Home » Products » Material Preparation, Analysis, and Testing » Grinding & Polishing systems » Buehler Specialty Grinder Polishers

Precision Mechanical Preparation

for Ultra-High Surface Quality

Buehler Specialty Grinder Polishers

Specialty Grinder Polishers are engineered solutions designed to address preparation requirements that exceed the capabilities of standard metallographic equipment. These systems are essential when an application demands an exceptionally high degree of flatness or a superior surface finish that is unattainable through conventional methods.

The core functionality of these specialized machines lies in their ability to deliver minimal subsurface deformation while achieving an impeccably smooth and pristine surface. This is accomplished through advanced features, including unique motor technology that facilitates an exceptionally gentle polishing action, crucial for revealing true material microstructures. Furthermore, these systems integrate specialized consumable media which feature particle sizes meticulously controlled down to sub-micron levels.

Addressing Planarity Deficiencies in Standard Preparation

The primary limitation encountered with general-purpose preparation equipment is its inability to consistently deliver the exceptional surface planarity mandated by advanced materials science. Standard grinding processes often result in a slight curvature or uneven material removal across the specimen face, which makes critical measurements or high-resolution imaging unreliable. This inherent geometric inaccuracy demands a specialized preparation method designed specifically to correct and maintain a perfect plane across the entire sample area, ensuring the structural integrity observed during analysis is a true representation of the material.

Eliminating Subsurface Deformation for High-Resolution Analysis

Analysts routinely struggle with residual subsurface deformation introduced during the early stages of mechanical preparation, which persists despite polishing. When preparing samples for high-magnification examination or techniques such as Scanning Electron Microscopy, even minute defects or disturbed layers can completely obscure the material's genuine microstructure or lead to erroneous phase identification. The need for absolute structural integrity at the atomic and crystalline level necessitates a specialized finishing technique that systematically removes these final, nearly invisible layers of damage to truly reveal the material's unblemished state for accurate characterization.

Implementing Unique Motor Technology for Superior Mechanical Finish

The solution to achieving the highest mechanical surface quality is found in the implementation of a unique motor and drive technology specifically engineered for vibratory polishing. Conventional rotary systems rely on shear forces that can create directional artifacts on the surface. In contrast, specialized vibratory action imparts an extremely gentle, multi-directional motion that promotes uniform material removal without creating new stress or flow-related features. This mechanism is critical for applications that demand the absolute removal of all processing-related imperfections, allowing the operator to confidently proceed to the most sensitive analytical steps.

Meeting Operational Demands in Confined and Hot Cell Environments

Many high-demand research and production facilities operate under severe spatial constraints, making it impractical to integrate large, multi-station preparation systems. Furthermore, critical applications, particularly those involving the handling of hazardous materials, necessitate the use of specialized, remote-operated enclosures, commonly referred to as hot cells. The challenge lies in performing a precise, multi-step preparation process with equipment that is compact enough to fit these limited spaces while remaining entirely reliable and capable of semi-automatic operation to ensure repeatable quality without direct manual intervention.

Managing Preparation Challenges of Delicate and Multi-Phase Materials

The preparation of delicate, multi-phase materials such as microelectronics, optical fibers, and complex petrographic samples presents a significant difficulty. These samples are prone to catastrophic failure, edge rounding, or differential polishing, where one phase is removed faster than another, distorting the true material interface. A specialized approach is required that manages the preparation of a single sample with extreme care, using a semi-automatic process that ensures consistent force application and reproducible motion, thereby eliminating operator variability when handling these sensitive components.

