Home » Products » Material Preparation, Analysis, and Testing » Grinding & Polishing systems » Buehler Manual Grinder Polishers

Robust Manual Metallographic

Sample Preparation Systems

Buehler Manual Grinder Polishers

Manual grinder polisher units serve as the essential and vital solution for quick, reliable single-sample preparation requirements, designed specifically for laboratories needing immediate testing or handling low sample volumes. These machines provide a straightforward method of specimen processing, placing the power of complete control into the operator’s hands, a critical advantage when a sample demands sensitive or modified handling based on immediate observation.

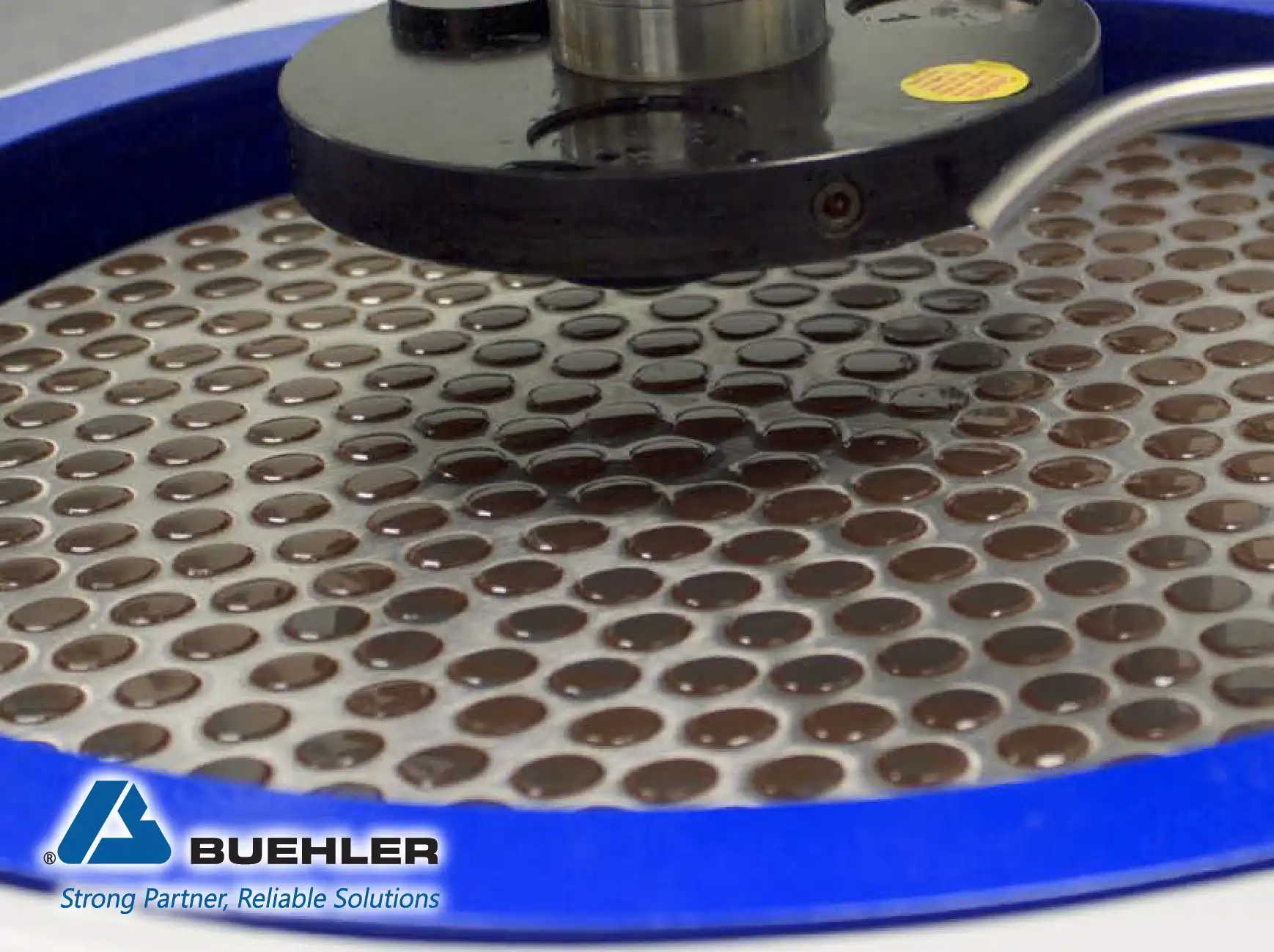

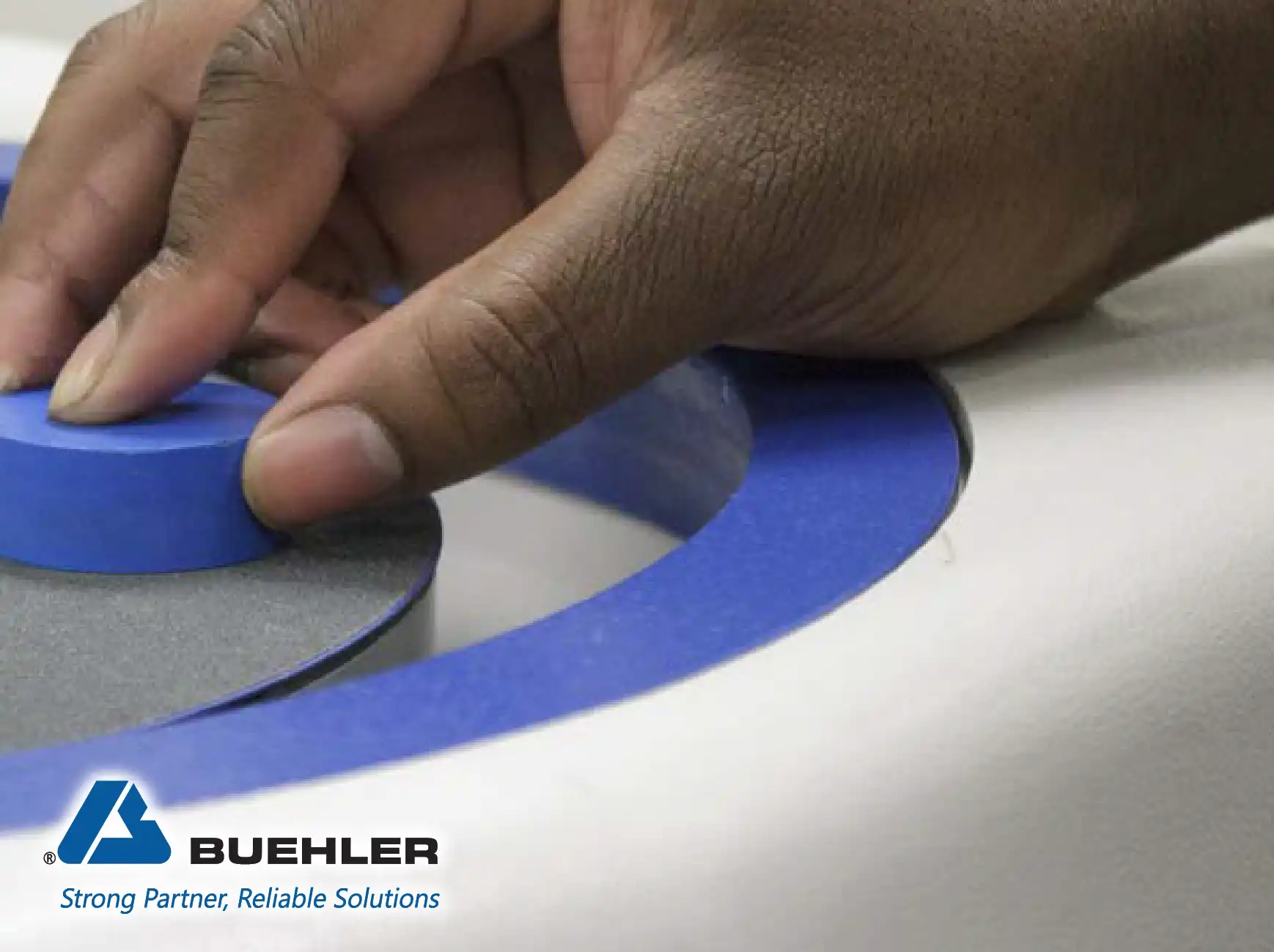

The capability of these manual units extends beyond mere basics by offering flexible design options that address spatial and throughput challenges within the manual workspace. The grinder polisher is distinguished by its capacity to accommodate platens up to 12 inches [305mm] in size, providing significant versatility in the range of specimen sizes that can be successfully prepared. Furthermore, the availability of single or dual platen configurations allows multiple operators to simultaneously utilize the equipment for different steps

