Home » Products » Material Preparation, Analysis, and Testing » Grinding & Polishing systems » Buehler Semi-Auto Grinder Polishers

Automated Metallographic

Sample Preparation Systems

Buehler Semi-Auto Grinder Polishers

The core function of these semi-automatic units is the capacity for batch processing, directly addressing laboratory requirements for increased sample volume without compromising the required quality of the final surface finish. Specific models cater to differing volume needs, utilizing platen sizes of 10-inch [254mm] for standard work and larger 12-inch [305mm] platens to accommodate high-volume throughput or preparation of oversized specimens.

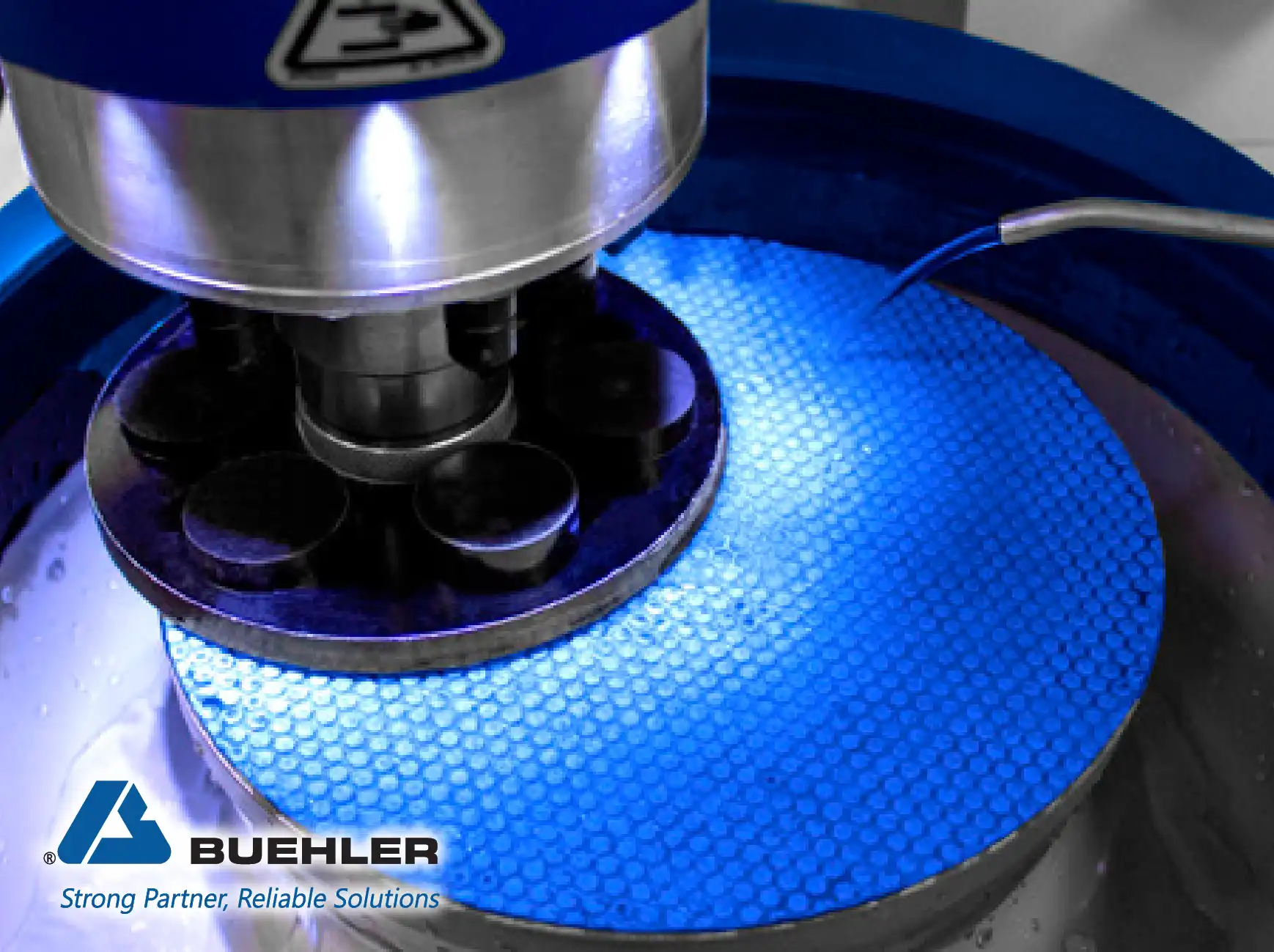

Integration of automated dispensing systems, such as the Burst modules, is a critical technical differentiator, meticulously controlling the precise application of polishing suspensions and lubricants onto the preparation surface. By removing human error from this vital step, the system guarantees optimal usage rates of expensive consumables while ensuring process parameters—like fluid concentration and timing—remain constant from one batch to the next.

Digital Control for Inter-Batch Consistency

Achieving absolute consistency across sequential sample preparation runs is vital for materials verification. These semi-automatic machines eliminate the reliance on individual operator technique by providing a fully programmable interface where all variables—force, speed, direction, and time—are digitized and saved as repeatable methods. This automation ensures that the mechanical interaction between the specimen holder and the platen is identical for every batch, removing the primary source of inter-sample preparation discrepancies that often delay quality control analysis.

