Technically, the pressure-loop or syringe-based transfer system ensures that only the volatile components enter the GC, protecting the column from non-volatile residues and simplifying sample preparation for complex environmental monitoring.

Integrated Pyrolysis for Solid Sample Characterization

The pyrolysis accessory allows for the direct analysis of solid materials such as plastics and resins without chemical dissolution. Technically, the unit utilizes a high-precision furnace to flash-pyrolyze the sample at temperatures up to 1000 C. The resulting fragments, or "pyrolyzates," are swept into the GC column. This technical approach provides a detailed "chemical fingerprint" of the polymer's structure, allowing for the identification of additives and monomer sequences.

Precision Electronic Flow Control (EFC) for Reproducibility

The EFC is the technical heart of gas management in modern GC. It utilizes high-speed sensors to regulate the carrier gas pressure and flow rate with millisecond response times. Technically, the EFC compensates for changes in oven temperature to maintain constant linear velocity, ensuring that retention times remain identical from run to run. This precision is essential for the accurate identification of compounds based on retention time mapping and for stable detector operation.

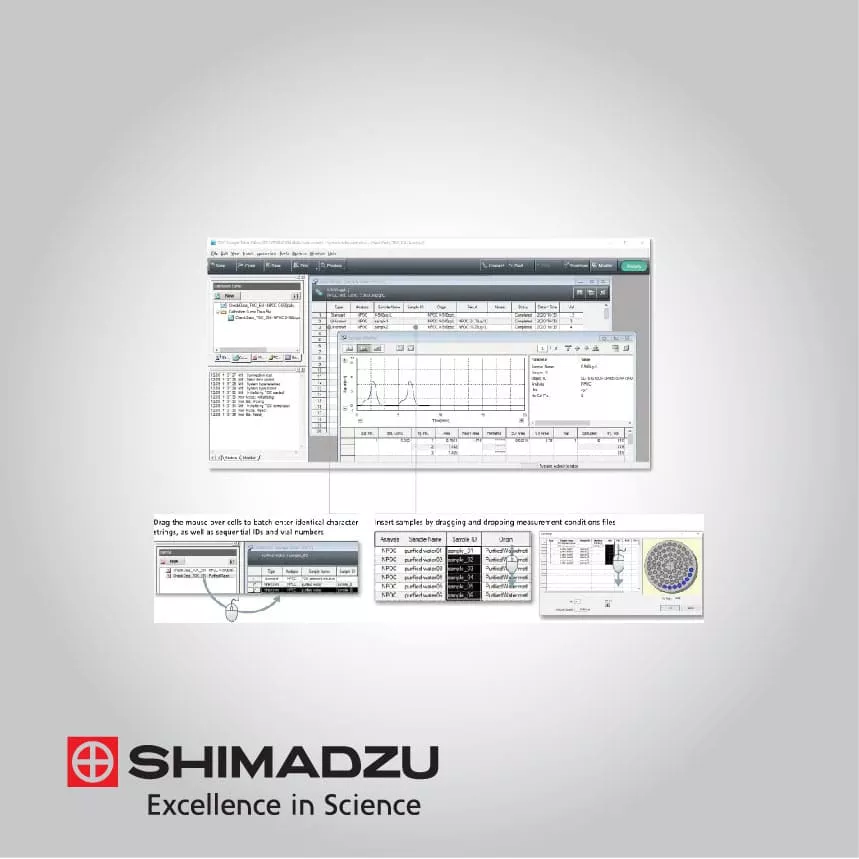

Liquid Autosampler Robotics and Injection Precision

High-throughput laboratories utilize robotic liquid samplers to ensure mechanical consistency during injection. These units are technically capable of varying injection speeds and depths to accommodate different sample viscosities. The robotics can perform automated internal standard addition and "sandwich" injections. This technical automation reduces human error and ensures that the timing of the injection is perfectly synchronized with the data acquisition software.

Specialized Methanizer Units for CO and CO2 Detection

For the trace detection of Carbon Monoxide and Carbon Dioxide using an FID, a methanizer accessory is technically required. This unit contains a nickel catalyst that reduces CO and CO2 to methane CH4 in the presence of hydrogen. Technically, this allows the FID to detect these inorganic gases with the same high sensitivity it applies to hydrocarbons, making it an essential tool for greenhouse gas analysis and high-purity gas quality control.

Click here for more information about Shimadzu range of products

Related Products

CONTACT US

CONTACT US

Taawon for Laboratory & Scientific Supplies

Taawon Group © 2026 - All Rights Reserved

We use cookies to optimize site functionality and give you the best possible experience