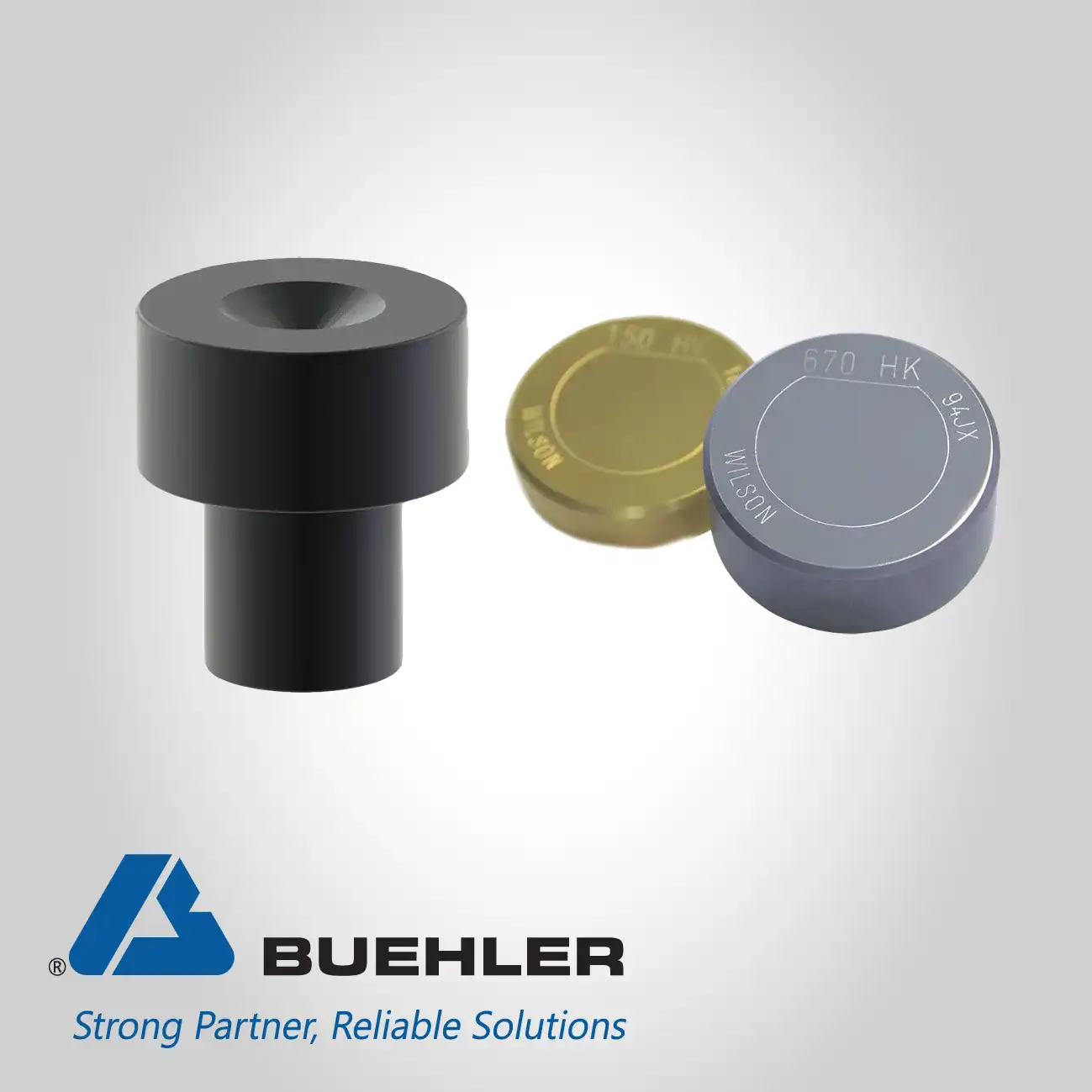

Utilizing Ultra-Fine Abrasive Control Down to Sub-Micron Levels

To achieve the ultimate surface quality, standard abrasive papers and cloths are often insufficient. Researchers face the ongoing issue of not having the necessary ultra-fine particle control required for final finishing. The specialized solution involves using dedicated consumables, such as diamond lapping films and abrasive discs, which are manufactured with particle sizes that span a precise range from thirty down to an infinitesimal zero point one microns. This meticulous control over abrasive dimensions is essential for gradually refining the surface, ensuring the minimal amount of material is removed while successfully eliminating all preceding preparation damage.

Maintaining Sample Integrity for Electronic and Petrographic Analysis

For geological, mineralogical, and electronic failure analysis, maintaining exceptional sample integrity and minimal physical deformation is the cornerstone of a successful result. Specifically, preparing petrographic thin sections or cross-sections of printed circuit boards and microelectronic components requires mechanical action that does not alter the grain boundaries or the delicate interconnections. The use of specialized preparation units is the direct response to this need, providing the necessary gentle yet precise mechanical action to protect the sample's inherent structure throughout the grinding and polishing sequence.

Ensuring Consistency and Reproducibility with Semi-Automatic Operation

The reliance on purely manual methods introduces an element of operator-to-operator variability, which compromises the consistency of results, especially for high-volume or critical quality control applications. The specialized, compact preparation systems offer a semi-automatic operation mode. This functionality, even in a single-sample or limited-space machine, is vital as it automates key mechanical steps, such as platen speed and application time. This ensures that the preparation method is reproducible cycle-to-cycle, effectively removing the dependency on individual skill and guaranteeing a standardized surface finish for subsequent analysis.

Click here to know more about Buehler products

.webp)