Scaling Capacity and Resolving Lab Bottlenecks

The inherent challenge in scaling up laboratory operations is maintaining precision while increasing throughput. By facilitating the automatic processing of multiple samples simultaneously, the equipment significantly increases the number of prepared specimens per hour. This enhanced capacity directly tackles bottlenecks in high-volume testing environments, allowing technicians to allocate their specialized skills to downstream analytical tasks rather than continuous, repetitive machine operation.

Automated Dosing Precision and Consumable Optimization

Variability in surface finish quality frequently arises from inconsistent application of diamond suspensions and final polishes. The integrated Burst dispensing systems provide micro-dose precision, ensuring the preparation surface is maintained at the optimal slurry concentration throughout the entire polishing step. This mechanical control over consumable delivery not only safeguards the consistency of the abrasive action but also leads to measurable reduction in the total volume of expensive polishing fluid consumed per sample.

Reducing Training Overhead through Process Simplification

Operator fatigue and the need for extensive, continuous training are significant resource drains in a busy lab. The user-friendly design, particularly on models featuring advanced touchscreen controls, simplifies complex preparation methods into intuitive, menu-driven processes. This approach reduces the necessary skill floor for operation, minimizes setup errors, and accelerates the onboarding process for new personnel, thereby freeing experienced specialists for more demanding analytical work.