Accelerating Single-Point Quality Inspection Cycles

Rapid preparation of single specimens is essential for immediate quality checks or incidental failure investigations. These manual machines are specifically designed to offer a direct "turn on and process" mechanism, minimizing the complex setup time demanded by automated systems. This immediacy allows technicians to prepare a test piece instantly when required, eliminating the delays associated with batch accumulation or automated cycle programming, thereby significantly reducing the time taken for critical quality control decisions.

Maintaining Result Accuracy through Standard Reliability

A major concern in any materials testing environment is the variation in machine mechanical performance over time, which leads to unreliable preparation results. These manual machines are noted as the "standard for reliability," signifying a robust mechanical architecture and wear-resistant components that ensure the operational parameters of grinding and polishing remain consistent regardless of usage intensity. This structural reliability is crucial for guaranteeing that the resulting surface quality remains free of preparation artifacts, a common vulnerability in less durable equipment.

Flexibility for Accommodating Larger Sample Sizes

Standard preparation units often restrict laboratories dealing with physically larger specimens, requiring them to either section the sample or prepare in stages, both of which compromise the outcome. These specific manual machines address this constraint by allowing for the fitment of up to a 12-inch [305mm] platen. This larger capacity ensures that bigger samples can be processed efficiently, facilitating the achievement of uniform flatness and edge retention across a substantially wider surface area, which is practically impossible to achieve on smaller platens.

Enabling Real-Time Process Modification

When preparing sensitive materials or those with vastly disparate mechanical phases, the process may require subtle, immediate adjustments that programmed systems cannot provide. Manual operation allows for absolute control over key parameters such as force, speed, and specimen positioning, enabling the technician to "feel" the sample's reaction and adjust their technique instantaneously. This ability to respond on the fly to the specimen's requirements is an invaluable tool for preparing difficult or novel samples.

Supporting Multi-User Workflows with Dual Platen Option

In laboratories where multiple technicians compete for the use of a single workstation, workflow bottlenecks arise. The availability of these manual grinder polishers in a dual platen configuration effectively alleviates this pressure. This design permits two colleagues to work on different stages of the preparation process (e.g., primary grinding and final polishing) simultaneously on one piece of equipment, maximizing the utilization of limited bench space and improving staff scheduling.

Superior Operational Simplicity for Easy Adoption

Laboratories often struggle with sustaining operations due to the complexity of machinery that requires extensive operational protocols. The "easy to use" nature of these manual units minimizes the interface complexity, demanding minimal interaction with a control screen. This simplification reduces the likelihood of setup error by new or occasional staff, ensuring the preparation process can be quickly and efficiently initiated every time without the need for complex recall of saved methods.

Structural Durability for Operation in Harsh Environments

Preparation equipment is often deployed in harsh environments with high exposure to corrosive fluids and suspended abrasive particles. These manual units are specifically built for "the most demanding environments," signifying engineering that employs materials and seals to protect against environmental damage. This robust construction is essential for ensuring the machine's operational longevity and reducing the need for frequent maintenance or component replacement due to environmental degradation.

Dedicated Preparation Solution in Confined Space

Some laboratories require a reliable preparation station but are heavily constrained by spatial limitations or logistical constraints, such as being situated within a hot cell or on a compact cart. As these units are optimized for quick, reliable single-sample processing, they offer a robust, compact solution without the need for the complex, large footprint systems associated with automated batch preparation. This ensures that labs with limited space can still meet their preparation quality demands efficiently.

Click here to know more about Buehler products

.webp)