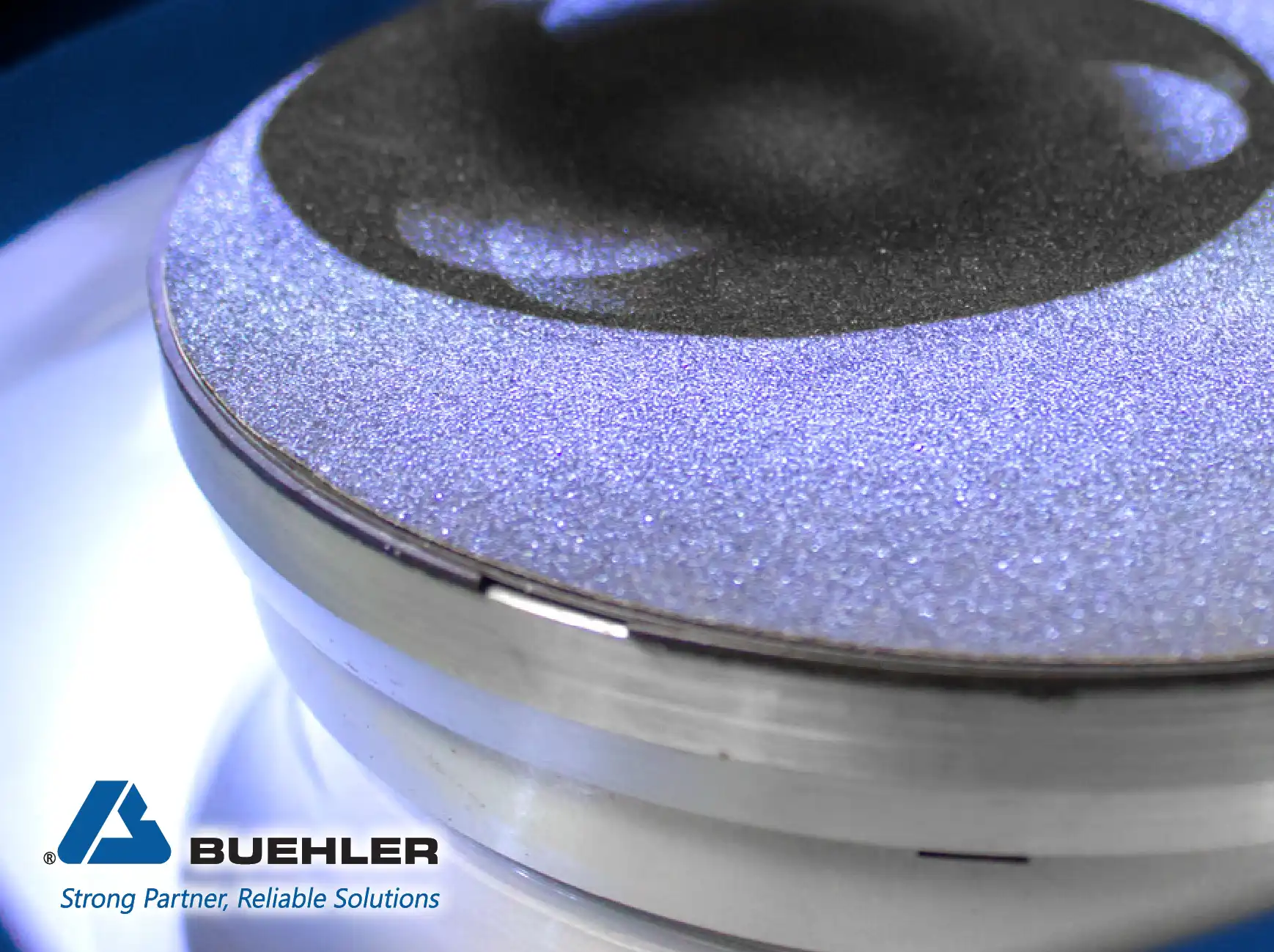

Enhanced Preparation Area with 12-inch Platen Options

When preparing large diameter specimens or high numbers of standard-sized samples, the physical platen size of the equipment becomes a limiting factor on overall output. Top-tier models address this limitation by utilizing 12-inch [305mm] platens, dramatically increasing the available preparation area. This feature is instrumental in enabling laboratories handling larger components or utilizing larger specimen mounts to achieve necessary flatness and edge retention across the entire surface of the specimen.

Precision Damage Elimination via Depth Grinding

For the most sensitive analyses, such as those requiring electron backscatter diffraction (EBSD), micro-level damage removal is critical. The advanced semi-automatic platform offers unique, specialized capabilities like depth grinding, allowing the operator to define and control the exact material removal thickness during the planarizing step. This level of precise material management is essential for eliminating subsurface damage from previous cutting operations, ensuring a truly stress-free surface for final analysis.

Engineering for Longevity and High-Intensity Operation

Laboratory environments subjected to non-stop operation require machinery engineered for exceptional longevity and minimal unscheduled downtime. The reliability of these systems is secured through robust mechanical design and quality components, often featuring durable membrane or sealed touchscreen panels that withstand constant exposure to fluids and abrasive dust. This architecture ensures that the grinder-polisher maintains high performance and tight tolerances even in the most intensive, multi-shift production schedules.

Maximizing Bench Space with Dual Platen Flexibility

Accommodating diverse workflows and multiple operators within a single laboratory space poses logistical challenges. Certain units are offered in flexible configurations, including single or dual platen layouts, enabling two independent users to perform different preparation steps simultaneously on the same machine footprint. This maximizes bench space utilization and allows for phased, multi-stage preparation protocols to be executed efficiently without requiring the purchase of redundant equipment.

Click here to know more about Buehler products

.webp)